Large energy long pulse fiber laser

A fiber laser, long-pulse technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of improving the quality of high-energy long-pulse laser beams, etc., to improve laser power stability and long service life. , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

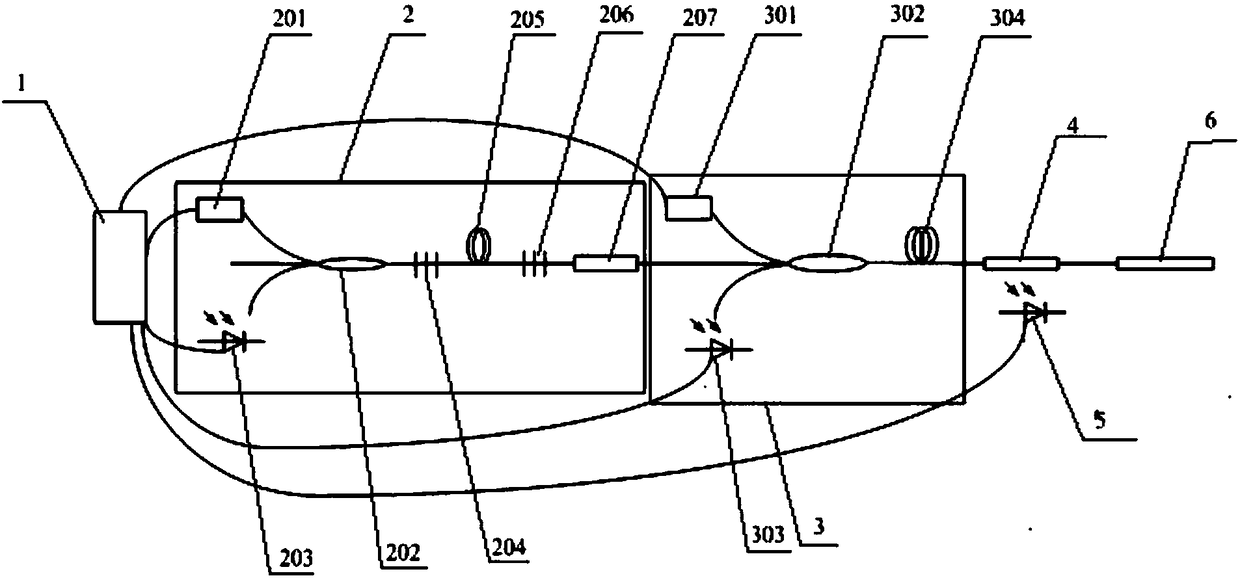

[0029] Such as figure 1 As shown, a high-energy long-pulse fiber laser includes a laser driver 1, a seed source 2, a laser amplifier 3, a cladding optical stripper 4, a photodetector III 5 and a laser output head 6,

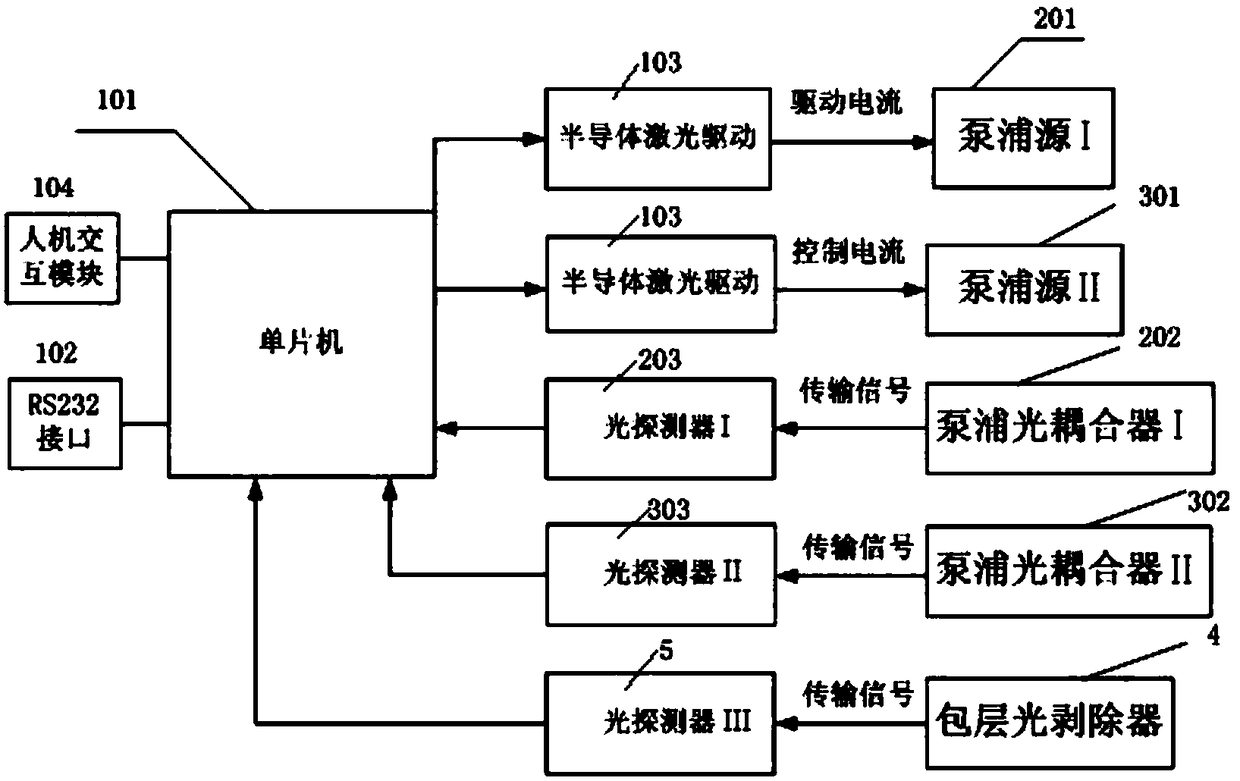

[0030] The laser driver 1 includes a single-chip microcomputer 101, an RS232 interface 102, a semiconductor laser driver module 103 and a human-computer interaction module 104;

[0031] The seed source 2 includes a pumping source I201, a pumping optical coupler I202, a photodetector I203, a high reflection grating 204, a gain fiber I205, a low reflection grating 206 and an isolator 207; the pumping source I201, the pumping Optical coupler I202, high reflection grating 204, gain fiber I205, low reflection grating 206 and isolator 207 are sequentially connected through optical fibers; the optical detector I203 is connected to pump optical coupler I202 through optical fibers;

[0032] The laser amplifier 3 includes a pump source II 301, a pump optical coupler II 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com