Method and apparatus for laser to induce plasma to inject into substrate

A plasma and laser-induced technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem of shallow implantation layer, achieve the effect of deep implantation layer, high hardness, and rapid acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

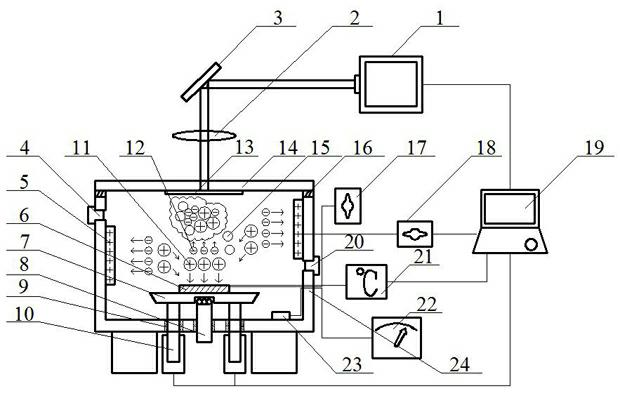

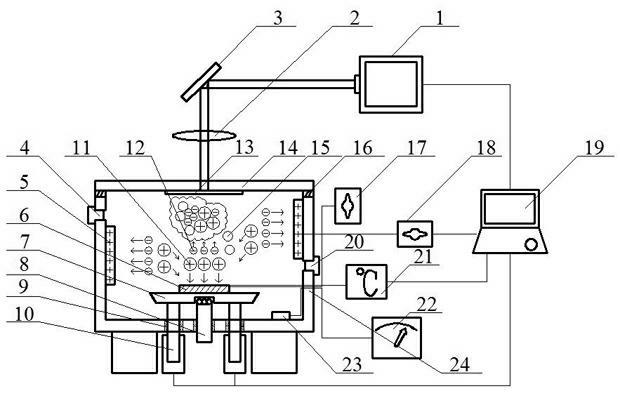

[0024] The details and working conditions of the method and device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0025] The material of the workpiece is 00Cr12 heat-resistant steel. Use sandpaper to remove the oxide layer on the surface of the workpiece and polish it, and then use absolute ethanol to degrease and clean it; raise the workbench support (10) to a certain height, and place the pretreated workpiece ( 6) Fix and clamp on the workbench (7), paste the temperature sensor (21) on the surface of the workpiece, connect the pulse negative high voltage source (17) connector on the side, then lower the workbench to the working height, adjust the radiation heater ( 8), then seal the contact part (9) between the heater, the workbench support and the high-pressure vacuum chamber; paste a layer of metal foil (13) on the upper glass plate (14), and then put the glass The plate cover is on the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com