Flux-cored wire preparation equipment and method based on electroplastic principle

A technology of flux-cored welding wire and electroplasticity, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of restricting the research and development and manufacturing of new flux-cored welding materials, serious work hardening, and increase production cost, and achieve low cost. , the effect of eliminating work hardening and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

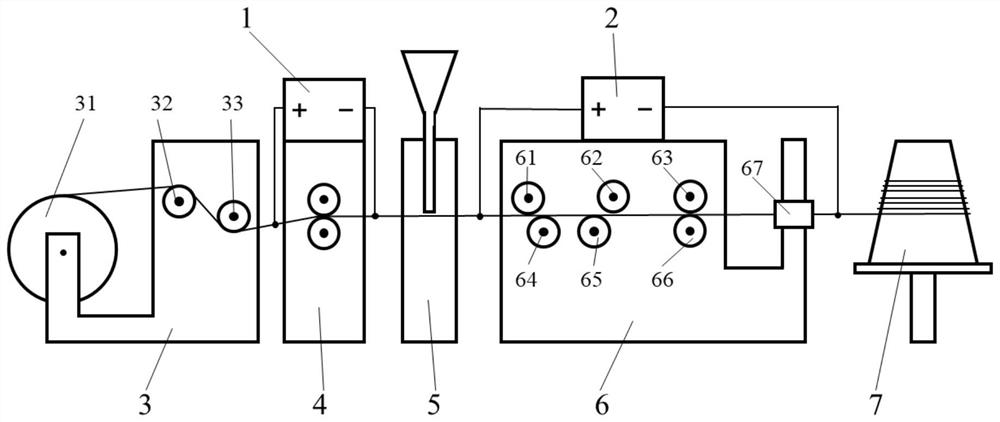

[0031] The present invention also provides a method for preparing flux-cored welding wire based on the principle of electroplasticity, using the above-mentioned preparation equipment for flux-cored welding wire based on the principle of electroplasticity, characterized in that the specific steps are as follows:

[0032] Step 1: Place the alloy strip on the strip device 3, connect the positive and negative poles of the first electric pulse processing equipment 1 to the alloy strip, turn on the first electric pulse processing equipment 1 installed on the rolling device 4, and turn it Adjust to appropriate parameters, conduct electric pulse assisted pre-rolling on the length of 0.5m ~ 1m at the front end of the alloy strip;

[0033] In step 1, the alloy strip is an iron-based alloy strip, copper and its alloy strip, nickel and its alloy strip, or titanium and its alloy strip.

[0034] In step 1, the electric pulse processing parameters are: frequency 150Hz-700Hz, current density ...

Embodiment 1

[0040] Step 1: Place the 316 stainless steel strip on the strip device 3, connect the positive and negative poles of the first electric pulse processing equipment 1 to the alloy strip, turn on the first electric pulse processing equipment 1 installed on the rolling device 4, and place the It is adjusted to appropriate parameters, and electric pulse-assisted pre-rolling is performed on the length of 1m at the front end of the alloy strip. The electric pulse processing parameters are: frequency 300Hz, current density 40A / mm 2 ;

[0041] Step 2: pass the pre-rolled alloy strip through the mold 67, fix it on the wire receiving device 7, and connect the positive and negative poles of the second electric pulse processing device 2 to the alloy strip;

[0042] Step 3: Simultaneously open the drawing device 6, the first electric pulse processing equipment 1, the second electric pulse processing equipment 2, and the powder filling device 5, and perform electric pulse-assisted rolling an...

Embodiment 2

[0046] Step 1: Place the pure copper strip on the strip device 3, connect the positive and negative poles of the first electric pulse processing device 1 to the alloy strip, turn on the first electric pulse processing device 1 installed on the rolling device 4, and place the It is adjusted to appropriate parameters, and electric pulse-assisted pre-rolling is performed on the length of 1m at the front end of the alloy strip. The electric pulse processing parameters are: frequency 250Hz, current density 38A / mm 2 ;

[0047] Step 2: pass the pre-rolled alloy strip through the mold 67, fix it on the wire receiving device 7, and connect the positive and negative poles of the second electric pulse processing device 2 to the alloy strip;

[0048]Step 3: Simultaneously open the drawing device 6, the first electric pulse processing equipment 1, the second electric pulse processing equipment 2, and the powder filling device 5, and perform electric pulse-assisted rolling and drawing on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com