Method for preparing aluminum alloy super-hydrophobic functional surface by laser marking machine

A laser marking and aluminum alloy technology, which is applied in the coating process of metal materials, etc., can solve the problems of high cost of femtosecond lasers and harsh working environment requirements, and achieve the effect of simple preparation process, low processing cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

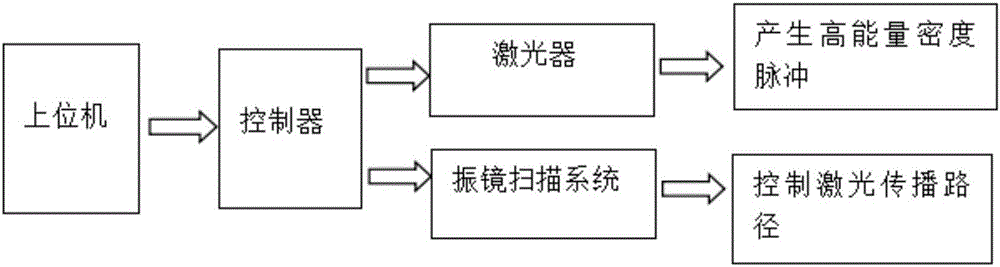

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

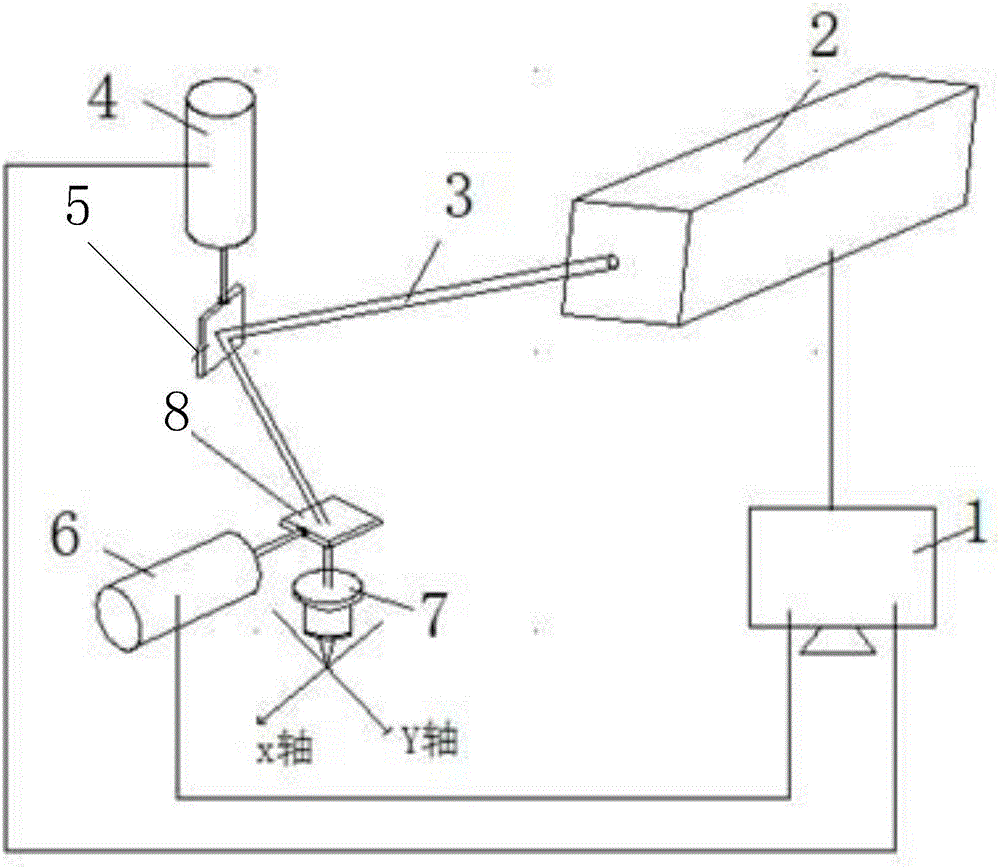

[0031] The method for preparing an aluminum alloy super-hydrophobic functional surface by the laser marking machine of this embodiment comprises the following steps:

[0032] (1) Pretreatment: the 6061 aluminum alloy samples to be treated are subjected to 400 # 、1000 # 、3000 # Grinding with sandpaper, the polished samples were ultrasonically cleaned with absolute ethanol and distilled water in sequence, the ultrasonic temperature was 40-60°C, the time was 20-30min, and then dried in a constant temperature oven at 60-80°C for 5-10min to obtain clean aluminum alloy samples;

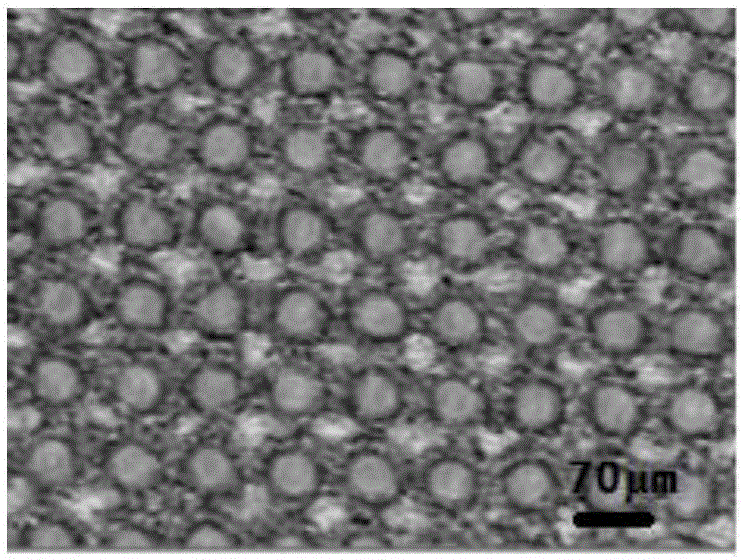

[0033] (2) Laser micromachining: Use an infrared laser marking machine to adjust the relevant process parameters to scan the surface of the sample; the wavelength of the laser is 1064nm, the maximum laser output power is 16W, the laser frequency is 20kHz, and the current used during processing The density is 13A, the laser aperture is 80μm, the single exposure time is 5ms for dot matrix processing, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com