Microporous array processing device and microporous array processing method

A microhole array and processing method technology, applied in the direction of microstructure devices, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting processing efficiency, inability to process multiple microholes at the same time, affecting productivity, etc., to improve work efficiency , small thermal impact, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

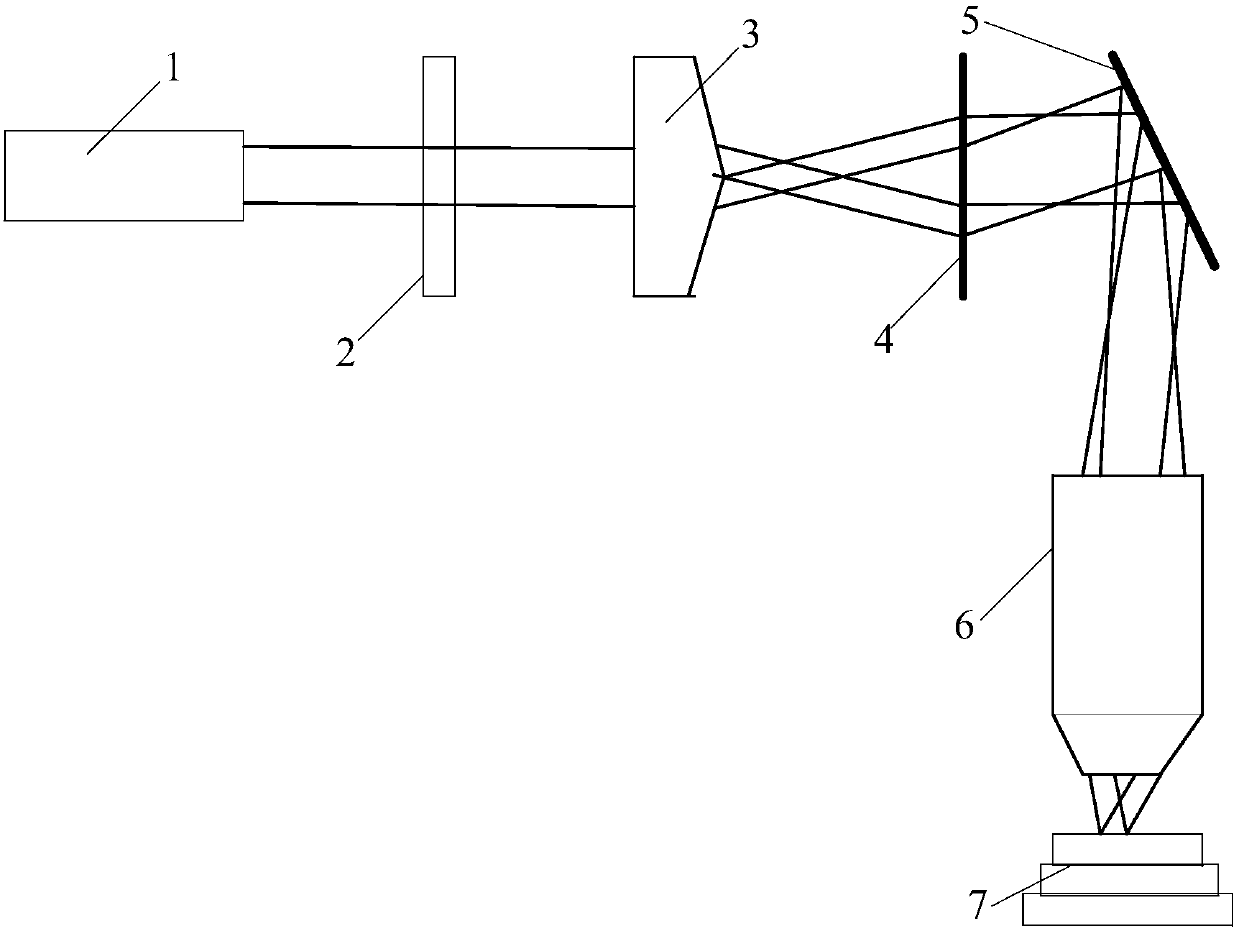

Embodiment 1

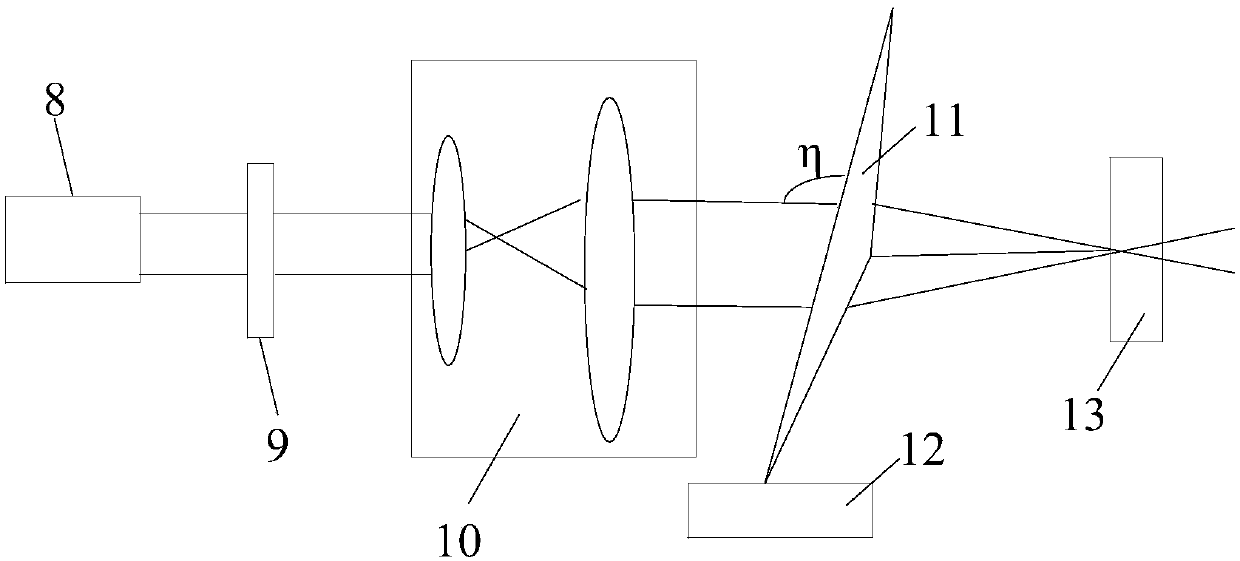

[0048] Such as figure 2 As shown, the present invention provides a microhole array processing device comprising: a laser, a light source adjustment assembly, an axicon 11, and a three-dimensional motion table 13 are sequentially arranged along the light propagation direction, and the axicon 11 is installed on a rotary table 12; The laser of the embodiment is preferably a femtosecond laser 8, which produces a femtosecond laser, which has the advantages of short action time, less thermal influence, little influence on the strength of the processed material, and no microcracks; the rotating table 12 is preferably five The axial precision rotary table can drive the axicon 11 to continuously change the angle. Specifically, the femtosecond laser 8 emits laser light and enters the axicon 11 to form a Bessel spot, and a computer program is used to control the movement of the three-dimensional motion table 13, so that the Bessel The Er area is located on the surface of the component t...

Embodiment 2

[0070] The difference between this embodiment and Embodiment 1 is that the number and distribution of light spots corresponding to the microhole array required by the element to be processed are obtained by adjusting the distance between the light field distribution plane and the axicon, as follows:

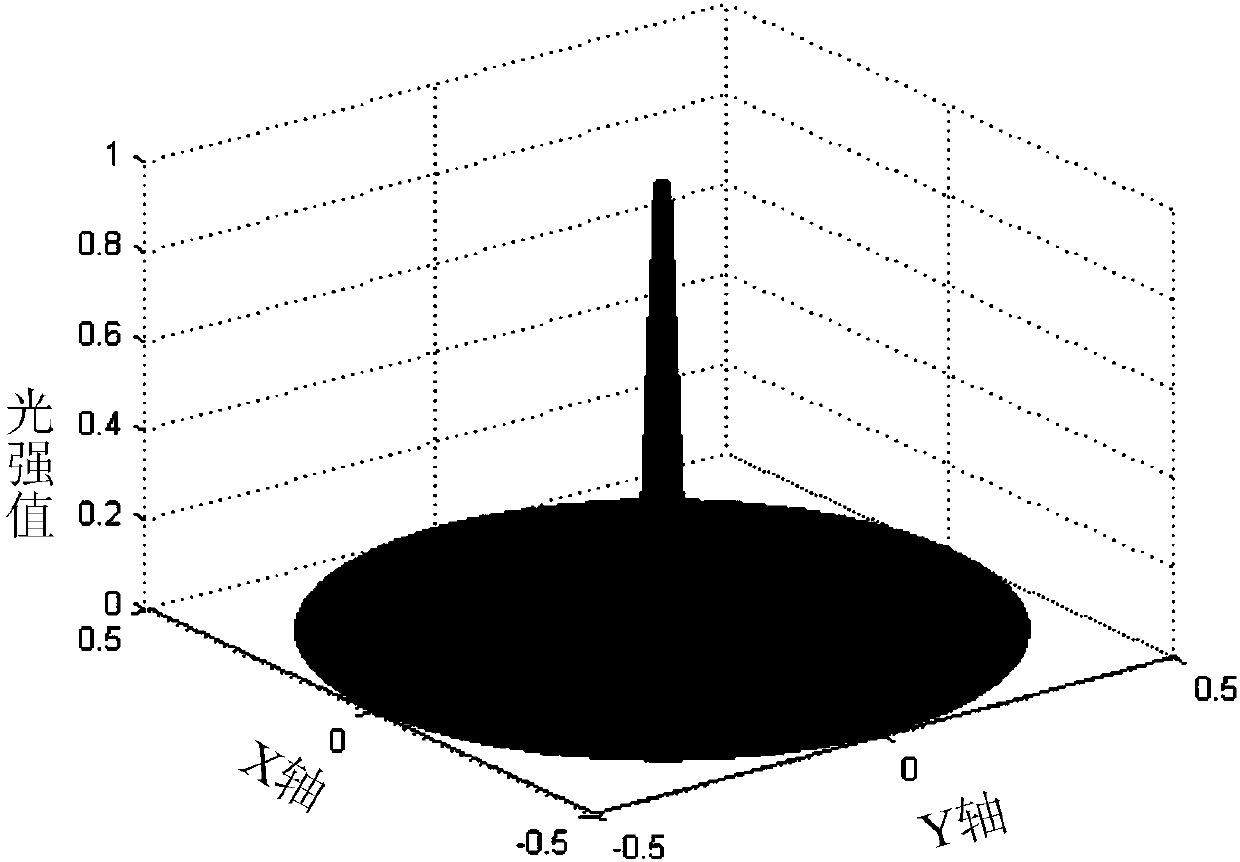

[0071] The N value is obtained by solving the light field distribution function: N=kz(n-1) 2 gamma 2 sin 2 η / 4, the specific decomposing steps have been listed in detail in Example 1, and will not be repeated in this example. It can be seen that N directly affects the light field distribution and the value of N is closely related to the angle n between the laser beam and the axicon 11 and the distance between the light field distribution plane and the axicon 11, the present embodiment will After the microhole array required by the component to be processed is substituted into the light field distribution function, the angle between the laser beam and the axicon 11 is 90°, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com