Laser preprocessing method for remanufacturing of blade part

A laser pretreatment and remanufacturing technology, which is applied in the field of plate parts remanufacturing, can solve problems such as shortening the service life of blades, achieve the effects of reducing maintenance costs, reducing maintenance times and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

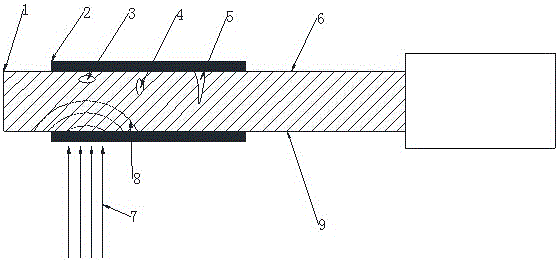

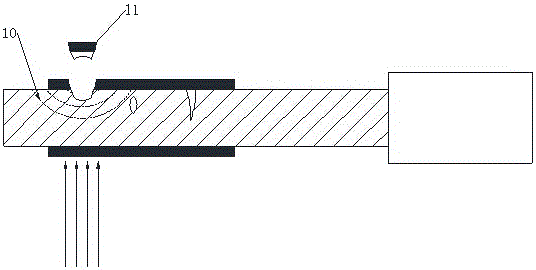

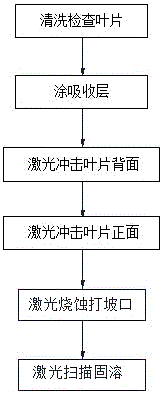

[0018] Such as Figure 1-3 As shown, a laser pretreatment method for remanufacturing blade parts of the present invention includes the following steps.

[0019] S1: Clean the blade 1 to be repaired, and inspect the blade 1 to determine the obvious crack 5 and the area where hidden cracks may exist. The hidden cracks include the transverse hidden crack 3 and the longitudinal hidden crack 4. Among them, the preliminary determination method of hidden cracks is ultrasonic flaw detection.

[0020] S2: The absorbing layer material 2 is coated on the surface of the blade 1, and the side of the blade 1 with cracks is defined as the front side of the blade, and the opposite side is defined as the back side of the blade. In this embodiment, the material 2 of the absorbing layer is black paint, and the thickness of the absorbing layer is 0.2-0.6 mm, especially when the thickness is 0.4 mm, the absorbing effect is the best. Of course, in practical applications, aluminum foil or carbon p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com