Stretch-bending forming device with insulated stretching head and forming method thereof

A stretch-bending forming and stretch-bending machine technology is applied in the field of electroplastic stretch-bending insulation pullers and forming devices for aluminum-lithium alloy profiles, which can solve the problems of difficulty in ensuring the stretching and bending requirements of profiles of different sizes, affecting performance, and low density. Achieve the effect of avoiding coating aging and falling off defects, enhancing atomic vibration, and increasing forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

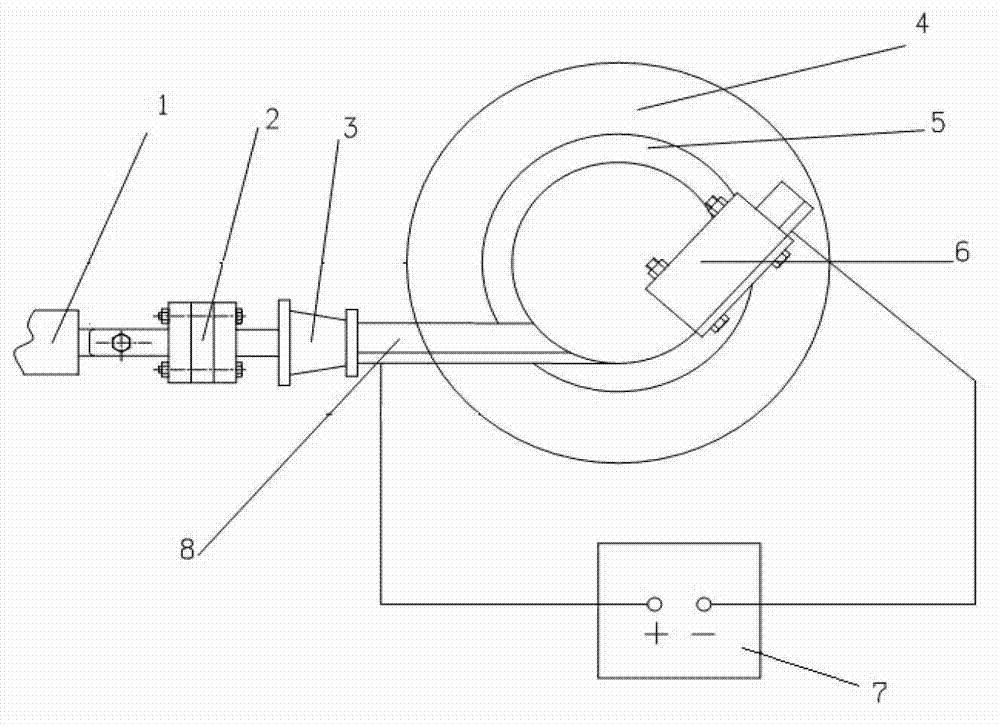

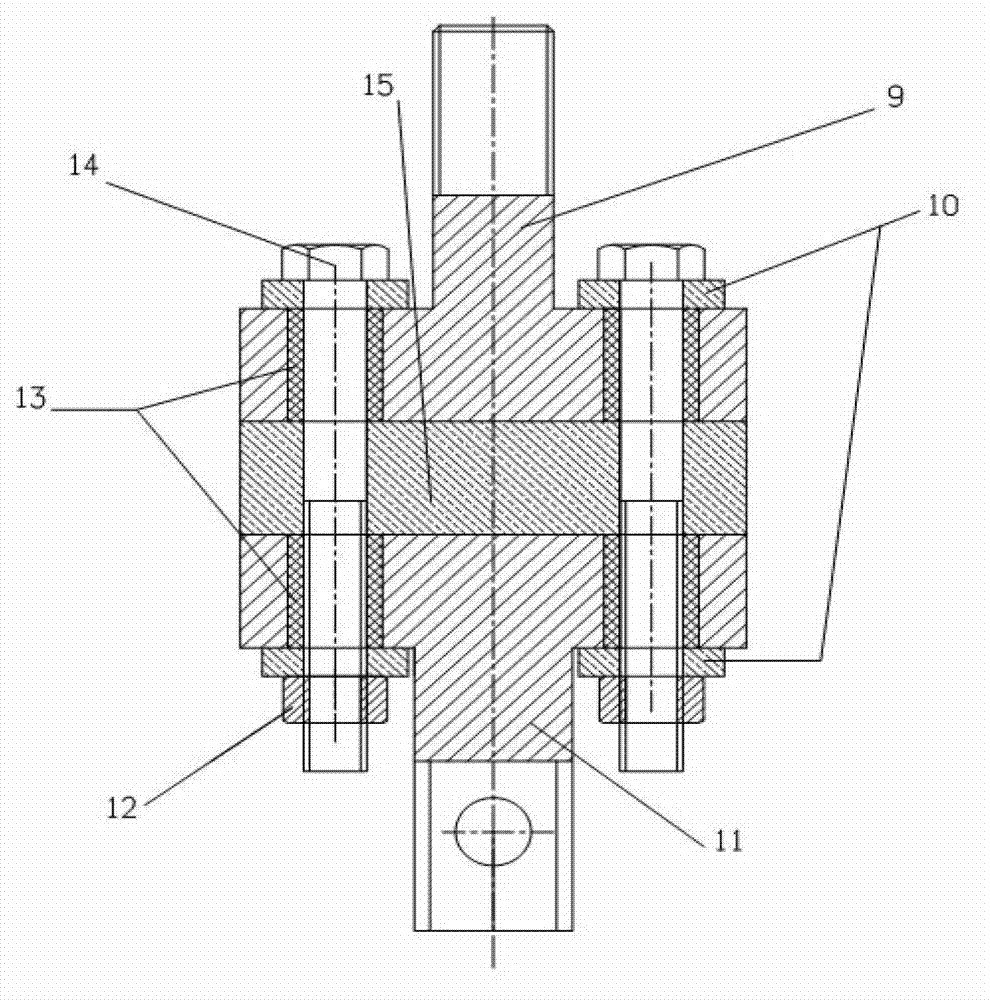

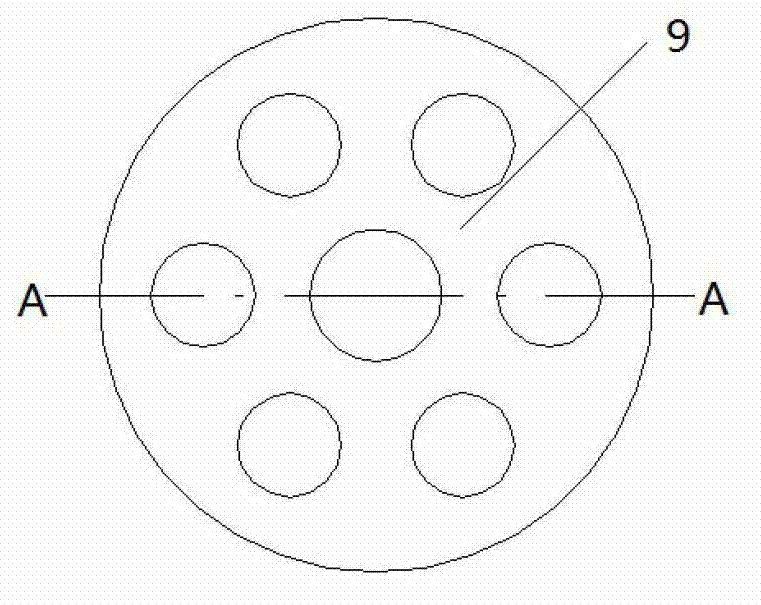

[0030] This embodiment is a stretch bending forming device for an aluminum-lithium alloy T-shaped bar with a thickness of 2mm, which is obtained after improving the stretch bending machine in the prior art.

[0031]This embodiment includes a stretch bending machine rotating support arm 1, an insulating slider 2, a pneumatic chuck 3, a stretch bending machine turntable 4, an insulating workbench 5, a stretch bending mold 6, and a pulse power supply 7 of the forming device. Among them: the insulating slider 2 is located between the rotating support arm 1 of the stretch bending machine and the pneumatic chuck 3, the front end of the insulating slider 2 is screwed into the threaded hole of the rear cover of the pneumatic chuck 3 through threaded connection, and the rear of the insulating slider 2 The end is connected with the rotating support arm 1 of the stretch bending machine through bolts, and the insulating workbench 5 is installed on the upper surface of the turntable 4 of th...

Embodiment 2

[0040] This embodiment is a method for forming an aluminum-lithium alloy T-shaped bar with a thickness of 2 mm by electroplastic stretch bending using the stretch bending forming device for the insulating slider described in Embodiment 1. The section height of the T profile is 28 mm, and the bending radius of the mold is 250 mm.

[0041] In this embodiment, the stretching force of the main stretching cylinder of the turntable type stretch bending machine is 0-8T, the maximum stroke of the main stretching cylinder is 2000mm, the working speed of the main stretching cylinder is 0-12mm / s, and the diameter of the turntable is 1000mm, the total electrode power is 30.8kw.

[0042] The specific process is:

[0043] The first step is to clamp the parts to be formed. An insulating board is laid on the turntable of the stretch bending machine, and the mold is placed on the insulating board. Put the aluminum-lithium alloy T-shaped bar on the mold and clamp it with a pneumatic chuck to...

Embodiment 3

[0050] This embodiment is a method for forming an aluminum-lithium alloy T-shaped bar with a thickness of 2 mm by electroplastic stretch bending using the stretch bending forming device for the insulating slider described in Embodiment 1. The section height of the T profile is 50 mm, and the bending radius of the mold is 450 mm.

[0051] In this embodiment, the stretching force of the main stretching cylinder of the turntable type stretch bending machine is 0-8T, the maximum stroke of the main stretching cylinder is 2000mm, the working speed of the main stretching cylinder is 0-12mm / s, and the diameter of the turntable is 1000mm, the total electrode power is 30.8kw.

[0052] The specific process is:

[0053] The first step is to clamp the parts to be formed. An insulating board is laid on the turntable of the stretch bending machine, and the mold is placed on the insulating board. Put the aluminum-lithium alloy T-shaped bar on the mold and clamp it with a pneumatic chuck to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com