Device and method for laser etching OLED display anode thin film material

A technology of laser etching and anode film, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex and cumbersome procedures, difficult spacing control, and weak selectivity, and achieve good etching linearity, High luminous efficiency and fine line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

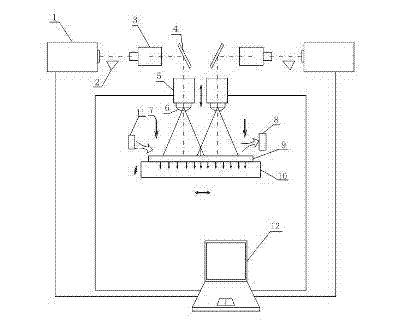

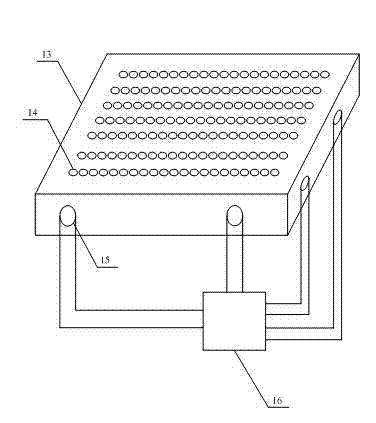

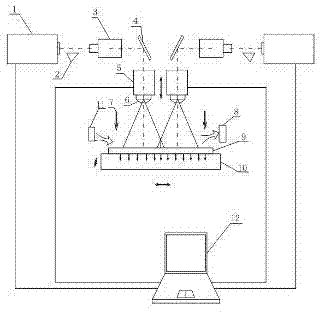

[0015] The present invention proposes a micromachining method and system for applying laser etching to the anode of OLED displays. Laser etching can avoid the inherent disadvantages of chemical wet methods, and the laser has the characteristics of non-contact, non-polluting environment, and easy control, making it an OLED display An important application hotspot of anode pattern line width control, and will gradually be widely used in industry. The use of lasers to etch the anode of OLED displays can achieve a relatively stable line width, making the line width of the anode as thin as 20um. During production, the etched pattern can be easily replaced without waste generation, which can save a lot of research and development costs and shorten the product development cycle. The high-precision control system can perform high-efficiency etching, which is fast, stable, and highly repeatable. It can ensure the stability and precision of processing and greatly improve the yield rate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com