Means and method for connecting thin metal layers

A thin metal layer and connection method technology, applied in metal processing equipment, welding equipment, laser welding equipment, etc., can solve the problem of not providing solar cell electrode connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

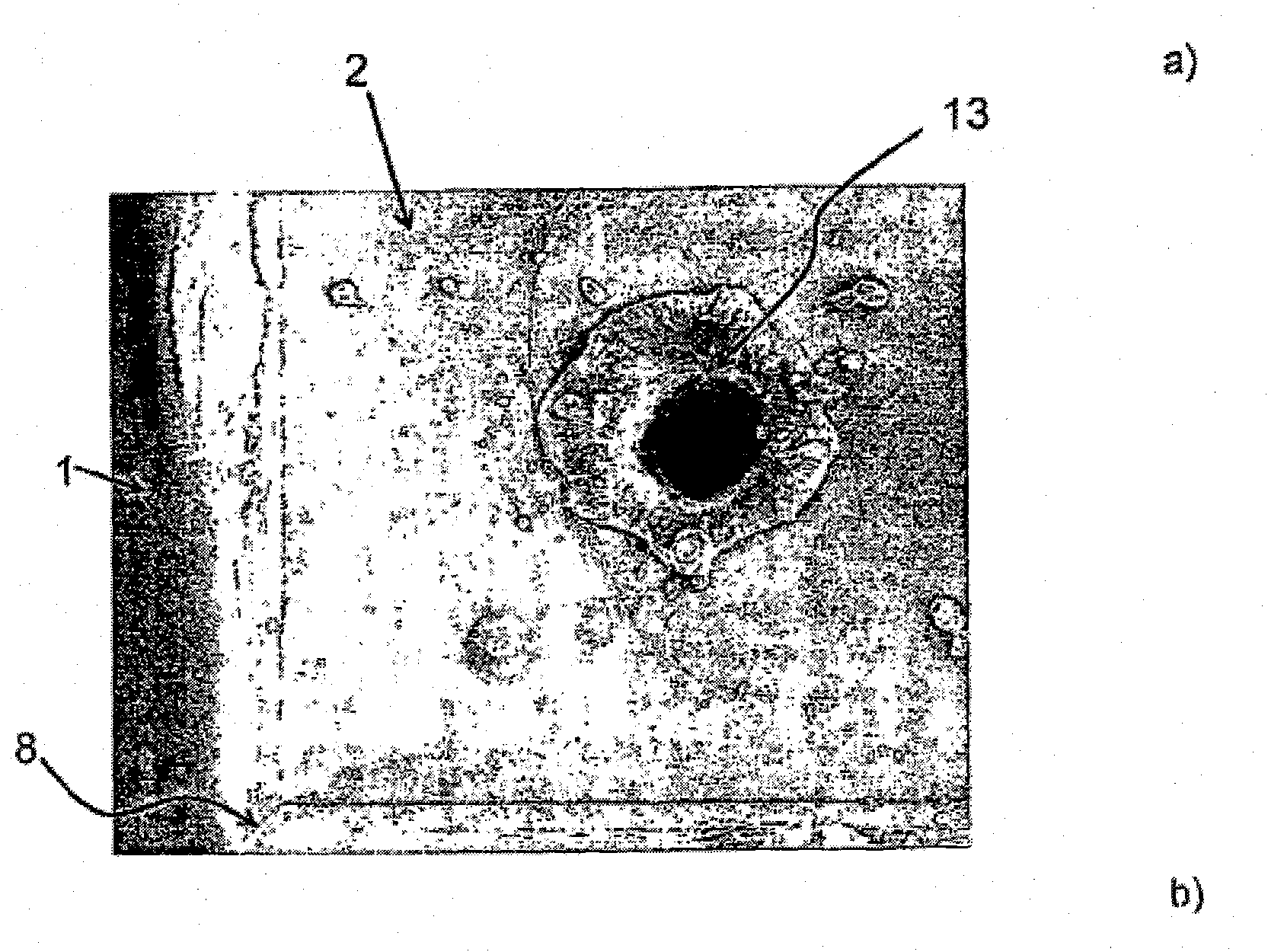

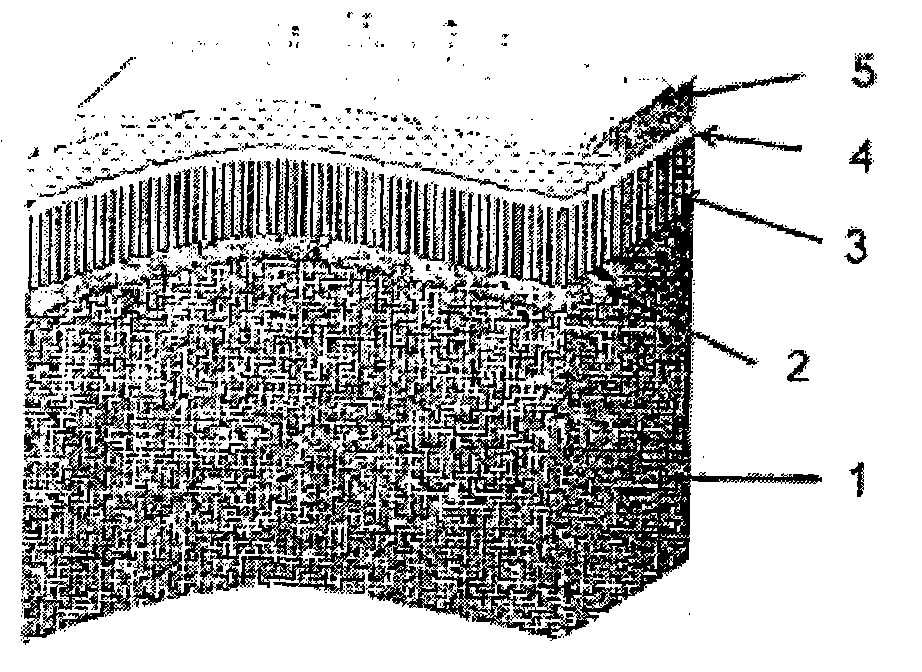

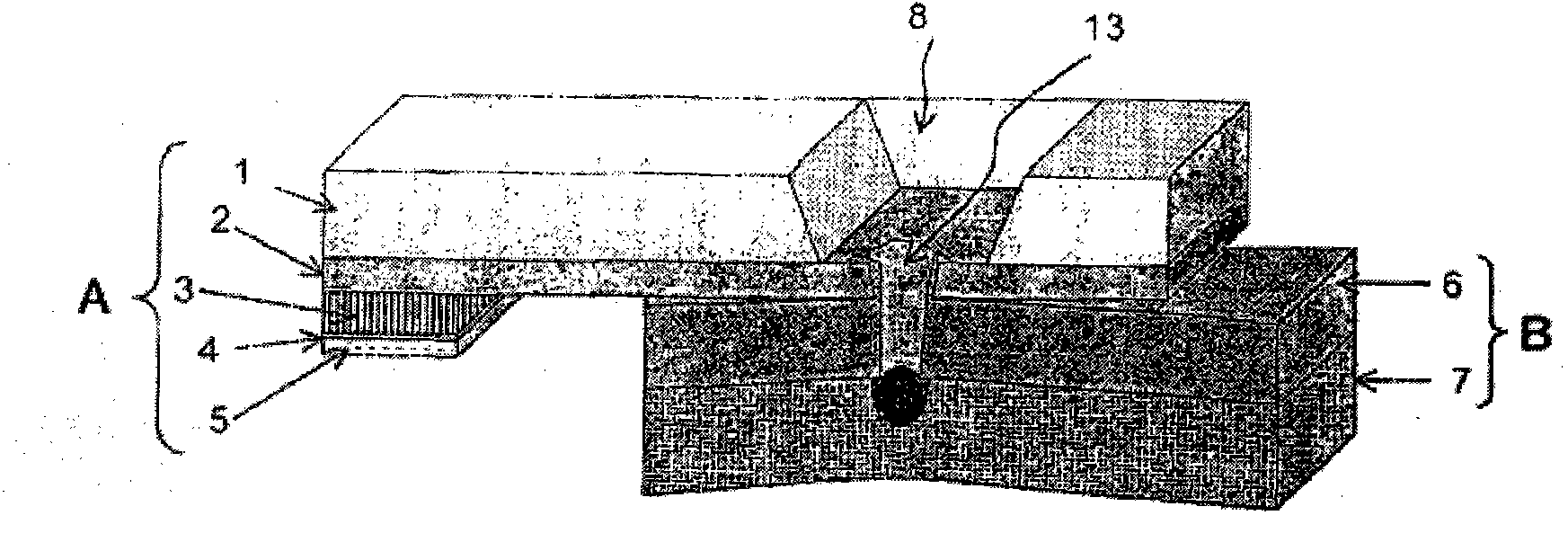

[0062] The present invention now describes in more detail the joining of a molybdenum thin film to a flexible small copper contact strip by a riveting process. This molybdenum thin film is used on the back contact layer of solar cells, such as CIGS solar cells, such as figure 1 shown. As far as this riveting process is concerned, the upper layer of the solar cell is used as the front contact layer, absorber layer, etc. In order to reveal the metal molybdenum layer, the front contact layer may be removed mechanically or laser ablated until the rear contact layer, such as image 3 (a) shown.

[0063] The polymer base film of the prepared solar cell can be removed by laser ablation method. In order to remove the polymer base film of the solar cell, the front side of the solar cell is closely attached to a holder in the ablated area behind the polymer base film and irradiated by laser light with sufficient pulse energy. To gradually ablate the polymer film (thickness about 25 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com