Light source assembly

A technology of light source components and light sources, applied in the directions of light sources, optical elements, point light sources, etc., can solve the problems of reduced light output rate, reduced light transmittance, and affected light field distribution of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

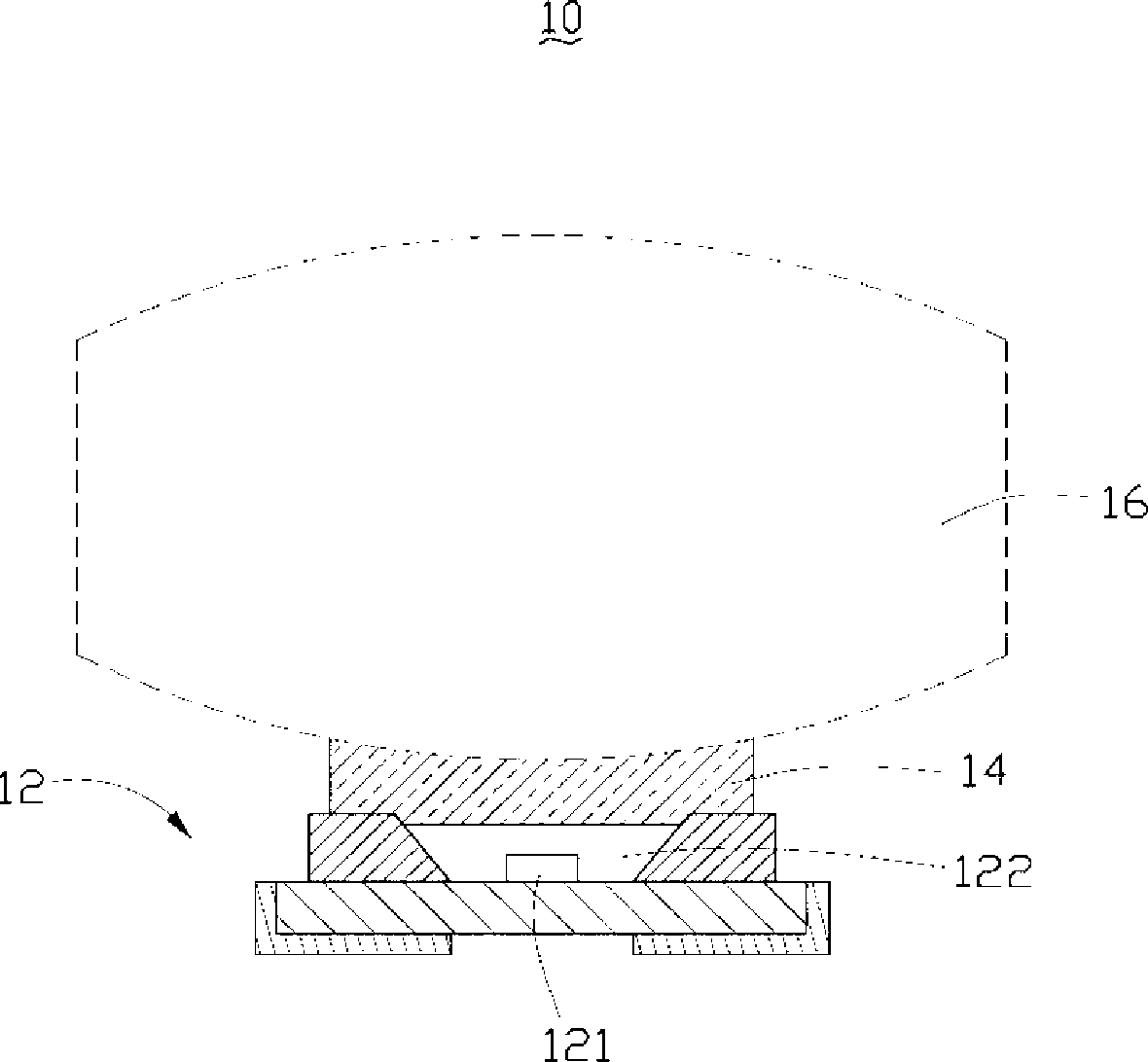

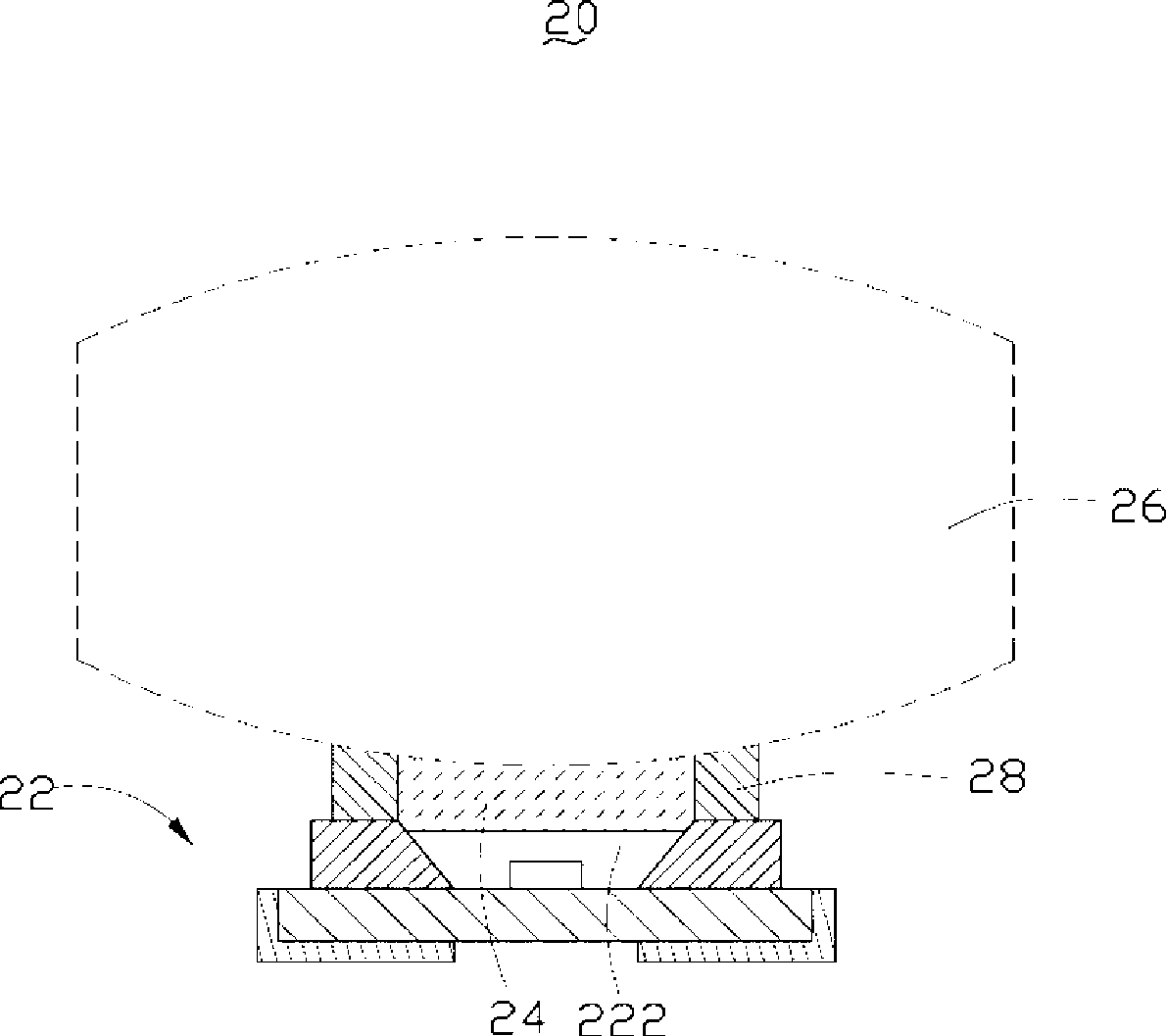

[0013] refer to figure 1 , the light source assembly 10 of the first embodiment includes a light source 12 , a light-transmitting filling layer 14 and a light processing element 16 . The light source 12 includes a light emitting portion 121 and a light emitting portion 122 . The light-transmitting filling layer 14 fills the gap between the light-exiting portion 122 and the light-processing element 16 , and the light-transmitting filling layer 14 makes the light-exiting portion 122 and the light-processing element 16 bond.

[0014] The light emitting unit 121 can be a light emitting diode or a diode laser, and of course other solid light sources are also applicable. The light emitting part 122 is the encapsulation shell of the light emitting part 121, and is usually made of a material with high transparency, such as glass, silica gel, transparent silicone rubber or transparent resin such as epoxy resin, polymethacrylic resin, and the like.

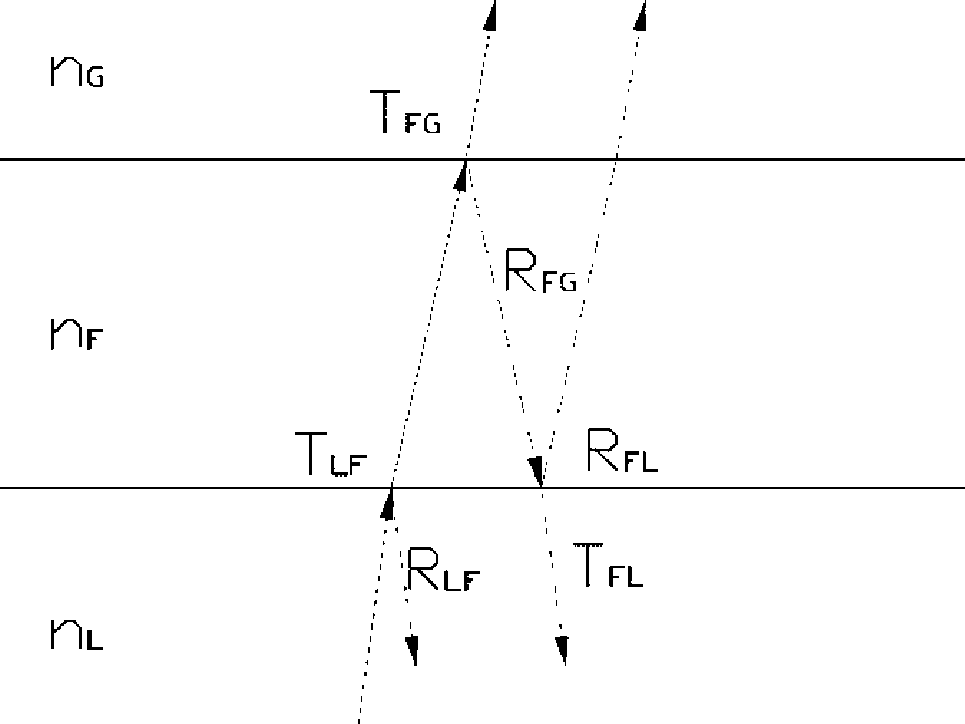

[0015] The light-transmitting fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com