Device and method for etching silver syrup on electronic product

A technology of electronic products and silver paste, applied in circuits, electrical components, laser welding equipment, etc., can solve the problems of low yield rate, poor linearity of screen printing silver paste pins, easy aging and brittleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method for high-frequency infrared pulse laser etching of invisible area film materials on the touch screen of the present invention adopts a high-frequency infrared short-pulse laser, and the processed materials are materials such as high-conductivity silver paste, copper or molybdenum-aluminum-molybdenum, and the laser is focused on the electronic On the non-visible area of the product, the silver paste, copper or molybdenum-aluminum-molybdenum layer absorbs the laser light to achieve the etching effect.

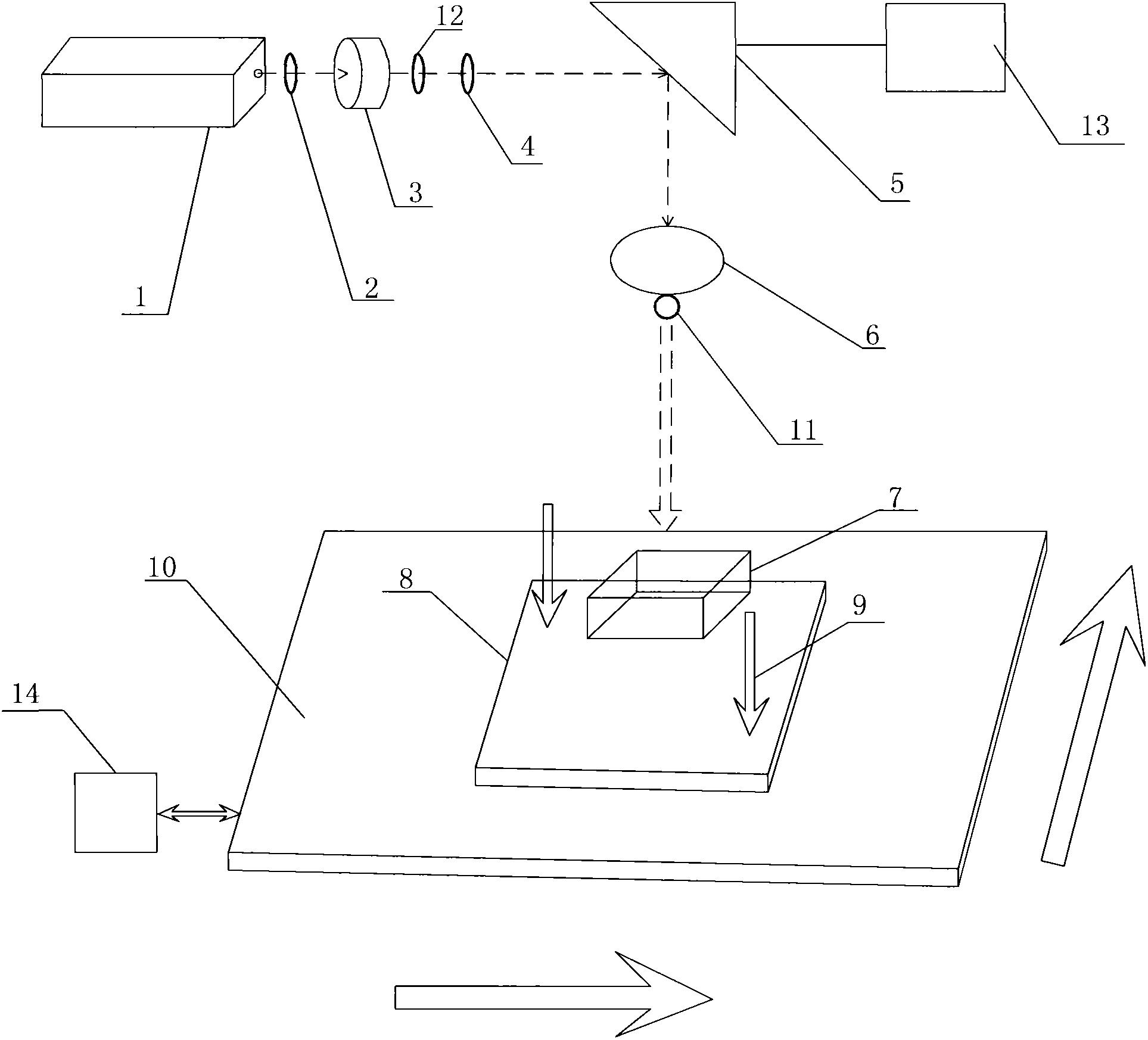

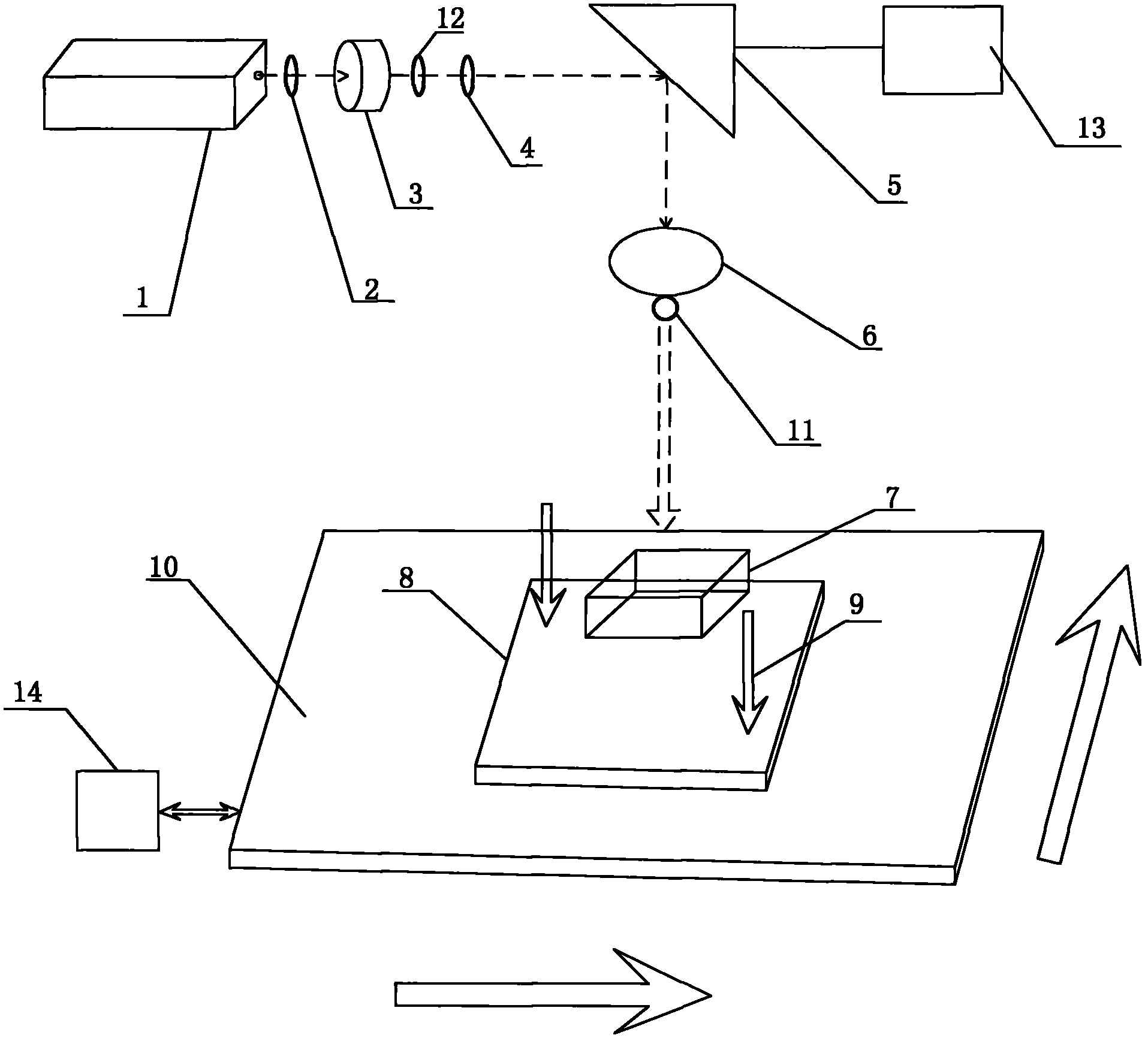

[0018] Such as figure 1 As shown in the device for etching silver paste on electronic products, the high-frequency short-pulse laser 1 is a laser with a wavelength of 1000nm-1100nm, a pulse width of 100ps-50ns, and a frequency of 10KHz-200KHz. The high-frequency short-pulse laser 1 The output end is arranged with an optical gate 2, and the output end of the optical gate 2 is provided with a beam expander 3, and the output end of the beam expander 3 is arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com