Method for producing polycrystalline thin film transistor

A polysilicon thin film and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reduced productivity, uneven distribution of laser energy, increased manufacturing cost, etc., and achieve improved uniformity and high additional effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

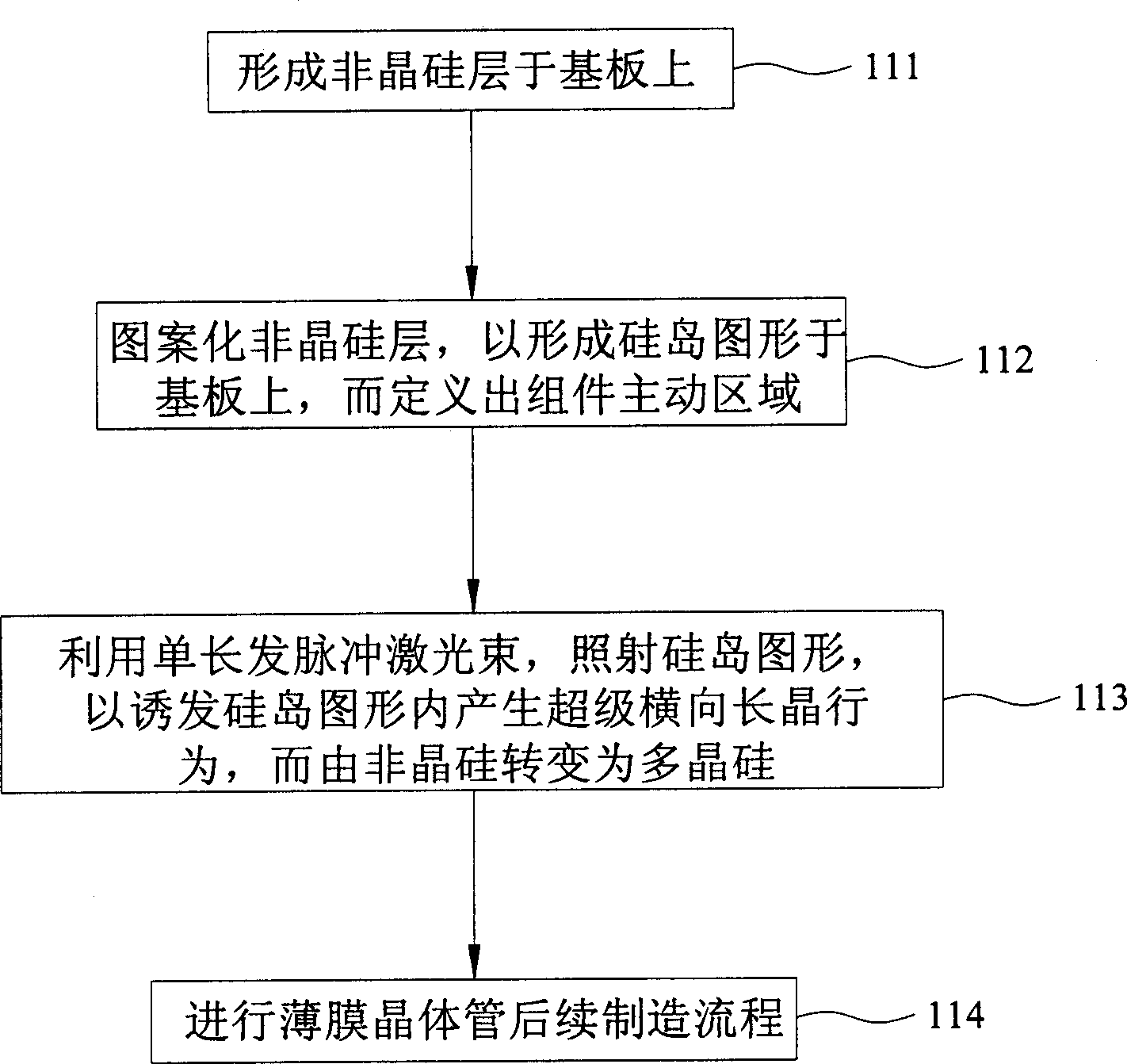

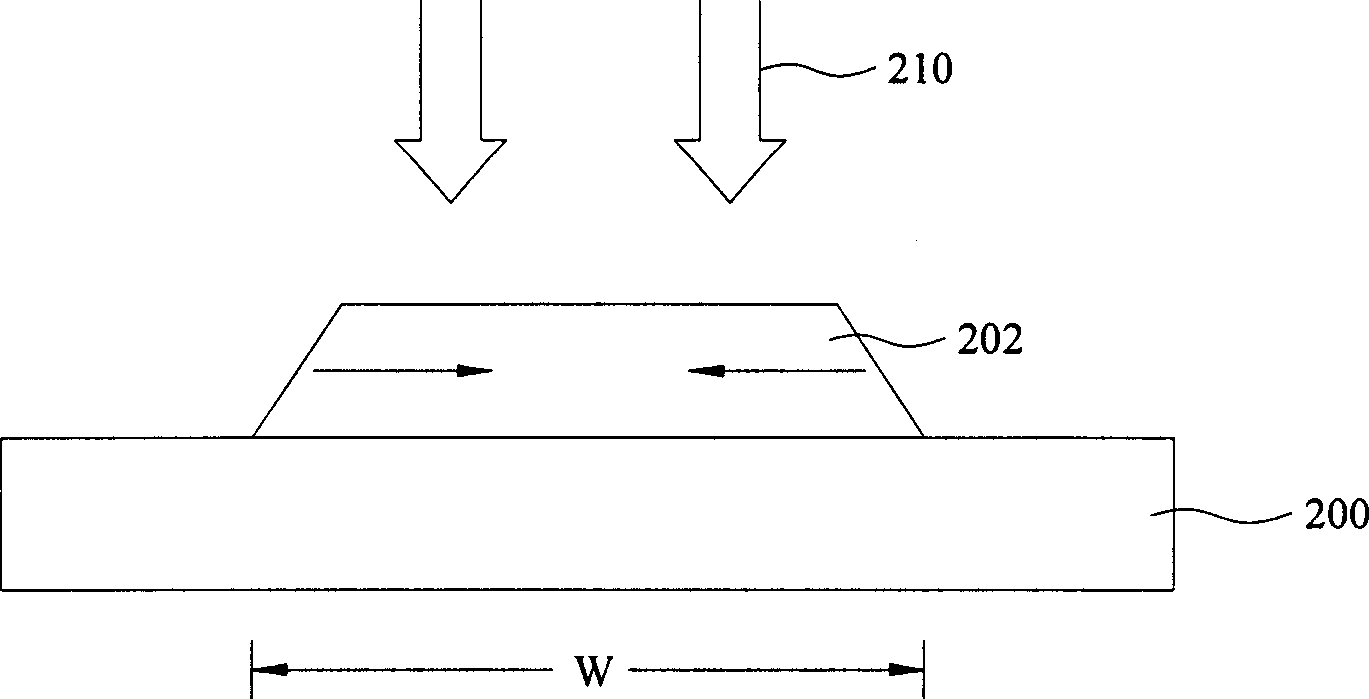

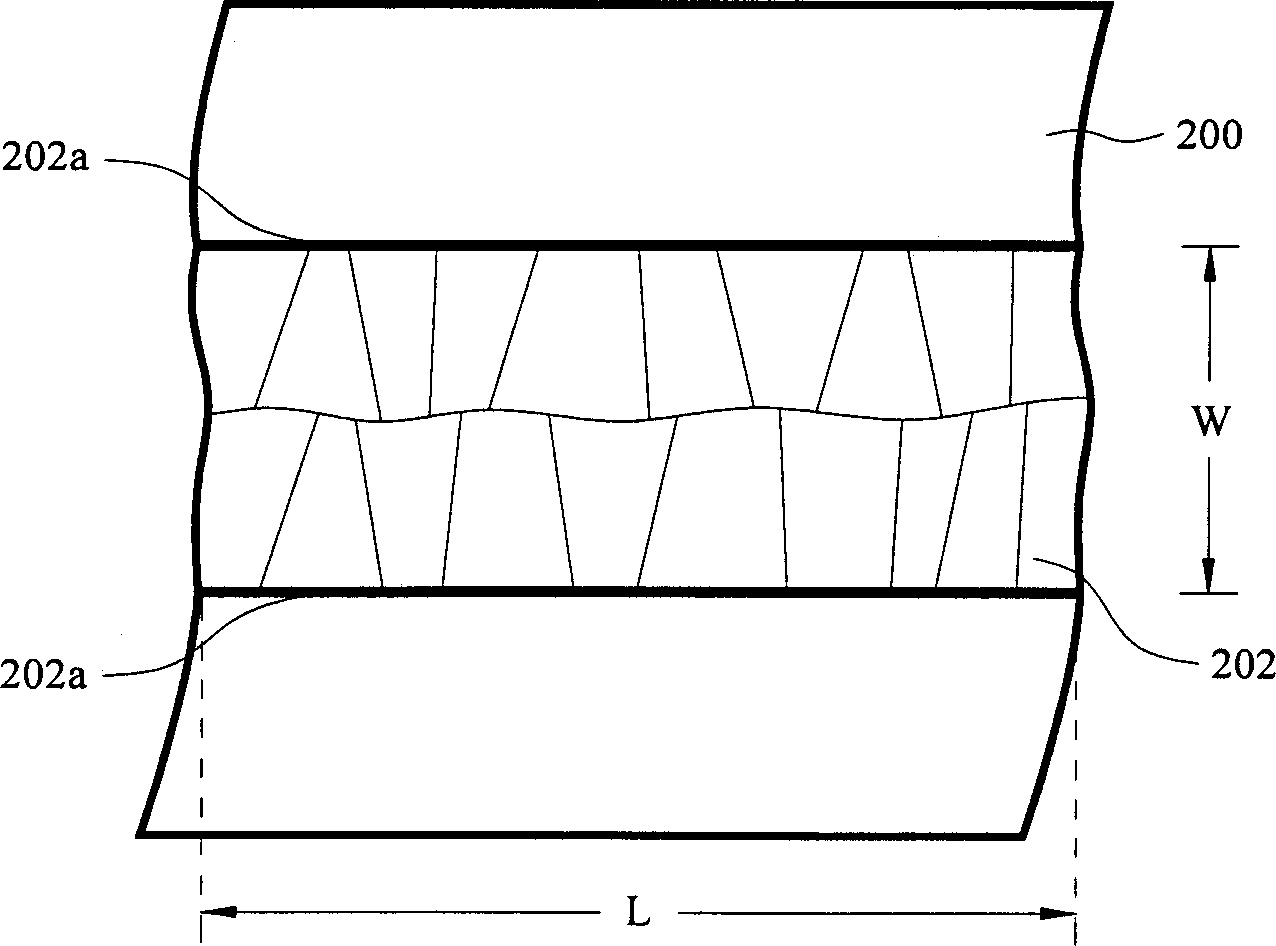

[0038] The invention discloses a method for manufacturing a polysilicon thin film transistor, with reference to figure 1 , Figure 2A as well as Figure 2B As shown, among them, figure 1 It is a flow chart of the steps of a method for manufacturing a polysilicon thin film transistor according to the first preferred embodiment of the present invention, and Figure 2A It is a schematic cross-sectional view of a part of the manufacturing process of a polysilicon thin film transistor according to the first preferred embodiment of the present invention. As for Figure 2B It is an enlarged top view diagram of the crystal structure in a polysilicon thin film transistor according to the first preferred embodiment of the present invention.

[0039] First, proceed figure 1 In the amorphous silicon layer forming step 111, then, the amorphous silicon layer is subjected to the patterning step 112 of defining the active area of the component to form an amorphous silicon island pattern...

Embodiment 2

[0051] The present invention discloses another manufacturing method of a polysilicon thin film transistor. A transistor with a top gate structure is a preferred embodiment, with reference to image 3 as well as Figures 4A-4B shown. in, image 3 It is a flow chart of the steps of a method for manufacturing a polysilicon thin film transistor according to the second preferred embodiment of the present invention, and Figures 4A-4B It is a schematic cross-sectional view of the manufacturing process of a polysilicon thin film transistor according to the second preferred embodiment of the present invention.

[0052] First, proceed image 3 The formation step 311 of the buffer layer and the amorphous silicon layer, cooperates Figure 4A As shown, the buffer layer 401 and the amorphous silicon layer 402 are sequentially formed on the substrate 400 respectively; wherein, the substrate 400 is also made of glass, and the buffer layer 401 can be, for example, a silicon oxide film. N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com