Composite dual-electrode plates preparation method of minisize directly connecting methanol fuel battery

A methanol fuel cell and bipolar plate technology, which is applied to fuel cell components, fuel cells, battery electrodes, etc., can solve the problems that the preparation of true three-dimensional microchannels cannot be realized, the processing of true three-dimensional microstructures is difficult, and the production cost is high. , to achieve the effect of light weight, low production cost and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

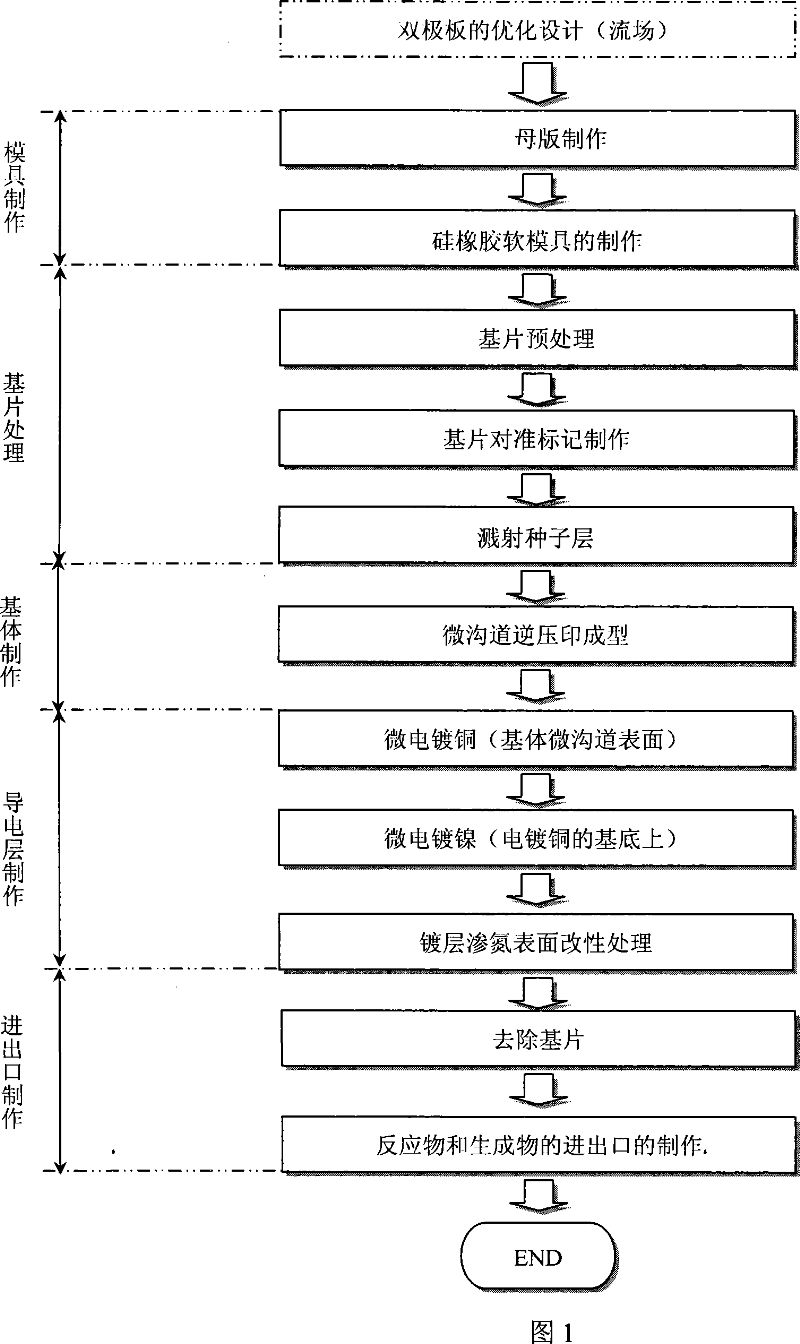

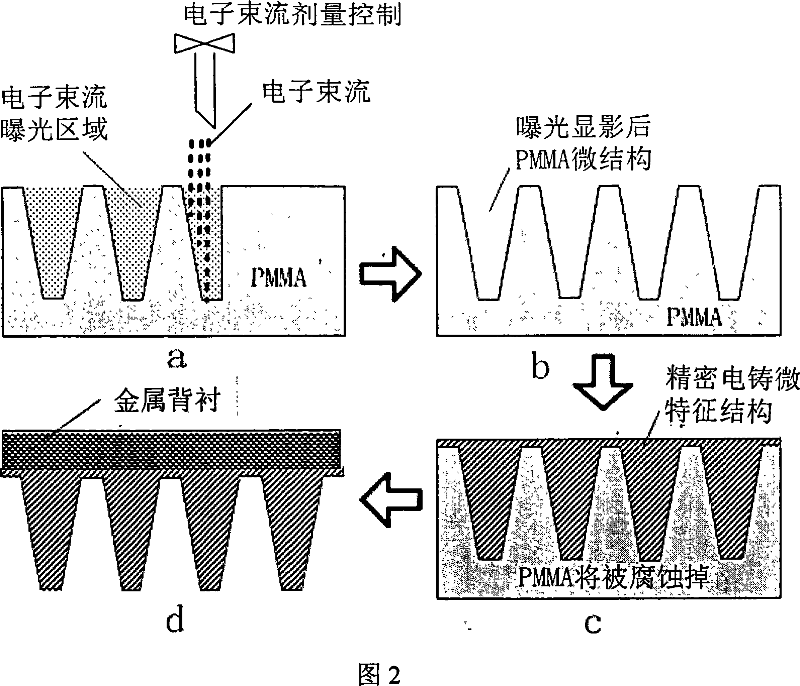

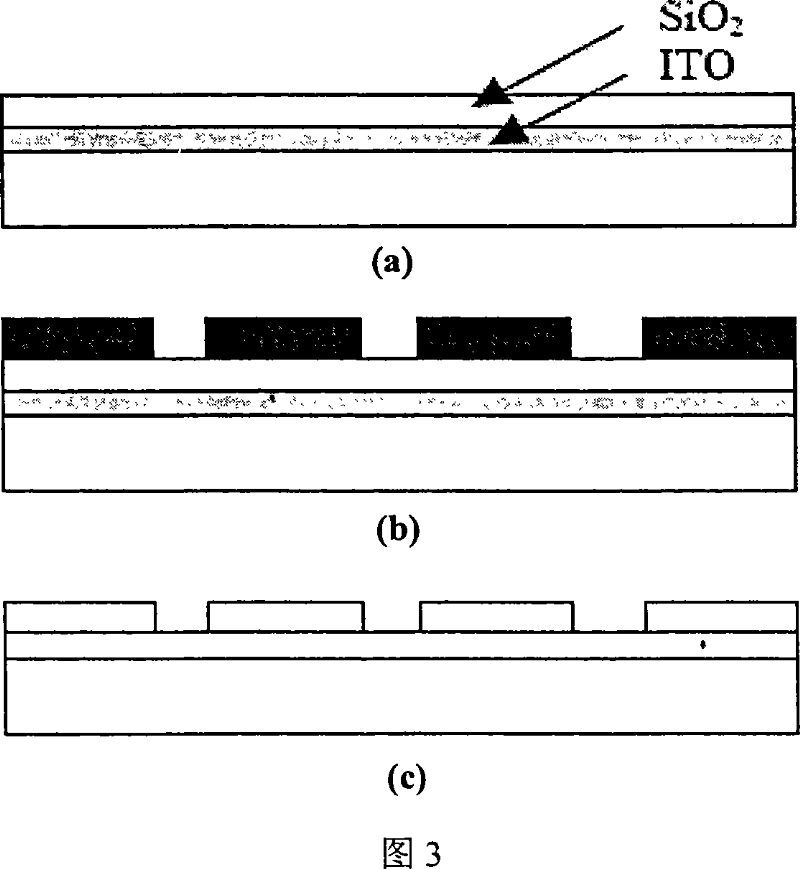

[0040] The preparation method of the composite bipolar plate of the miniature direct methanol fuel cell of the present invention uses the modified polymethyl methacrylate spin-coated on the glass substrate as the base material, and deposits high-conductivity copper on the base as the conductive layer. A layer of micro-electroplated nickel or Cr or Ni-50Cr alloy is used as an anti-corrosion protection material, and a composite bipolar plate of a miniature direct methanol fuel cell is prepared by a non-silicon composite manufacturing process. Its preparation method adopts a new non-silicon composite manufacturing process, which combines the advantages of micro-imprinting and micro-electroplating deposition processes, and improves the resistance of the composite bipolar plate by performing nitriding surface modification on the copper-nickel coating. Corrosive, reduces contact resistance.

[0041] See Figure 1 for the technical route of non-silicon composite fabrication of polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com