Laser drilling method

A laser drilling and laser technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult discharge of slag, increased control cost, and poor drilling quality, so as to prolong life and increase evaporation rate, the effect of increasing the drilling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples serve to illustrate the invention, but do not limit it. The details of the method proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

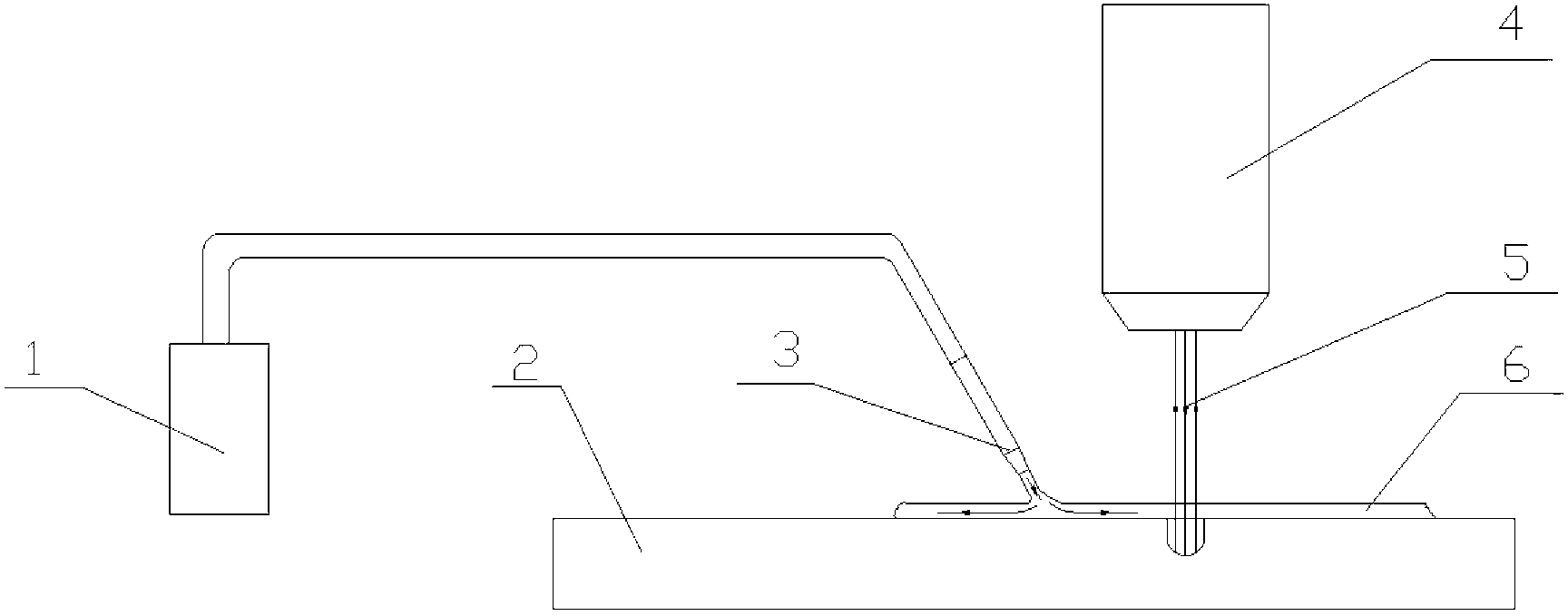

[0021] The invention provides a laser drilling method, such as figure 1 As shown, the spray head 3 is fixed above the workpiece 2 at a certain angle; the laser drill 4 is aligned with the position on the workpiece 2 that needs to be drilled, the spray head 3 should keep a certain distance from the laser drill 4 and the airflow emitted by the spray head 3 Or the liquid should not be directly facing the drilling position; turn on the pressurization device 1, the spray head 3 sprays gas or liquid to form a high-speed fluid layer 6 on the surface of the workpiece 2, and the fluid flow direction of the high-speed fluid layer 6 is parallel to the surface of the workpiece; then start the laser to emit The laser beam 5 drills holes on the surface of the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com