Non-graphitization complex profile PCD forming tool cutting edge laser processing method

A laser processing method and technology for forming tools, which are applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient processing efficiency and precision of PCD forming tools, and shorten the production cycle and reduce costs. , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

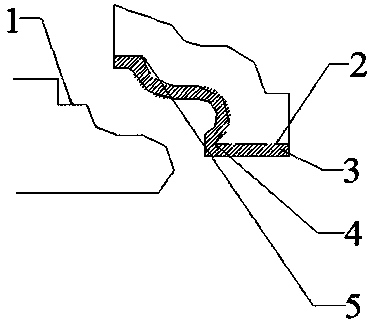

[0026] A compound laser processing method for processing complex contour PCD forming tool edge, comprising the following specific steps:

[0027] S1. Design the contour shape of the PCD blade according to the contour of the processing surface, and reserve enough machining allowance;

[0028] S2. Cut the PCD composite sheet into required PCD blades with a long pulse laser;

[0029] S3. Vacuum welding the PCD blade to the cemented carbide substrate to obtain the required PCD cutter;

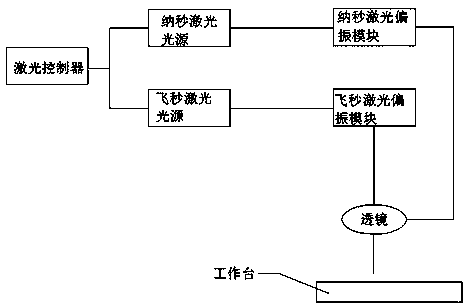

[0030] S4. The welded PCD tool is clamped on the laser machine tool to provide an integrated laser processing system. The integrated laser is equipped with a long-pulse laser laser probe and a short-pulse laser laser probe at the same time, and the long-pulse laser laser probe is used for rough machining of the PCD tool , and reserve enough finishing allowance for subsequent finishing, and inject auxiliary gas at the same time to reduce the processing surface temperature and blow away the slag; am...

Embodiment 2

[0039] A compound laser processing method for processing complex contour PCD forming tool edge, comprising the following specific steps:

[0040] S1. Design the contour shape of the PCD blade according to the contour of the processing surface, and reserve enough machining allowance;

[0041]S2. Cut the PCD composite sheet into required PCD blades with a long pulse laser;

[0042] S3. Vacuum welding the PCD blade to the cemented carbide substrate to obtain the required PCD cutter;

[0043] S4. The welded PCD tool is clamped on the laser machine tool, and an integrated laser is provided. The integrated laser is equipped with a long-pulse laser laser probe and a short-pulse laser laser probe at the same time. The PCD tool is rough-machined by the long-pulse laser laser probe, and Sufficient finishing allowance is reserved for subsequent finishing, and auxiliary gas is injected at the same time to reduce the processing surface temperature and blow away the slag; among them, the l...

Embodiment 3

[0052] A compound laser processing method for processing complex contour PCD forming tool edge, comprising the following specific steps:

[0053] S1. Design the contour shape of the PCD blade according to the contour of the processing surface, and reserve enough machining allowance;

[0054] S2. Cut the PCD composite sheet into required PCD blades with a long pulse laser;

[0055] S3. Vacuum welding the PCD blade to the cemented carbide substrate to obtain the required PCD cutter;

[0056] S4. The welded PCD tool is clamped on the laser machine tool, and an integrated laser is provided. The integrated laser is equipped with a long-pulse laser laser probe and a short-pulse laser laser probe at the same time. The PCD tool is rough-machined by the long-pulse laser laser probe, and Reserve sufficient finishing allowance for subsequent finishing, and inject auxiliary gas at the same time to reduce the processing surface temperature and blow away the slag; among them, the long puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com