Laser-aided-heating long-pulse-laser perforating device and method

A laser-drilling and laser-assisted technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of easy micro-cracks and low quality of long-pulse laser drilling, achieve high degree of automation, improve removal Efficiency, high processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

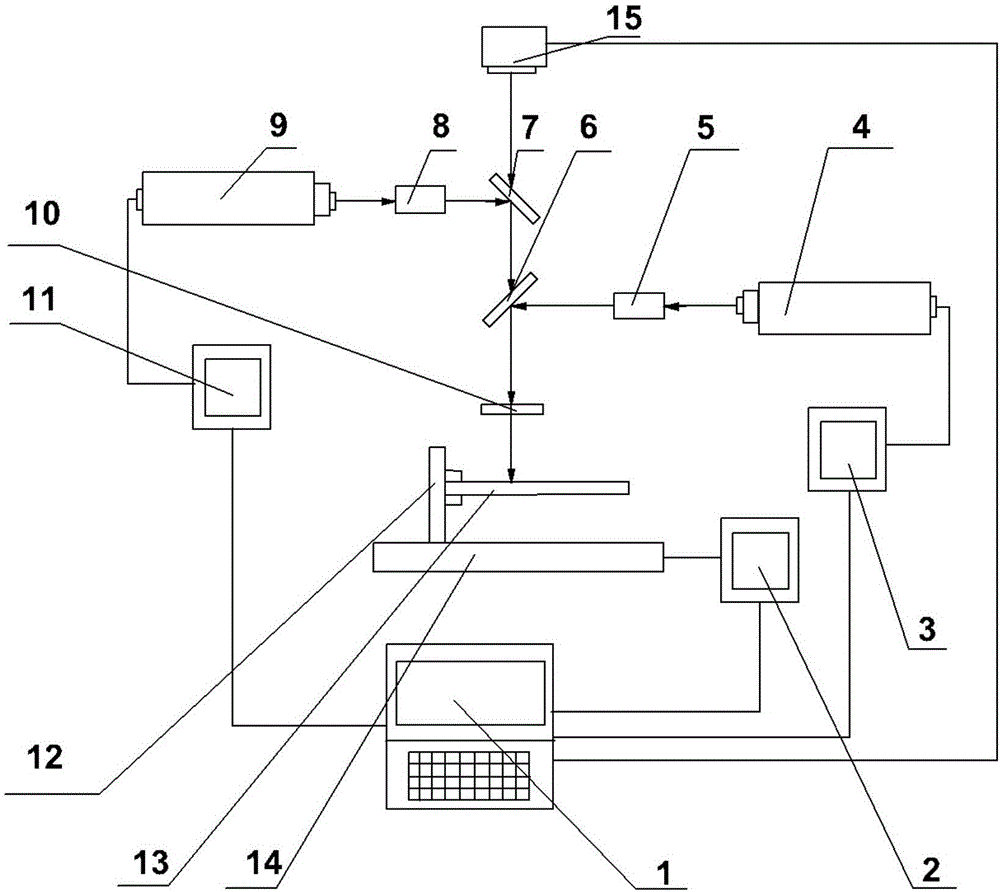

[0034] A laser-assisted heating long-pulse laser drilling device, comprising a long-pulse laser 9, a first beam expander 8, a CCD camera 15, a reflective plane mirror 7, a transmission / reflection plane mirror 6, a convex lens 10, a second beam expander 5, a continuous Laser 4, long pulse laser controller 11, continuous laser controller 3, workpiece 13, fixture 12, movable workbench 14, workbench controller 2 and computer 1;

[0035] Described CCD camera 15 is positioned at the top, and is electrically connected with computer 1, and directly below CCD camera 15 places reflective flat mirror 7, transmission / reflective flat mirror 6, convex lens 10 and workpiece 13 successively; Described workpiece 13 is fixed on the fixture 12, so The bottom of the fixture 12 is fixed on the movable workbench 14;

[0036] The long-pulse laser 9, the first beam expander 8 and the reflective flat mirror 7 are located on the same optical path in turn; one end of the long-pulse laser controller 11 i...

Embodiment 2

[0041] A drilling method using the laser-assisted heating of the long-pulse laser drilling device described in Embodiment 1. Before, during, and after processing the workpiece 13 with the long-pulse laser 9, the continuous laser 4 is used to process the workpiece 13. The area to be processed on the upper surface is heated. The long-pulse laser 9 refers to a laser with a pulse width of about 1 to 100 ms; the continuous laser 4 refers to a laser that can continuously emit laser light; the processing situation is monitored in real time by a CCD camera 15 . Specifically include the following steps:

[0042] S1, grinding and polishing the surface of the workpiece 13;

[0043] S2, fixing the workpiece 13 on the fixture 12, and the fixture 12 is fixed on the movable workbench 14;

[0044] S3. Under the monitoring of the CCD camera 15, use the workbench controller 2 to control the movable workbench 14 to adjust the position of the workpiece 13;

[0045] S4, setting the output parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com