Laser welding method for metal sheets applied to ultra low temperature environment

A metal thin plate, laser welding technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unfavorable energy security and other issues, and achieve the improvement of ultra-low temperature corrosion resistance and mechanical properties, weld quality and mechanical properties Improve and accelerate the effect of particle diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

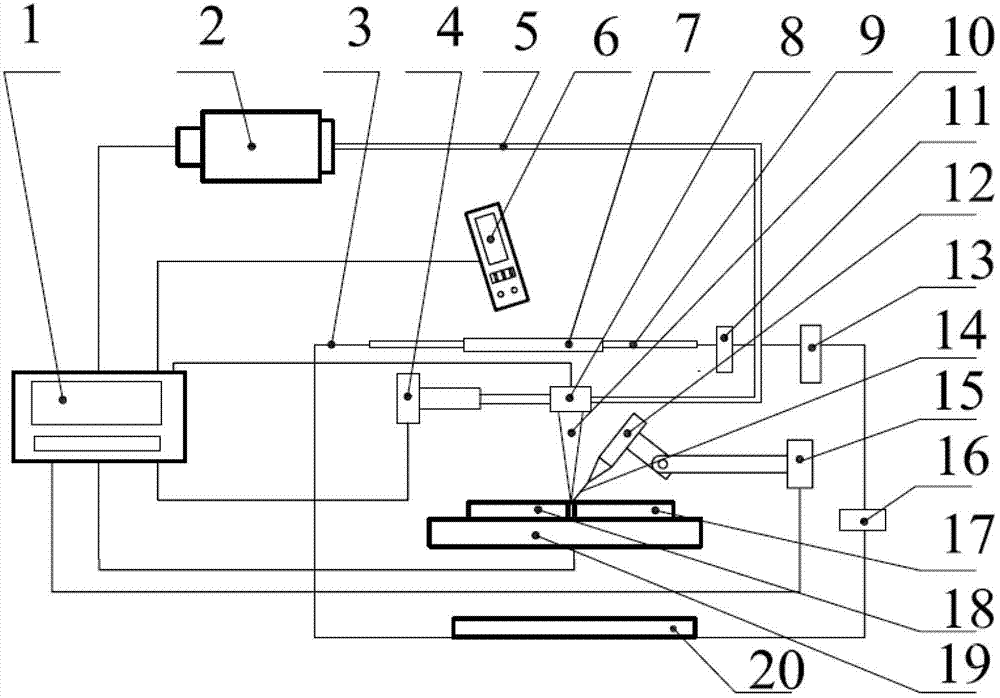

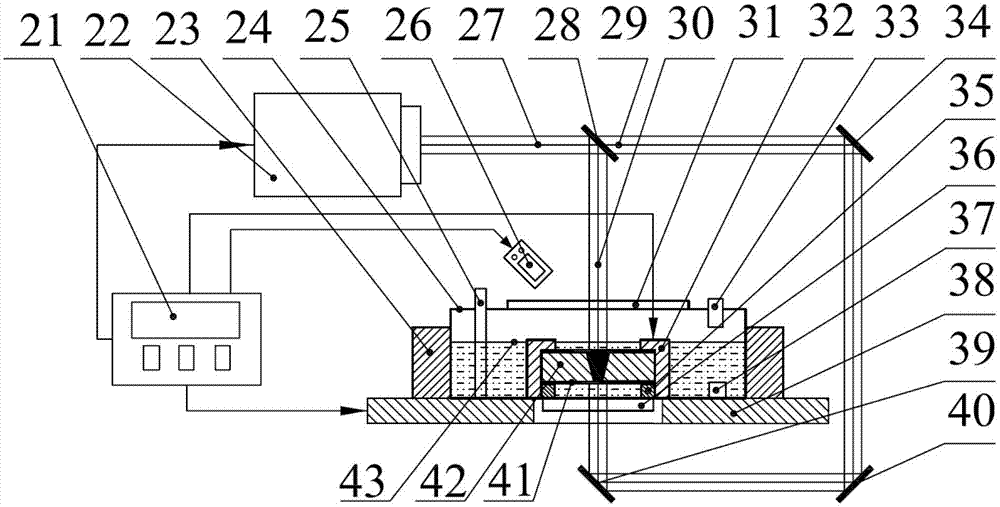

[0031] The embodiment of the present invention discloses a laser welding method for thin metal plates applied in an ultra-low temperature environment, including:

[0032] (1) Provide sheet metal I and sheet metal II;

[0033] (2) Clean the parts to be welded of the metal sheet I and the metal sheet II with alcohol or acetone;

[0034] (3) Clamping and fixing the metal sheet I and the metal sheet II, a weld area is formed between the metal sheet I and the metal sheet II;

[0035] (4) placing metal sheet I and metal sheet II integrally in an inert gas environment and heating to the dynamic strain aging temperature of metal sheet I and metal sheet II;

[0036] (5) Fiber laser is used to perform filler wire welding on the weld area;

[0037] (6) Grind, polish and clean the weld area;

[0038] (7) Cover the upper and lower surfaces of the welded metal sheet with aluminum foil as a laser shock energy absorption layer;

[0039] (8) Place the welded metal sheet in a liquid nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com