Method and apparatus for multi-laser-beam-combined welding of glass material

A glass material and laser beam technology, applied in glass forming, glass remolding, glass manufacturing equipment, etc., can solve the problems of inability to form welds, low adhesive strength performance, and reduced sealing performance, and improve welding performance. Good effect on efficiency, strength and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

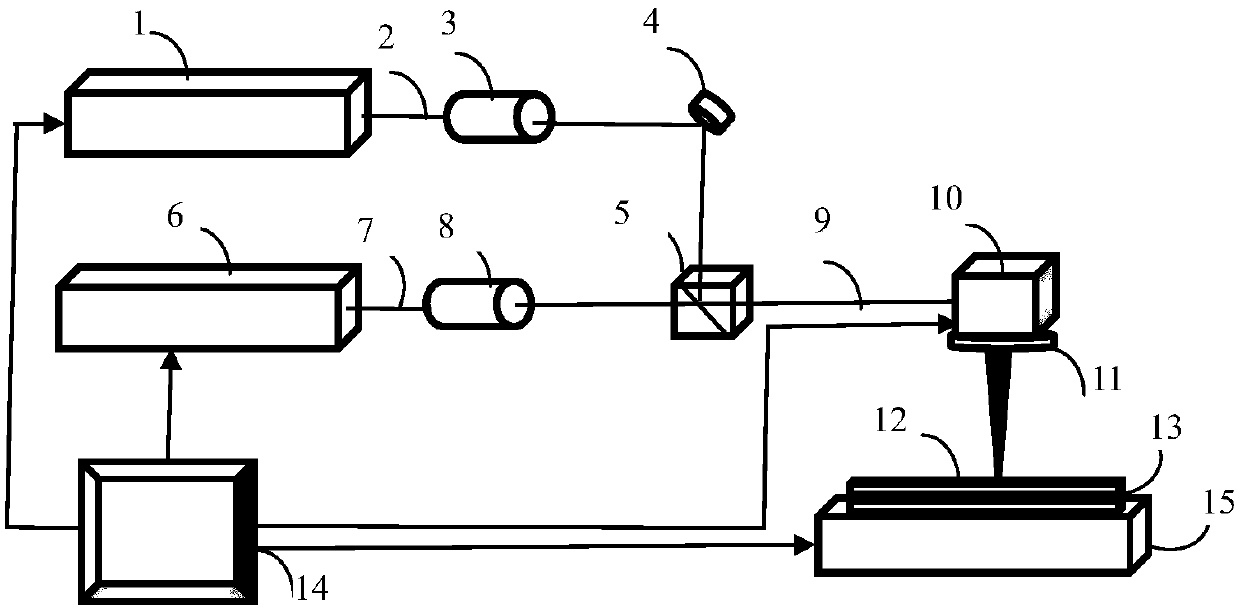

[0024] Example 1: Using such figure 1 The first multi-laser beam combined processing equipment shown uses an ultra-short-second pulse laser with a pulse width of 10 picoseconds, a wavelength of 1064 nm and a laser beam output in the P polarization direction, and a laser beam with a wavelength of 1064 nm and an output laser beam in the S polarization direction. Continuous fiber laser. The output power and repetition frequency of the ultra-short-second pulse laser are 15W and 10MHz, respectively, the output power of the continuous fiber laser is 10W, and the scanning speed of the galvanometer is 1000mm / s. The distance between the two pieces of soda lime glass is 8μm, and the focal point of the combined laser beam is at the contact position between the two pieces of soda lime glass, and galvanometer scanning welding is performed to obtain a weld with good sealing and strength.

example 2

[0025] Example 2: Using such figure 1 The first multi-laser beam combined processing equipment shown uses an ultra-short-second pulse laser with a pulse width of 10 picoseconds, a wavelength of 1064 nm and a laser beam output in the P polarization direction, and a laser beam with a wavelength of 1064 nm and an output laser beam in the S polarization direction. Continuous fiber laser. The output power and repetition frequency of the ultra-short-second pulse laser are 20W and 10MHz, respectively, the output power of the continuous fiber laser is 25W, the scanning speed of the galvanometer is 1000mm / s, the distance between two pieces of quartz glass is 12μm, and the focus point of the combined laser beam is located at two At the contact position between the pieces of quartz glass, galvanometer scanning welding is performed to obtain a weld with good sealing and strength.

example 3

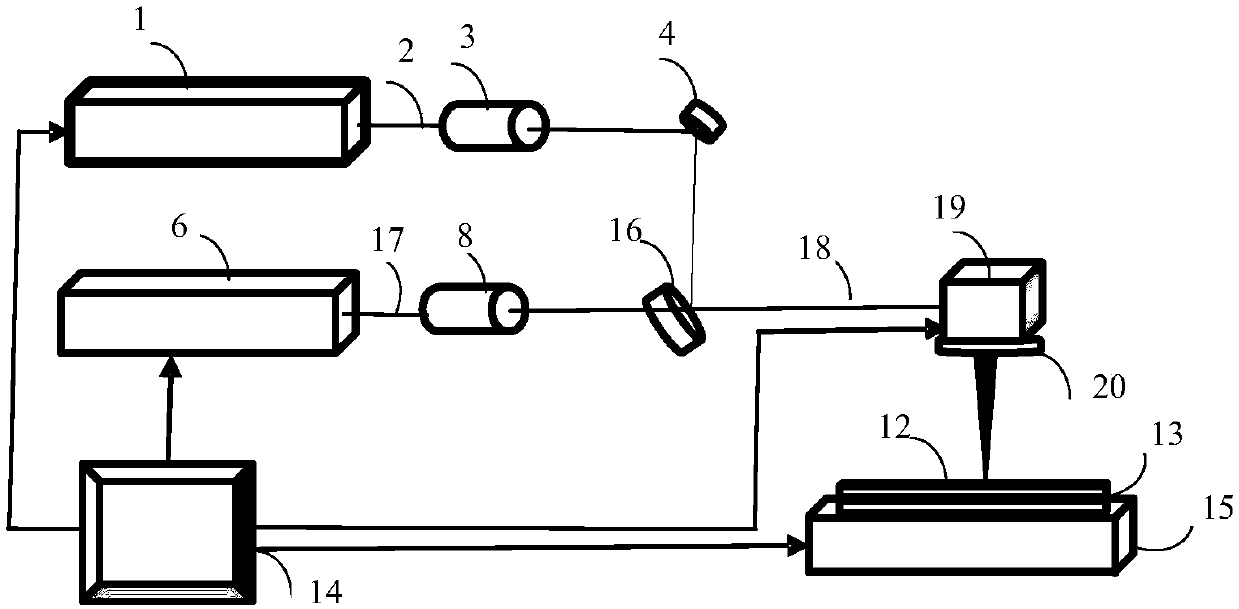

[0026] Example 3: Using such figure 2 The second multi-laser beam combined processing equipment shown uses an ultra-short-second pulse laser with a pulse width of 10 picoseconds, a wavelength of 532nm and a laser beam output in the P polarization direction, and a wavelength of 1064nm and a laser beam output in any polarization direction. Continuous fiber laser. The output power and repetition frequency of the ultra-short-second pulse laser are 10W and 10MHz, respectively, the output power of the continuous fiber laser is 20W, the scanning speed of the galvanometer is 1000mm / s, the distance between two pieces of white glass is 10μm, and the focus point of the combined laser beam is located at two At the contact position between the pieces of white glass, the galvanometer scan and the worktable are welded in parallel mode to obtain a large area of sealing and good strength weld.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com