Device and method for abnormally cutting toughened glass by ultra-short pulse laser

An ultra-short pulse laser, tempered glass technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as affecting product use, obvious taper, etc., and achieve the effect of high cutting efficiency and smooth cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

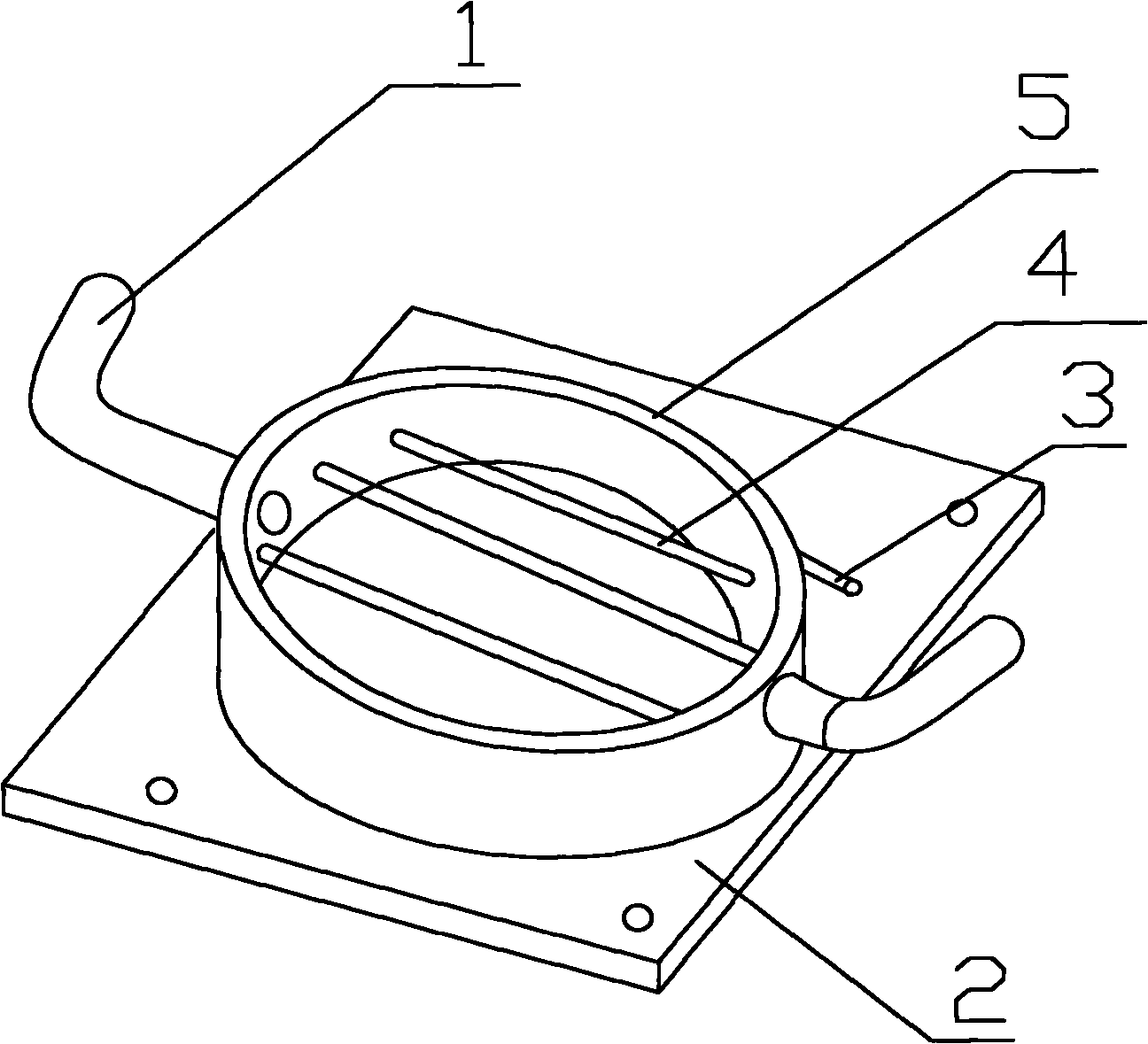

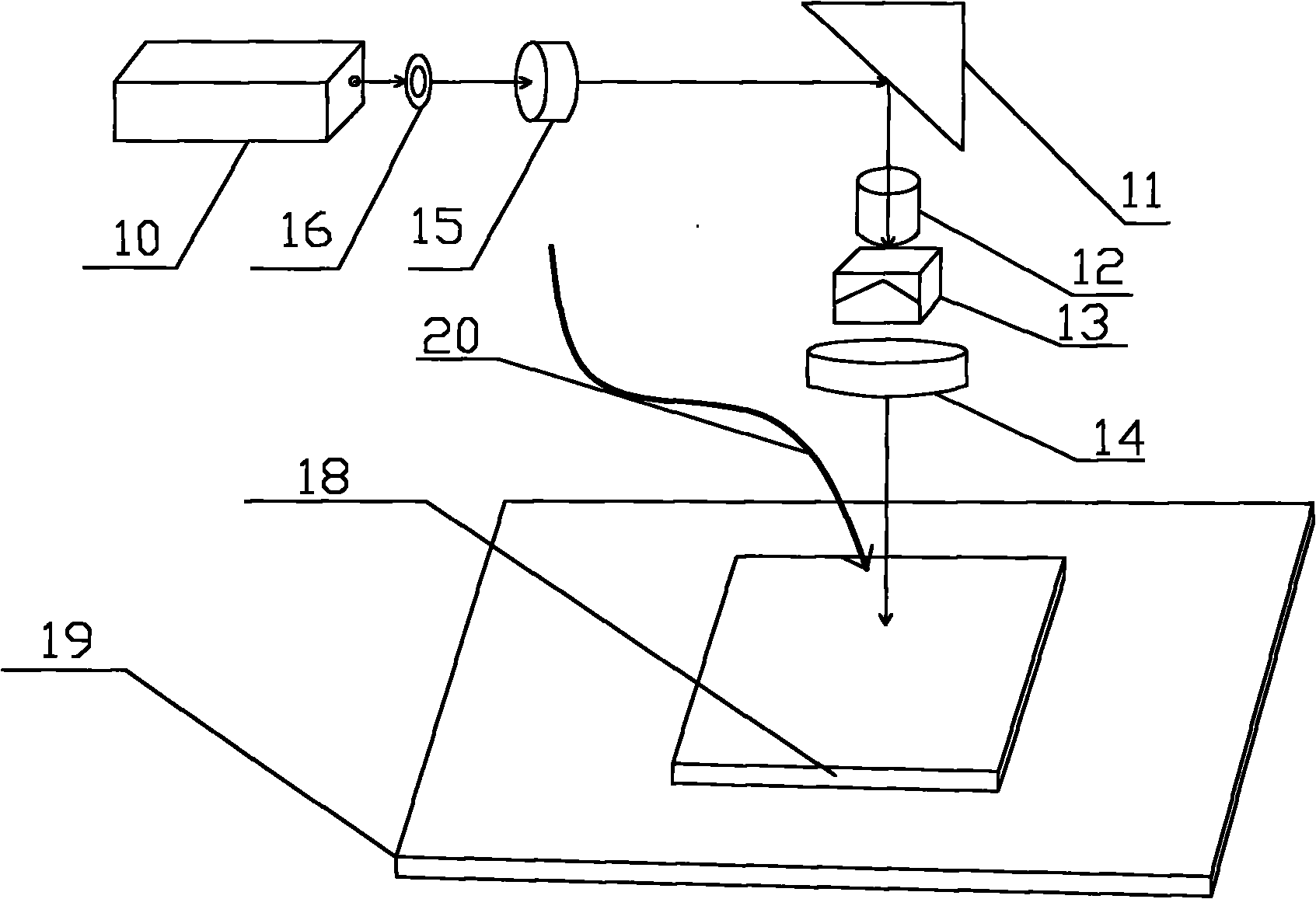

[0021] The invention utilizes a three-dimensional dynamic focusing galvanometer focusing optical path system to carry out special-shaped cutting of glass within 10mm, and realizes a laser cutting glass method in which the cutting surface is relatively smooth and the strength of the glass after cutting is kept high.

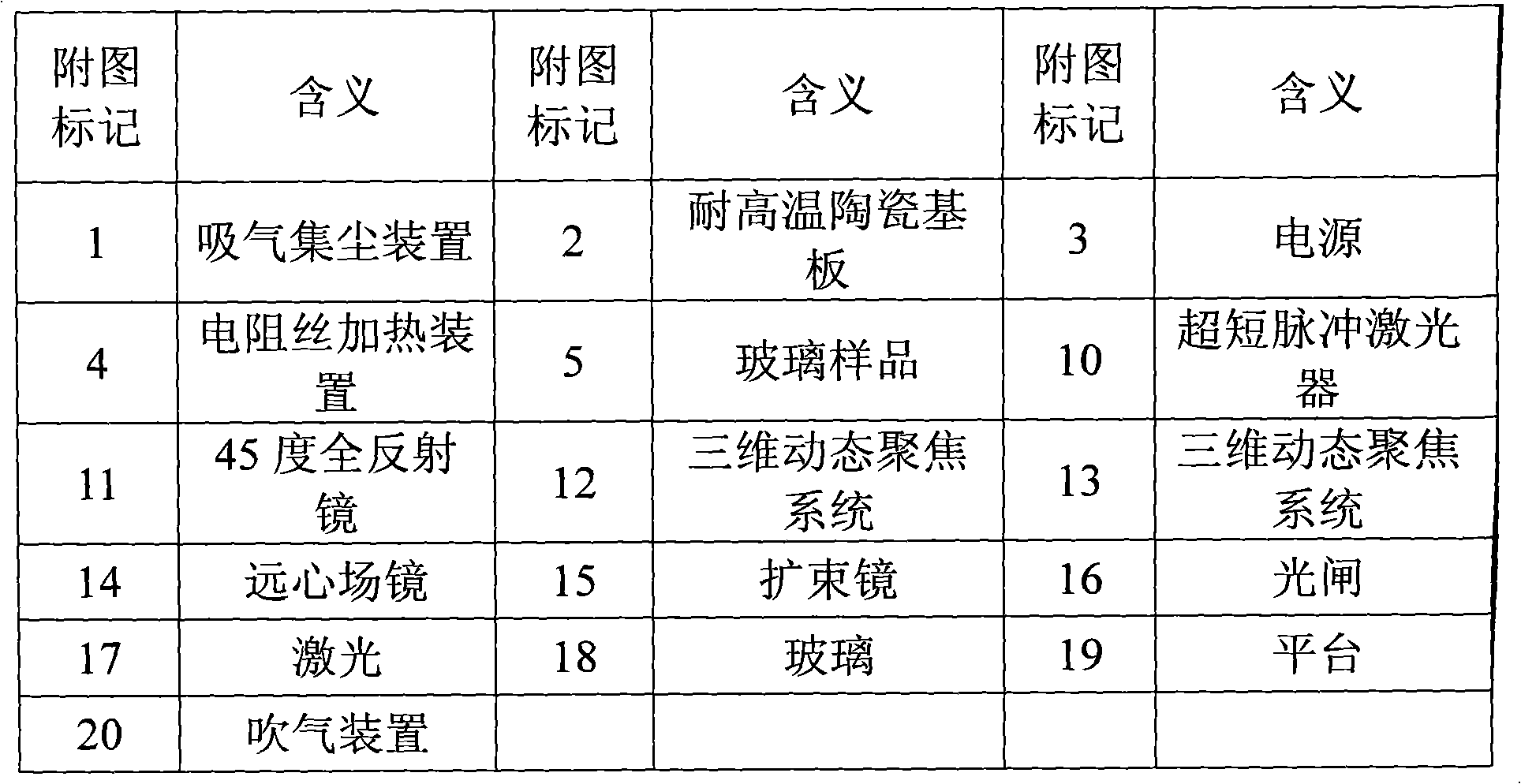

[0022] Such as figure 2 As shown in the device for cutting toughened glass with ultrashort pulse laser, the output end of the ultrashort pulse laser 10 is arranged with an optical gate 16, the ultrashort pulse laser 10 is a laser with a wavelength of 532nm in the green band, and the output end of the optical gate 16 is set There is a beam expander 15, the output end of the beam expander 15 is arranged with a 45-degree total reflection mirror 11, and the output end of the 45-degree total reflection mirror 11 is arranged with a three-dimensional dynamic focusing system 12 and a three-dimensional dynamic focusing system 13, and the three-dimensional dynamic focusing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com