Patents

Literature

77results about How to "Thin line width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

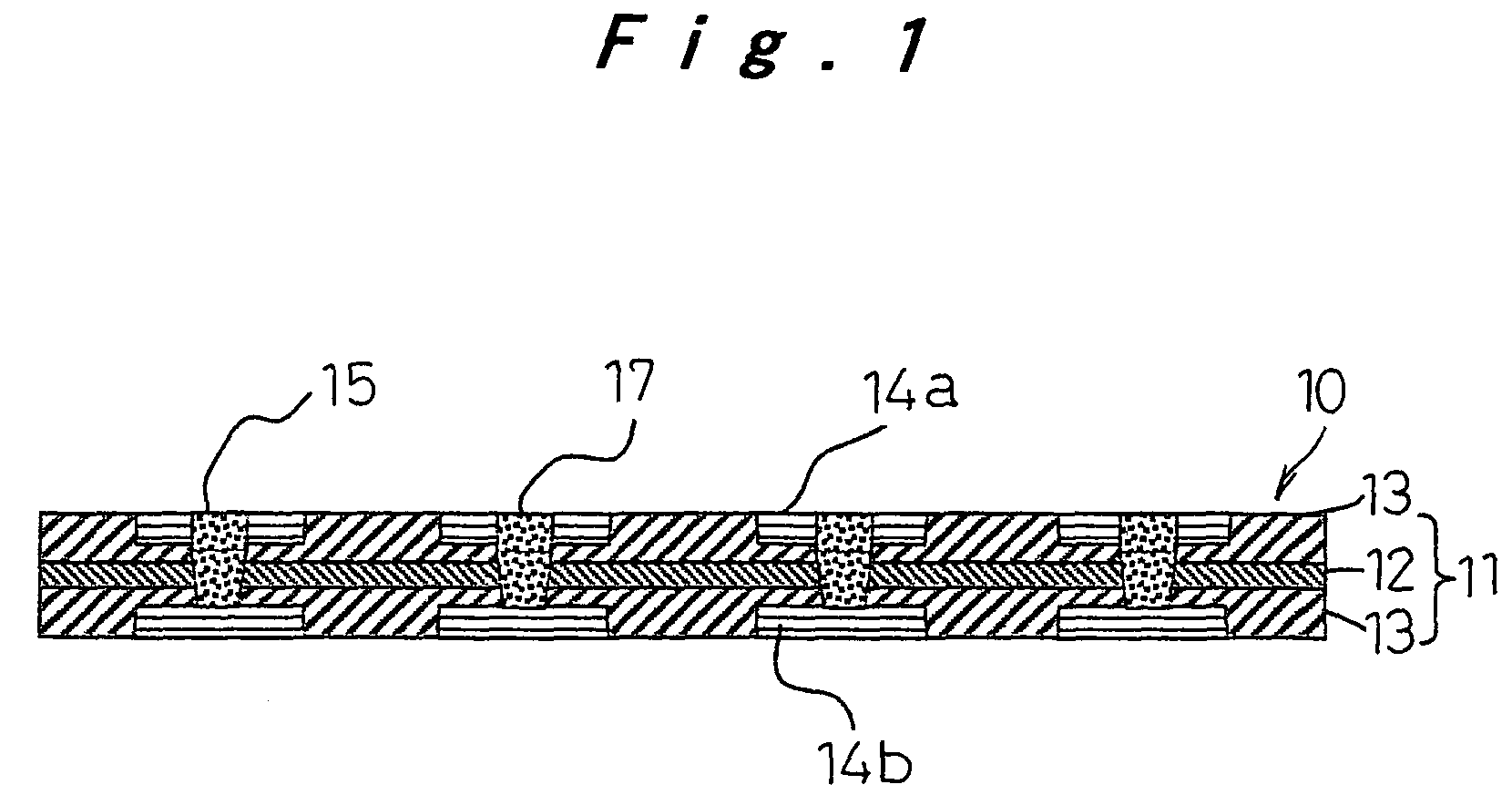

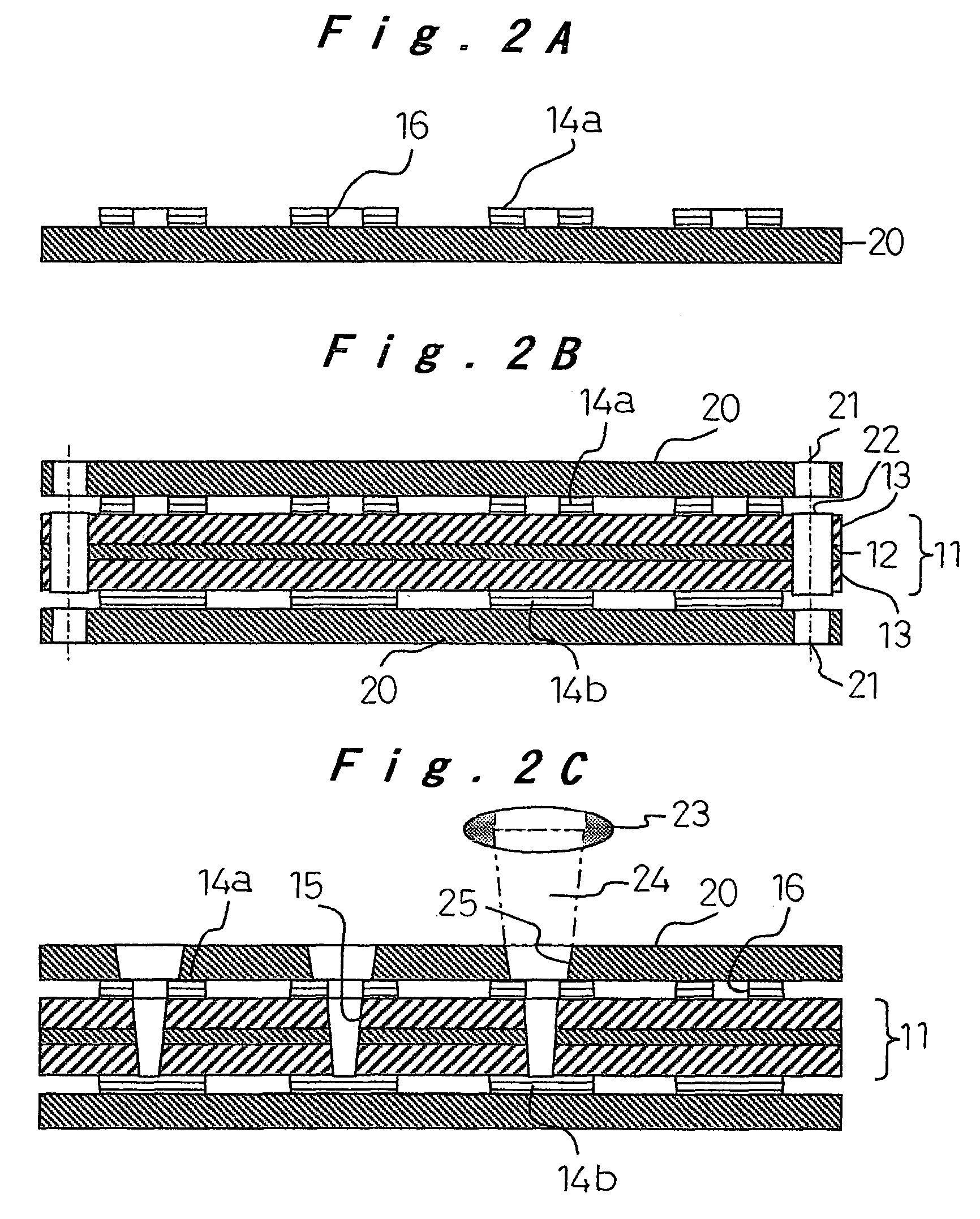

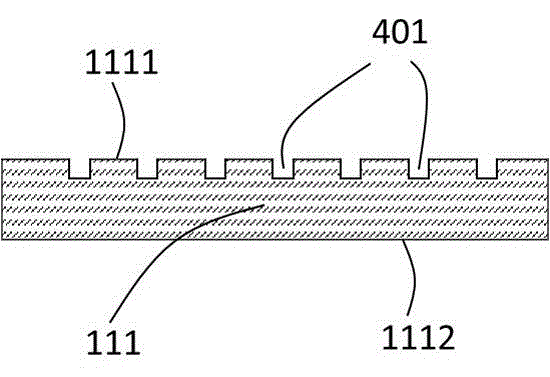

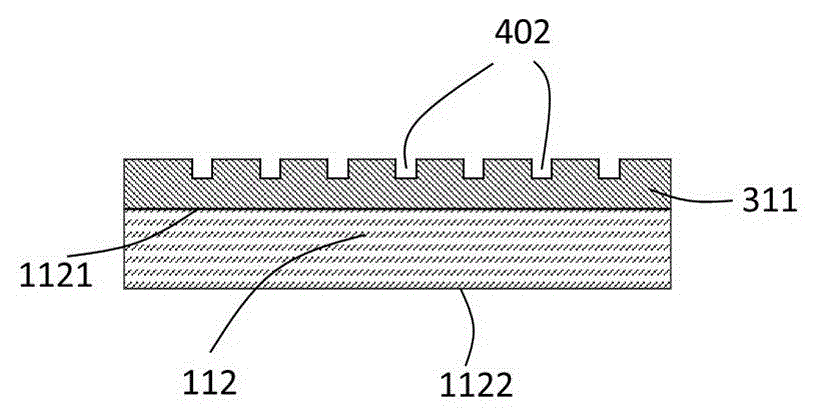

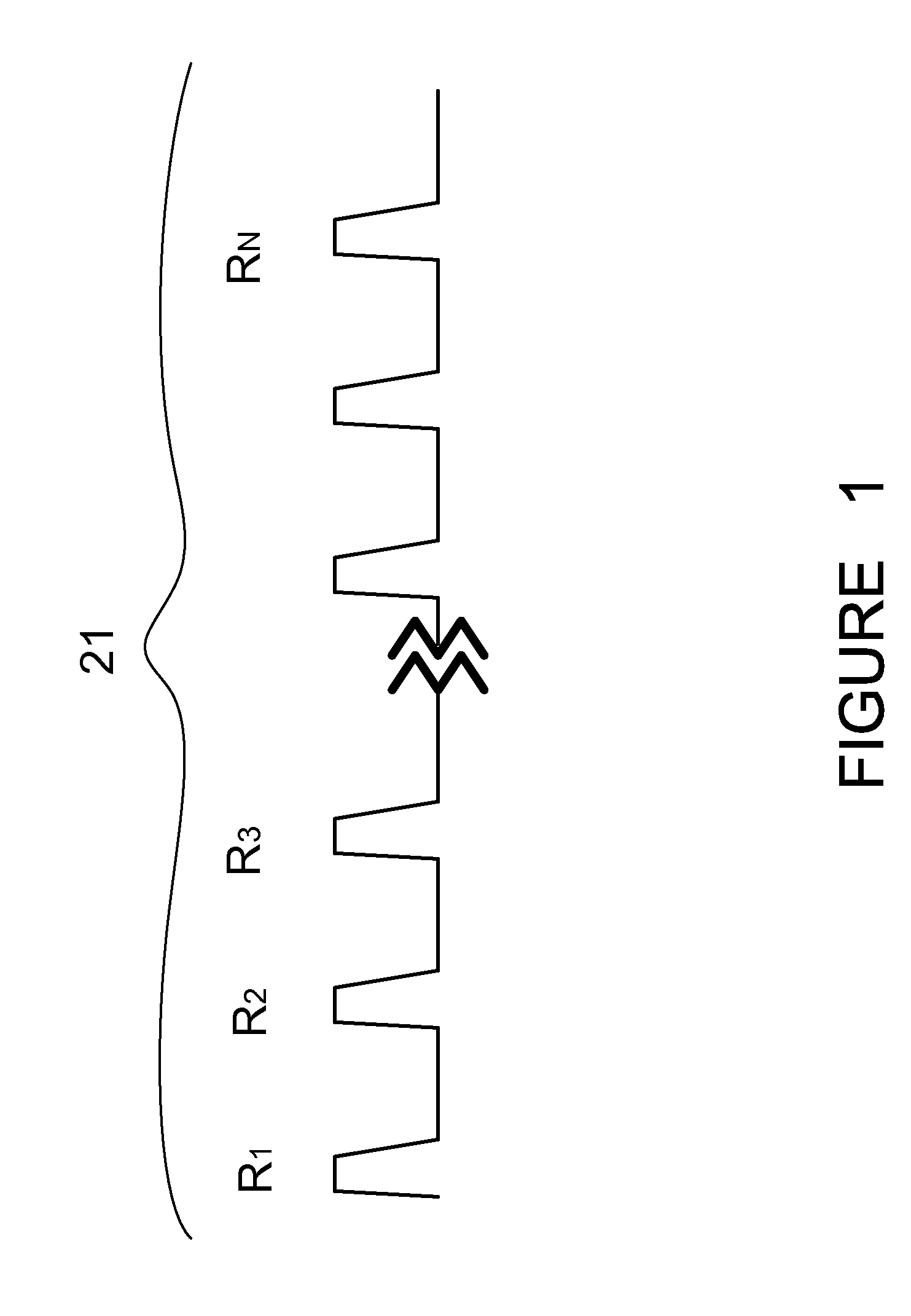

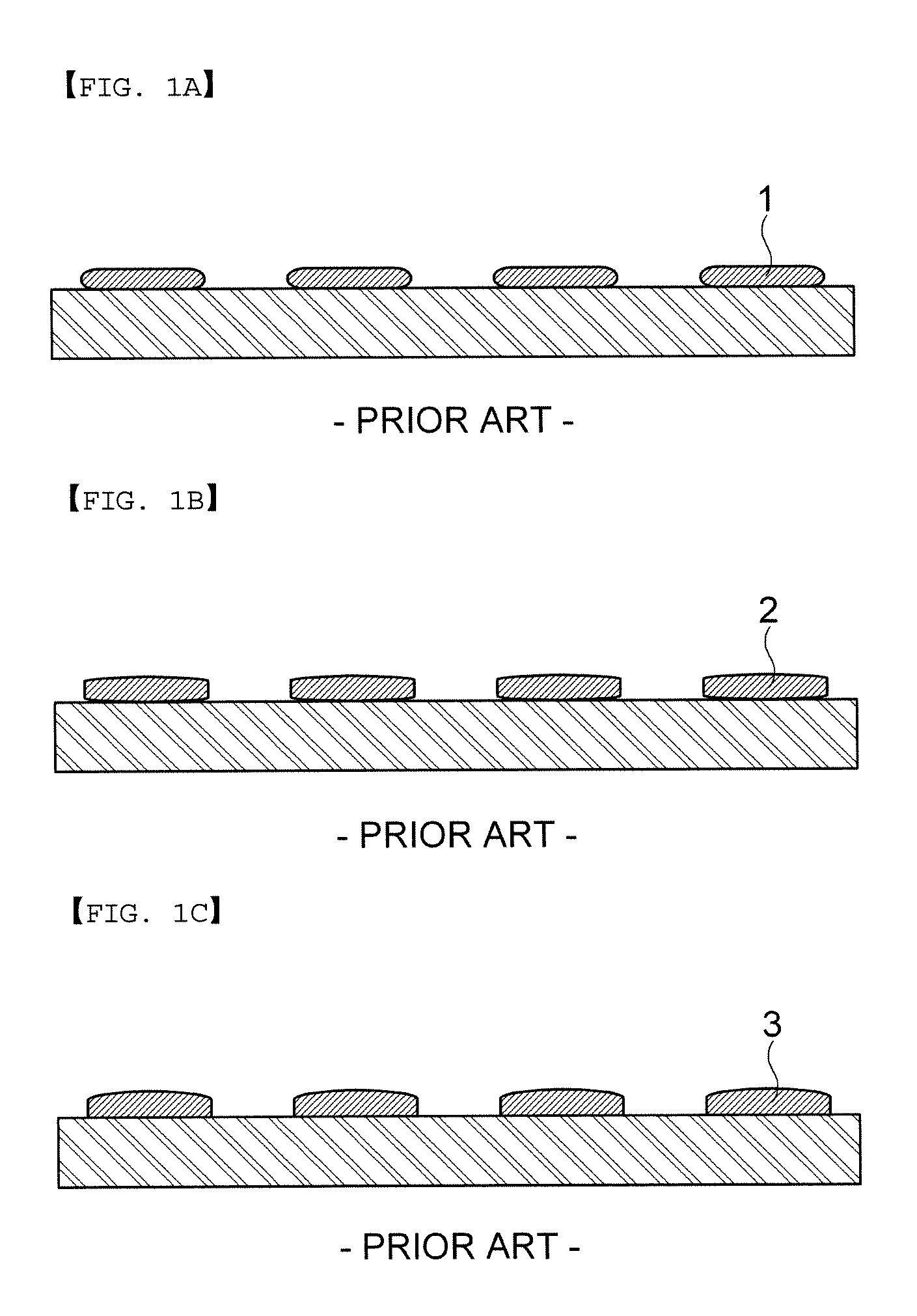

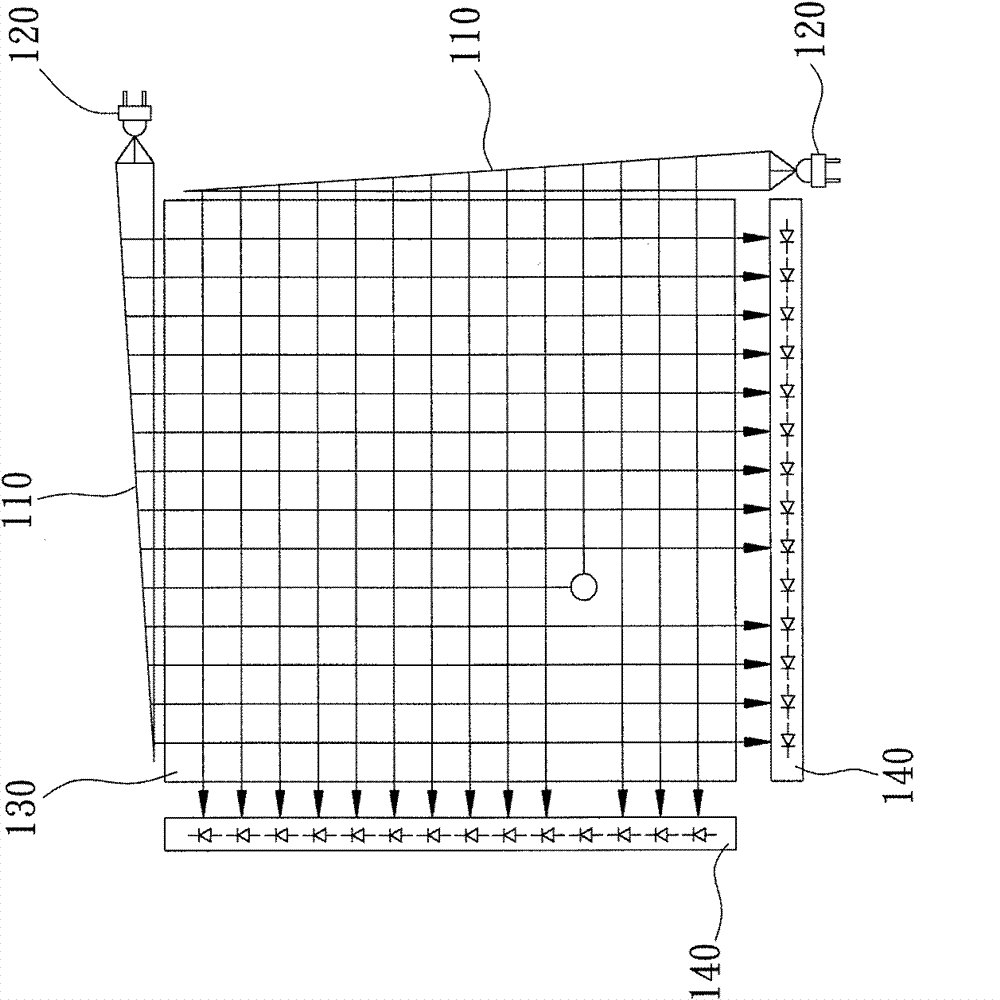

Electroconductive sheet and touch panel

ActiveUS20130327560A1High transparencyHigh detection sensitivityNon-insulated conductorsSuperimposed coating processThin metalEngineering

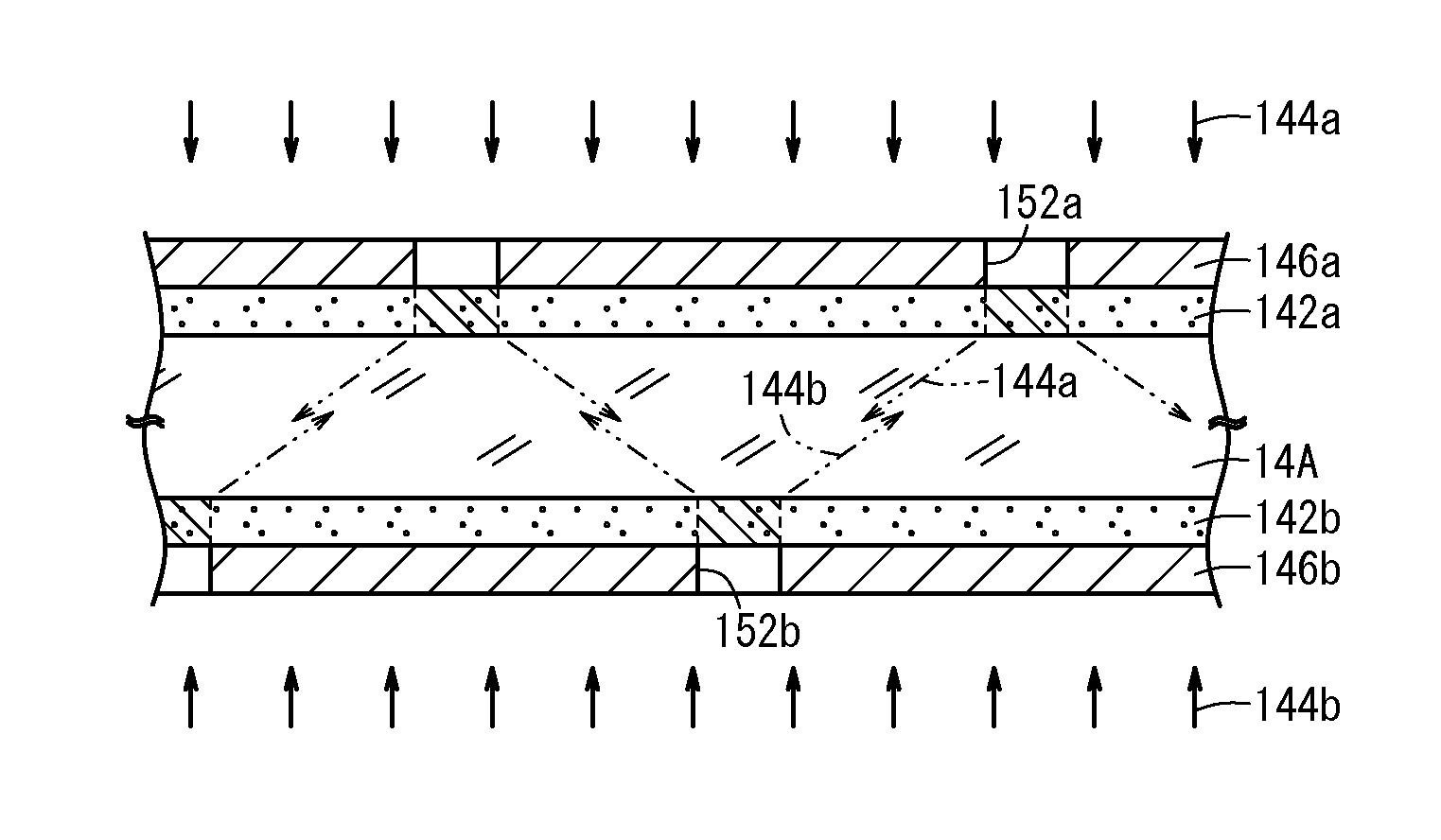

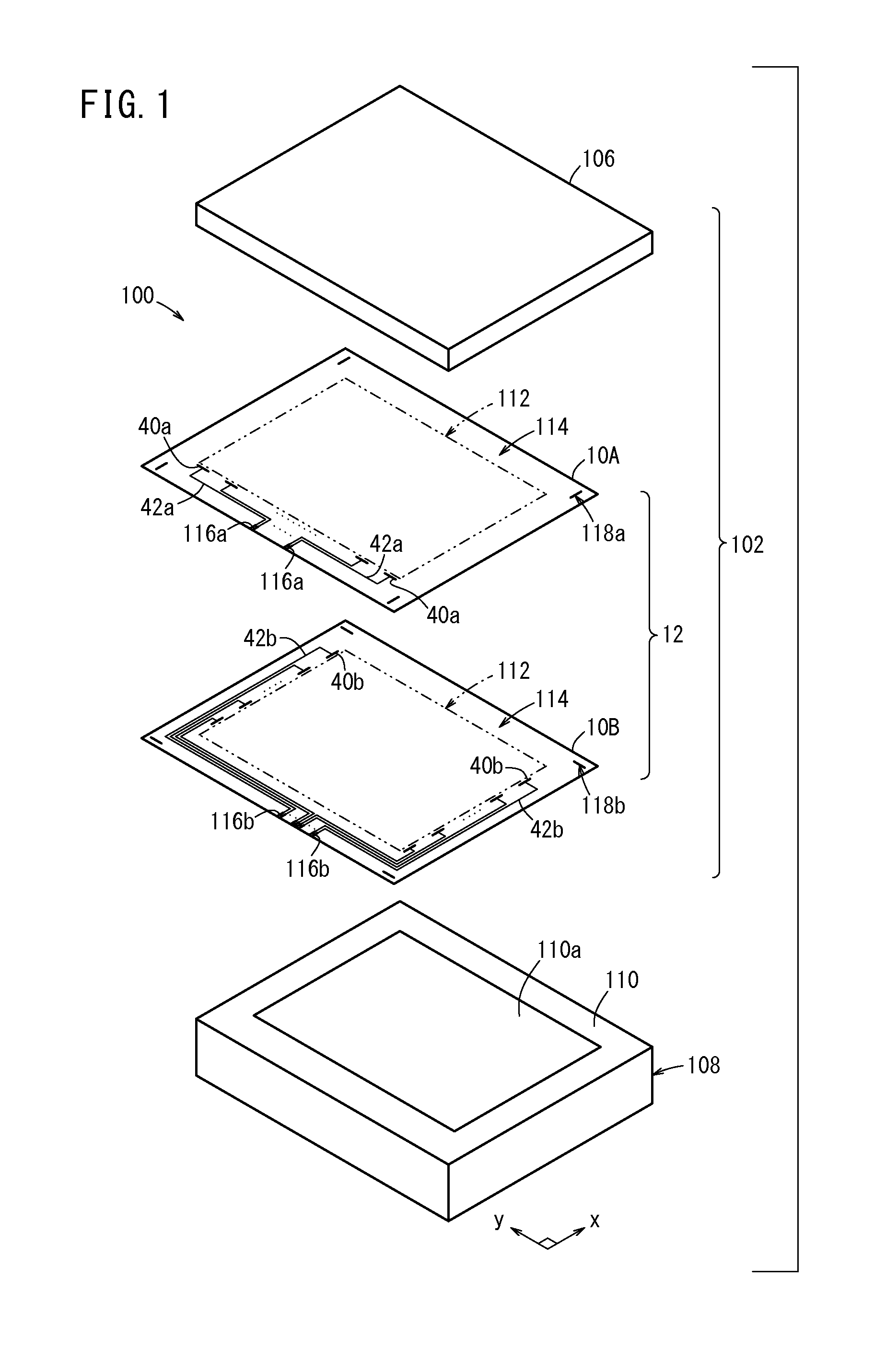

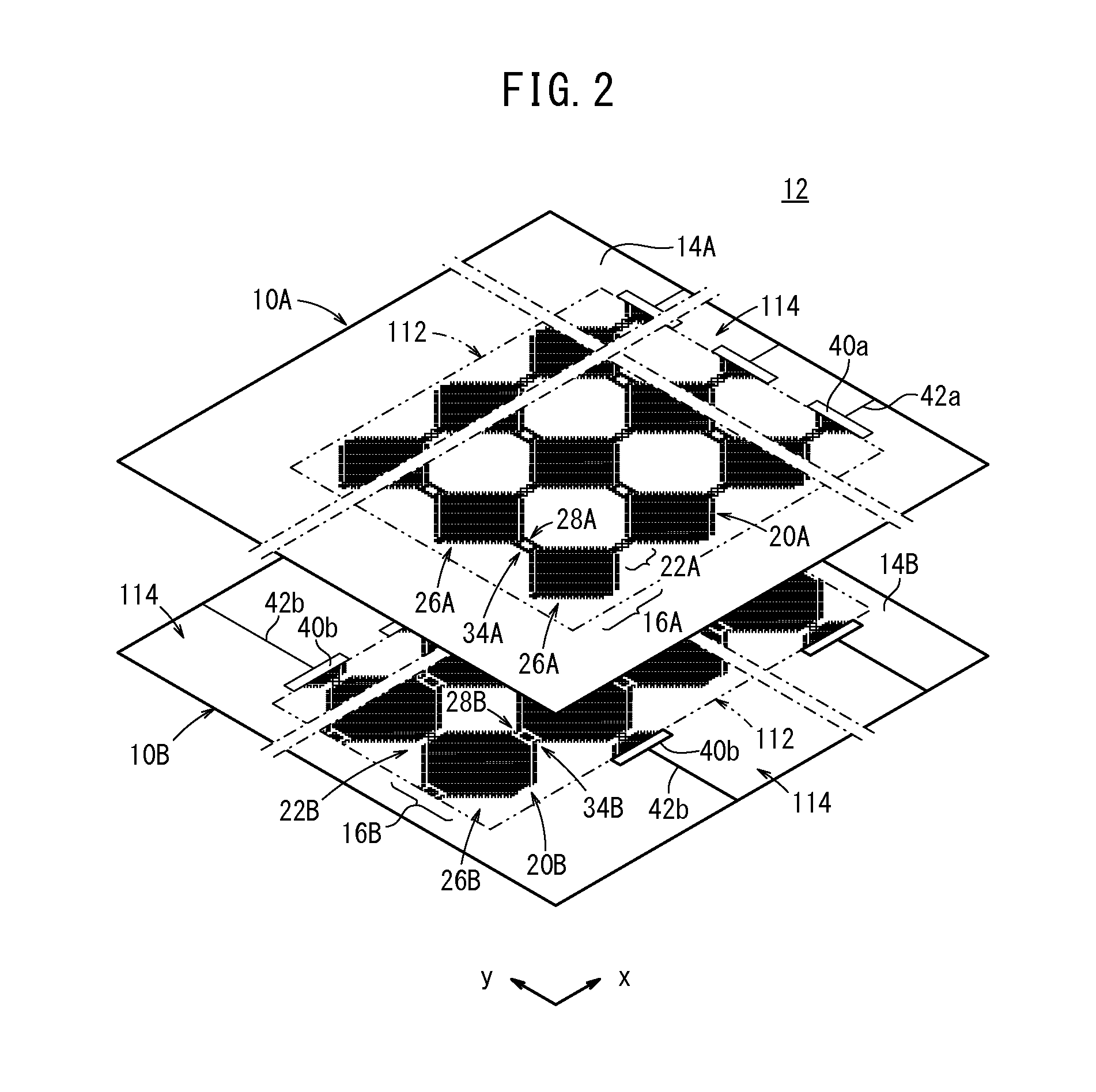

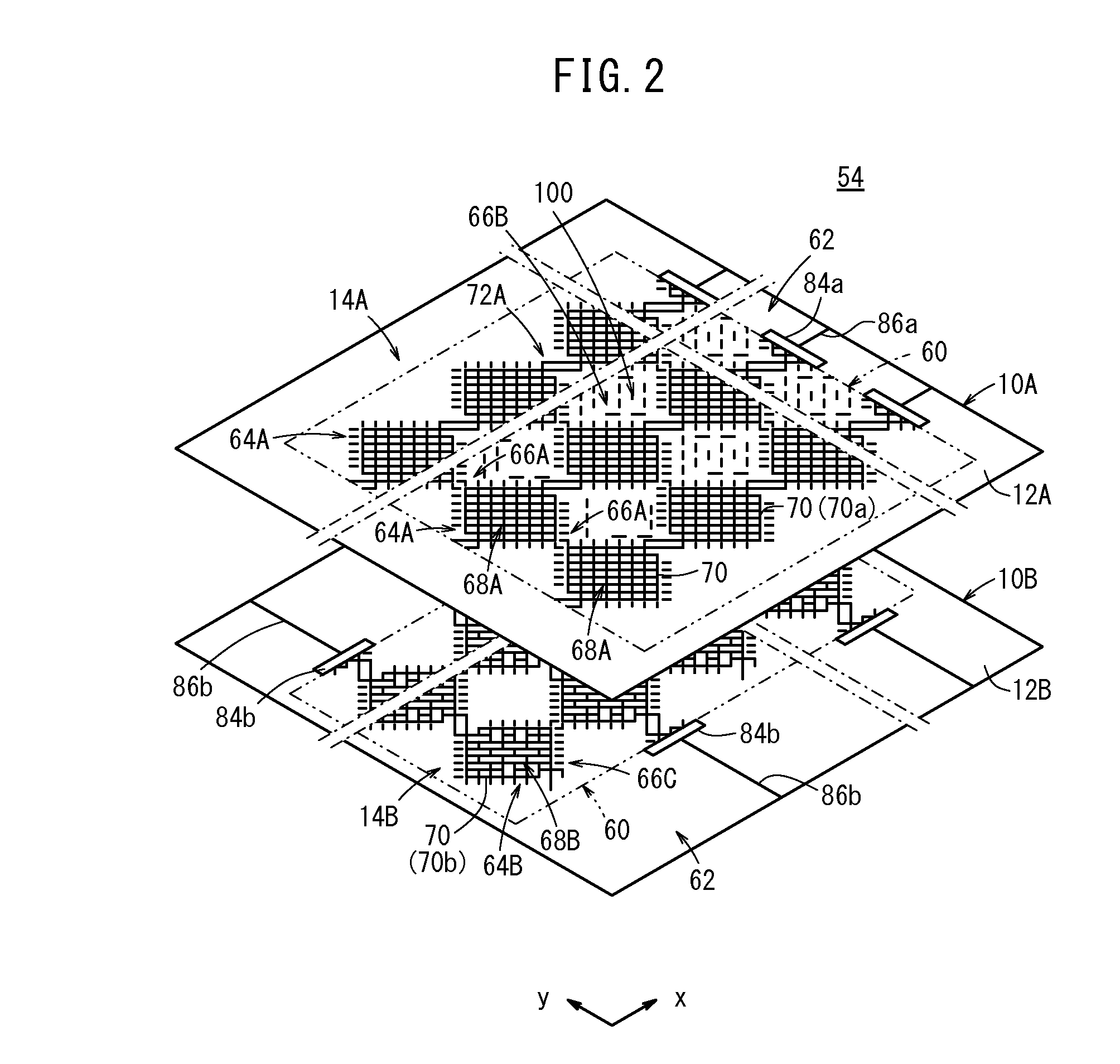

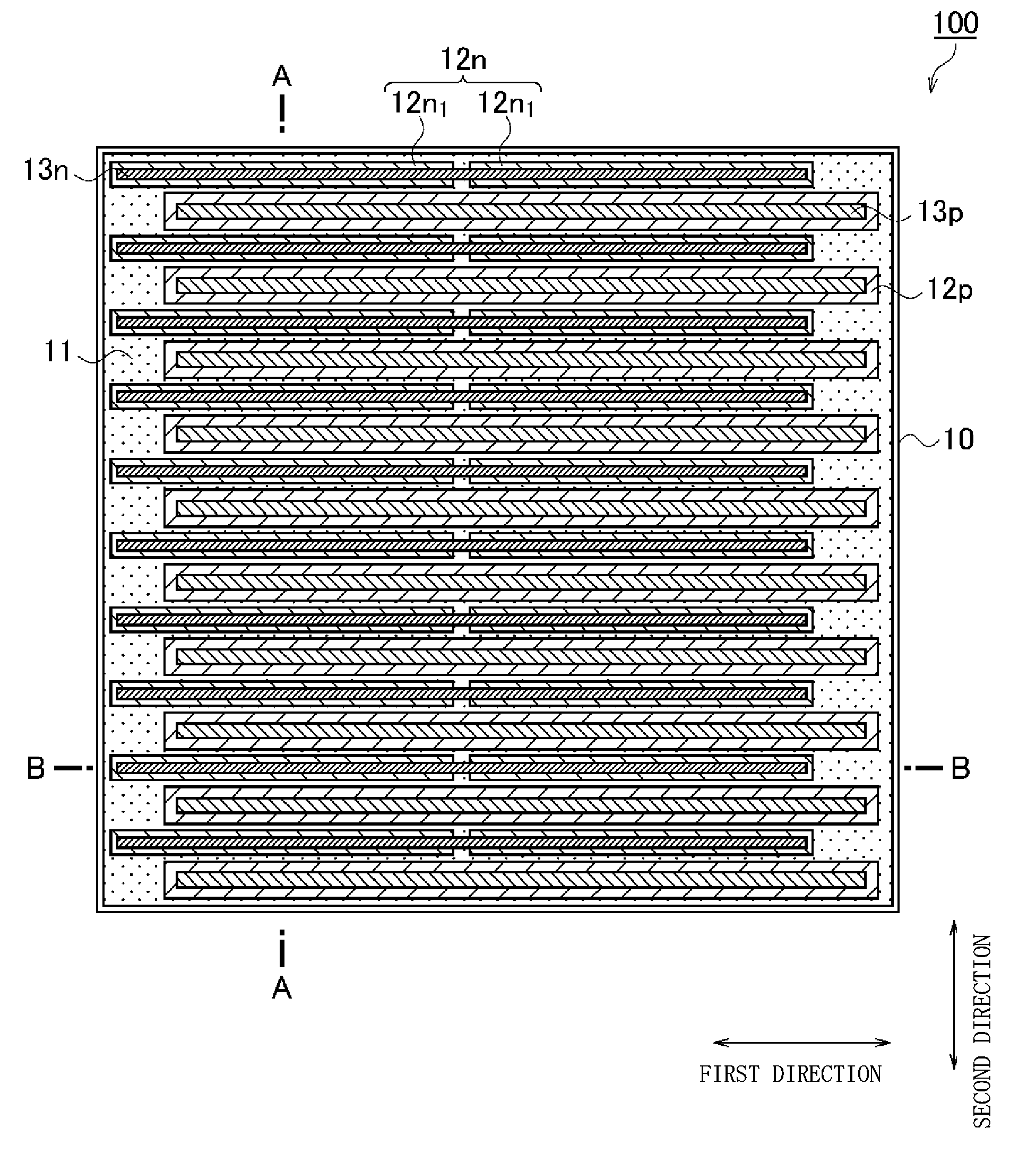

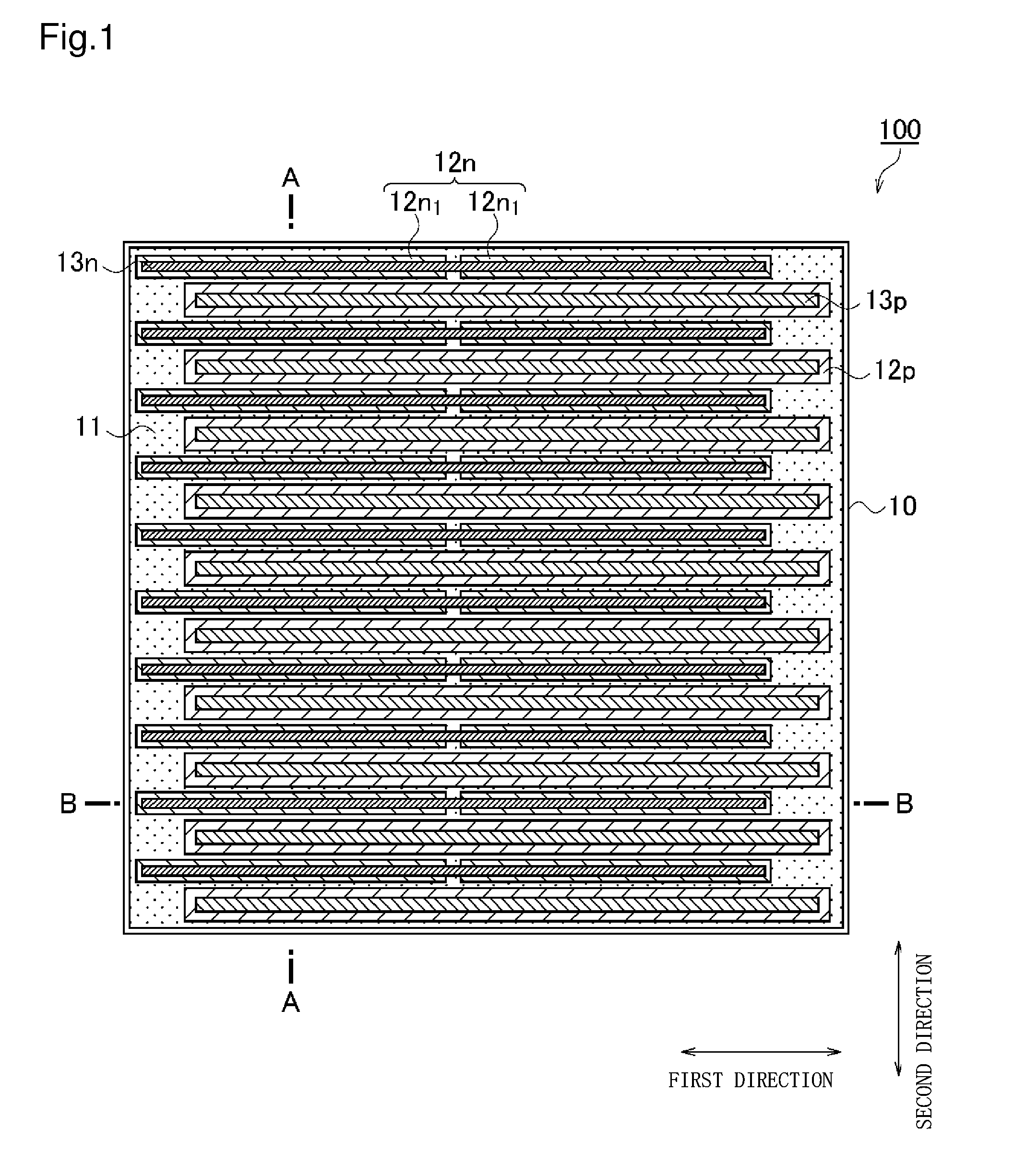

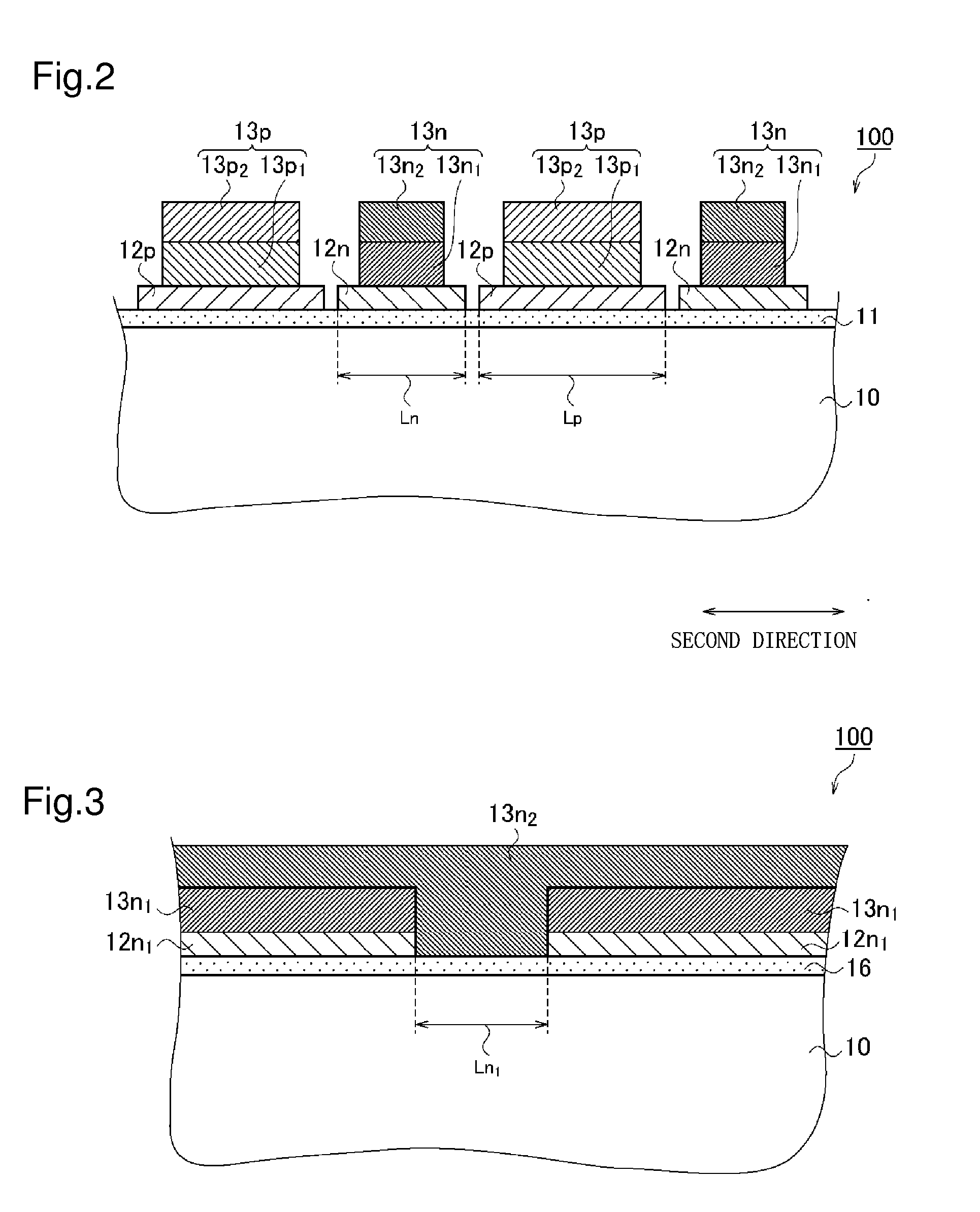

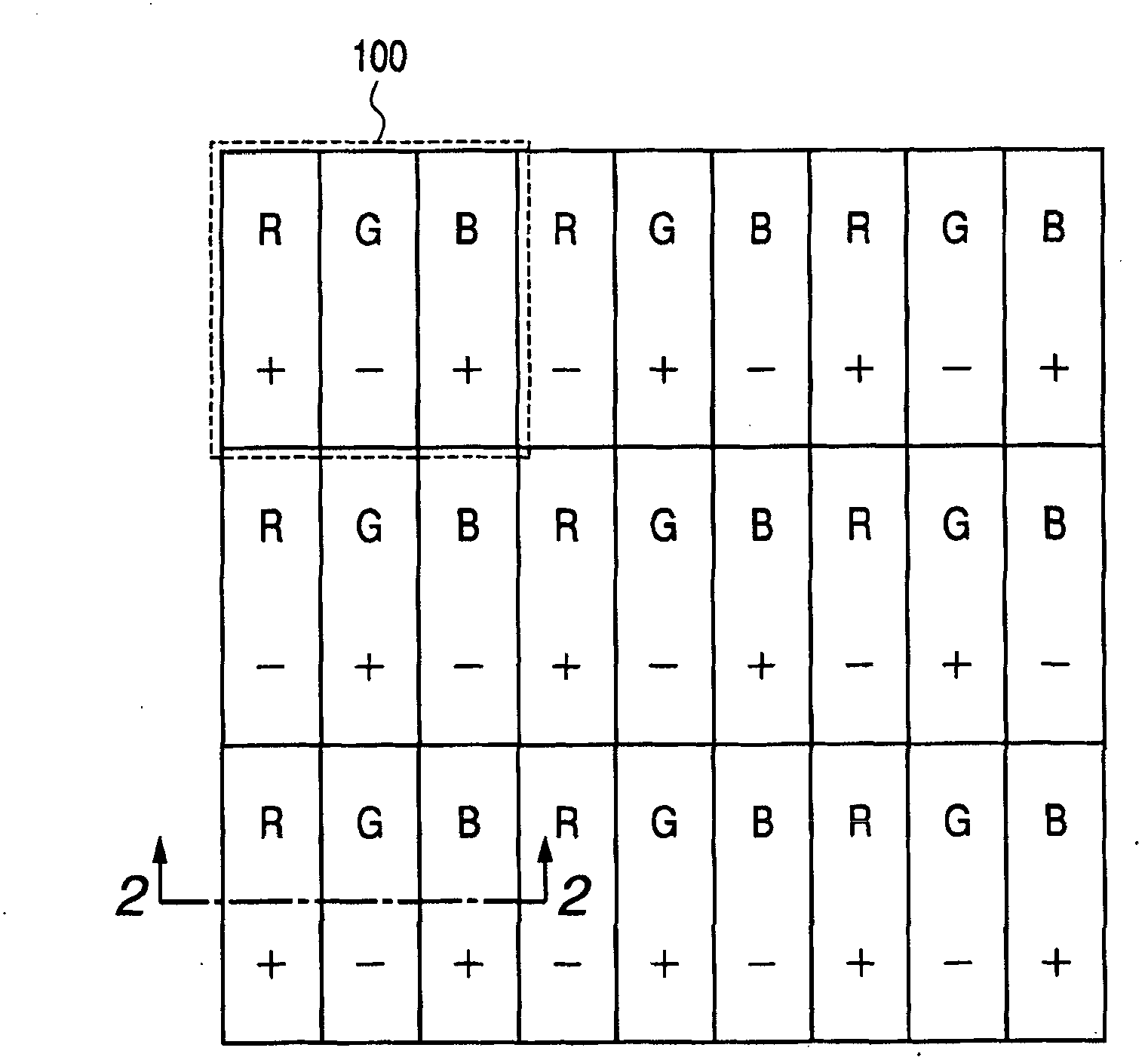

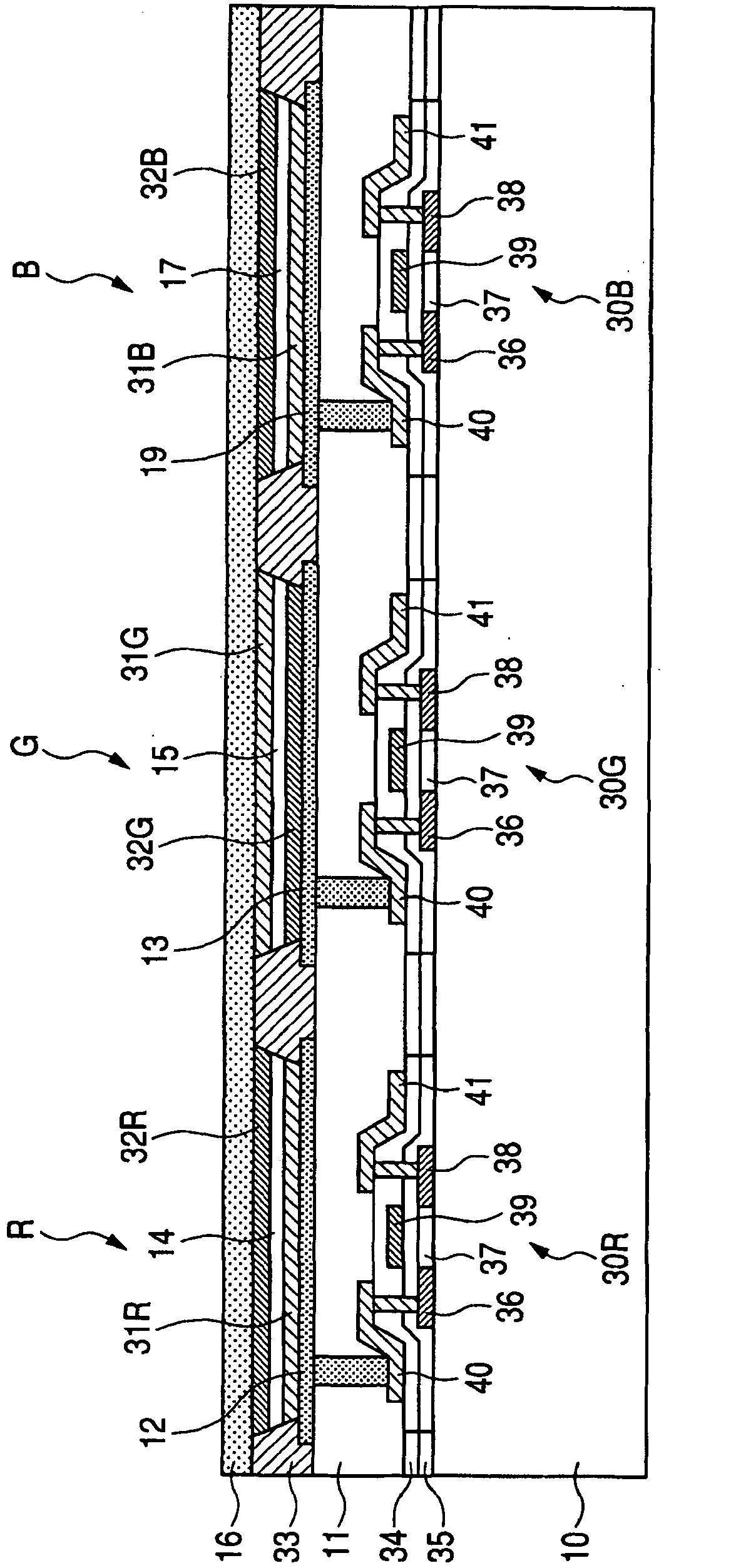

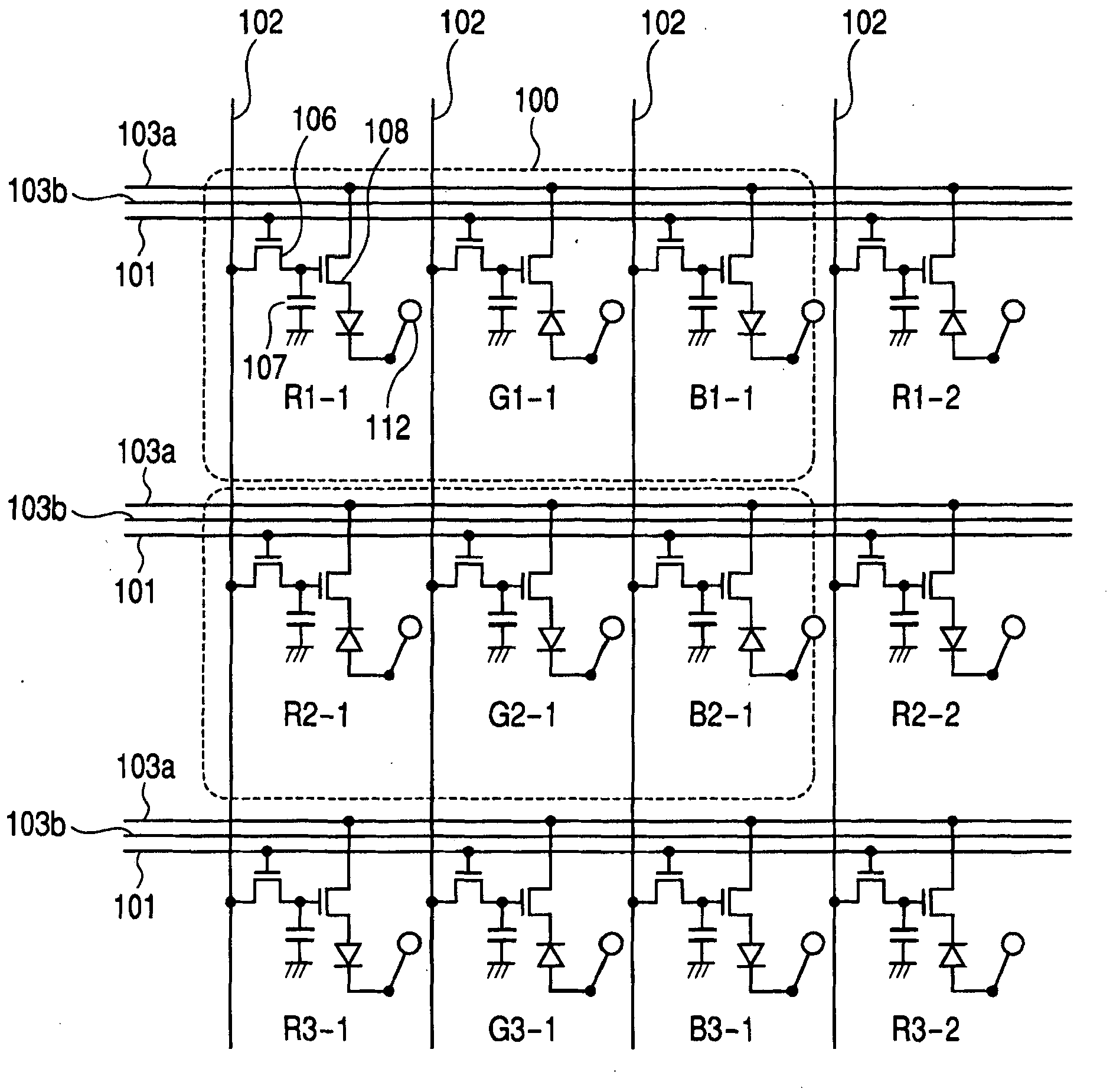

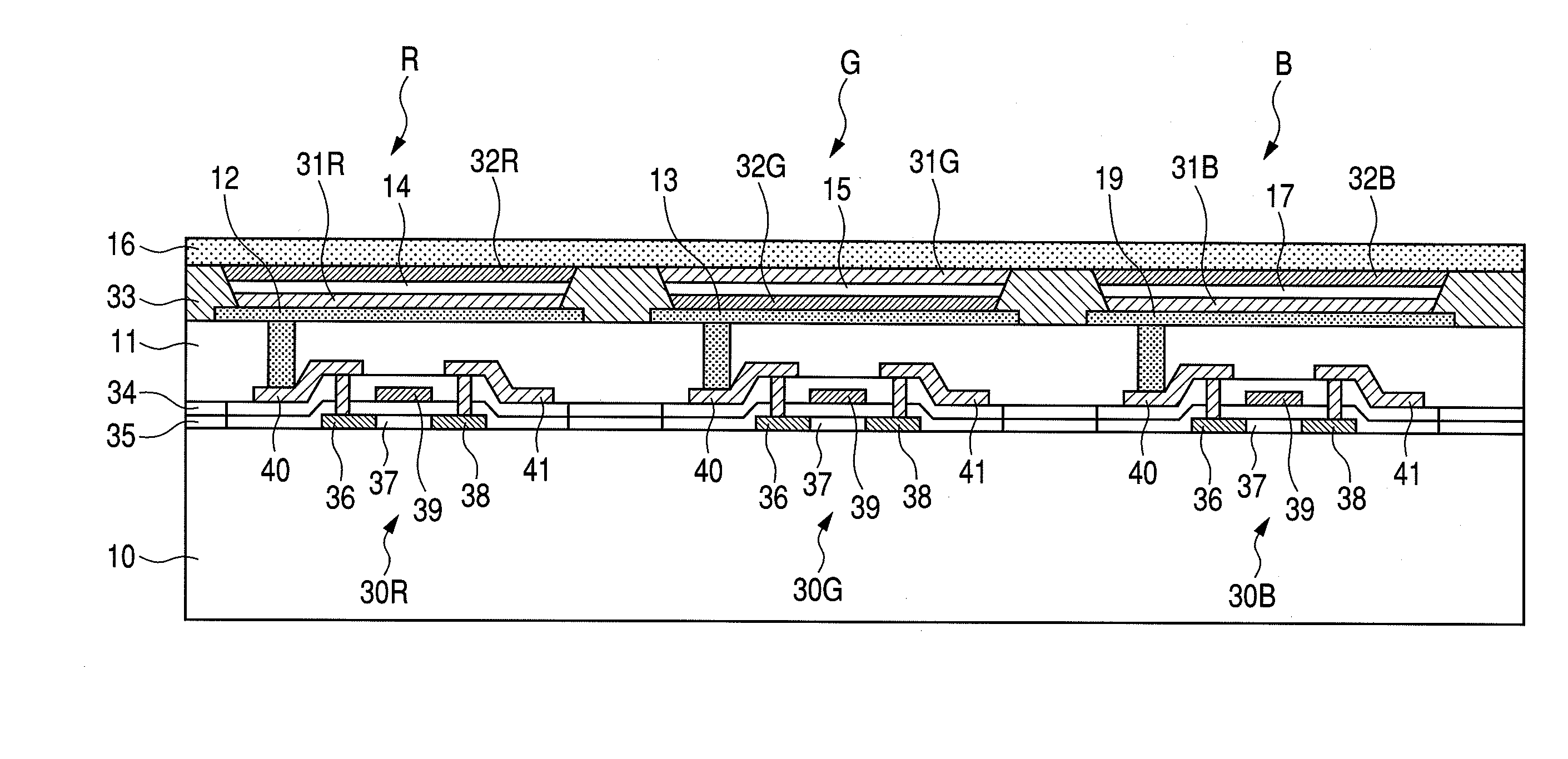

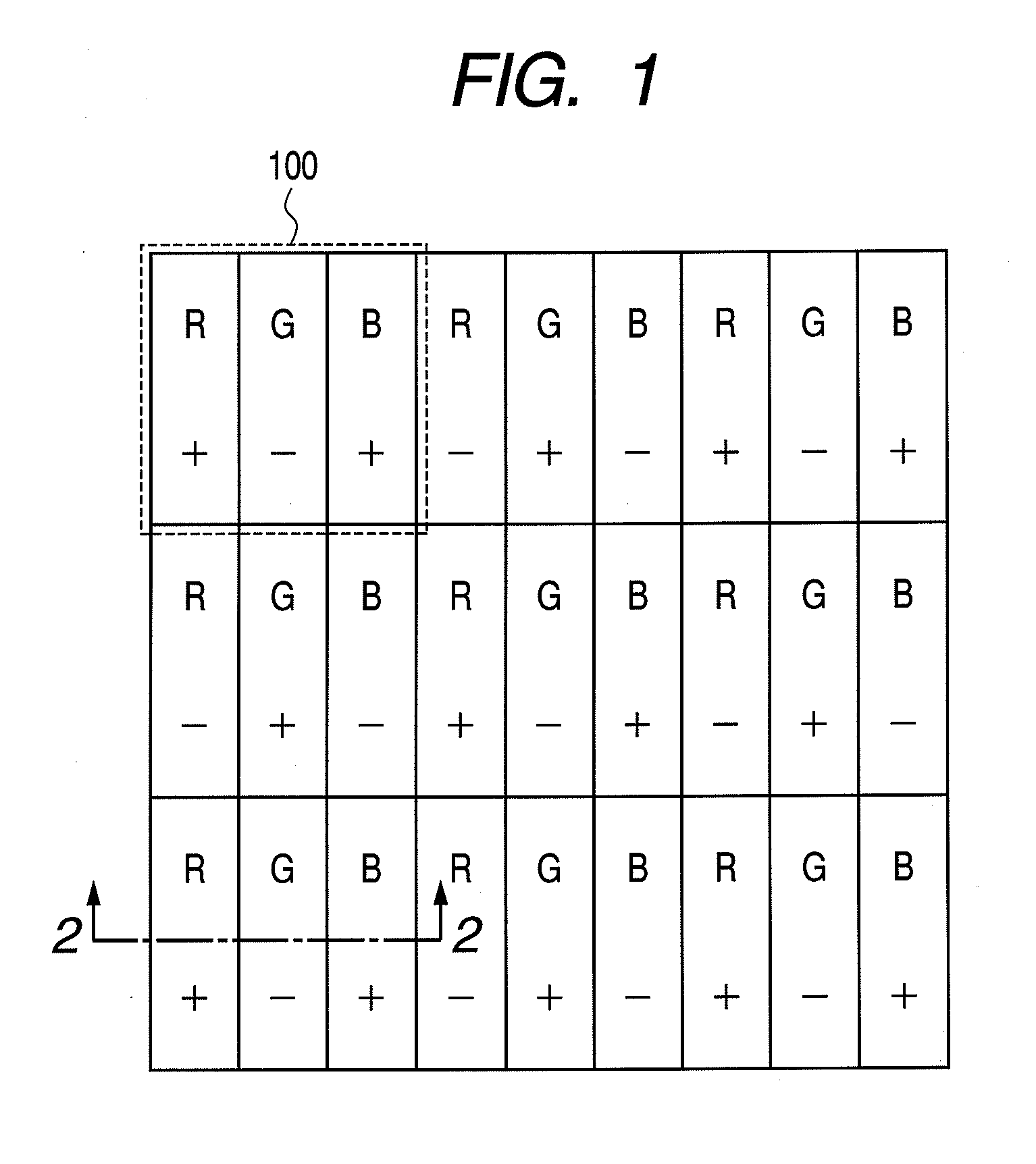

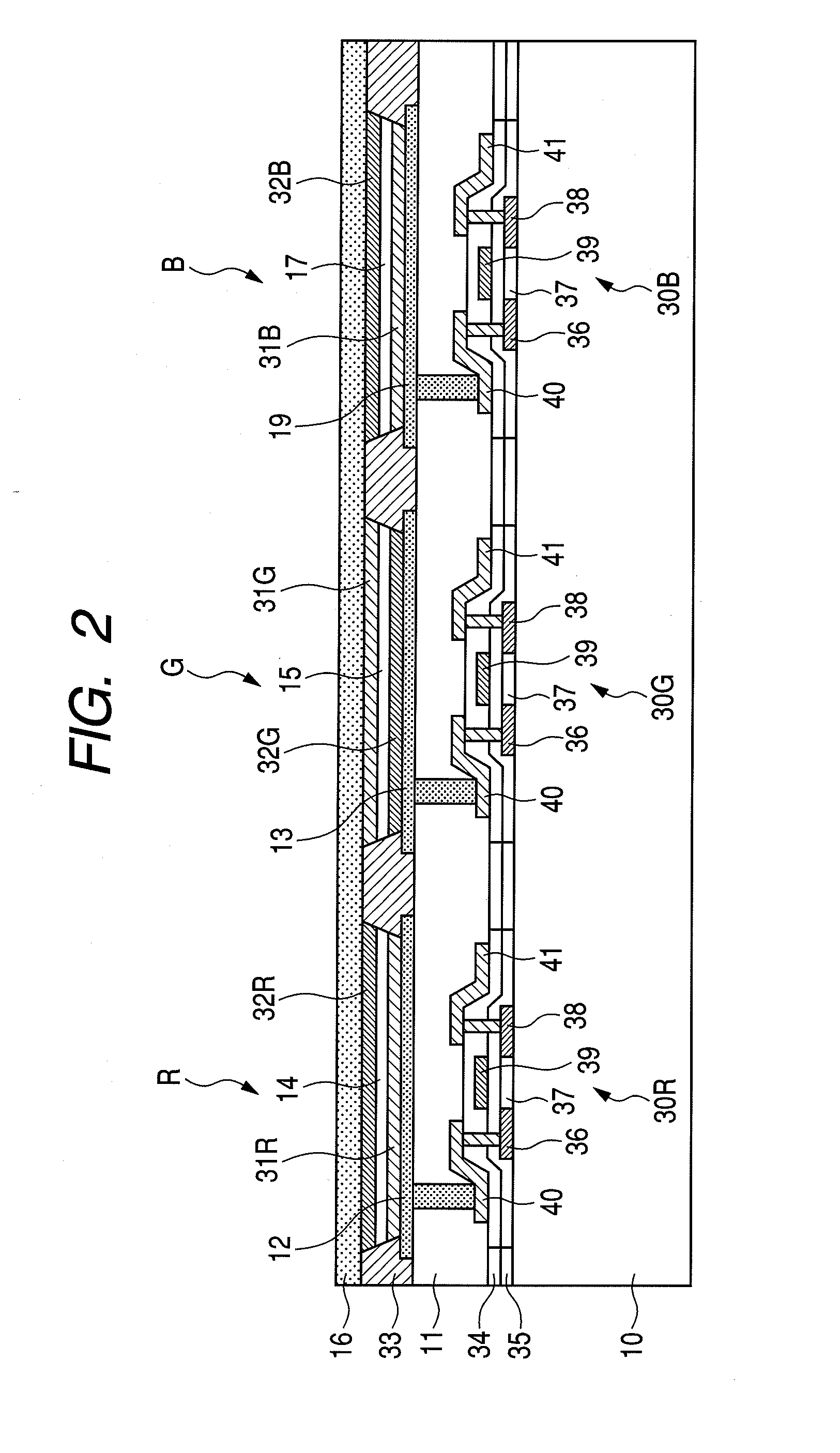

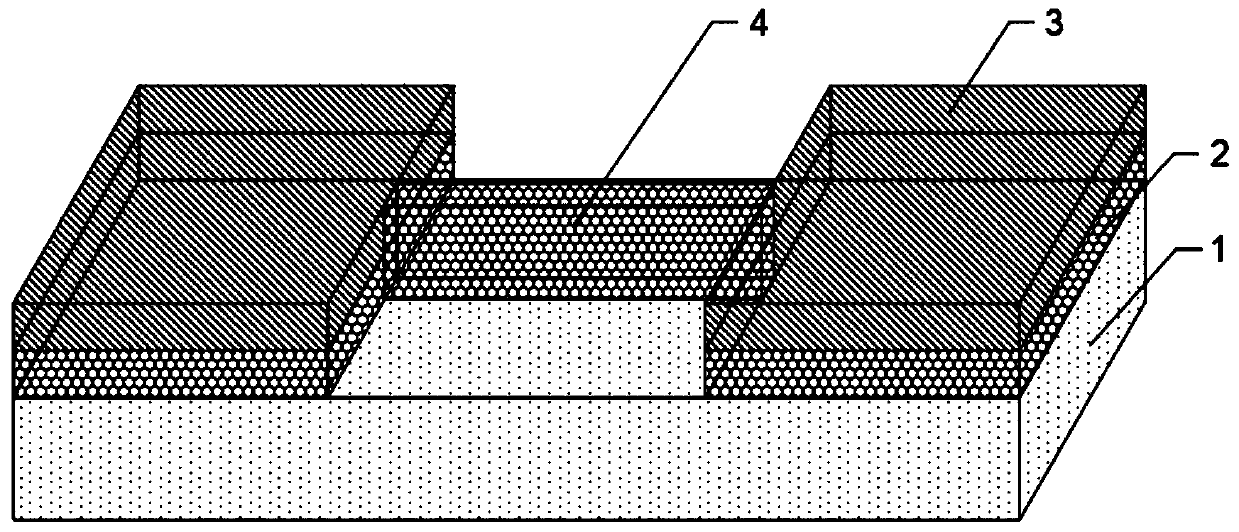

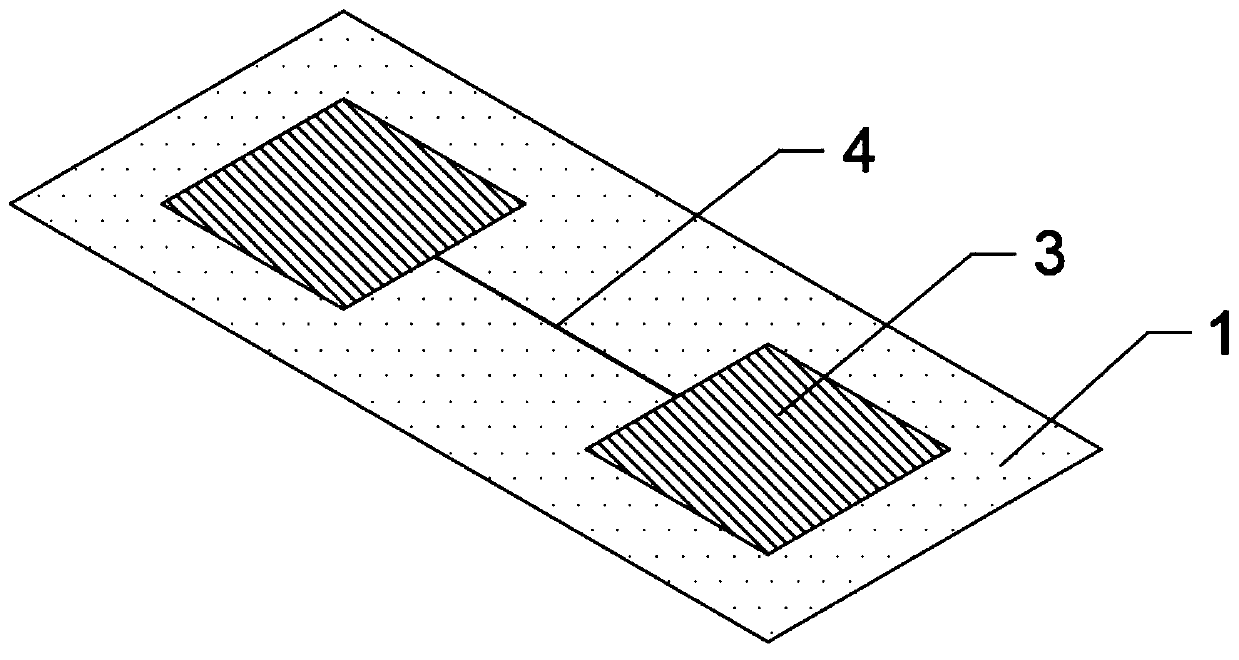

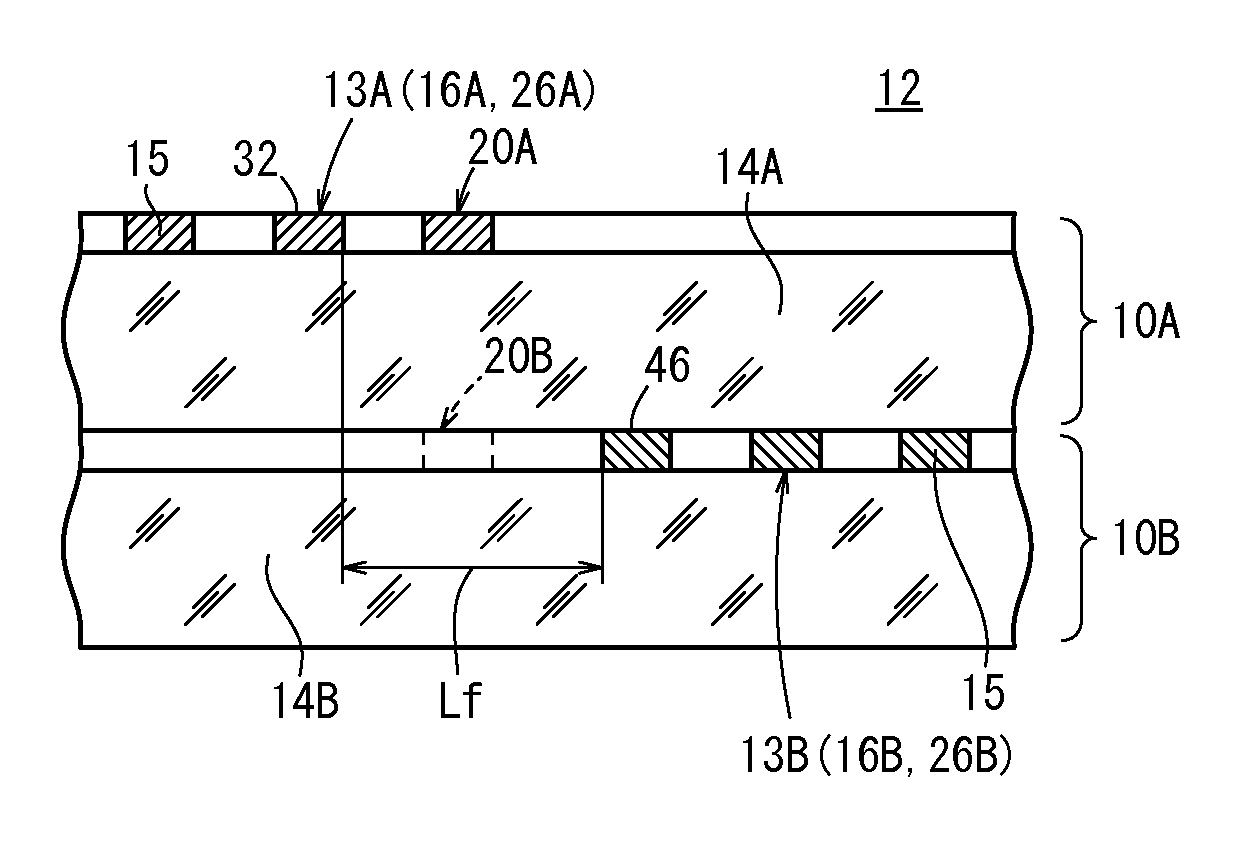

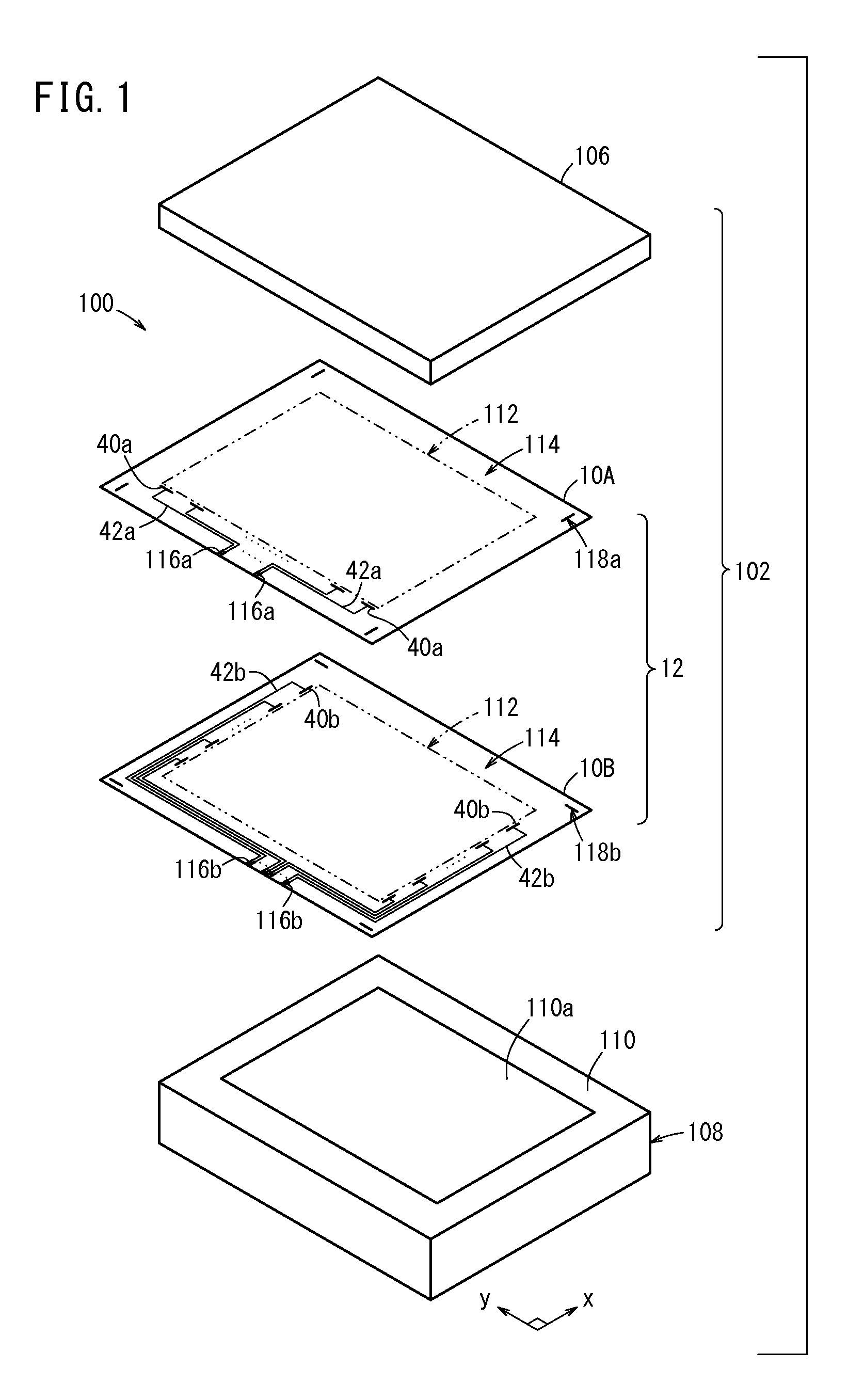

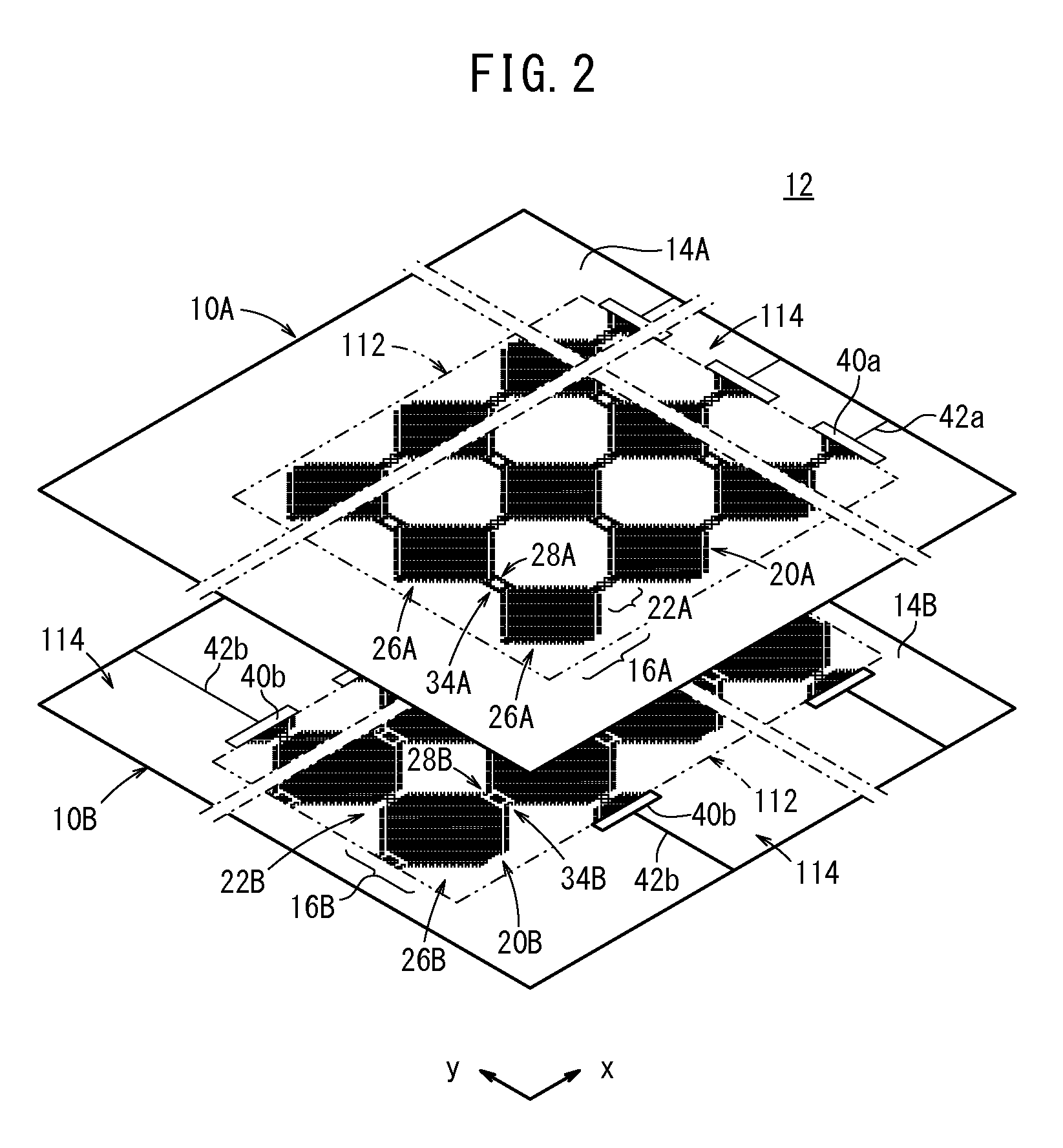

An electroconductive sheet and a touch panel having a first electroconductive section and a second electroconductive section, the second electroconductive section being disposed on the display-panel side. The first electroconductive section has a plurality of first electroconductive patterns arranged in the x-direction, a plurality of first large grids being respectively connected to the first electroconductive patterns. The second electroconductive section has a plurality of second electroconductive patterns arranged in the y-direction, a plurality of second large grids being respectively connected to the second electroconductive patterns. The area occupied by thin metal wires in the second electroconductive patterns is larger than the area occupied by thin metal wires in the first electroconductive patterns. The area occupied by thin metal wires in the second large grids is larger than the area occupied by thin metal wires in the first large grids.

Owner:FUJIFILM CORP

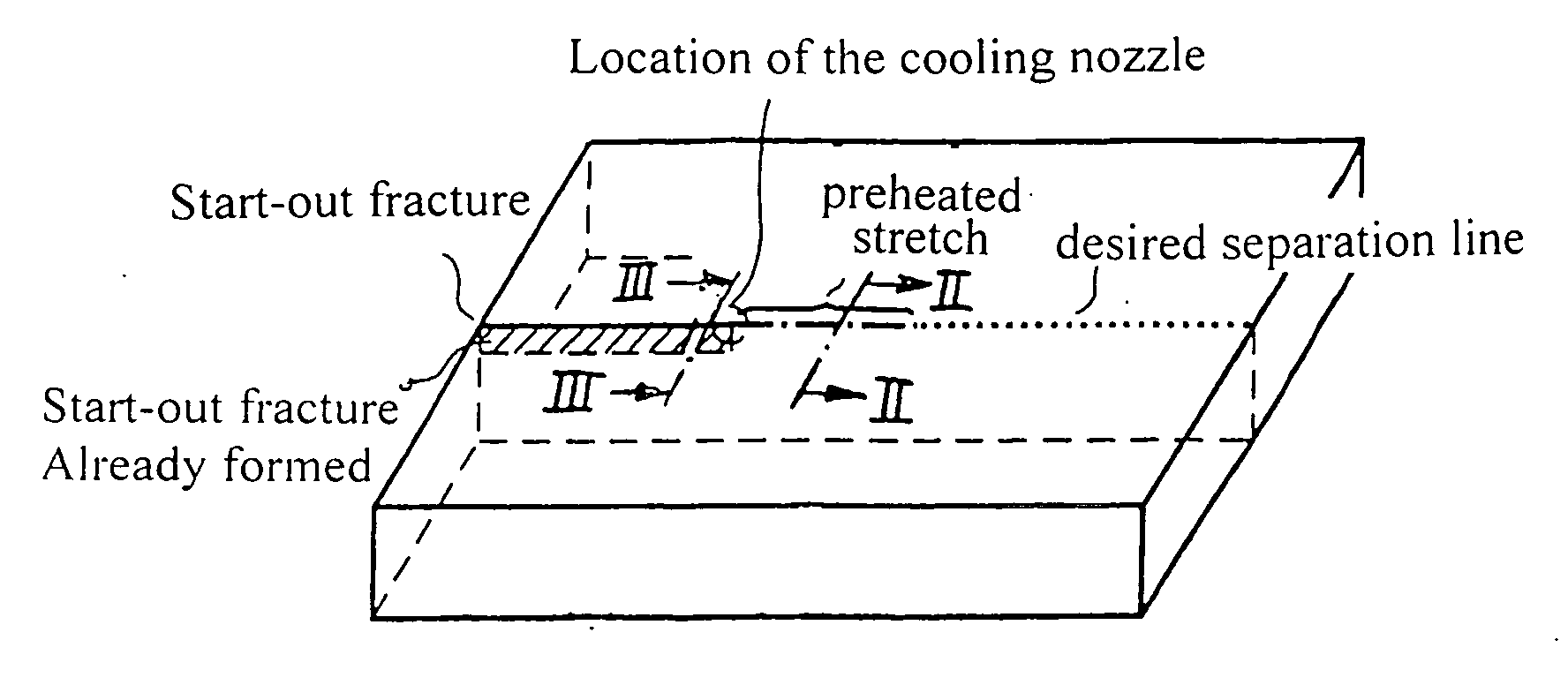

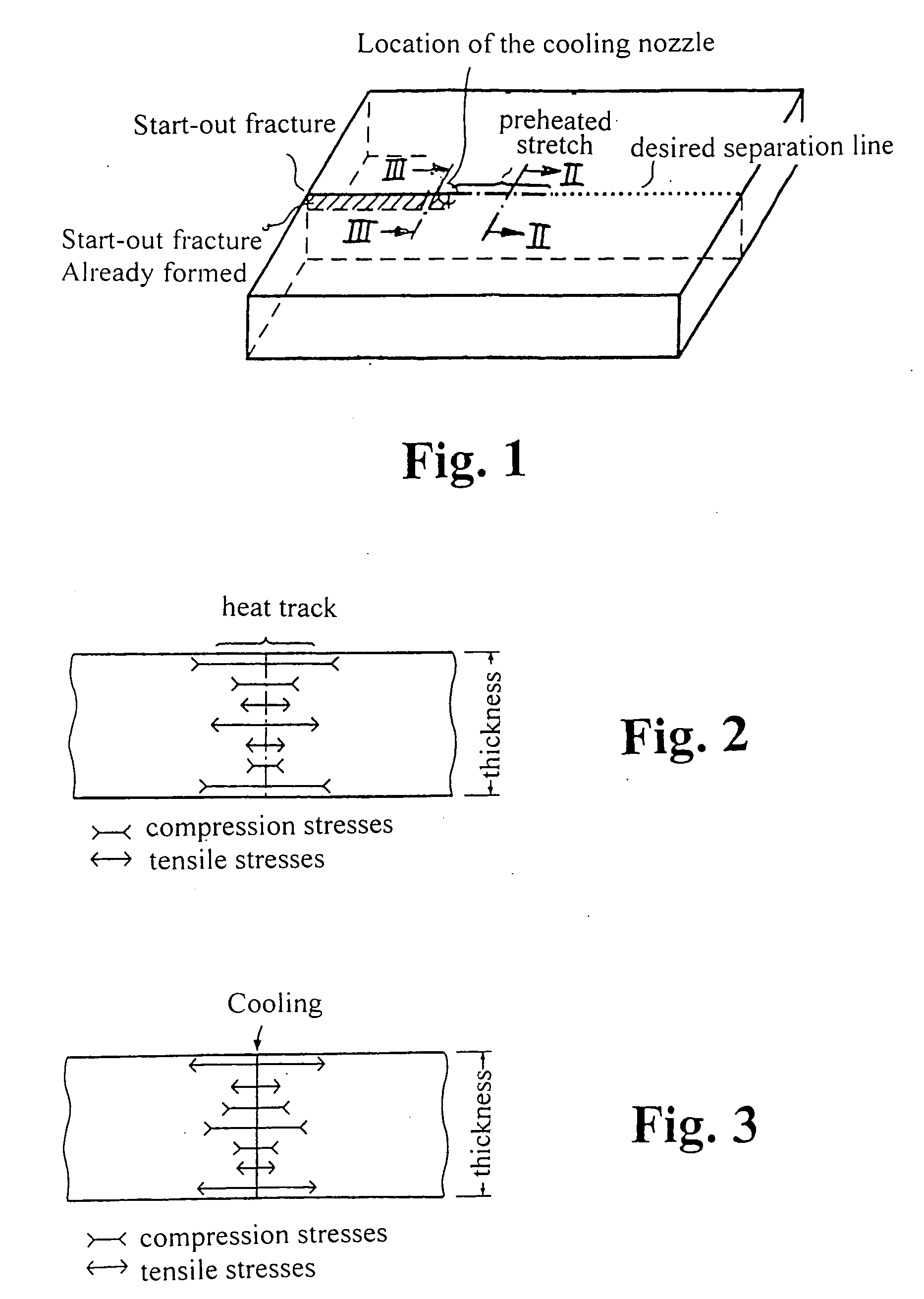

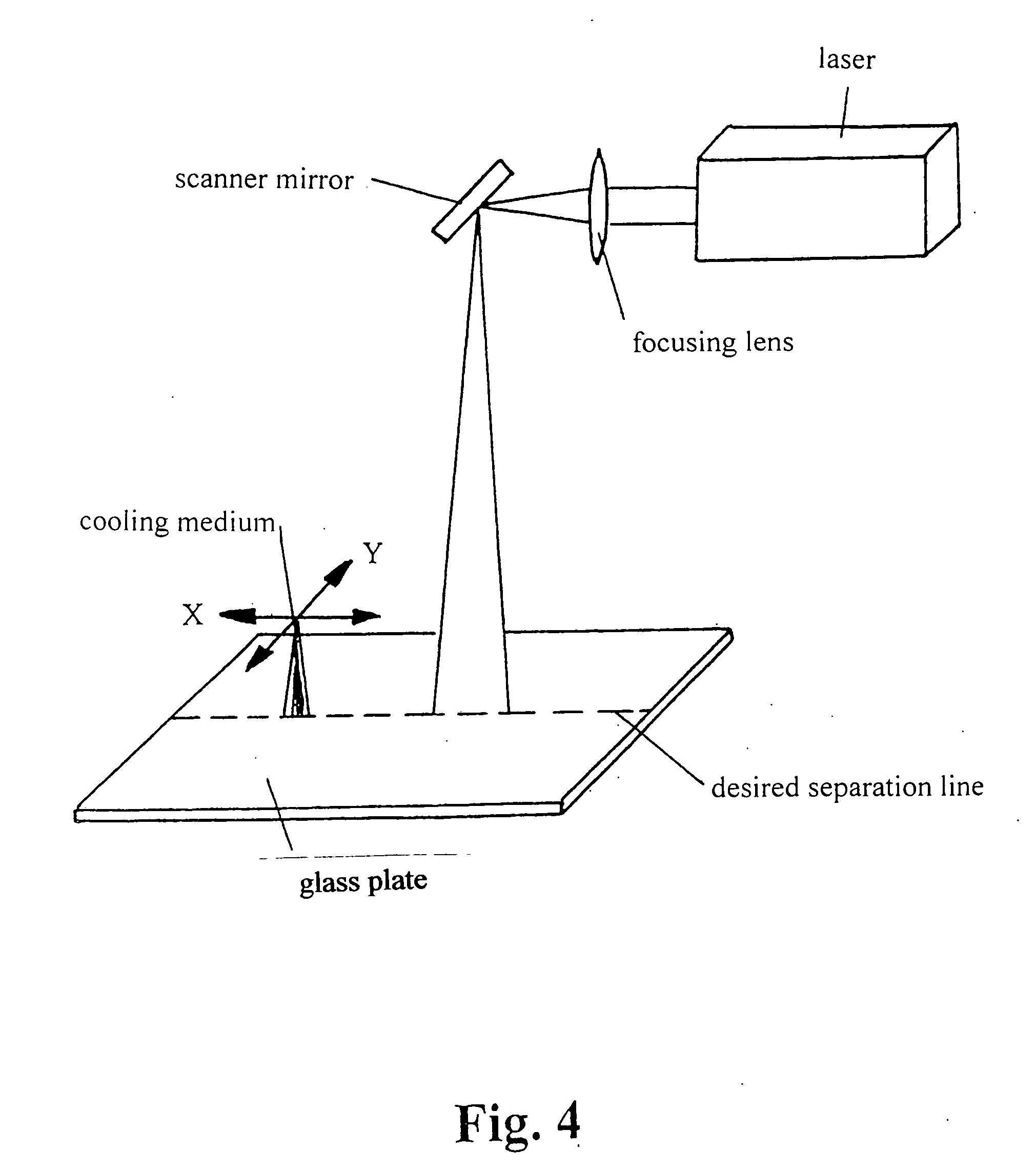

Method for laser-induced thermal separation of plate glass

InactiveUS20070151962A1Reduce surface temperatureFast cutting speedGlass severing apparatusWelding/soldering/cutting articlesFlat glassLaser heating

In a method for a laser-induced thermal separation of plate glass by thermal scoring using a laser beam heating the glass along a desired separation line with subsequent cooling of the laser-heated line, wherein the heat is applied by the laser beam in a number of repetitive passes at intensities based on glass thickness and desired cutting speeds.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

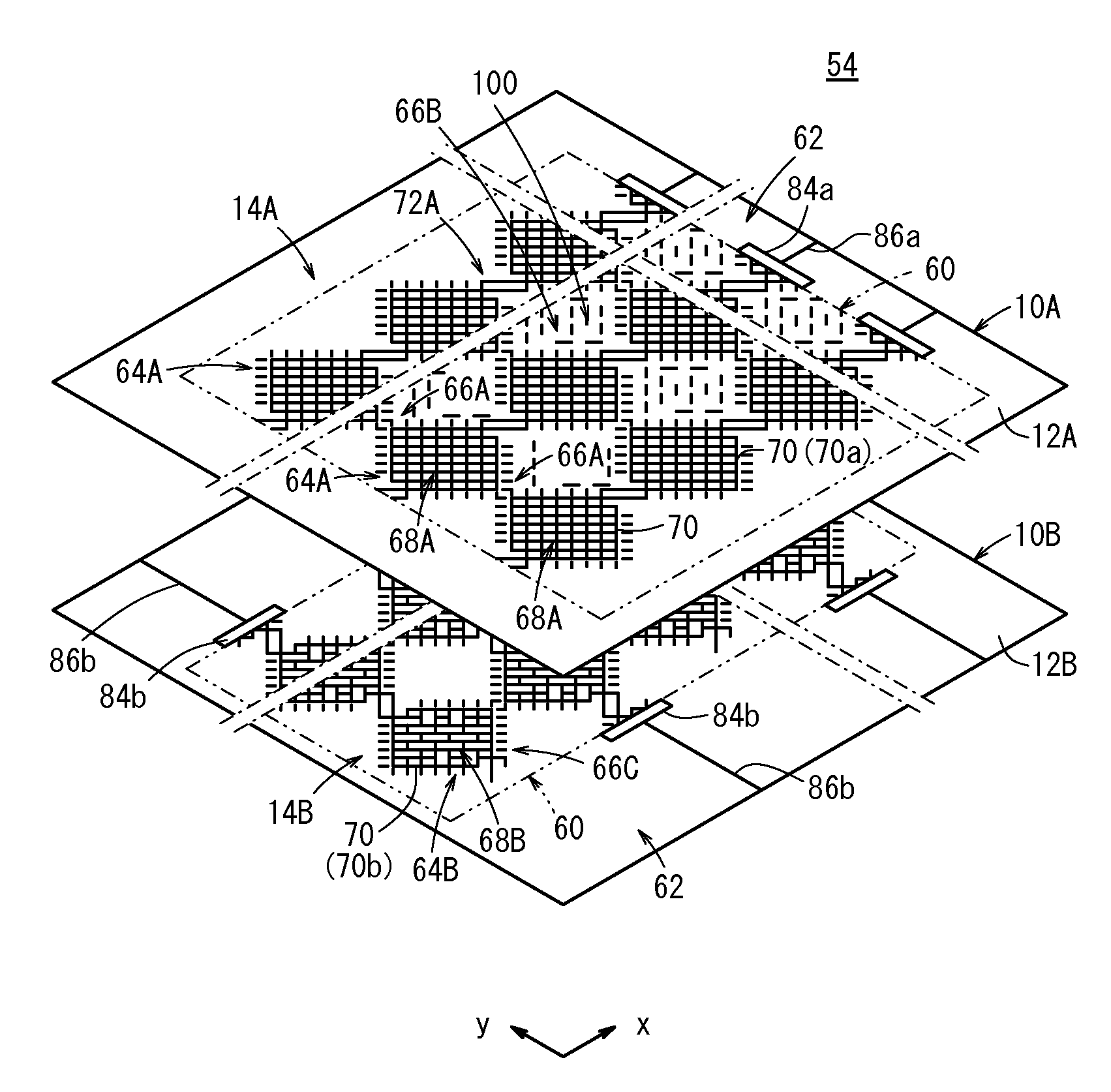

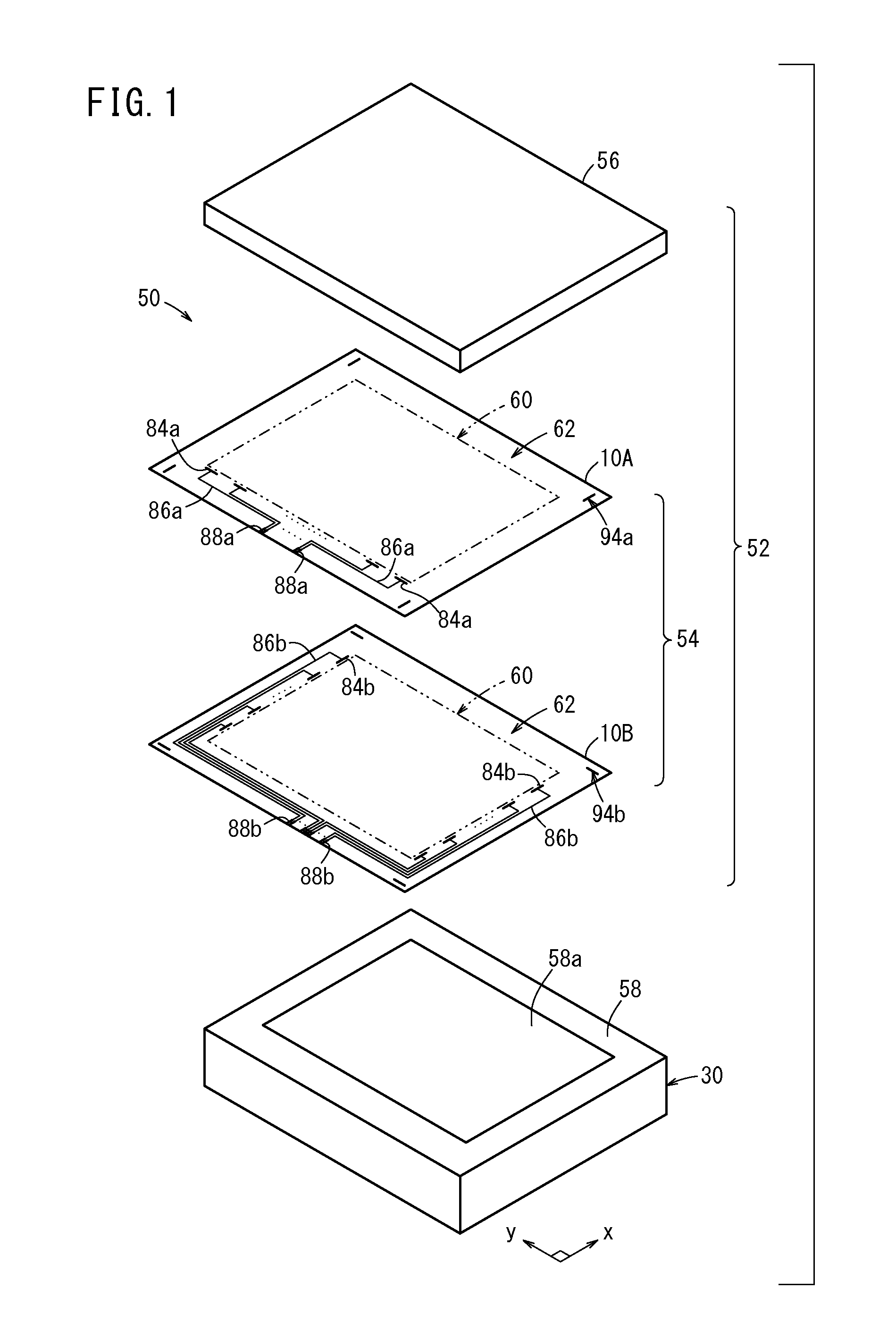

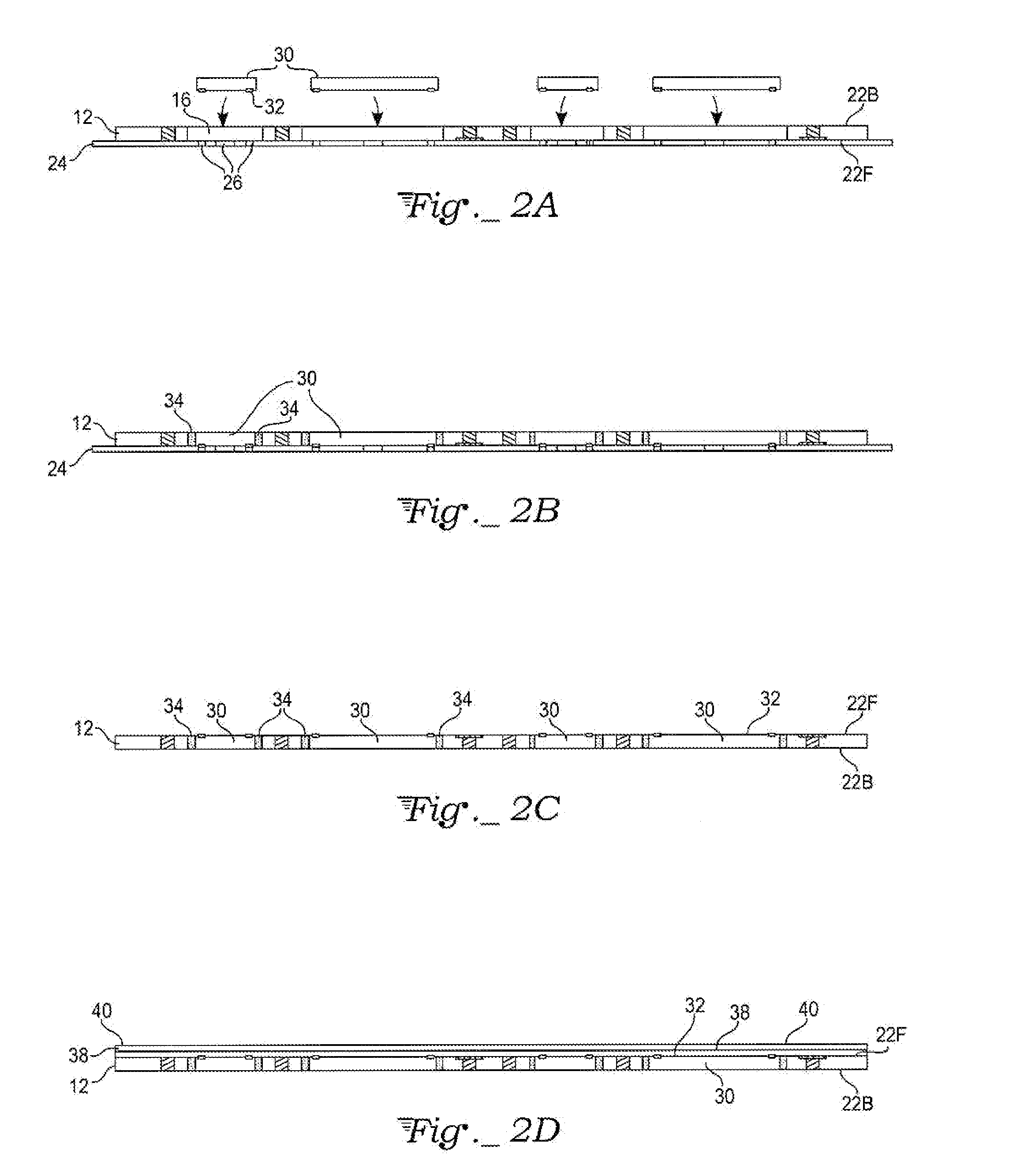

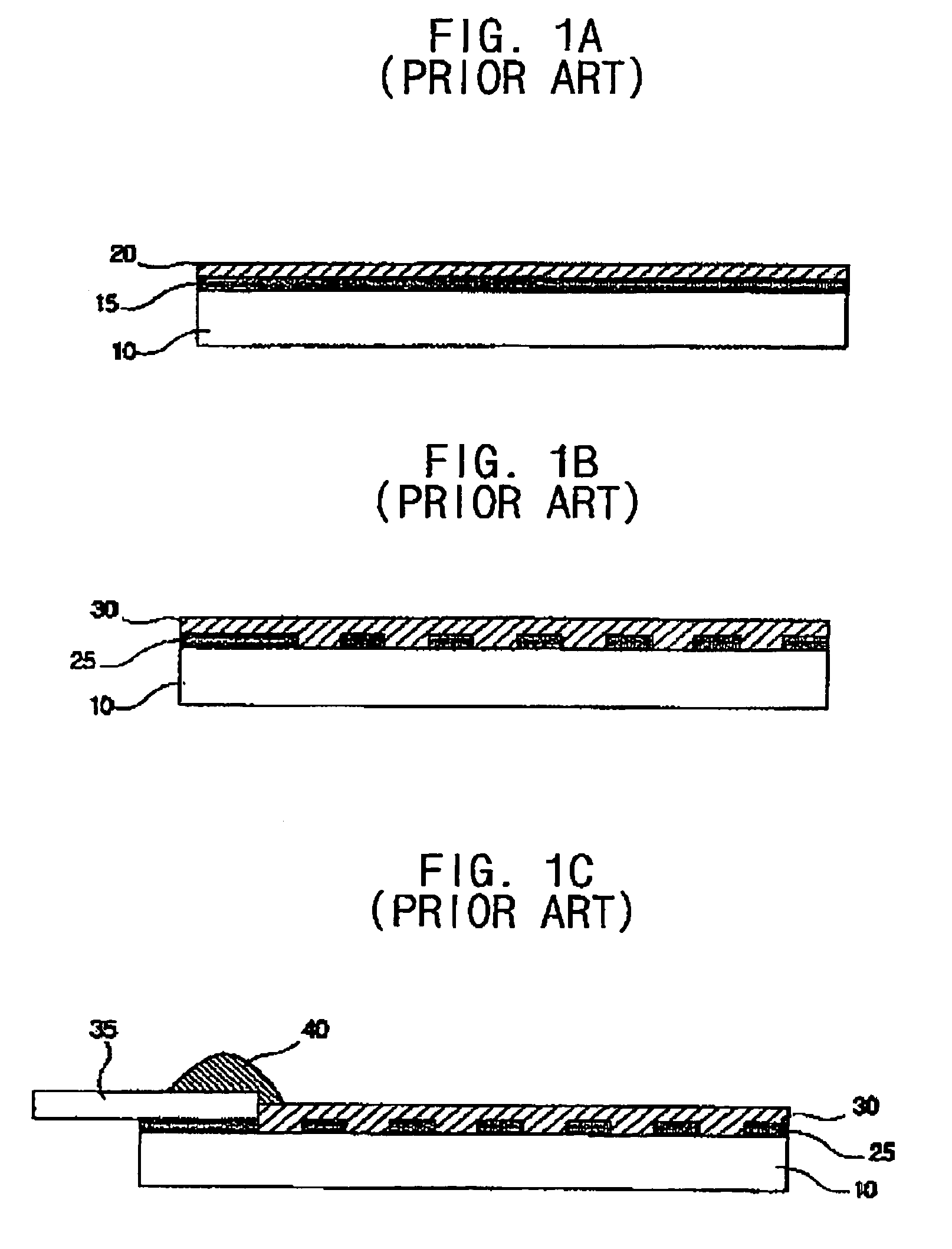

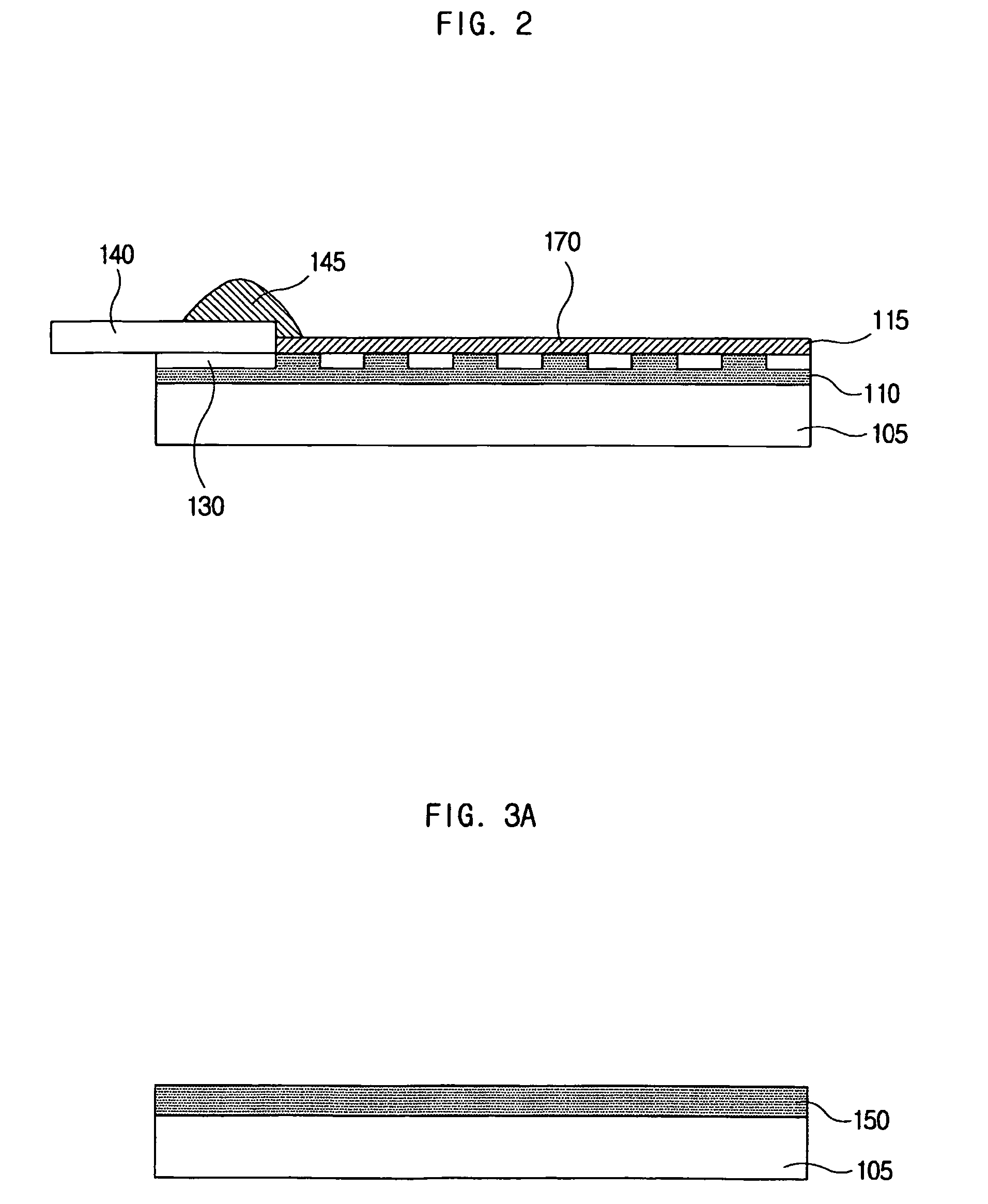

Electroconductive sheet and touch panel

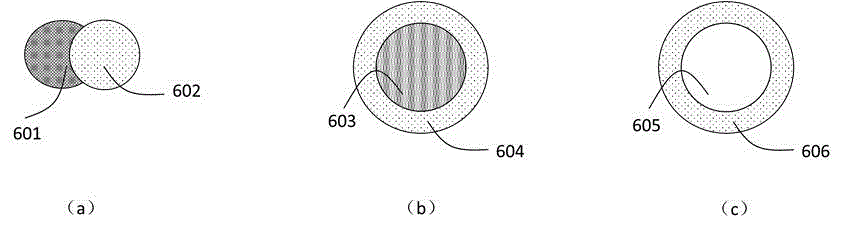

InactiveUS20140054070A1Increase awarenessThin line widthCircuit optical detailsPrinted circuit aspectsTouch panelElectrical and Electronics engineering

An electroconductive sheet and a touch panel, wherein the electroconductive sheet has a first electroconductive section and a second electroconductive section; the first electroconductive section has a plurality of first electroconductive patterns arrayed in one direction and to which a plurality of first electrodes, respectively, are connected; the second electroconductive section has a plurality of second electroconductive patterns arrayed in a direction orthogonal to the arrayed direction of the first electroconductive patterns and to which a plurality of second electrodes, respectively, are connected; and the electroconductive sheet has dummy electrodes disposed between the first electrodes and the second electrodes, and other dummy electrodes disposed in portions corresponding to the second electrodes.

Owner:FUJIFILM CORP

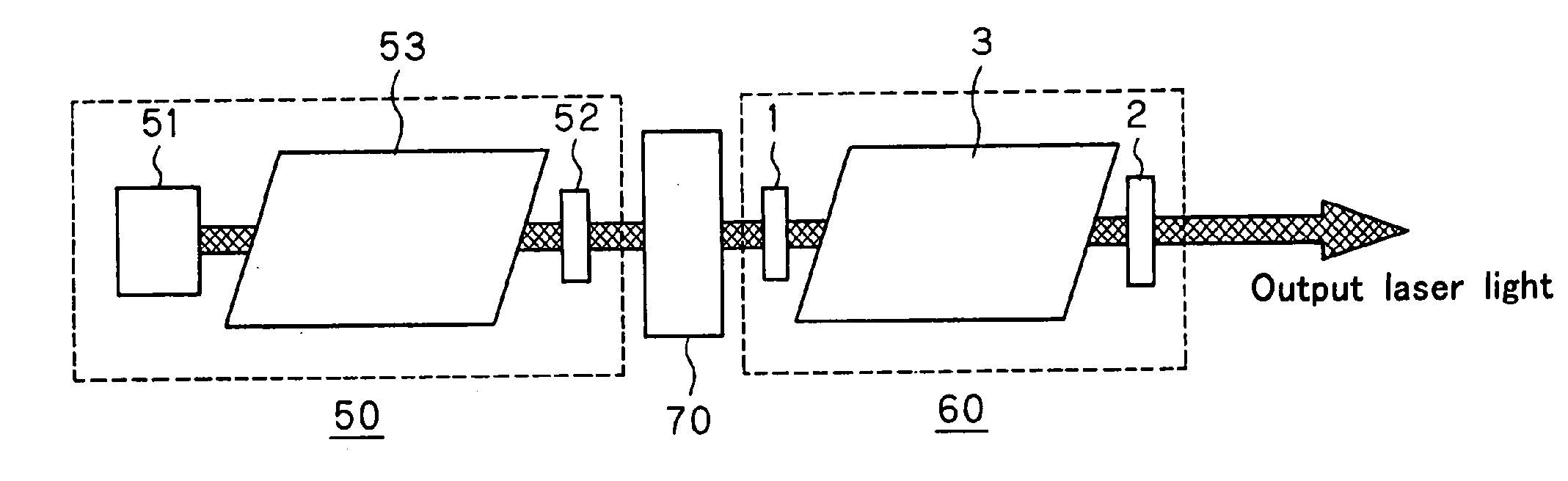

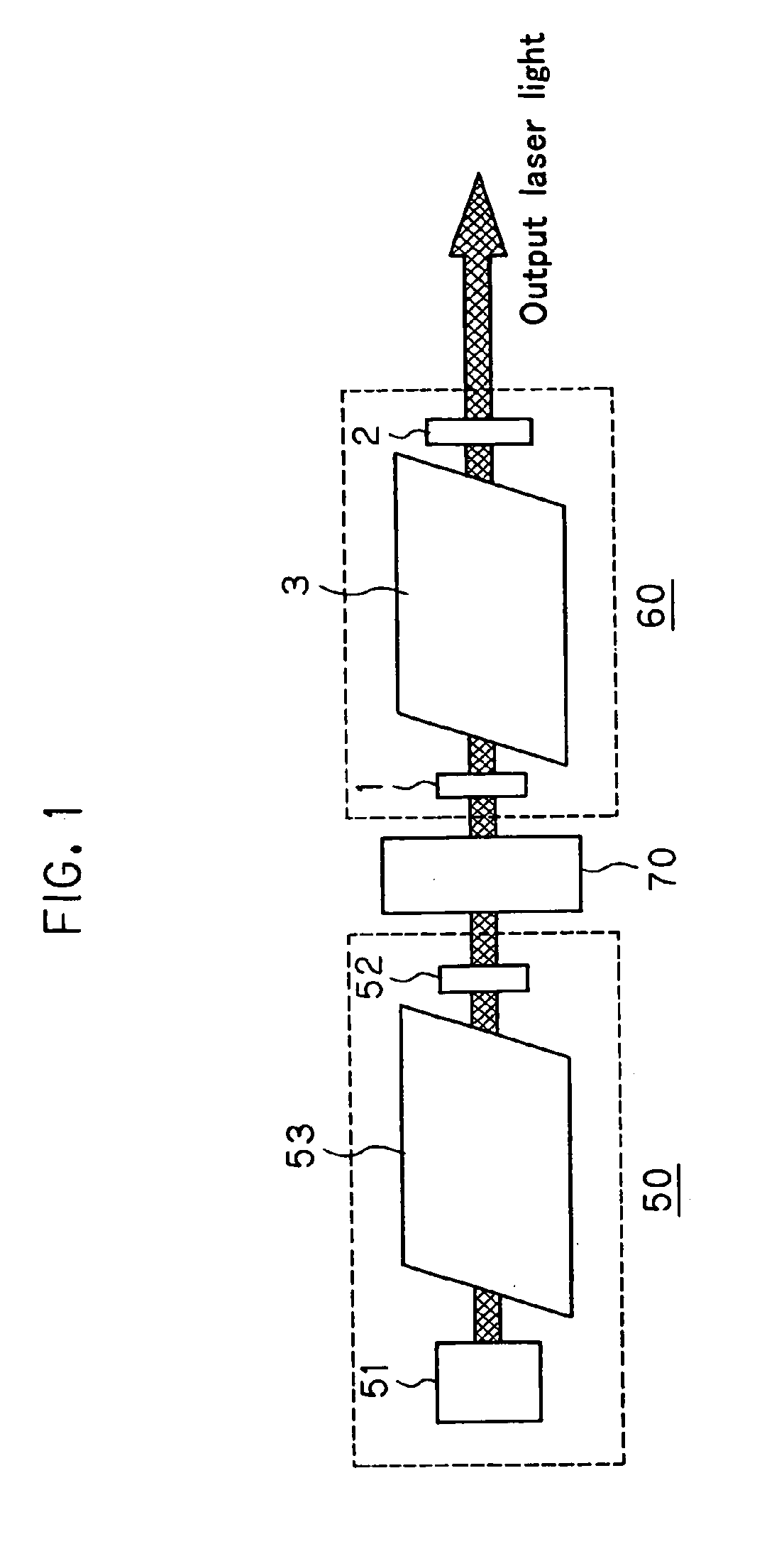

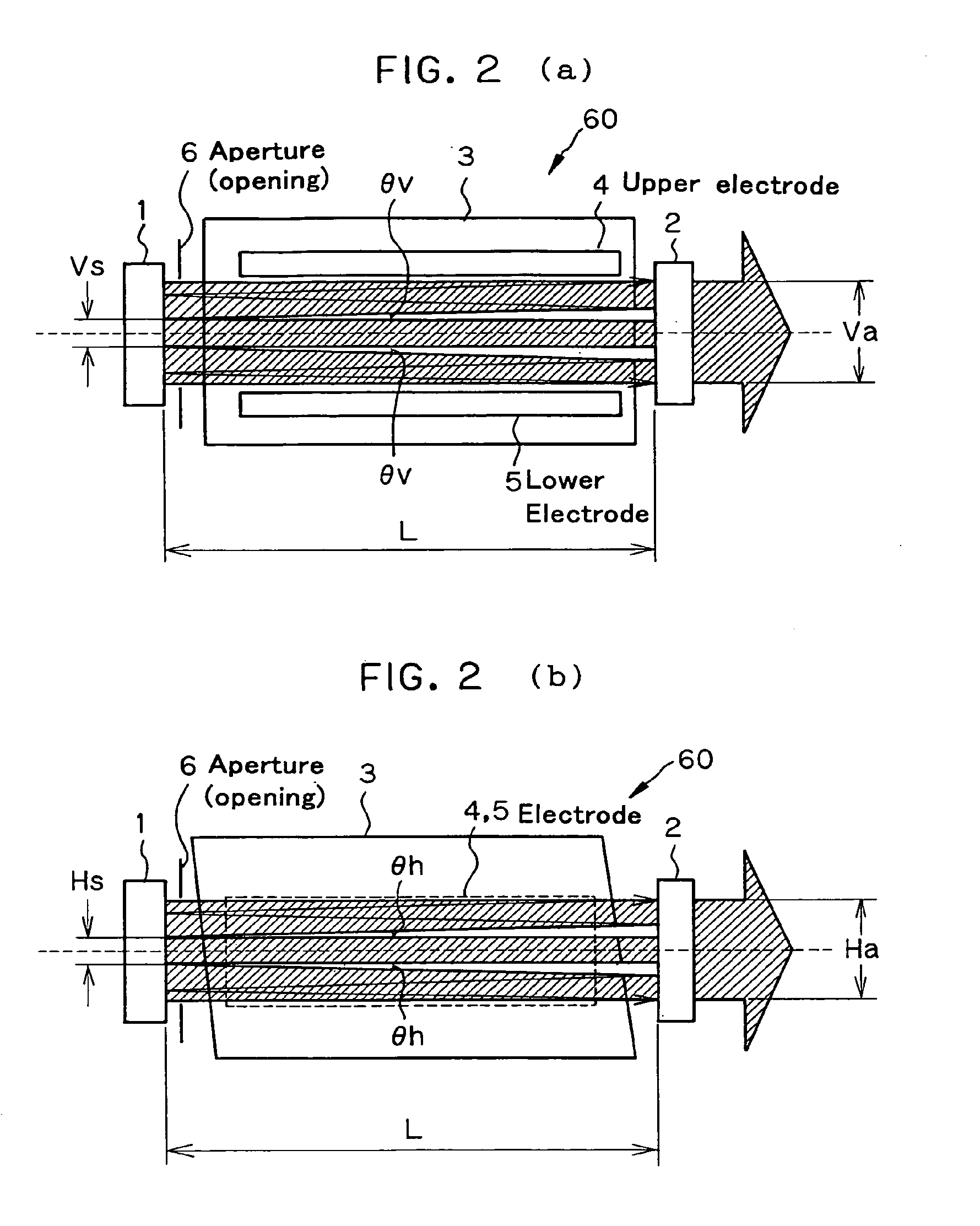

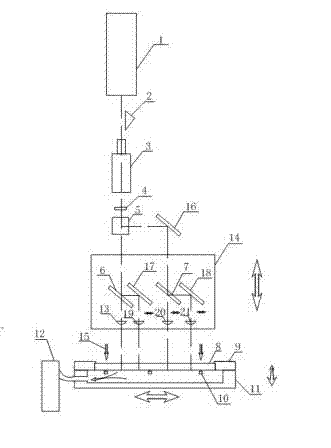

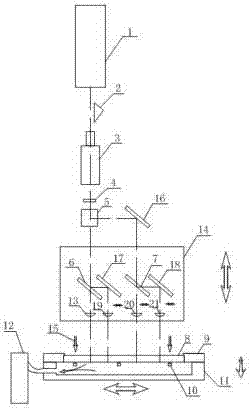

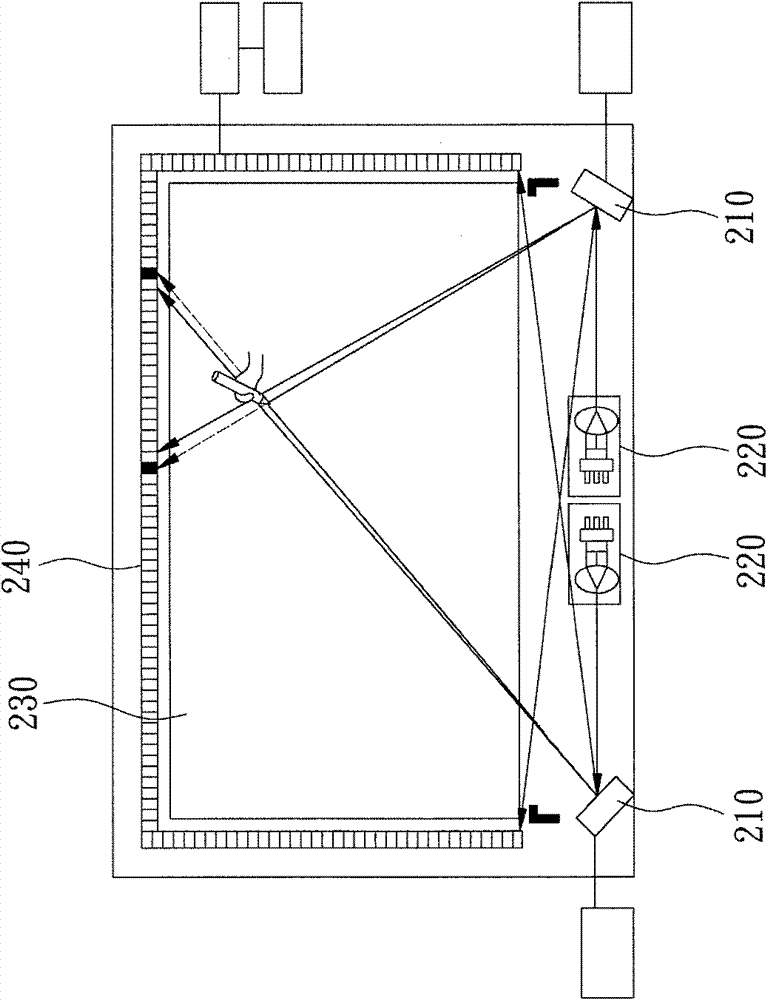

Two-stage laser system for aligners

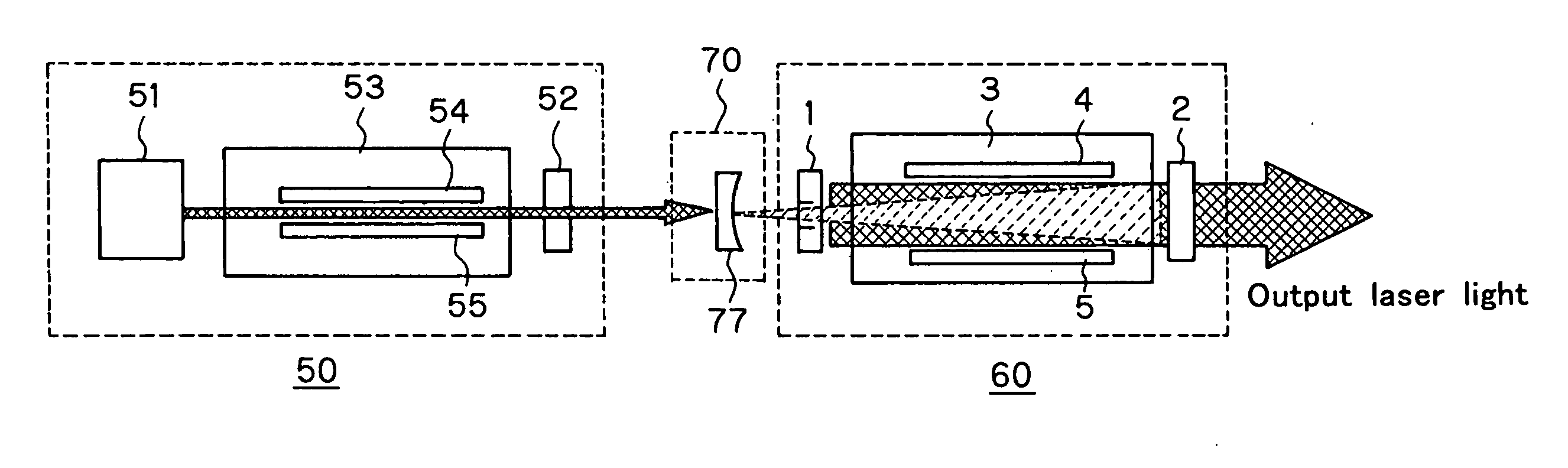

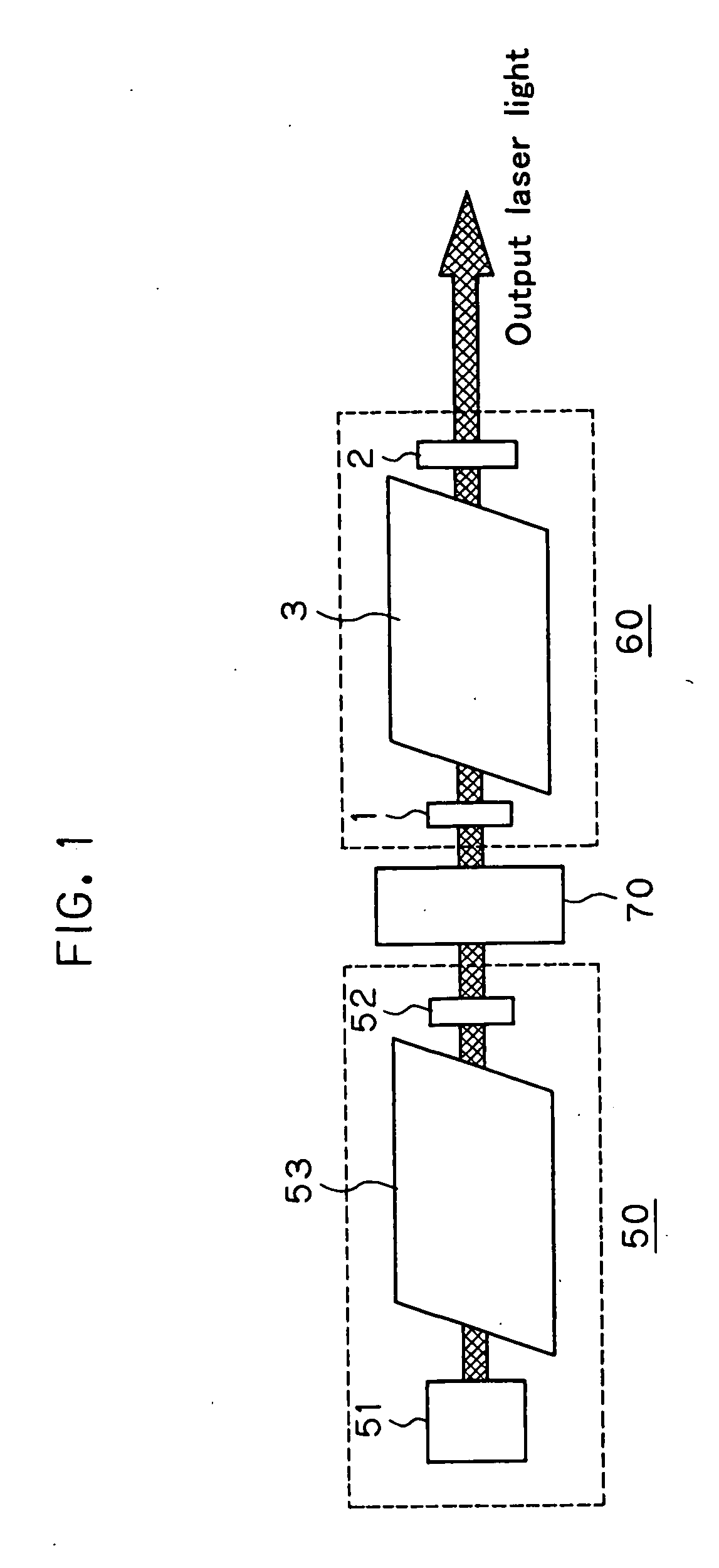

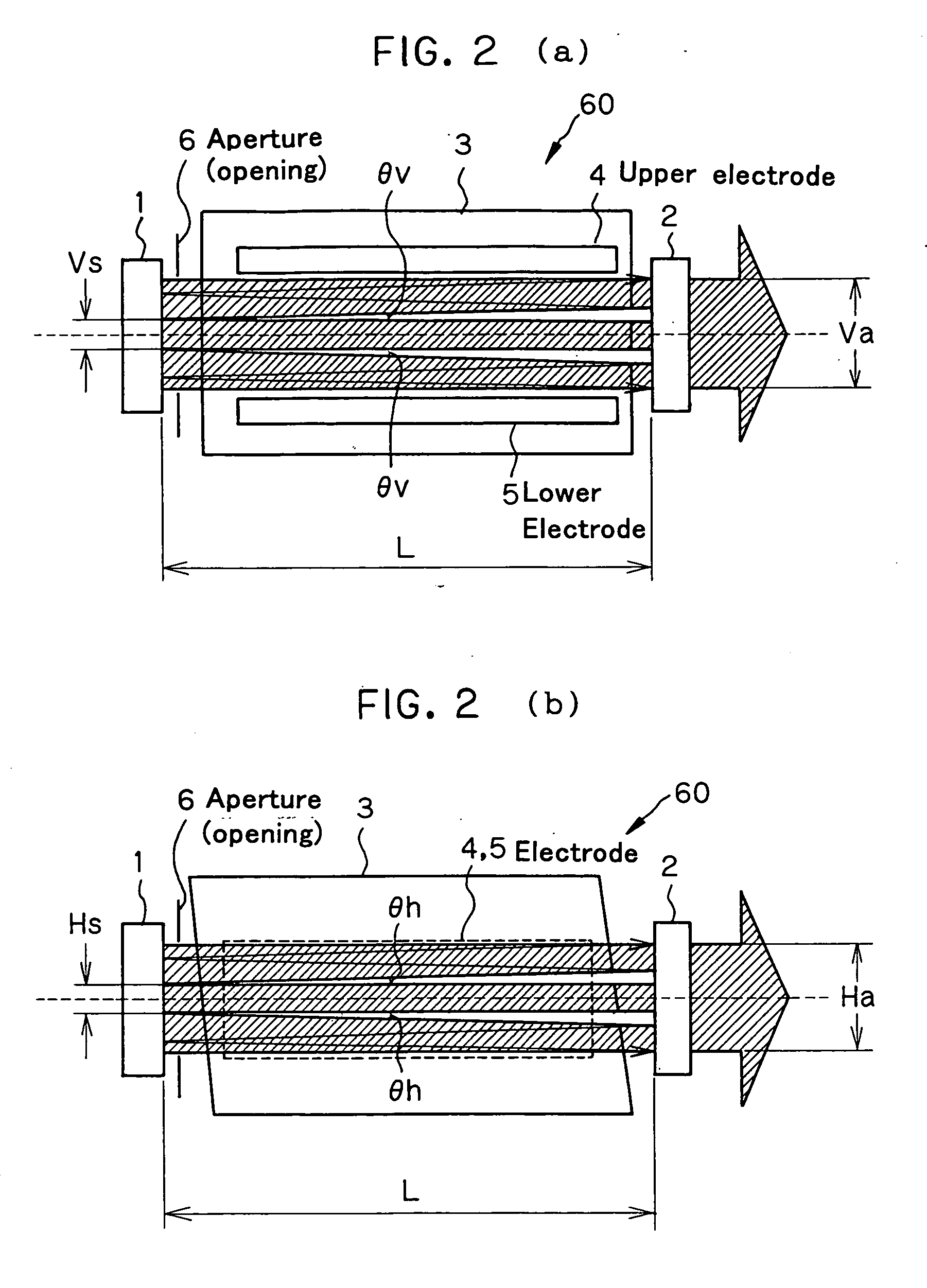

ActiveUS20070091968A1Reduce spacingImprove stabilityLaser arrangementsActive medium materialFine lineLaser light

The invention relates to a two-stage laser system well fit for semiconductor aligners, which is reduced in terms of spatial coherence while taking advantage of the high stability, high output efficiency and fine line width of the MOPO mode. The two-stage laser system for aligners comprises an oscillation-stage laser (50) and an amplification-stage laser (60). Oscillation laser light having divergence is used as the oscillation-stage laser (50), and the amplification-stage laser (60) comprises a Fabry-Perot etalon resonator made up of an input side mirror (1) and an output side mirror (2). The resonator is configured as a stable resonator.

Owner:GIGAPHOTON

Two-stage laser system for aligners

ActiveUS20070297483A1Reduce spacingImprove stabilityLaser arrangementsActive medium materialFine lineLaser light

The invention relates to a two-stage laser system well fit for semiconductor aligners, which is reduced in terms of spatial coherence while taking advantage of the high stability, high output efficiency and fine line width of the MOPO mode. The two-stage laser system for aligners comprises an oscillation-stage laser (50) and an amplification-stage laser (60). Oscillation laser light having divergence is used as the oscillation-stage laser (50), and the amplification-stage laser (60) comprises a Fabry-Perot etalon resonator made up of an input side mirror (1) and an output side mirror (2). The resonator is configured as a stable resonator.

Owner:GIGAPHOTON

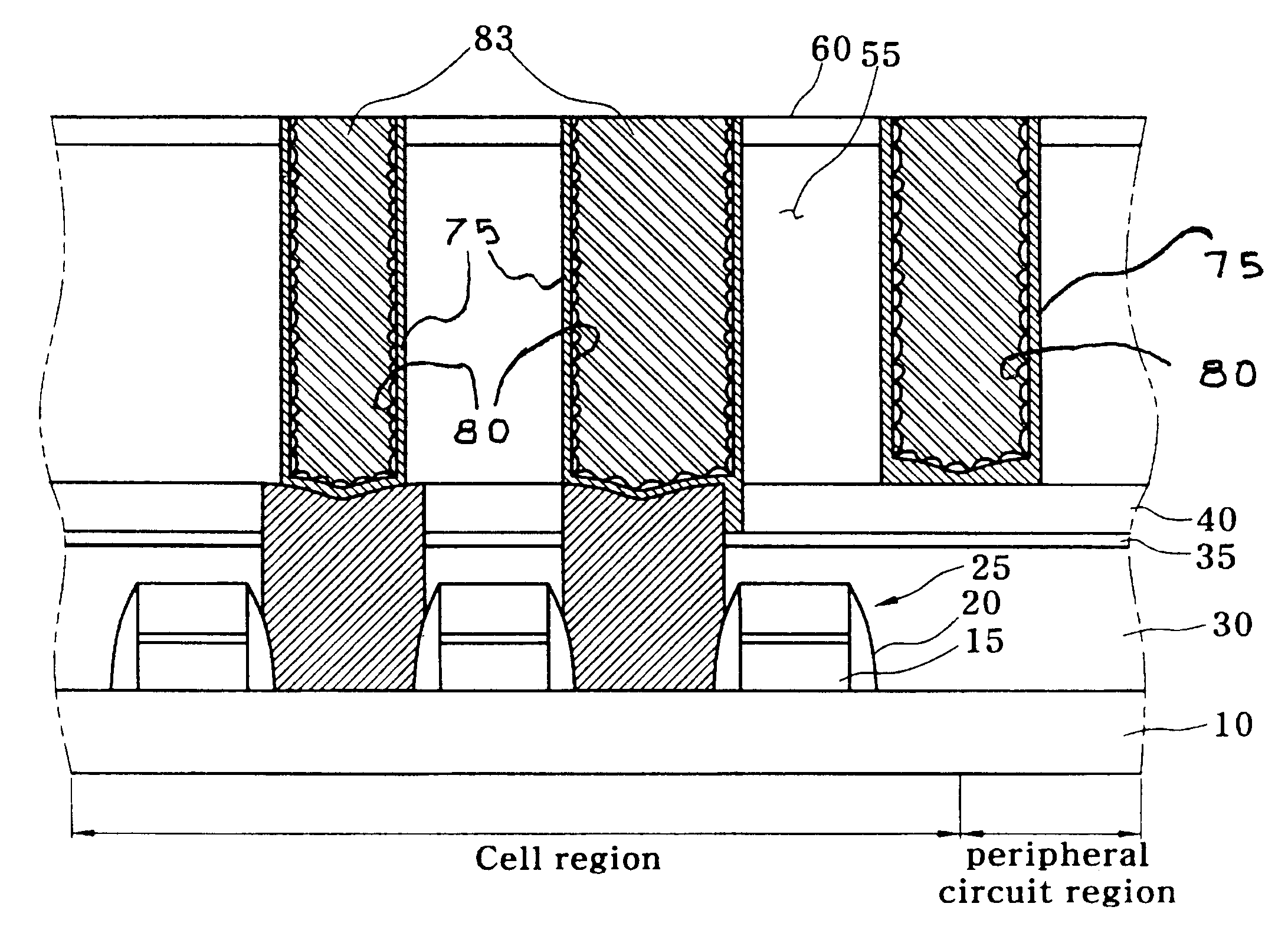

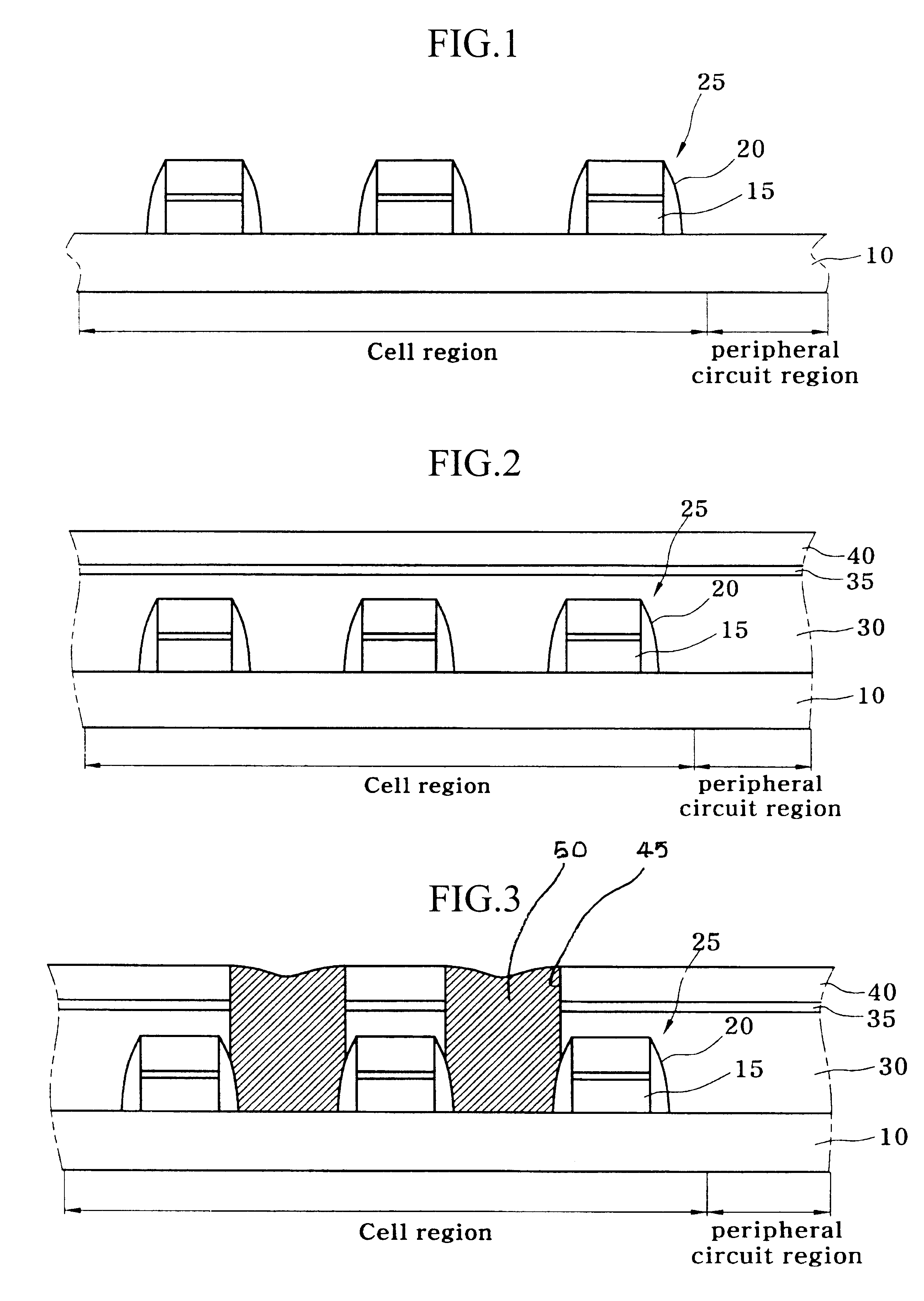

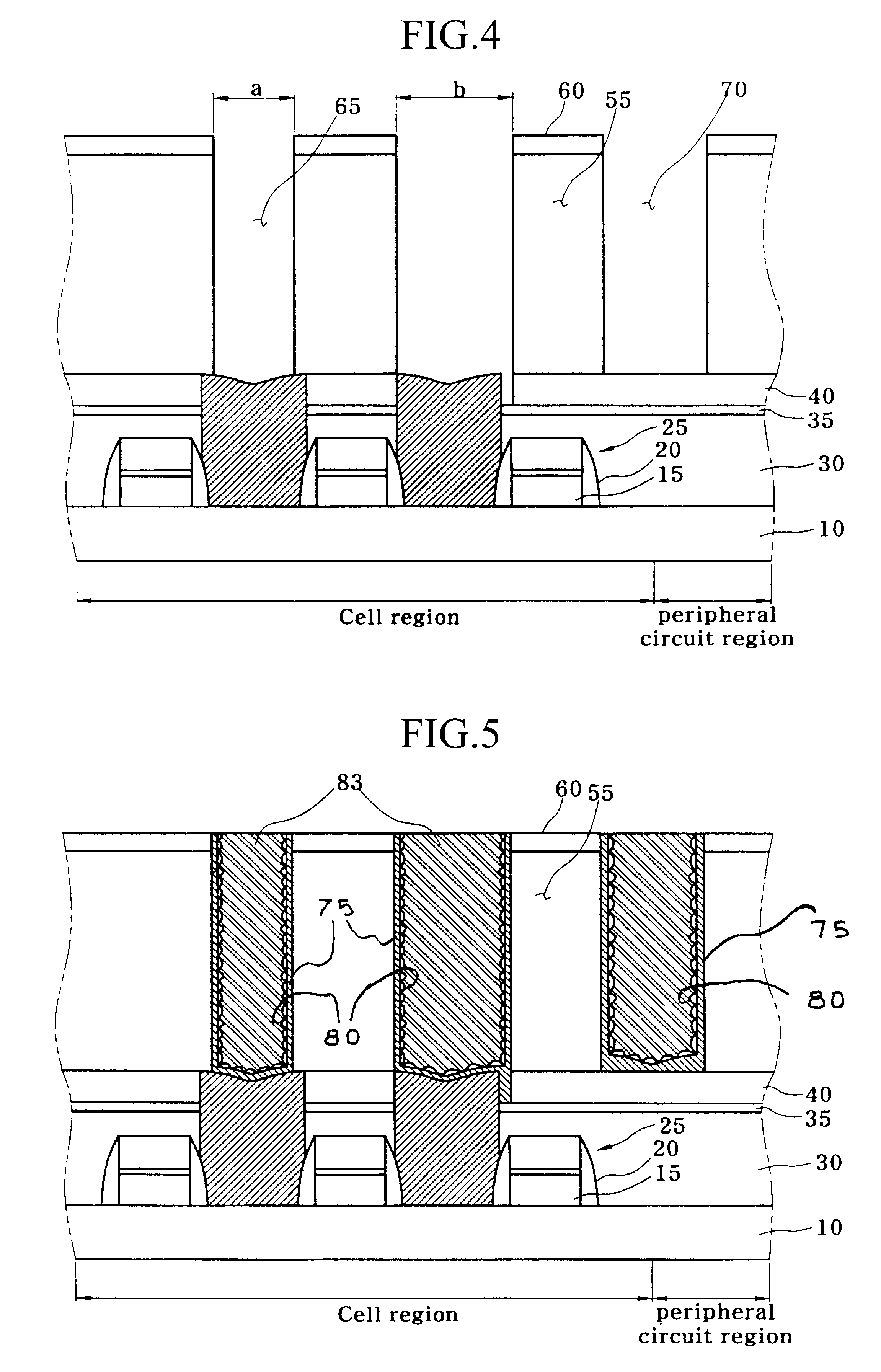

Method for forming a storage node of a capacitor

InactiveUS6562679B2Excellent electrical propertiesSimplify the manufacturing processTransistorSolid-state devicesFine lineCell region

A method for forming the storage node of a capacitor which simplifies its process, and improves the electrical characteristics of semiconductor products by forming the storage node of a capacitor with no stepped portion between cell regions and peripheral circuit regions necessary for memory storage of semiconductor products of the next generation to which a fine line width is applied, and, at the same time, forming a guard ring for dividing the cell regions and the peripheral circuit regions.

Owner:INTERLOTT TECH +1

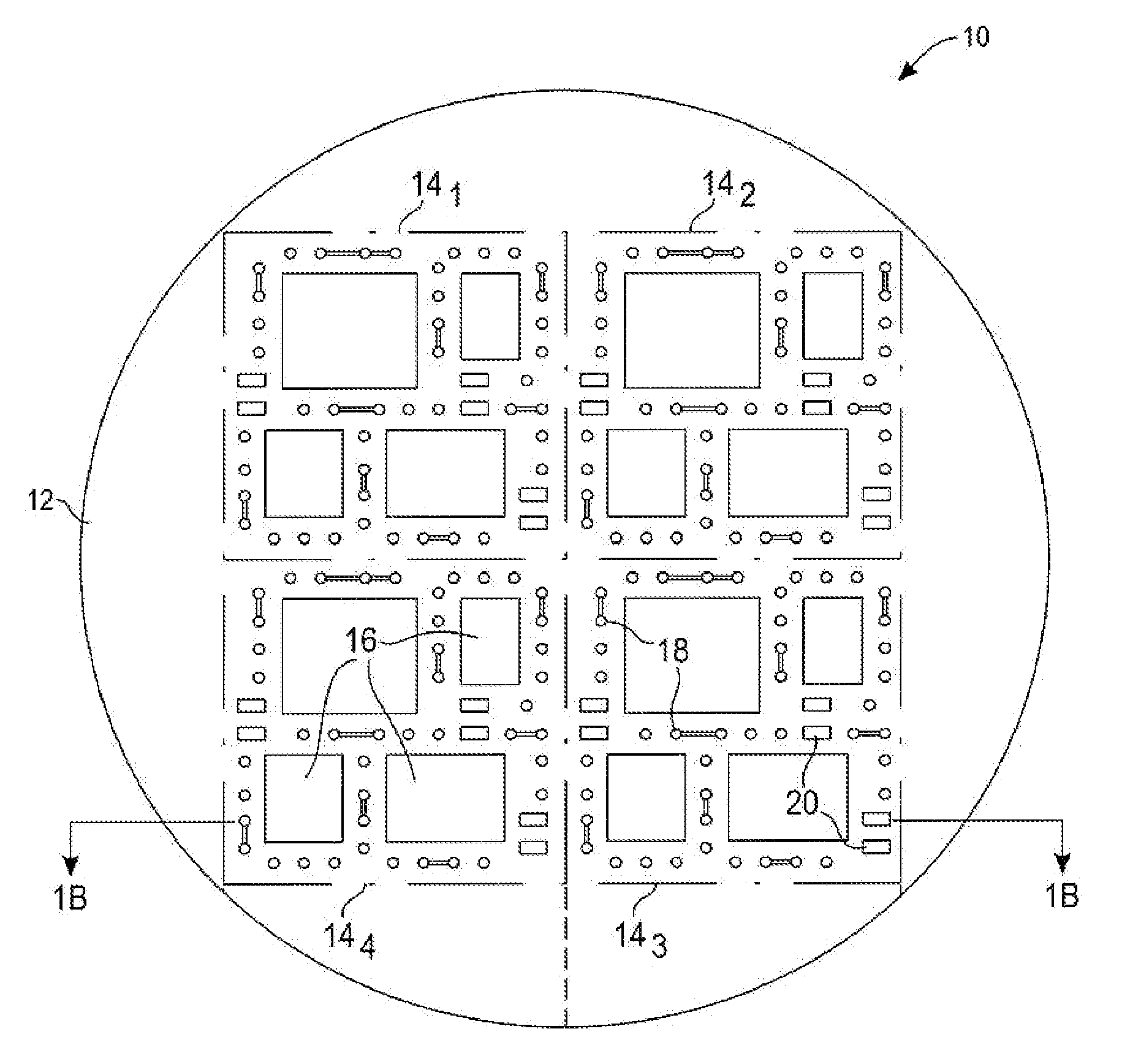

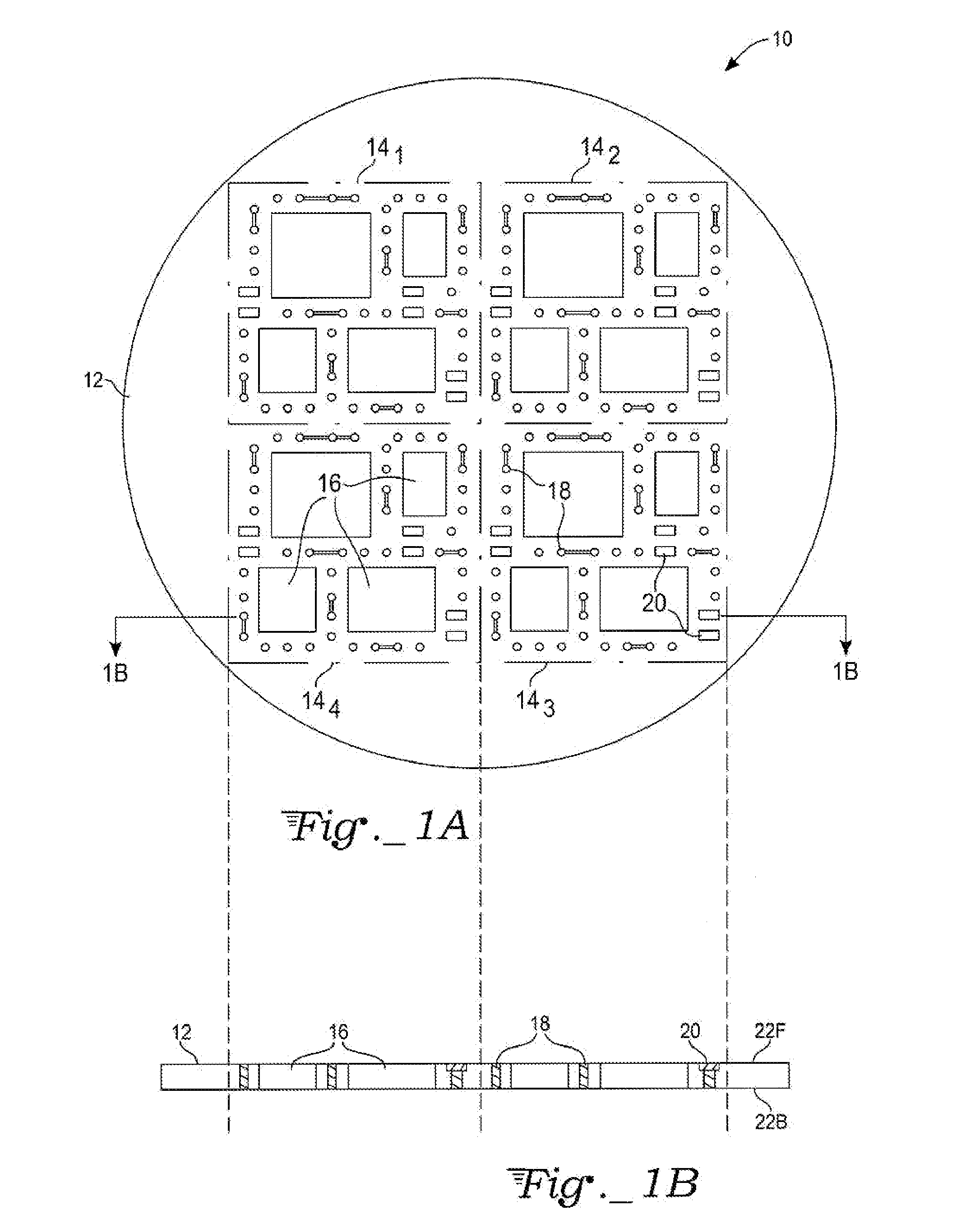

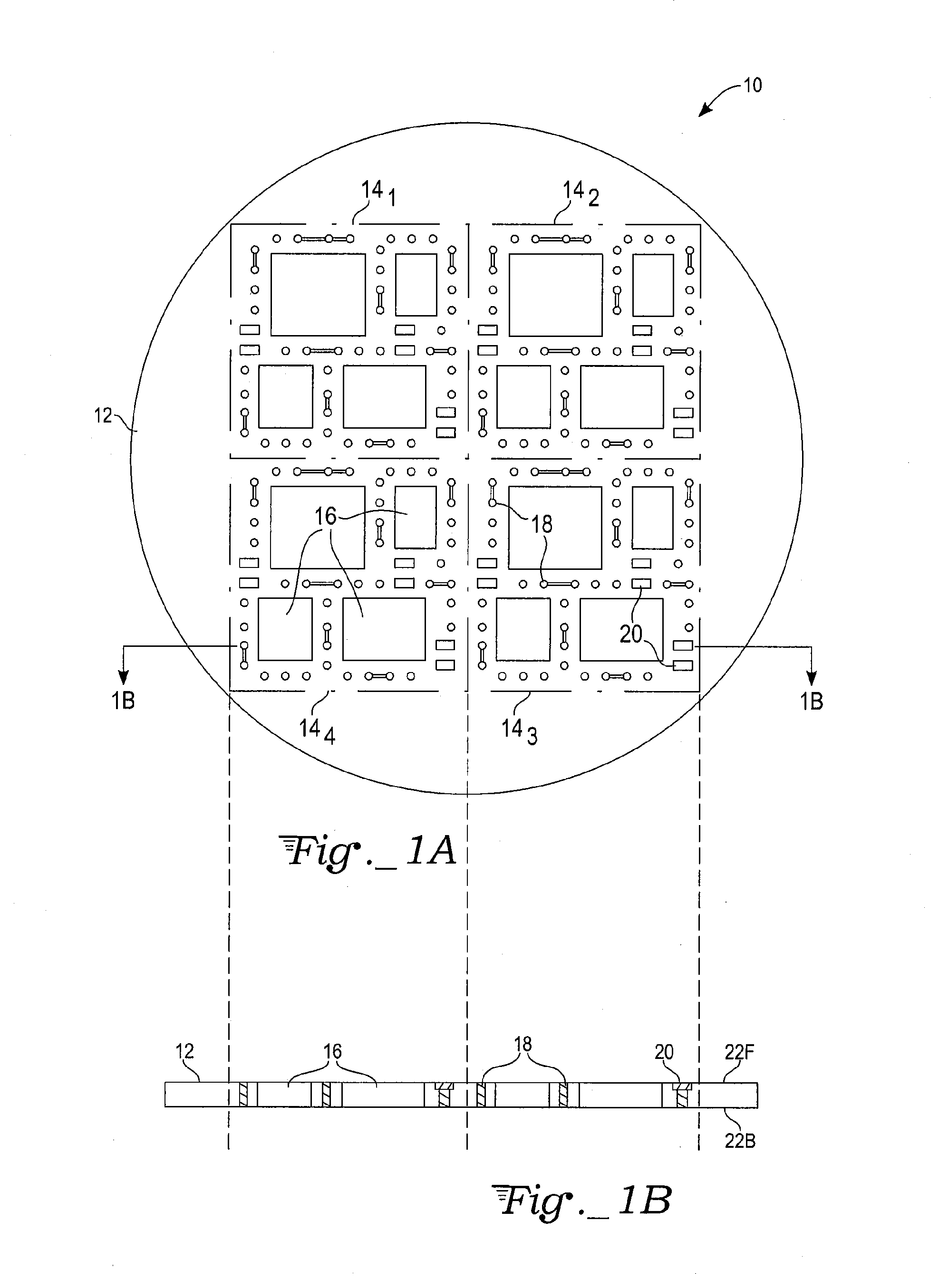

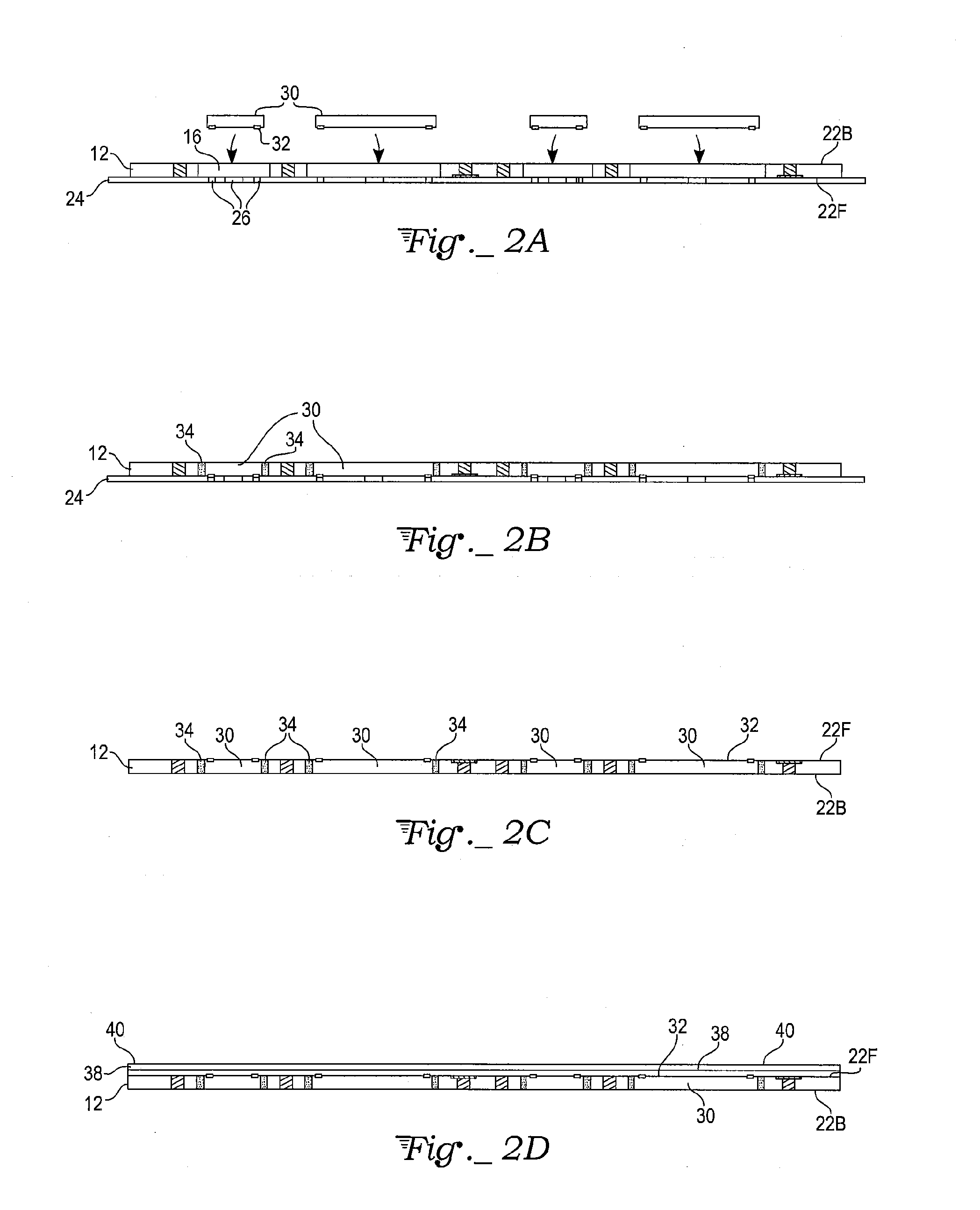

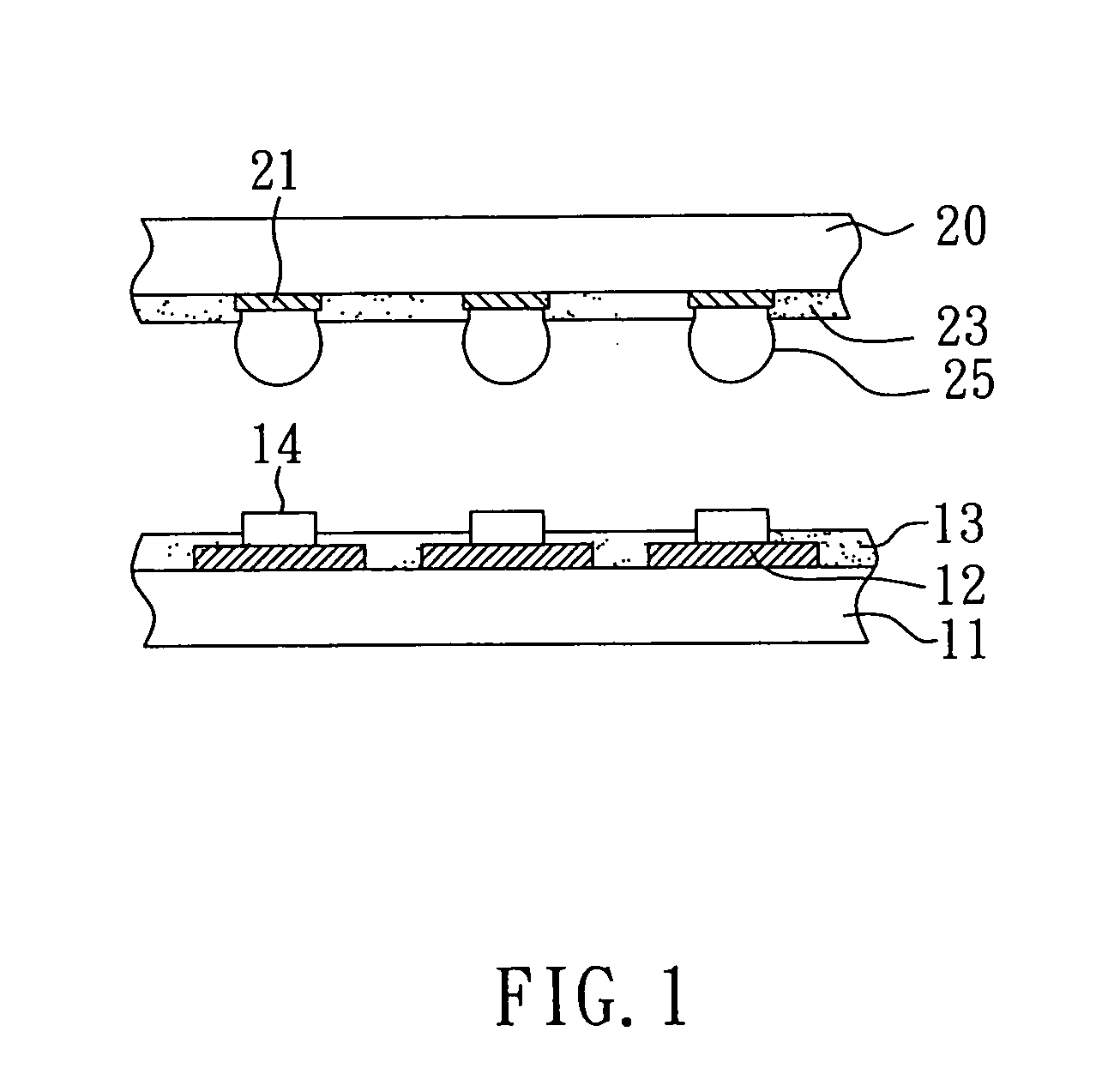

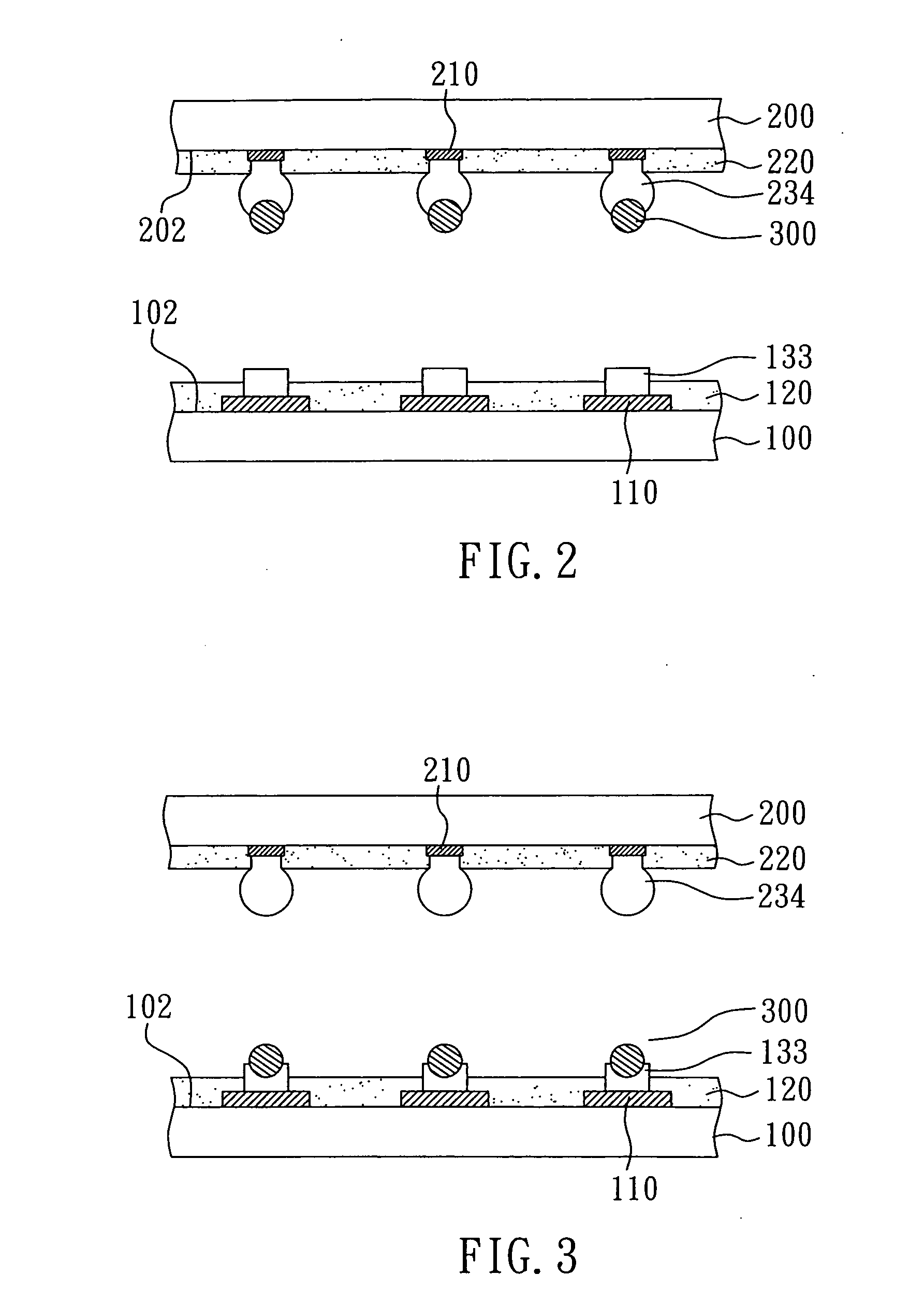

Multi-component electronic package with planarized embedded-components substrate

InactiveUS20080123318A1Easy to useSmall footprintSemiconductor/solid-state device detailsCircuit arrangements on support structuresContact padElectrical connection

An electronic multi-component package is assembled by placing multiple electronic components within multiple openings of a package substrate, then depositing and curing adhesive filler in gaps between the components and the inner peripheries of the openings. Circuit features, including conductive interconnects, are formed by thin-film photolithography over both front and back surfaces of the package substrate. Preformed conductive vias through the package substrate provide electrical connection between circuit features on opposite substrate surfaces. Additional electronic components may be attached to conductive lands on at least one side of the package. The circuit features also include contact pads for external package connections, such as in a ball-grid-array or equivalent structure.

Owner:ATMEL CORP

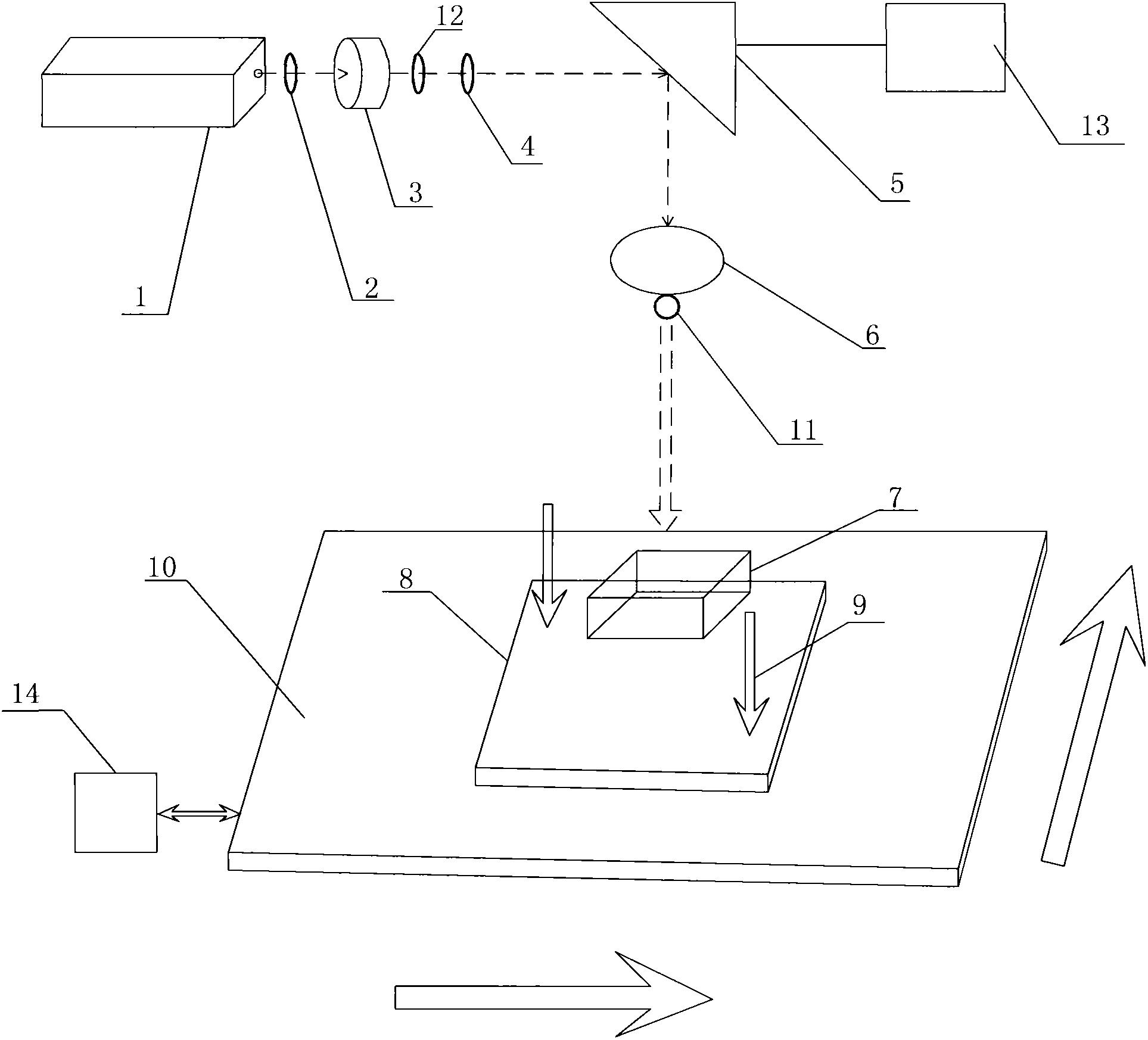

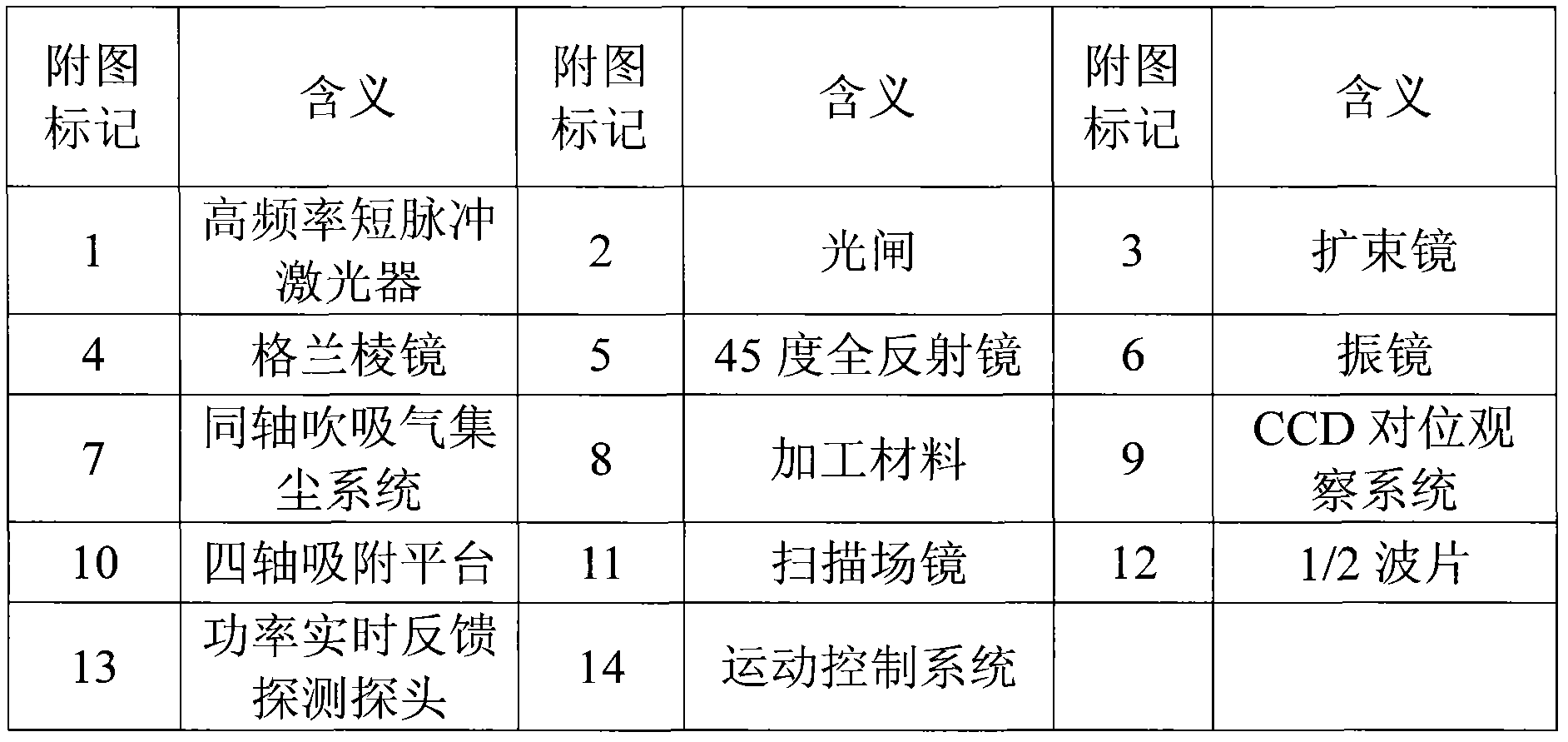

Device and method for etching silver syrup on electronic product

InactiveCN102205468AImprove divergence angleHighlight substantive featuresSemiconductor/solid-state device manufacturingLaser beam welding apparatusPrismCopper

The invention relates to a device and a method for etching silver syrup on an electronic product. The device is characterized in that an optical shutter is arranged at an output end of a high-frequency short pulse laser, wherein a beam expanding lens is arranged at the output end of the optical shutter; a 1 / 2 wave plate and a Glan prism are arranged at the output end of the beam expanding lens in turn; a 45-degree holophote is arranged at the output end of the Glan prism; a vibrating lens and a scanning field lens are arranged at the output end of the 45-degree holophote in turn; the scanning field lens is opposite to a four-shaft absorbing platform; a coaxial blowing and sucking dust-collecting system is arranged on the four-shaft absorbing platform; and CCD (charge coupled device) contraposition systems are respectively arranged at opposite angle positions of the four-shaft absorbing platform. The method is characterized by using a high-frequency infrared pulse laser as a laser source, processing a target position of a material by using a diagonal CCD grabbing target, ensuring a processing chart being one-to-one corresponding to a sample position on a platform, and etching the silver syrup, copper films or molybdenum aluminum layers in invisible areas of different touch screen products, thereby achieving the etching purpose by gasifying film materials in the invisible areas under the action of the high-frequency short pulse infrared laser.

Owner:SUZHOU DELPHI LASER +1

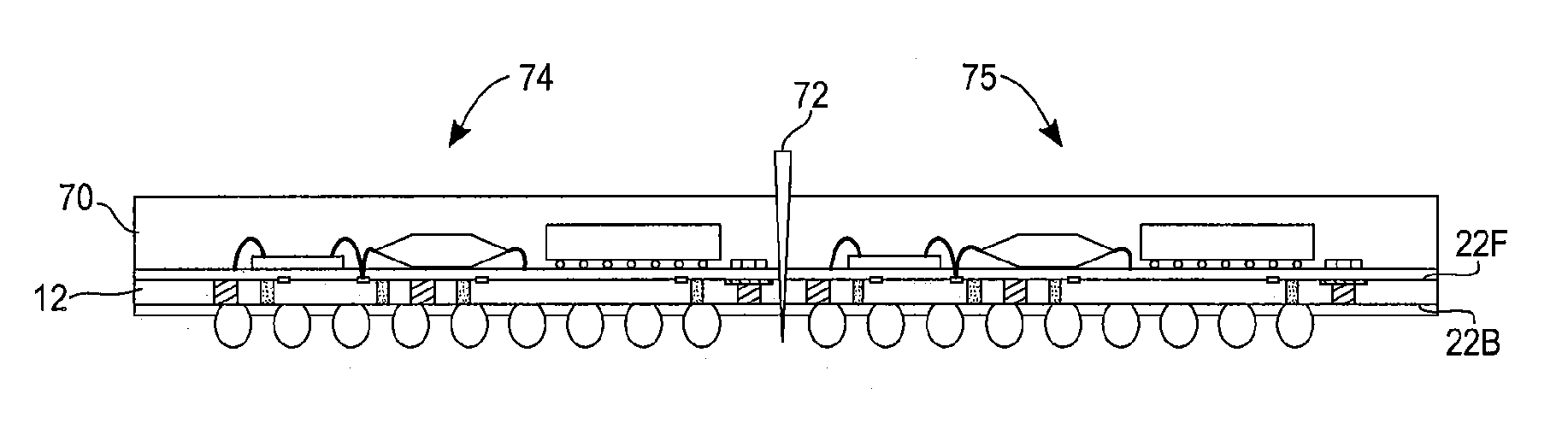

Multi-component electronic package

ActiveUS20110001215A1Easy to useSmall footprintSemiconductor/solid-state device detailsSolid-state devicesContact padElectrical connection

An electronic multi-component package is assembled by placing multiple electronic components within multiple openings of a package substrate, then depositing and curing adhesive filler in gaps between the components and the inner peripheries of the openings. Circuit features, including conductive interconnects, are formed by thin-film photolithography over both front and back surfaces of the package substrate. Preformed conductive vias through the package substrate provide electrical connection between circuit features on opposite substrate surfaces. Additional electronic components may be attached to conductive lands on at least one side of the package. The circuit features also include contact pads for external package connections, such as in a ball-grid-array or equivalent structure.

Owner:ATMEL CORP

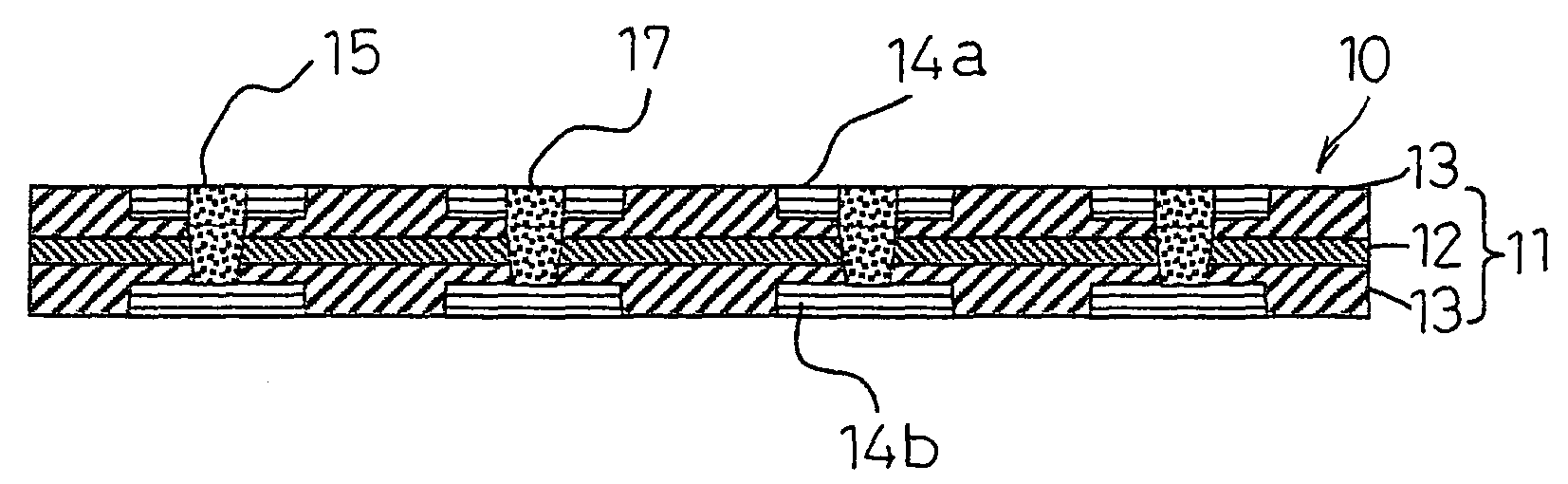

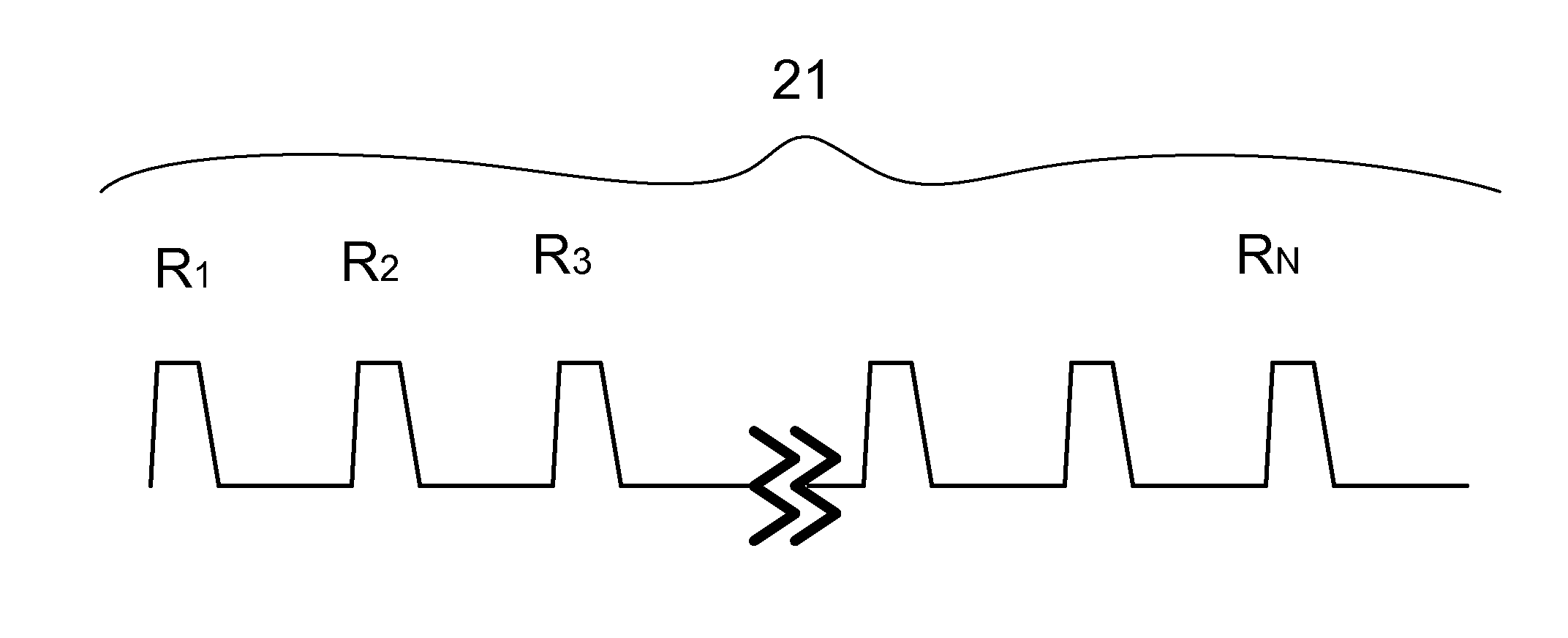

Multilayer circuit board and manufacturing method thereof

InactiveUS7737367B2Low electrical connection resistanceImprove reliabilityPrinted circuit aspectsElectrical connection printed elementsConductive pasteElectrical connection

Holes having the same diameter as via holes are formed in predetermined positions in advance when forming wiring patterns on releasable carriers. The carriers with the wiring patterns are bonded on an insulating material, and a laser beam is irradiated from the side of the carrier using the holes in the wiring pattern as a laser mask to form via holes in the insulating material. The via holes and the holes in the carrier are then filled with a conductive paste. With the holes in the carrier that are matched in position with the via holes, lands in the conductor layers are precisely positioned relative to the via holes. A multilayer circuit board thus produced has lower electrical connection resistance and excellent mountability with improved performances. Also a manufacturing method thereof is achieved.

Owner:PANASONIC CORP

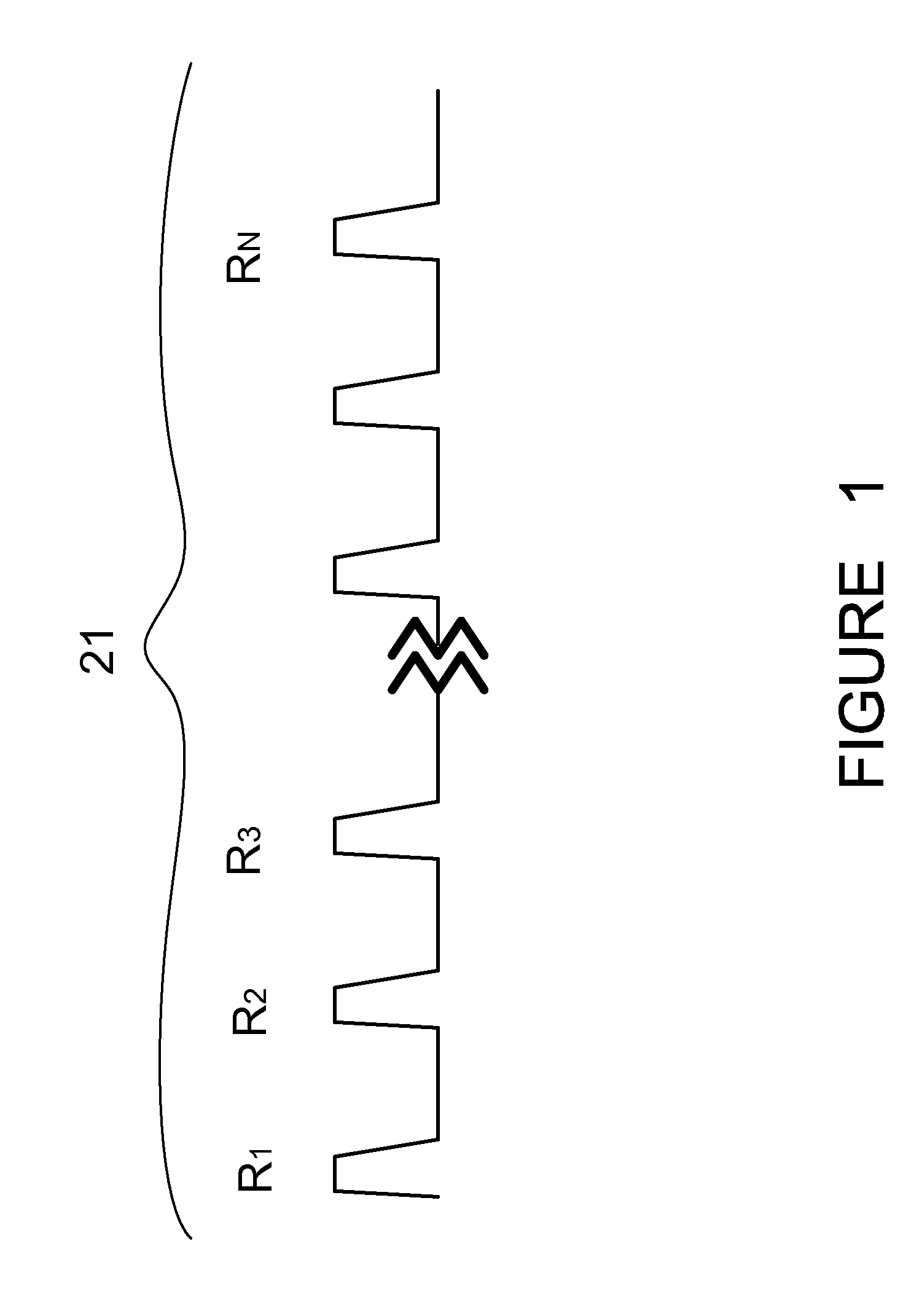

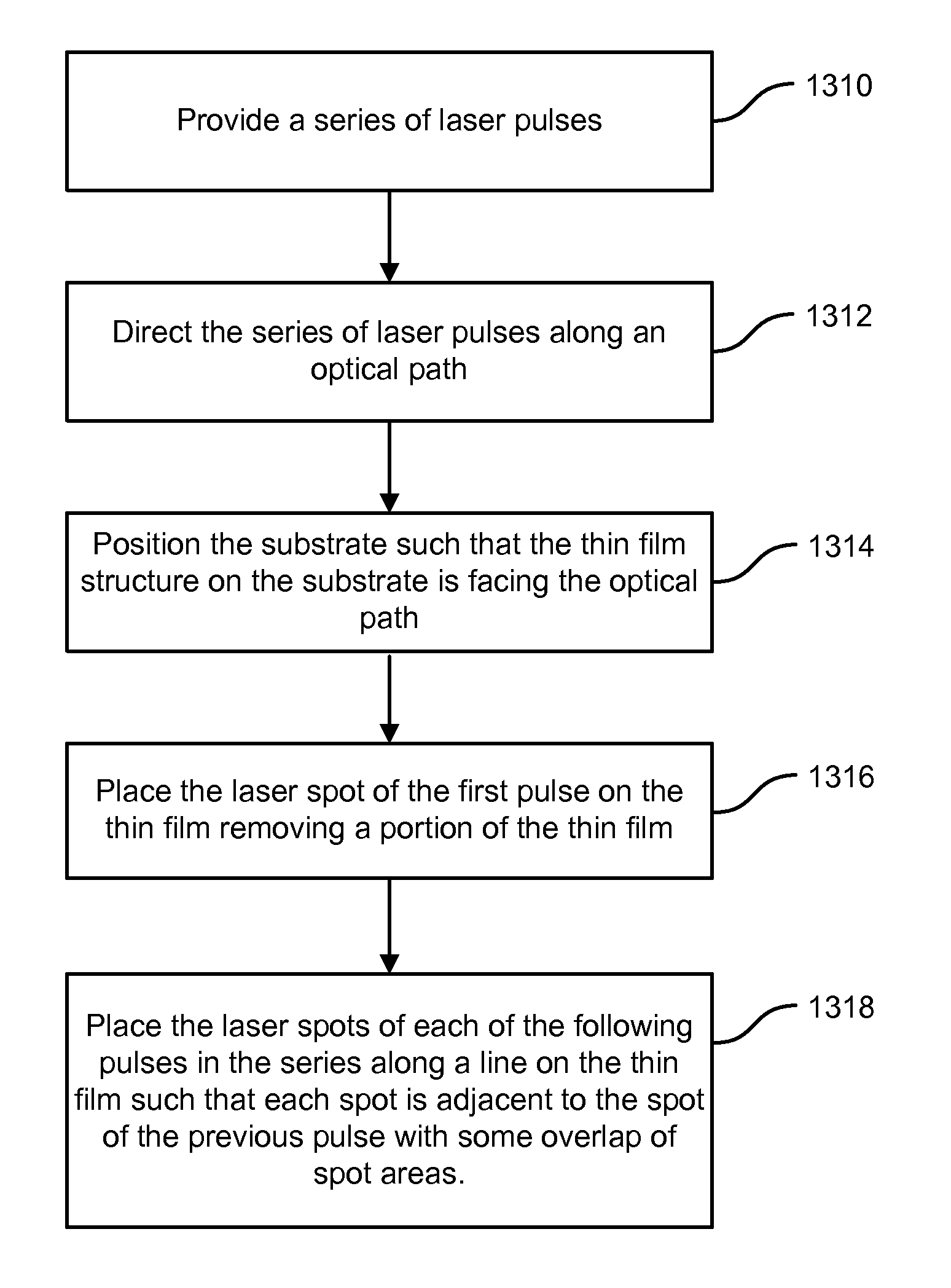

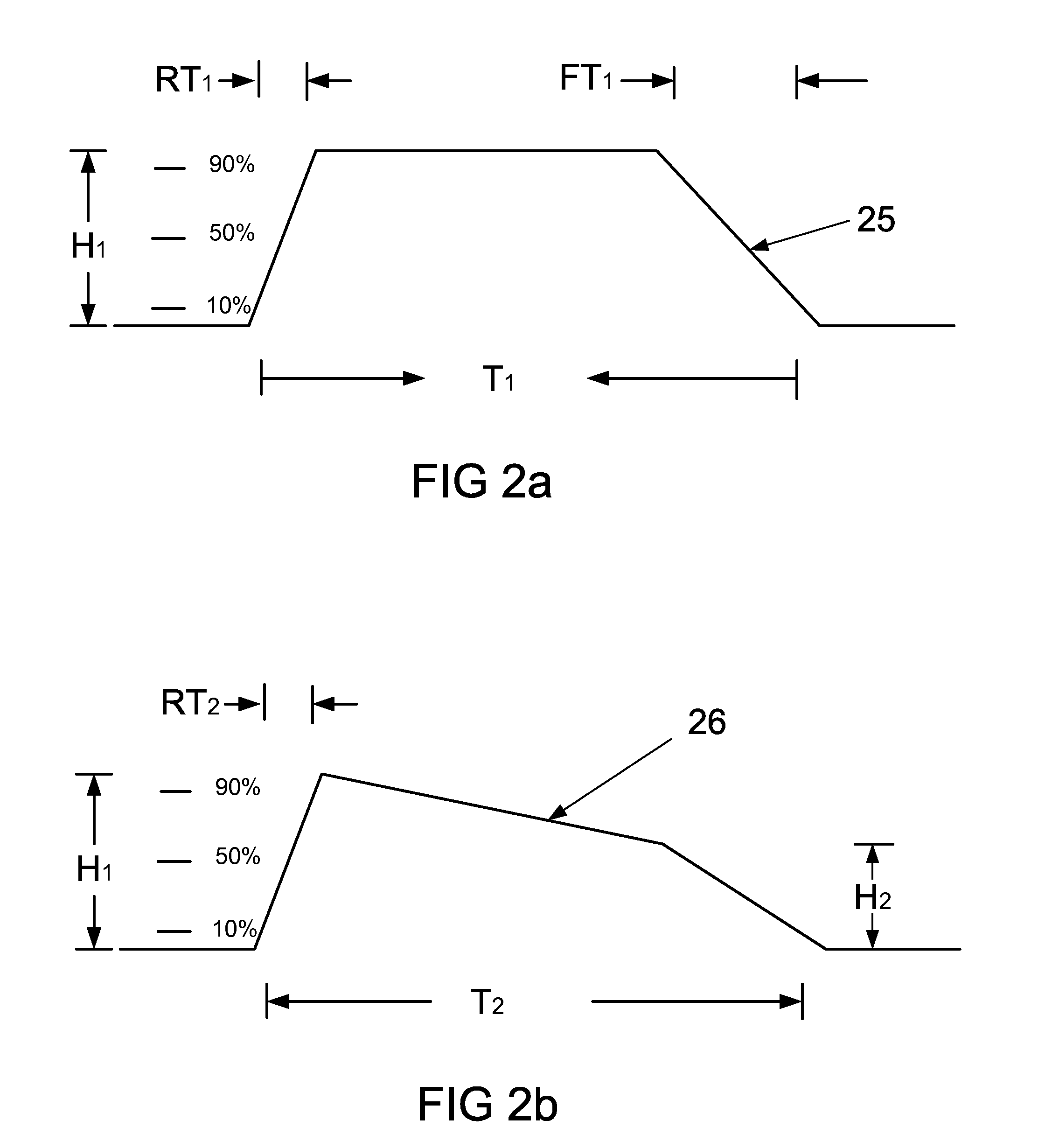

Method and apparatus for scribing a line in a thin film using a series of laser pulses

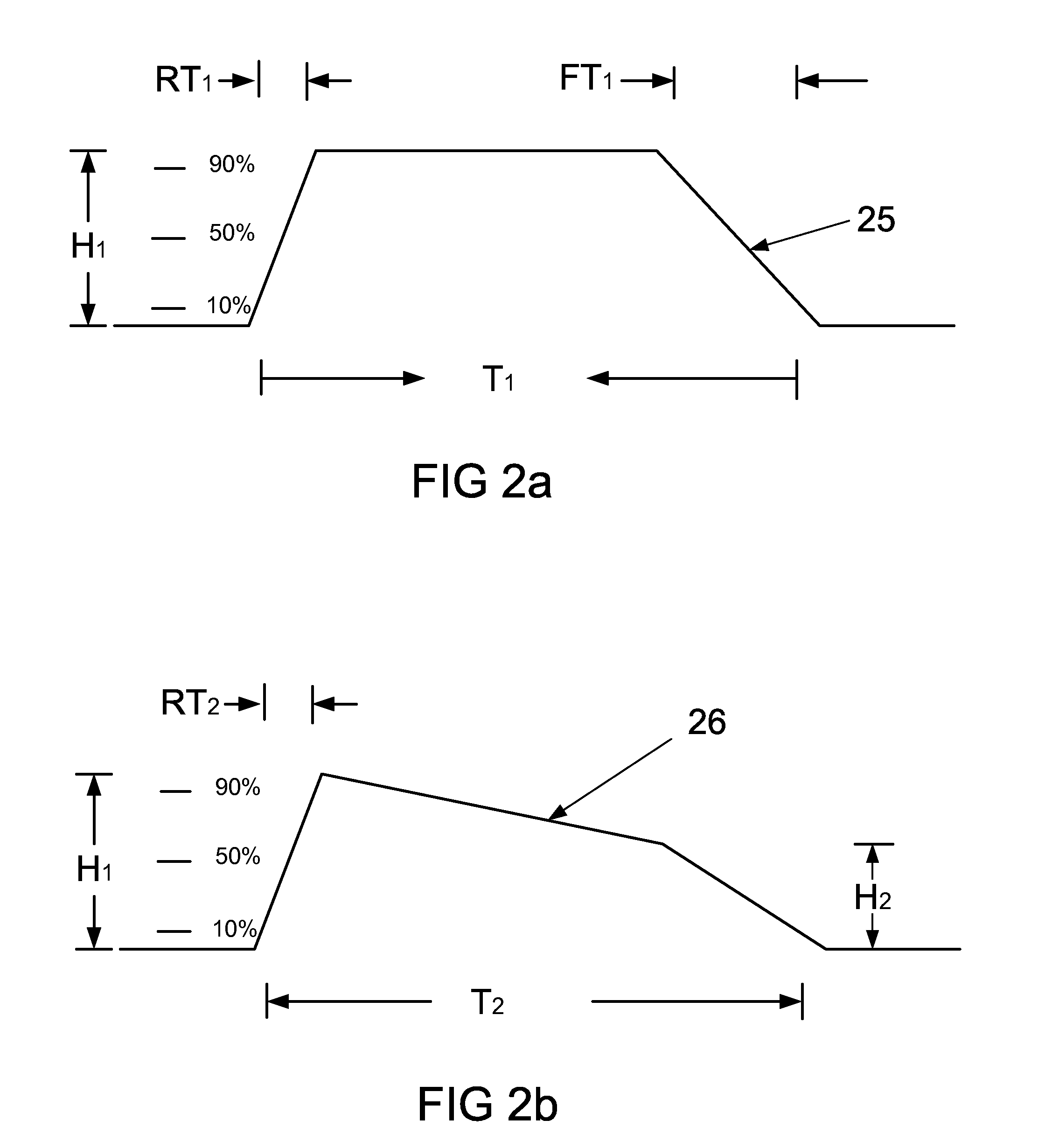

InactiveUS20110129958A1Quality improvementHigh yieldLaser detailsSemiconductor/solid-state device manufacturingOptoelectronicsPulse shaping

A series of laser pulses in a pulse train, each pulse with a predetermined temporal power shape, scribes a line in a thin film of material on a substrate. The predetermined temporal pulse shape has a fast risetime and fast falltime and a pulse length between 10% power points of less than 10 ns. Scribing a line in the thin film is achieved by placing the series of laser pulse spots on the line to be scribed such that there is some overlapping area between adjacent laser pulse spots along the line. The use of a series of laser pulses with the predetermined pulse shape to scribe a line in the thin film results in a better quality and cleaner scribing process compared to that achieved with a conventional pulse shape.

Owner:ELECTRO SCI IND INC

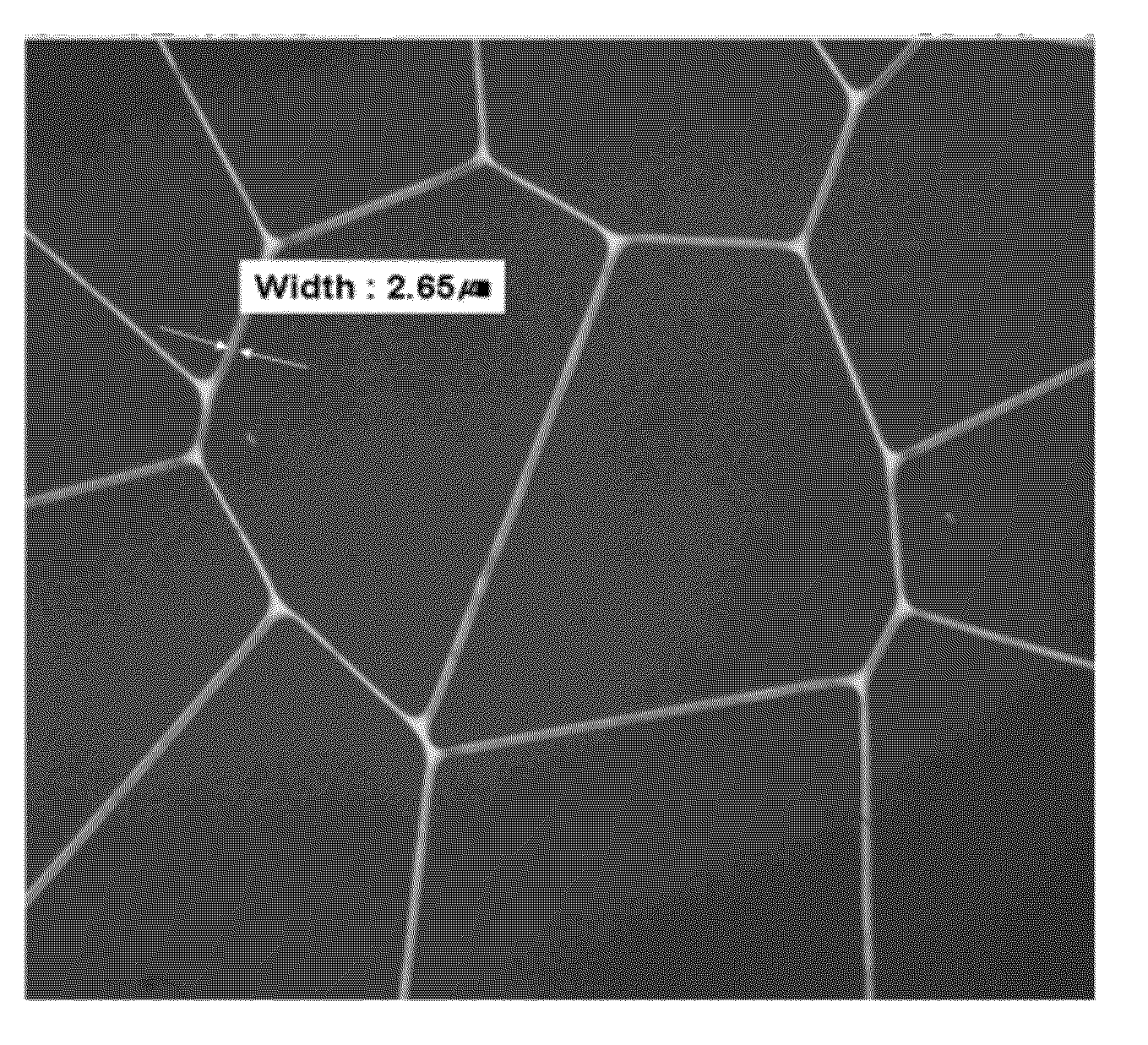

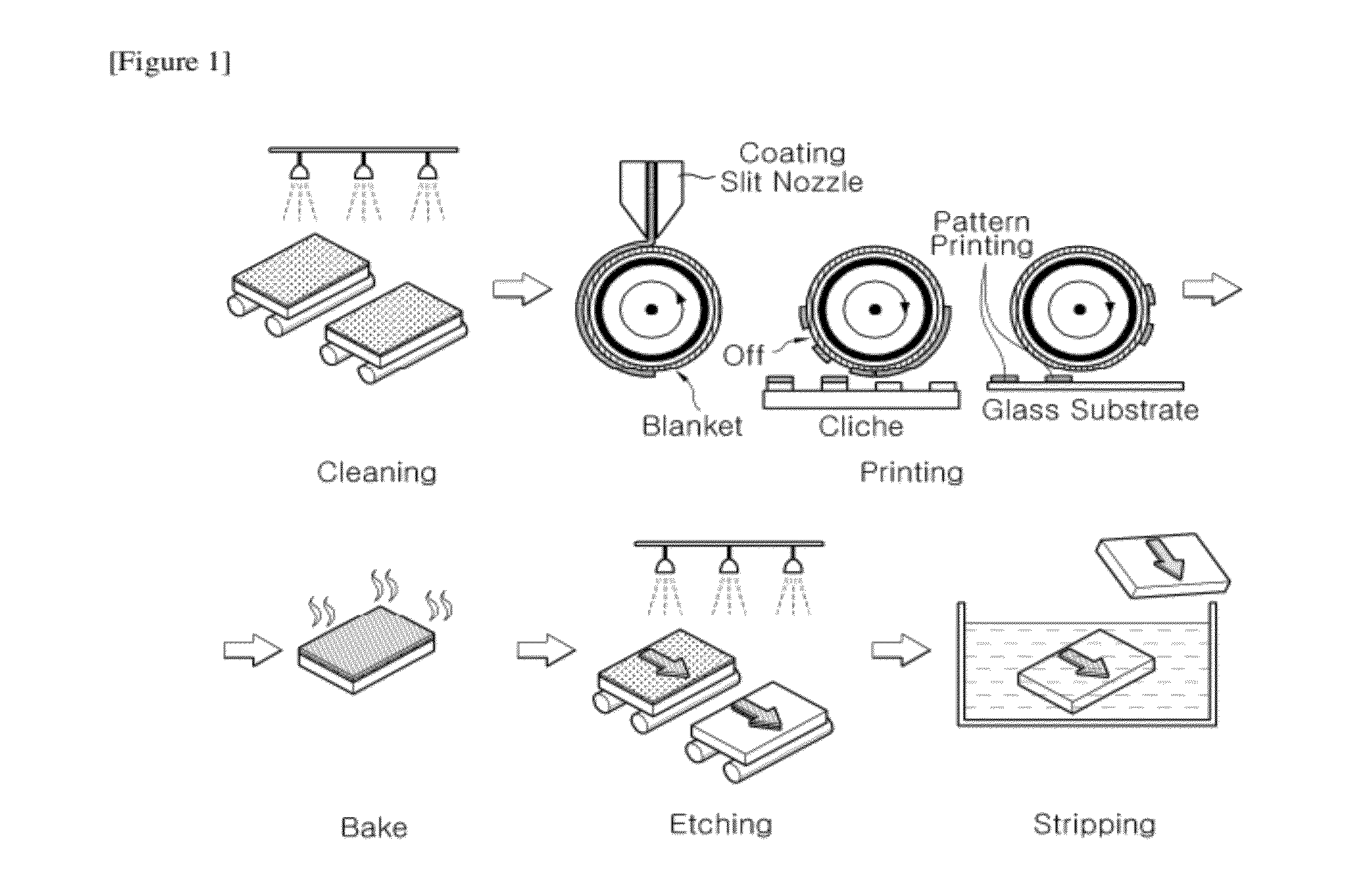

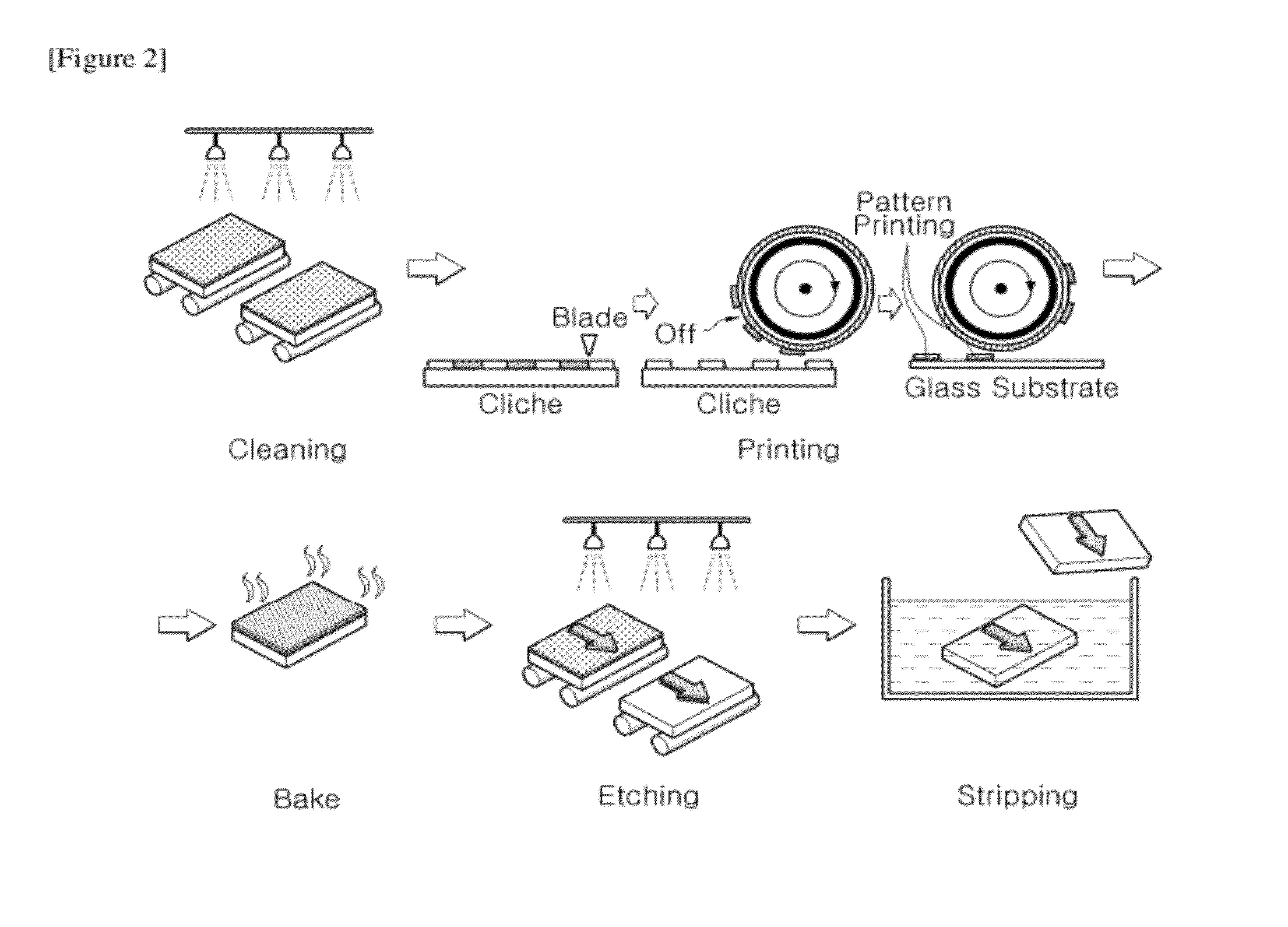

Conductive pattern and manufacturing method thereof

ActiveUS20120031647A1Thin line widthEasy to implementDual purpose resistPhotosensitive material processingResistElectrically conductive

The present invention provides a method for manufacturing a conductive pattern, comprising the steps of: a) forming a conductive film on a substrate; b) forming an etching resist pattern on the conductive film; and c) forming a conductive pattern having a smaller line width than a width of the etching resist pattern by over-etching the conductive film by using the etching resist pattern, and a conductive pattern manufactured by using the same. According to the exemplary embodiment of the present invention, it is possible to effectively and economically provide a conductive pattern having a ultrafine line width.

Owner:LG CHEM LTD

Device and method for laser etching cathode film material of OLED display

InactiveCN102284789AImprove luminous efficiencyThin line widthLaser beam welding apparatusErosionCathode

The invention relates to a device and method for laser etching cathode thin film materials of OLED displays. An electric shutter and an electric beam expander are arranged at the output end of the high-frequency short-pulse laser, and a 1 / 2 wave plate is arranged at the output end of the electric beam expander. 1 The output end of the / 2 wave plate is arranged with a polarization beam splitter, the output end of the polarization beam splitter is arranged with a first half-mirror and a first 45-degree reflector, and the output end of the first half-mirror is arranged with a first focusing mirror and a first half-mirror. The second 45-degree reflective mirror, the output end of the second 45-degree reflective mirror is arranged with a second focusing mirror, the output end of the first 45-degree reflective mirror is arranged with a second half mirror, and the output end of the second half mirror is arranged There is a third focusing mirror and a third 45-degree reflecting mirror, and a fourth focusing mirror is arranged at the output end of the third 45-degree reflecting mirror, and the output end of the focusing mirror is facing the two-axis adsorption platform. The cathode material of the OLED display is vaporized under the action of a high-frequency short-pulse laser to achieve the purpose of erosion, and the four beams realize the line etching of the cathode area.

Owner:SUZHOU DELPHI LASER

Preparation method and product of high-performance metal grid transparent conductive film

ActiveCN106373664AResilientImprove toughnessMaterial nanotechnologyConductive layers on insulating-supportsContact formationMetallurgy

The invention provides a preparation method and product of a high-performance metal grid transparent conductive film. The metal grid transparent conductive film at least comprises a transparent substrate comprising a first surface and a second surface in opposite arrangement; and a metal grid wire formed by close contact between graphene and metal nanometer particles in-situ growing thereon, wherein the metal grid wire is directly or / and indirectly arranged on the first surface or / and the second surface of the transparent substrate. The prepared metal grid solves the problems of unbendable conventional metal grids, visible metal grids, metal migration and the like. The preparation method is simple, thereby facilitating large-scale production.

Owner:BEIJING HINANO TECH CO LTD

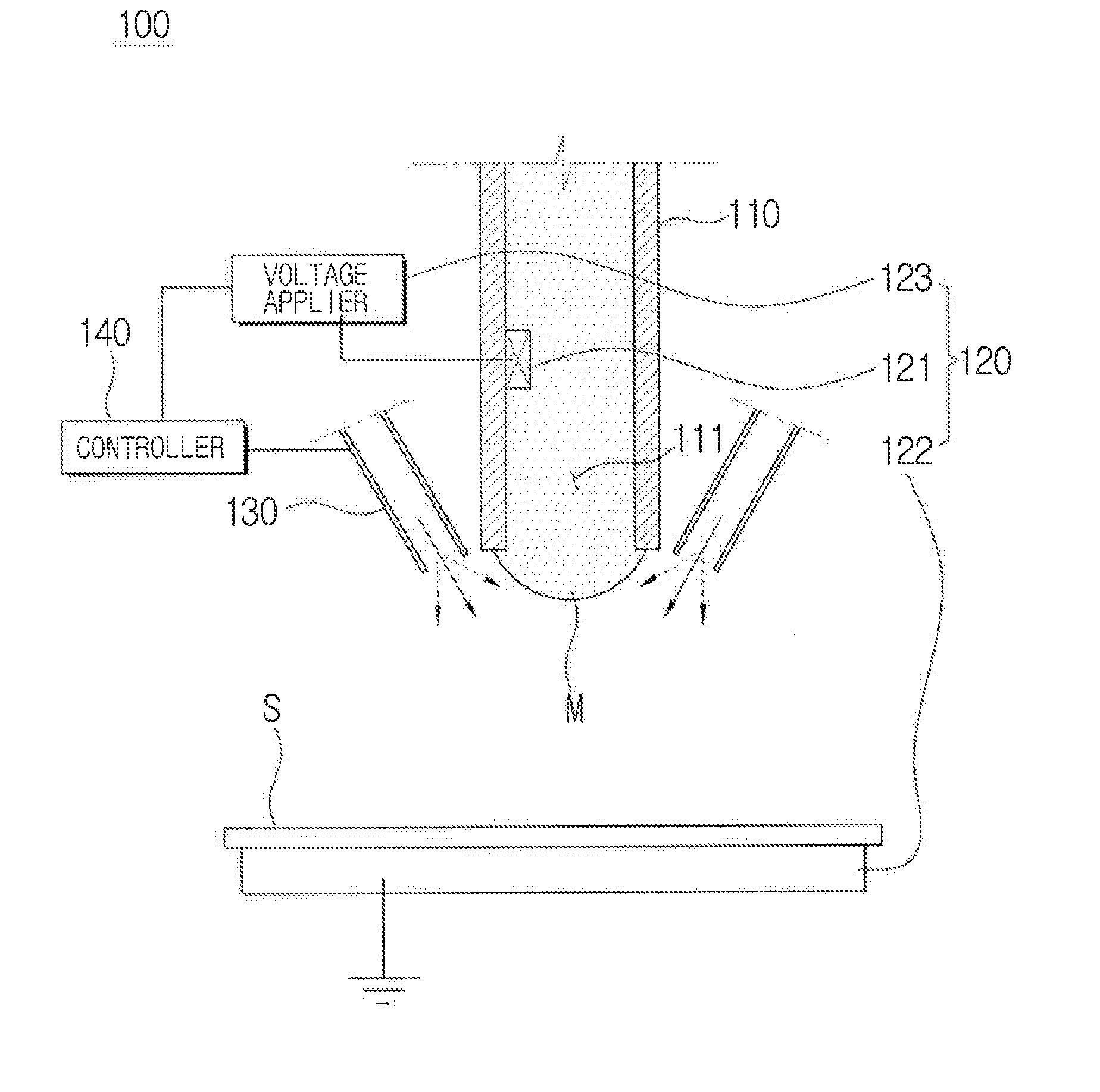

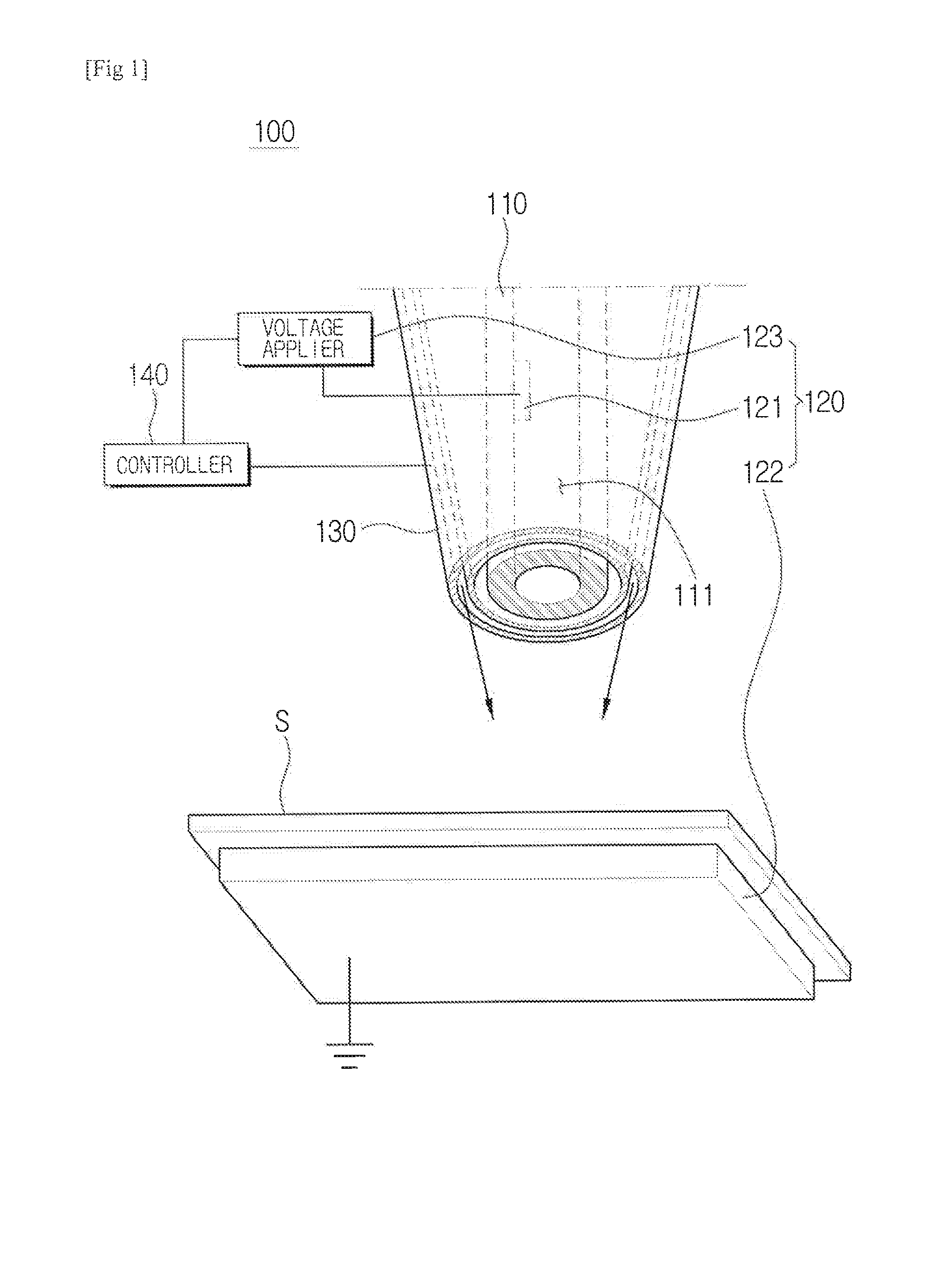

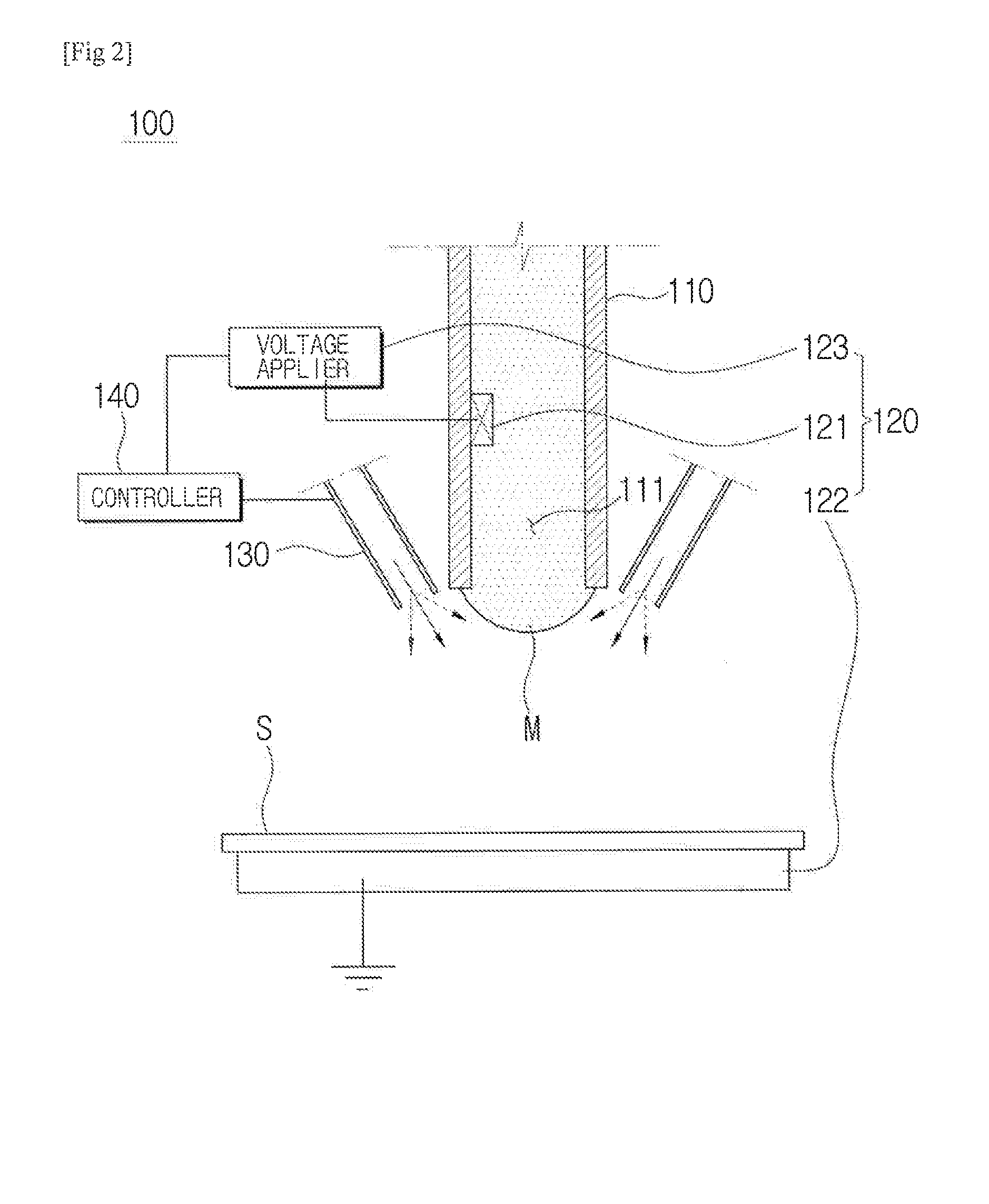

Device for Discharging Ink Using Electrostatic Force

Provided herein is a device for discharging ink using electrostatic force, the device including a nozzle portion for discharging ink through an electric field to a substrate; an electrode portion for creating an electric field between the nozzle and the substrate; and a gas discharge portion for discharging guide gas from outside of the nozzle portion to control a cross-section area of ink being discharged from the nozzle portion.

Owner:ENJET CO LTD

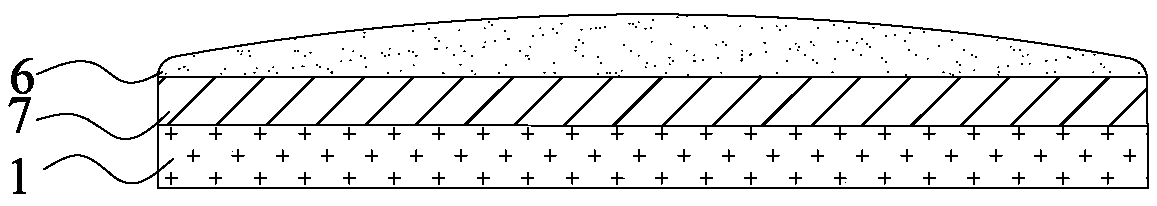

Solar cell and method of manufacturing the same

ActiveUS20100078069A1Thin line widthHigh carrier-collection efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationConductive pasteEngineering

A method of manufacturing a solar cell, including: forming a first conductivity type semiconductor layer extending along a predetermined direction on aback surface of a semiconductor substrate that has a light-receiving surface and the back surface opposite to the light-receiving surface, the first-conductivity-type semiconductor layer being divided into plural island-shaped sections arranged side by side in the predetermined direction; forming a semiconductor layer of a second conductivity type in the predetermined direction on the back surface; and forming conductive layers respectively on the first-conductivity-type semiconductor layer and the second-conductivity-type semiconductor layer by using a conductive paste, the conductive layer to be formed on the first-conductivity-type semiconductor layer being formed by a printing method such that the conductive layer to be formed on the first-conductivity-type semiconductor layer extends on a line of the plural island-shaped sections to bridge adjacent two of the plural island-shaped sections.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Light-emitting apparatus

InactiveCN102077385AReduce voltage dropNarrow frame widthElectroluminescent light sourcesSolid-state devicesEngineeringLight emitting device

Provided is a light-emitting apparatus including a plurality of light-emitting devices arranged on a substrate, the plurality of light-emitting devices each including a pair of electrodes and an organic emission layer which is interposed between the pair of electrodes with one of the pair of electrodes serving as an anode and another one of the pair of electrodes serving as a cathode, wherein one of the pair of electrodes is an electrode common to the plurality of light-emitting devices, and wherein, of the plurality of light-emitting devices, ones that have the common electrode as their anodes and ones that have the common electrode as their cathodes are arranged alternately.

Owner:CANON KK

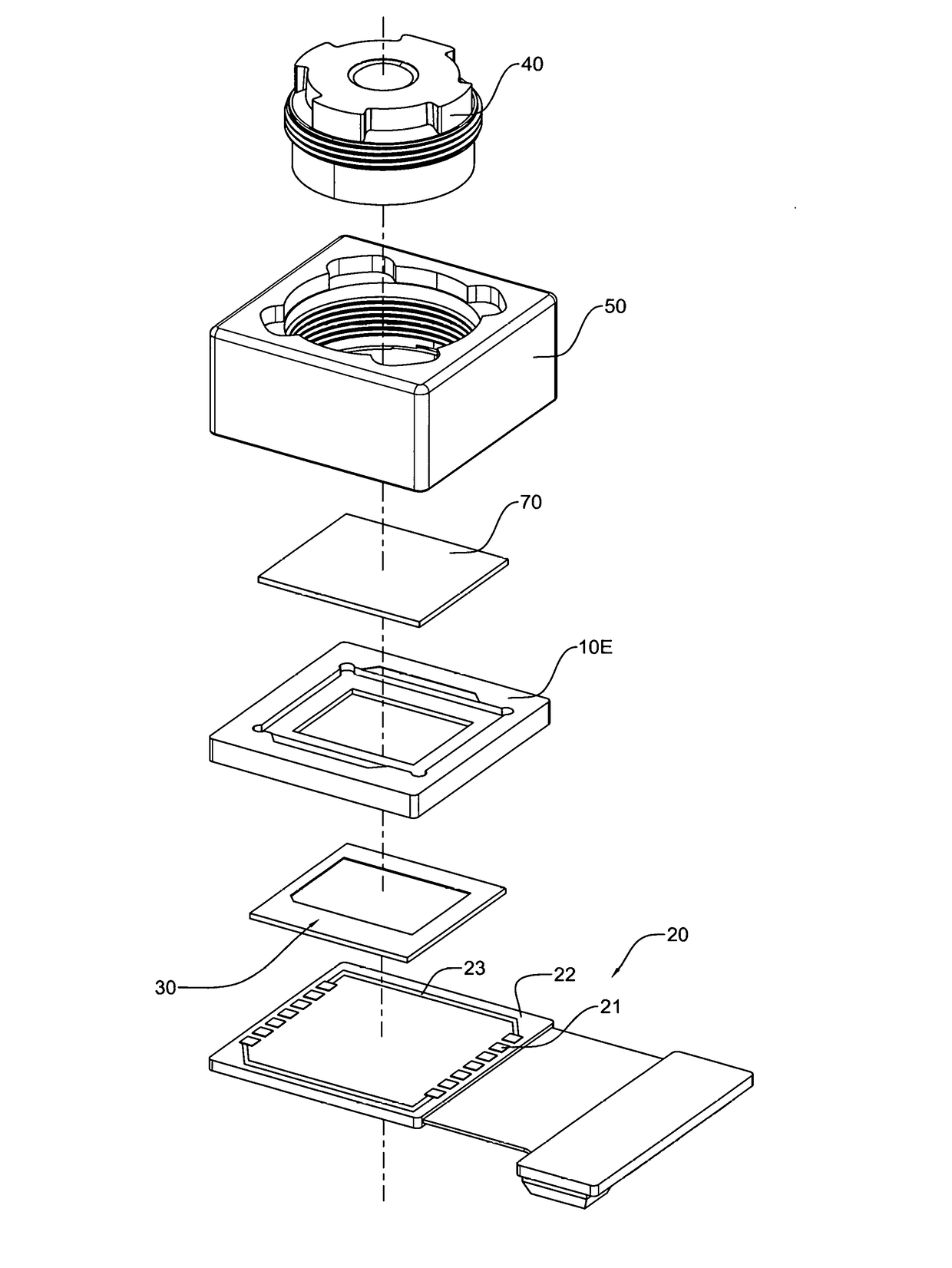

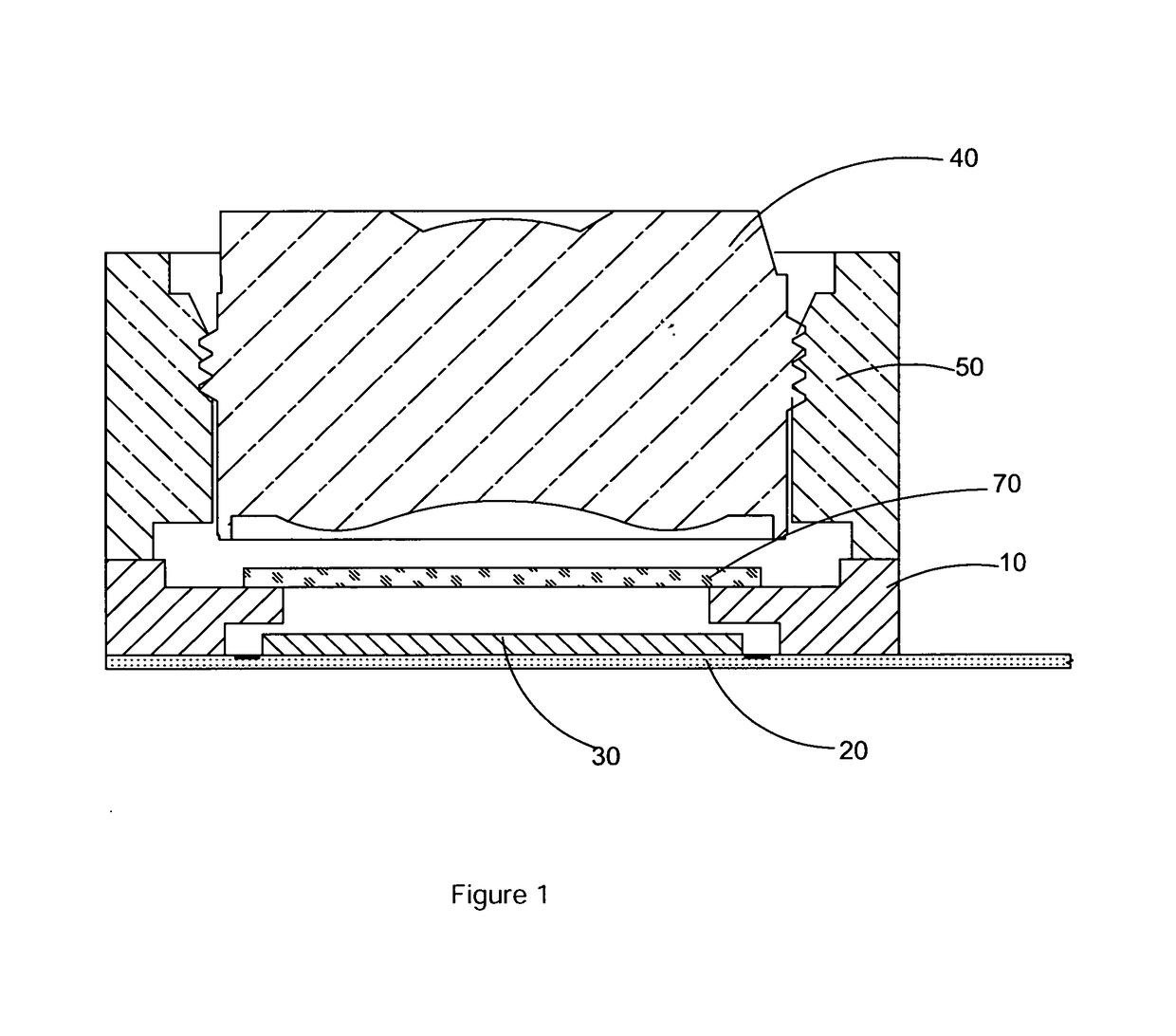

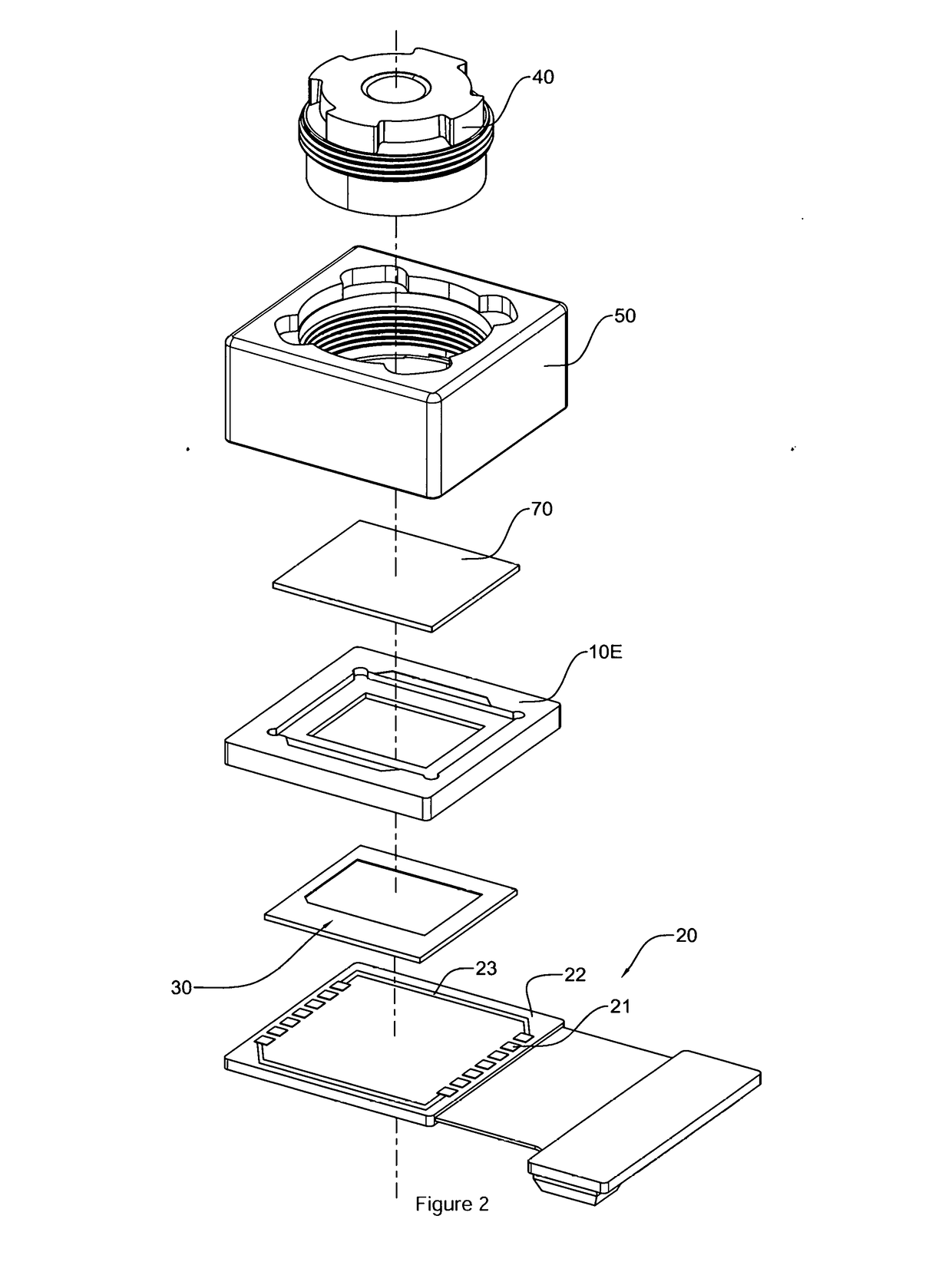

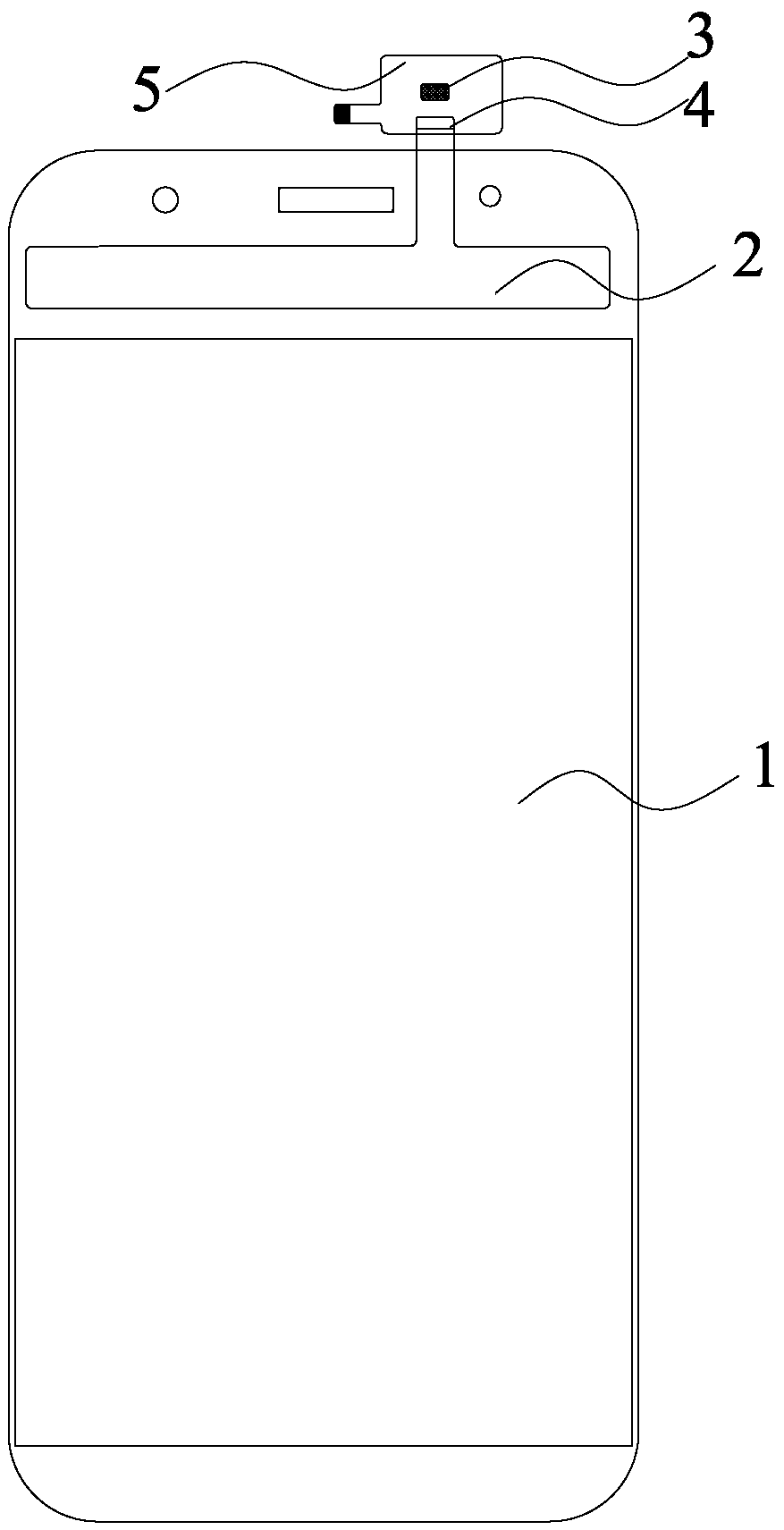

Camera Module with Compression-Molded Circuit Board and Manufacturing Method Thereof

ActiveUS20170245363A1Minimized in sizeIncrease in circuit sizePrinted circuit assemblingTelevision system detailsCompression moldingComputer module

A camera module with compression-molded circuit board is manufactured by compression-molding that can obtain properties such as high flatness, ultra-thin, fine wiring width and high integration.

Owner:NINGBO SUNNY OPOTECH CO LTD

Method and apparatus for scribing a line in a thin film using a series of laser pulses

InactiveUS7998838B2Thin line widthRemove cleanLaser detailsSemiconductor/solid-state device manufacturingPulse shapingOptoelectronics

A series of laser pulses in a pulse train, each pulse with a predetermined temporal power shape, scribes a line in a thin film of material on a substrate. The predetermined temporal pulse shape has a fast risetime and fast falltime and a pulse length between 10% power points of less than 10 ns. Scribing a line in the thin film is achieved by placing the series of laser pulse spots on the line to be scribed such that there is some overlapping area between adjacent laser pulse spots along the line. The use of a series of laser pulses with the predetermined pulse shape to scribe a line in the thin film results in a better quality and cleaner scribing process compared to that achieved with a conventional pulse shape.

Owner:ELECTRO SCI IND INC

Method for manufacturing metal thin film resistor

InactiveUS6993828B2Minimized in sizeImprove responsivenessSemiconductor/solid-state device detailsResistor manufacture by lithographyHigh resistanceForming processes

A metal resistor and a method for manufacturing the resistor are provided. A first insulation film is formed on a substrate, a photosensitive film is applied on the insulation film, and an insulation film pattern is formed by patterning the insulation film. After a metal thin film is formed among the insulation film pattern and on the photosensitive film, with removing the photo-sensitive film is a metal thin film pattern formed among the insulation film pattern. On the metal thin film pattern and the insulation film pattern is a second insulation film formed and at the pad region of the metal thin film pattern is a lead wire connected, after that, a metal thin film resistor is manufactured with forming a preservation film on and around the lead wire. Using a pattern-forming process by etching of the insulation film for forming the metal thin film pattern, the deterioration of the device or the lowering of the durability can be overcome, the resistance of the metal thin film resistor can be easily controlled, and the resolving power can be improved by producing the high-resistance metal thin film temperature having reduced line with of the metal thin film pattern.

Owner:INOSTEK

GG monolayer multipoint borderless touch screen and preparation process thereof

InactiveCN105511681AGood light transmissionImprove clarityInput/output processes for data processingSputteringGlass cover

The invention relates to the technical field of touch screens and particularly relates to a GG monolayer multipoint borderless touch screen and a preparation process thereof. The touch screen comprises a tempered glass cover plate, a transparent optical adhesive layer and ITO conductive glass, wherein a border wiring area of the ITO conductive glass comprises a transverse wiring area arranged at one end of the touch screen, the ITO conductive glass is provided with a monolayer multipoint electrode pattern of single-end outgoing line, and an FPC is mounted in the transverse wiring area in a press-fitting manner and is connected with an IC chip. According to the GG monolayer multipoint borderless touch screen and the preparation process thereof, the FPC is mounted in the transverse wiring area at one end of the touch screen in the press-fitting manner, and original left and right longitudinal wiring areas are canceled, so that longitudinal sides of the touch screen do not need wiring, and thus, a borderless visual effect is built; ultraviolet illumination is adopted during magnetron-sputtering ITO film plating, so that the photoelectric properties of the ITO conductive glass are improved, only one-time FPC press-fitting is required during preparation, the process is simple, the yield of products is high, and excellent properties and production stability for the touch screen can be guaranteed.

Owner:深圳市欣联科技有限公司

Light-emitting apparatus

InactiveUS20110241036A1Reduce shadowsSimple and inexpensive structureElectroluminescent light sourcesSolid-state devicesEngineeringLight emitting device

Provided is a light-emitting apparatus including a plurality of light-emitting devices arranged on a substrate, the plurality of light-emitting devices each including a pair of electrodes and an organic emission layer which is interposed between the pair of electrodes with one of the pair of electrodes serving as an anode and another one of the pair of electrodes serving as a cathode, wherein one of the pair of electrodes is an electrode common to the plurality of light-emitting devices, and wherein, of the plurality of light-emitting devices, ones that have the common electrode as their anodes and ones that have the common electrode as their cathodes are arranged alternately.

Owner:CANON KK

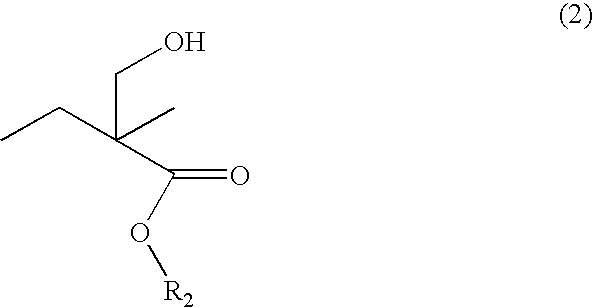

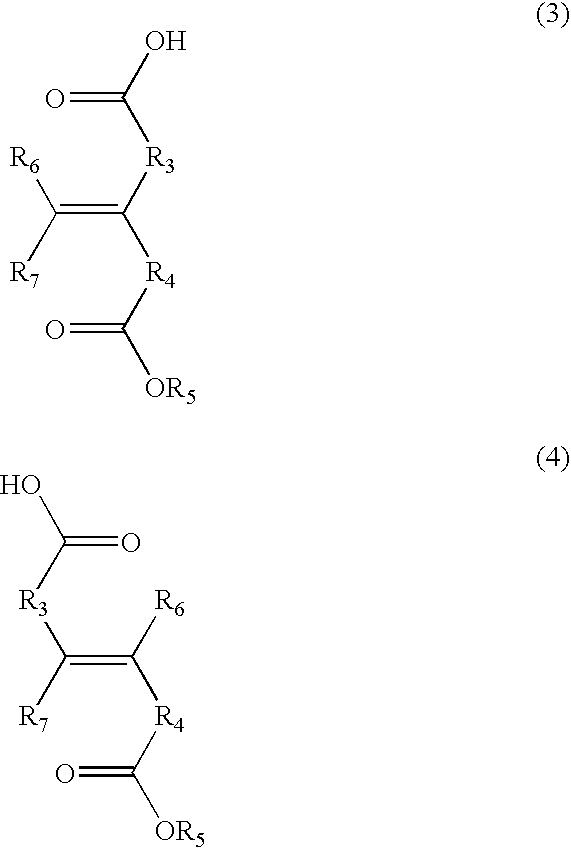

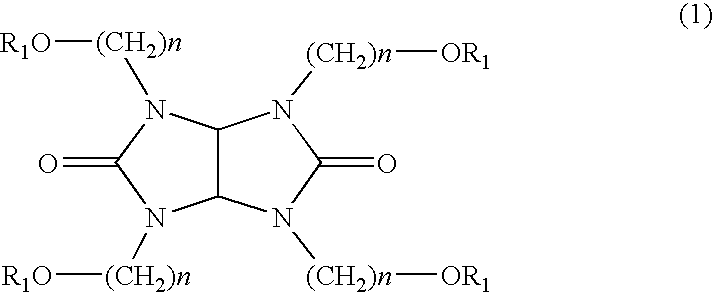

Resist material for liquid immersion lithography process and method for forming resist pattern using the resist material

InactiveUS20060110676A1High resolutionThin line widthSemiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersImage resolutionRefractive index

A negative resist material for a liquid immersion lithography process containing a resin component and a crosslinker component for this resin component, wherein the crosslinker component is poorly soluble in a liquid immersion medium, and a method for forming a resist pattern by the use thereof are provided. These simultaneously prevent alteration of a resist film and alteration of the liquid used during the liquid immersion lithography and enable to form the resist pattern with high resolution using the liquid immersion lithography. In the liquid immersion lithography process, the resolution of the resist pattern is enhanced by exposing the resist film to light with the intervening liquid with a predetermined thickness whose refractive index is higher than that of air and lower than that of the resist film on at least the resist film in a path of lithography exposure light reaching the resist film.

Owner:TOKYO OHKA KOGYO CO LTD

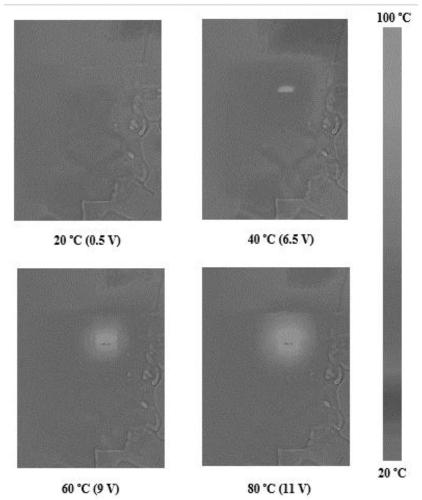

Preparation method of self-heating laser-induced graphene flexible NO2 gas sensor

InactiveCN111537575AFast response/recoveryGood repeatabilityGrapheneNanotechnologyPorous grapheneHigh energy

The invention relates to a preparation method of a self-heating laser-induced graphene flexible NO2 gas sensor. The gas sensor comprises an insulating region, an electrode region, a silver coating region and a gas sensitive region; the insulating region is arranged at the bottom end; the electrode region and the gas sensitive region are arranged on the upper surface of the insulating region; the silver coating region is arranged on the electrode connecting regions at the two ends of the electrode region; and the electrode region and the gas sensitive region are three-dimensional porous graphene patterns which are prepared through high-energy one-step induction of laser and have larger porosity structures. Due to the unique graphene three-dimensional structure size of the gas sensitive region, the step of additionally adding a gas sensitive material can be omitted, and gas adsorption with the same or even better effect is achieved. The method is beneficial to rapid desorption of NO2 gasmolecules, improves the use repeatability of the sensor, reduces the manufacturing cost, is short in manufacturing period and high in sensitivity, has the detection limit reaching 10ppb, and has a wide application prospect in the aspects of environmental monitoring and medical diagnosis.

Owner:HEBEI UNIV OF TECH

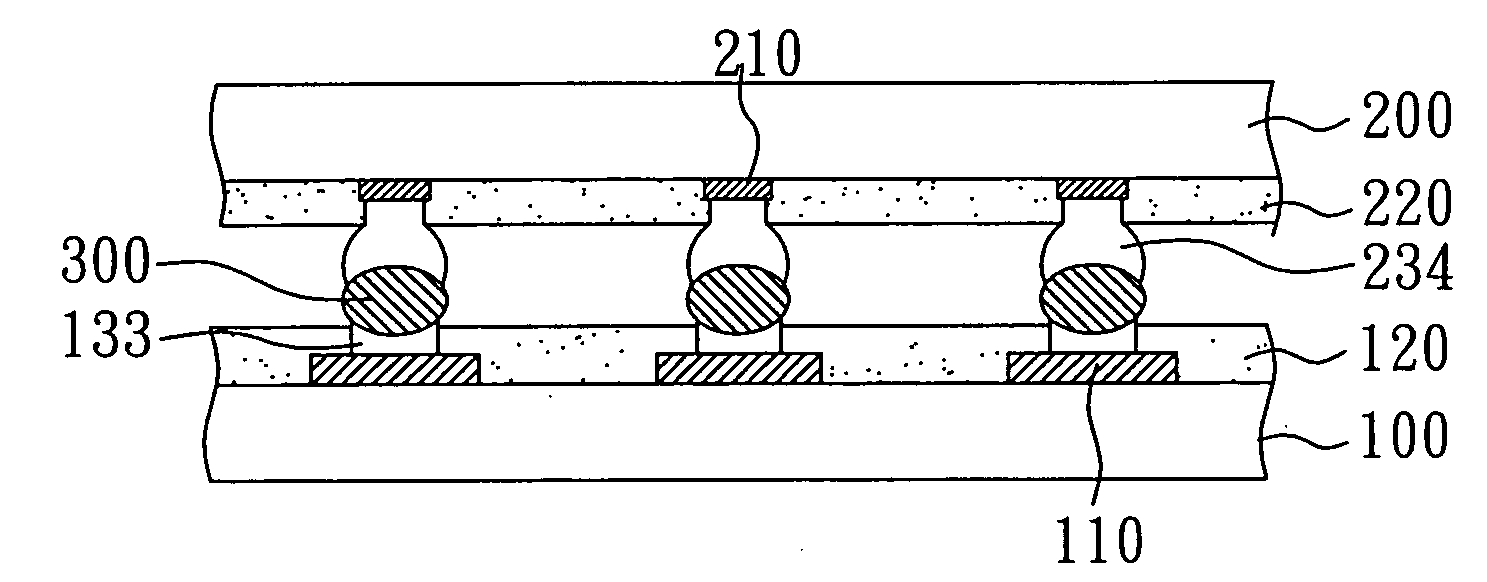

Flip-chip package structure, and the substrate and the chip thereof

InactiveUS20090014896A1Thin line widthIncrease pressureFinal product manufactureSemiconductor/solid-state device detailsSemiconductor chipEngineering

A flip-chip package structure is disclosed, which comprises: a packaging substrate having an upper surface and a plurality of conductive pads formed on the upper surface; a semiconductor chip having an active surface and a plurality of electrode pads formed on the active surface; and a plurality of first solder bumps; wherein each first solder bump connects to an electrode pad and a conductive pad, and each first solder bump contains a solid grain.

Owner:PHOENIX PRECISION TECH CORP

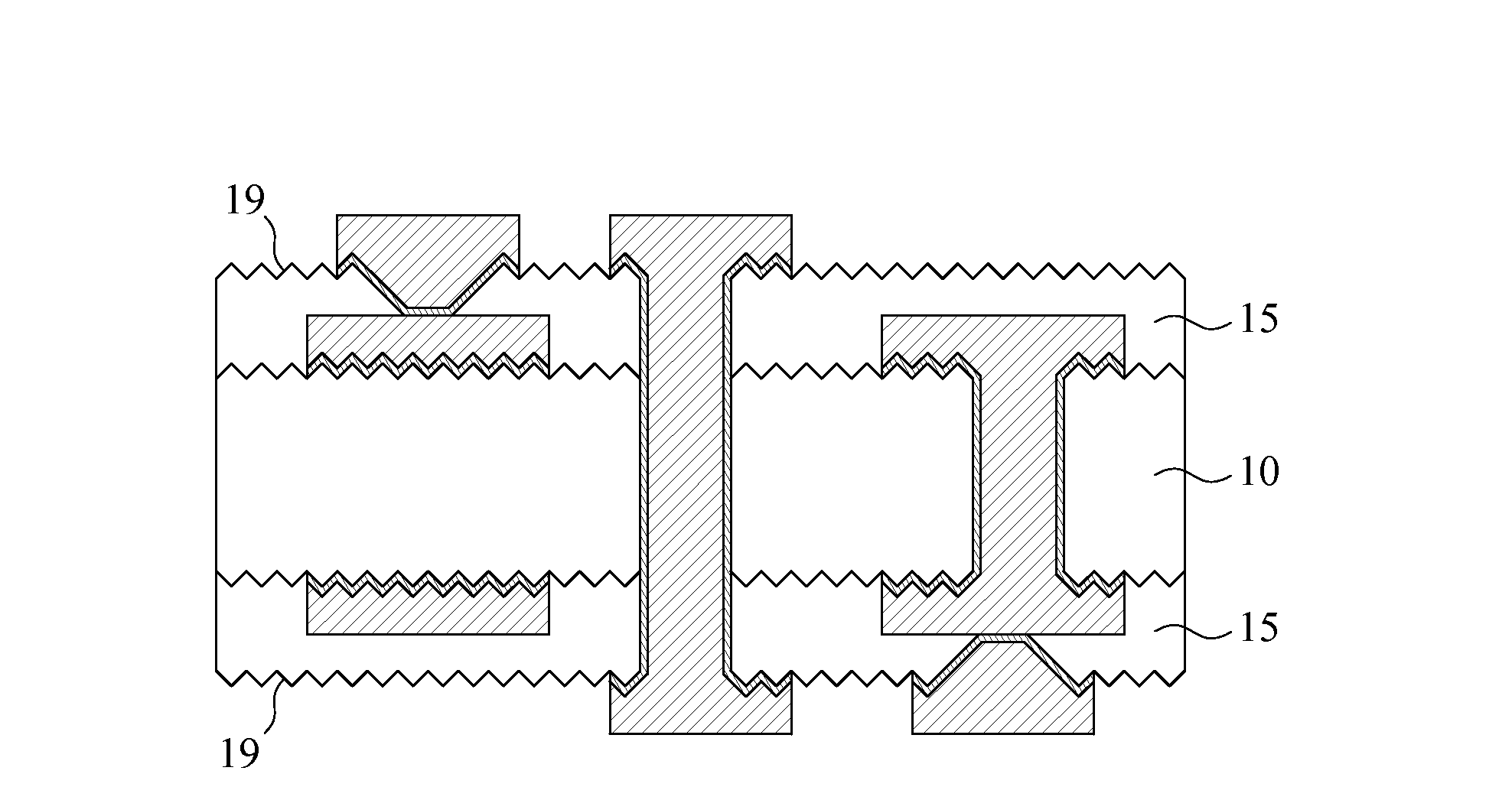

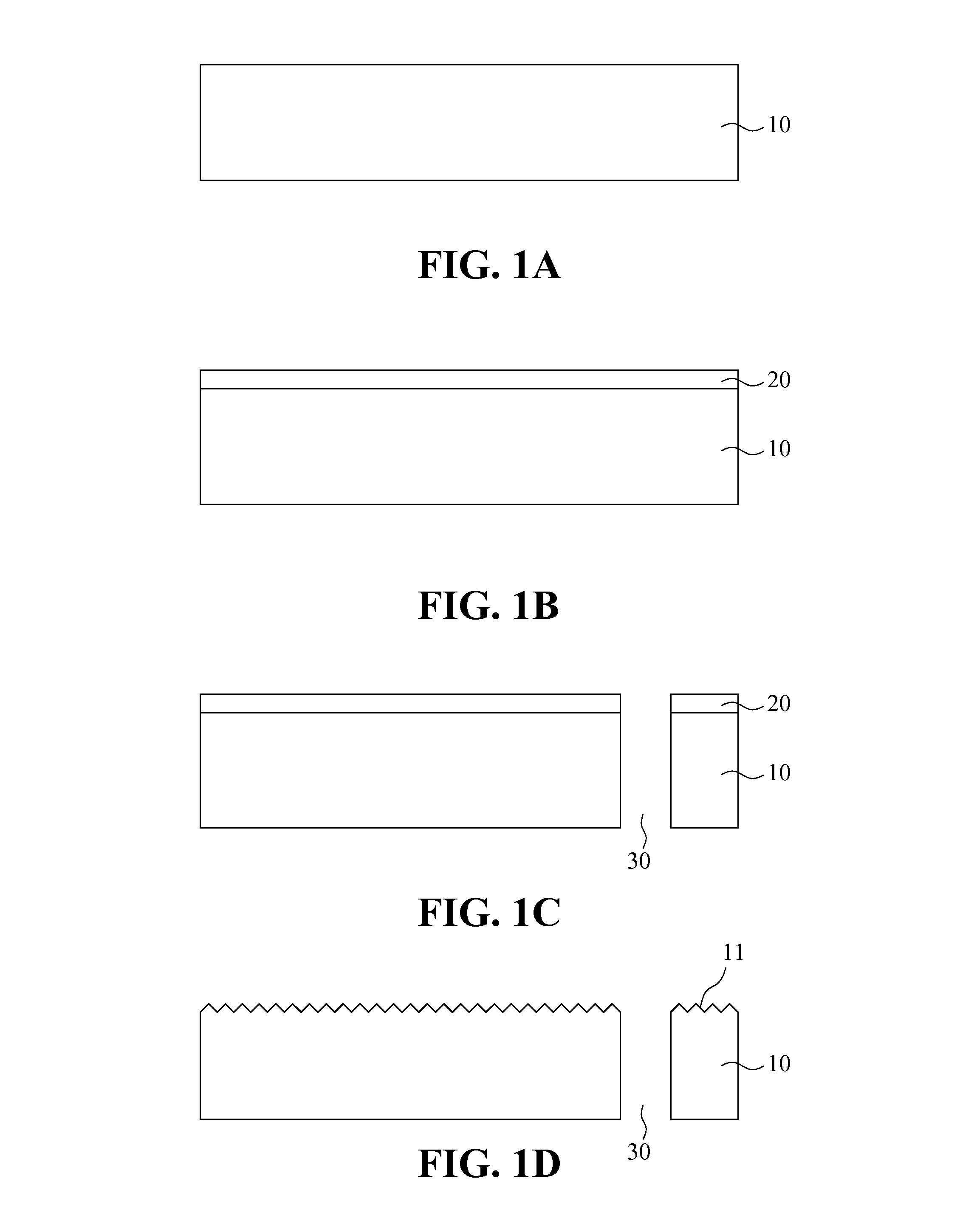

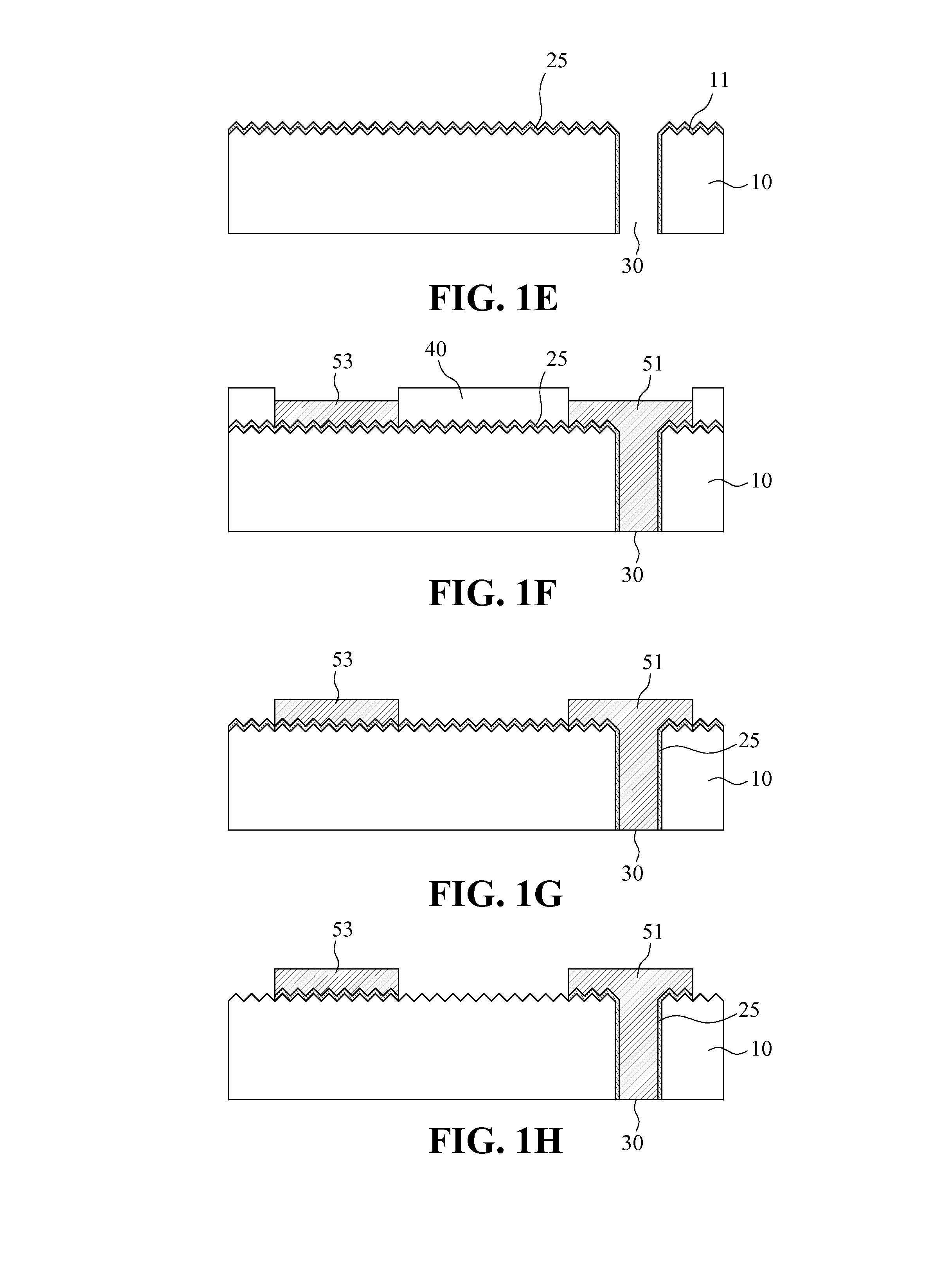

Method For Forming Package Substrate With Ultra-Thin Seed Layer

InactiveUS20130072012A1High yieldThin line widthPrinted circuit aspectsSemiconductor/solid-state device manufacturingRough surfaceLine width

A method for forming a package substrate with a seed layer is provided, which includes a step of etching away the metal foil laminated on the substrate, so that the substrate has a rough surface, and a step of forming an ultra-thin seed layer on the rough surface of the substrate, wherein the ultra-thin seed layer is formed along the rough surface of the substrate, and thereby the ultra-thin seed layer has a rough surface. Consequently, the adhesion between the metal bumps or circuits formed on the ultra-thin rough seed layer and the substrate can be increased. Furthermore, because the seed layer is ultra thin, the metal bumps or the circuit lines formed on the package substrate can be made finer in line widths and line pitches, and the good yield of the package substrate with fine circuit lines can be increased.

Owner:KINSUS INTERCONNECT TECH

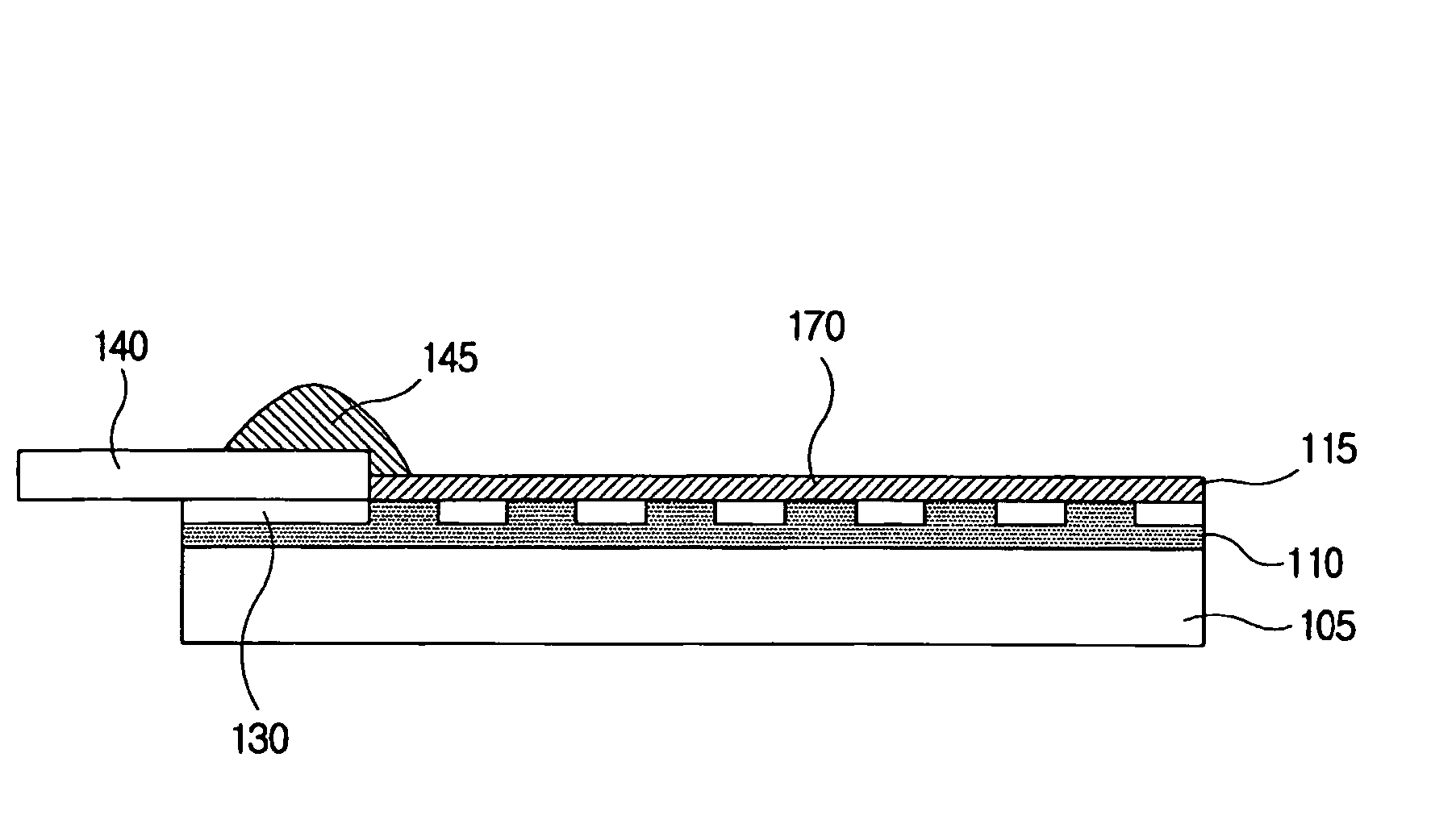

Electroconductive sheet and touch panel

ActiveUS9312048B2Increase awarenessThin line widthNon-insulated conductorsInput/output processes for data processingThin metalEngineering

An electroconductive sheet and a touch panel having a first electroconductive section and a second electroconductive section, the second electroconductive section being disposed on the display-panel side. The first electroconductive section has a plurality of first electroconductive patterns arranged in the x-direction, a plurality of first large grids being respectively connected to the first electroconductive patterns. The second electroconductive section has a plurality of second electroconductive patterns arranged in the y-direction, a plurality of second large grids being respectively connected to the second electroconductive patterns. The area occupied by thin metal wires in the second electroconductive patterns is larger than the area occupied by thin metal wires in the first electroconductive patterns. The area occupied by thin metal wires in the second large grids is larger than the area occupied by thin metal wires in the first large grids.

Owner:FUJIFILM CORP

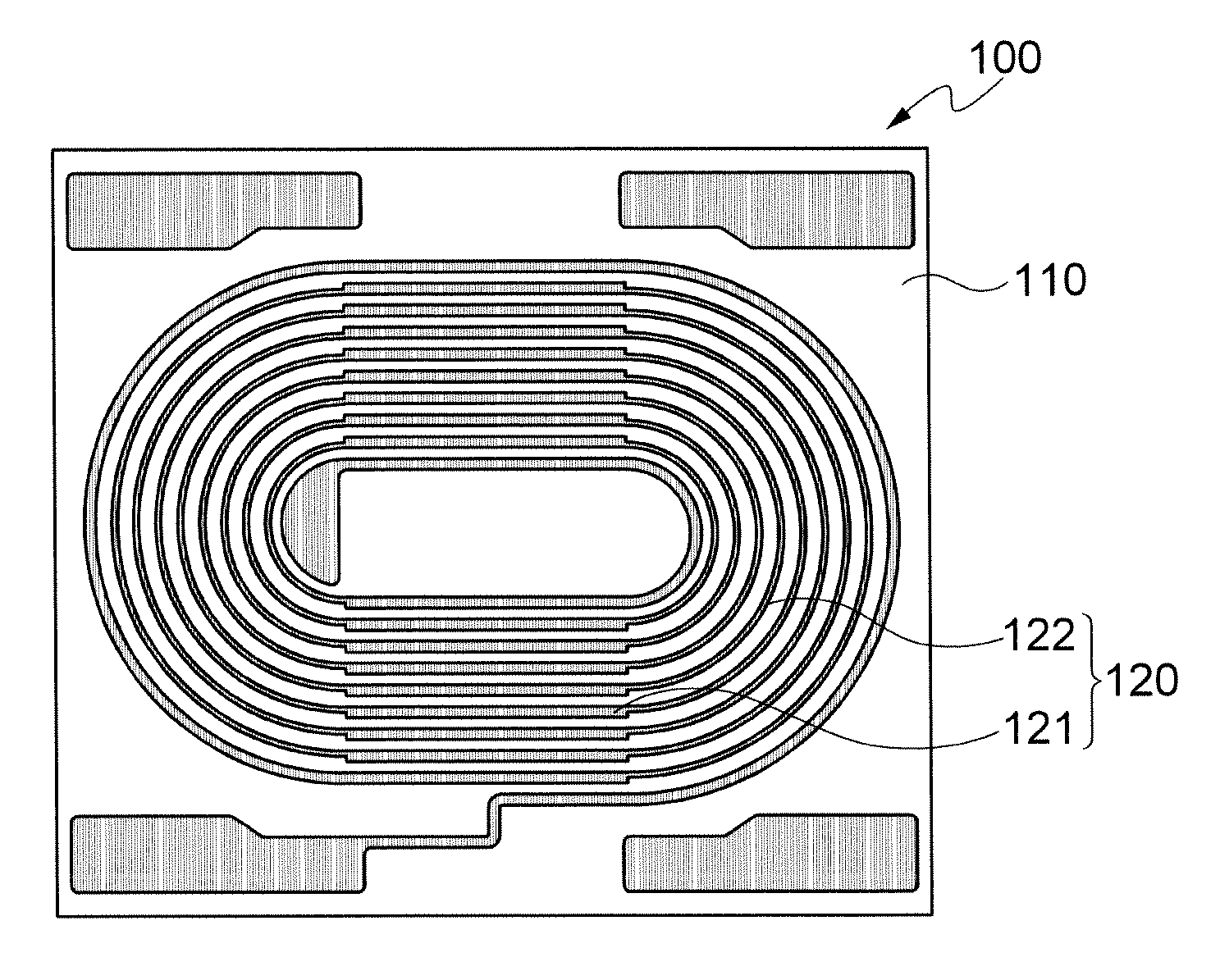

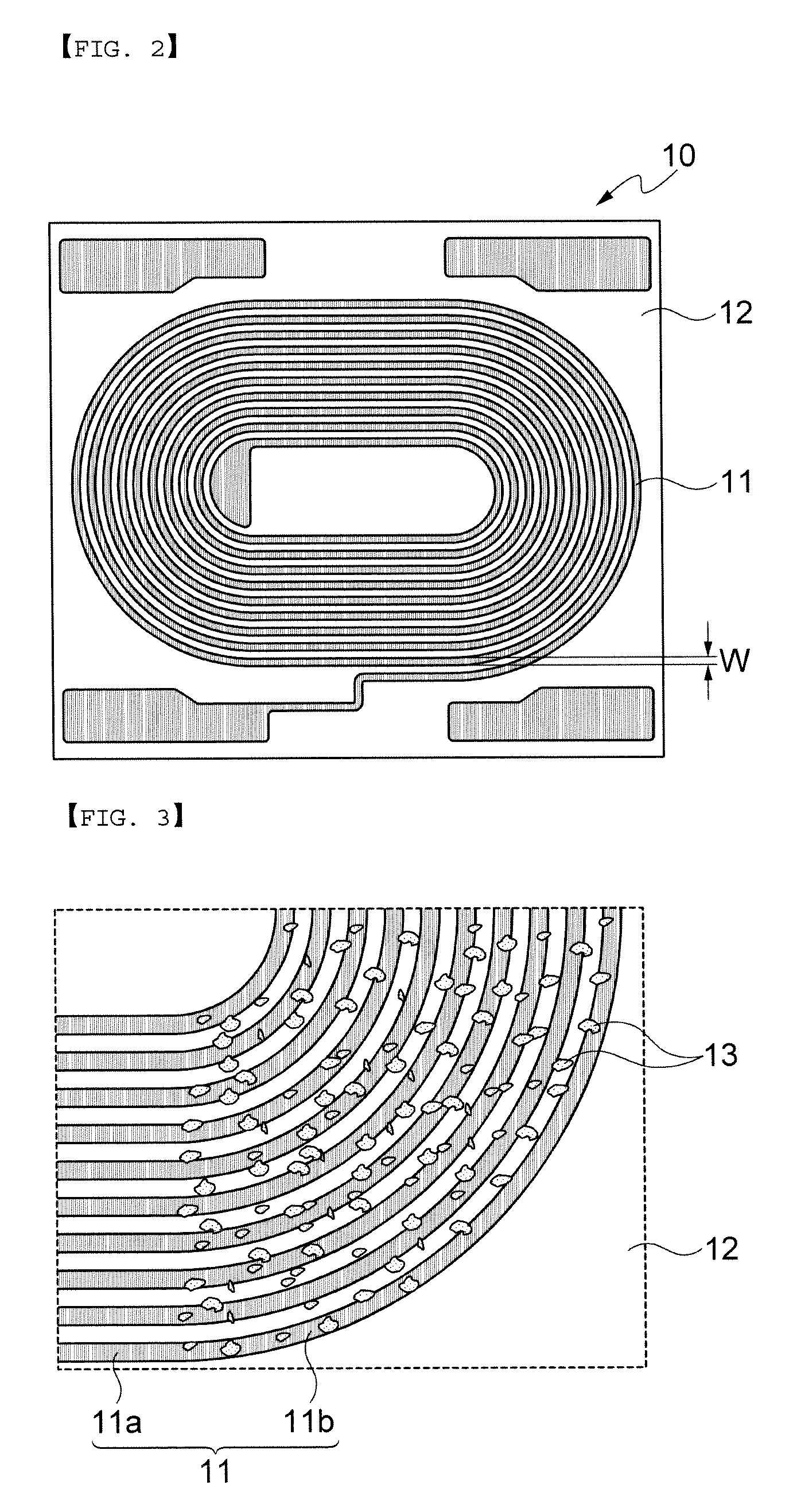

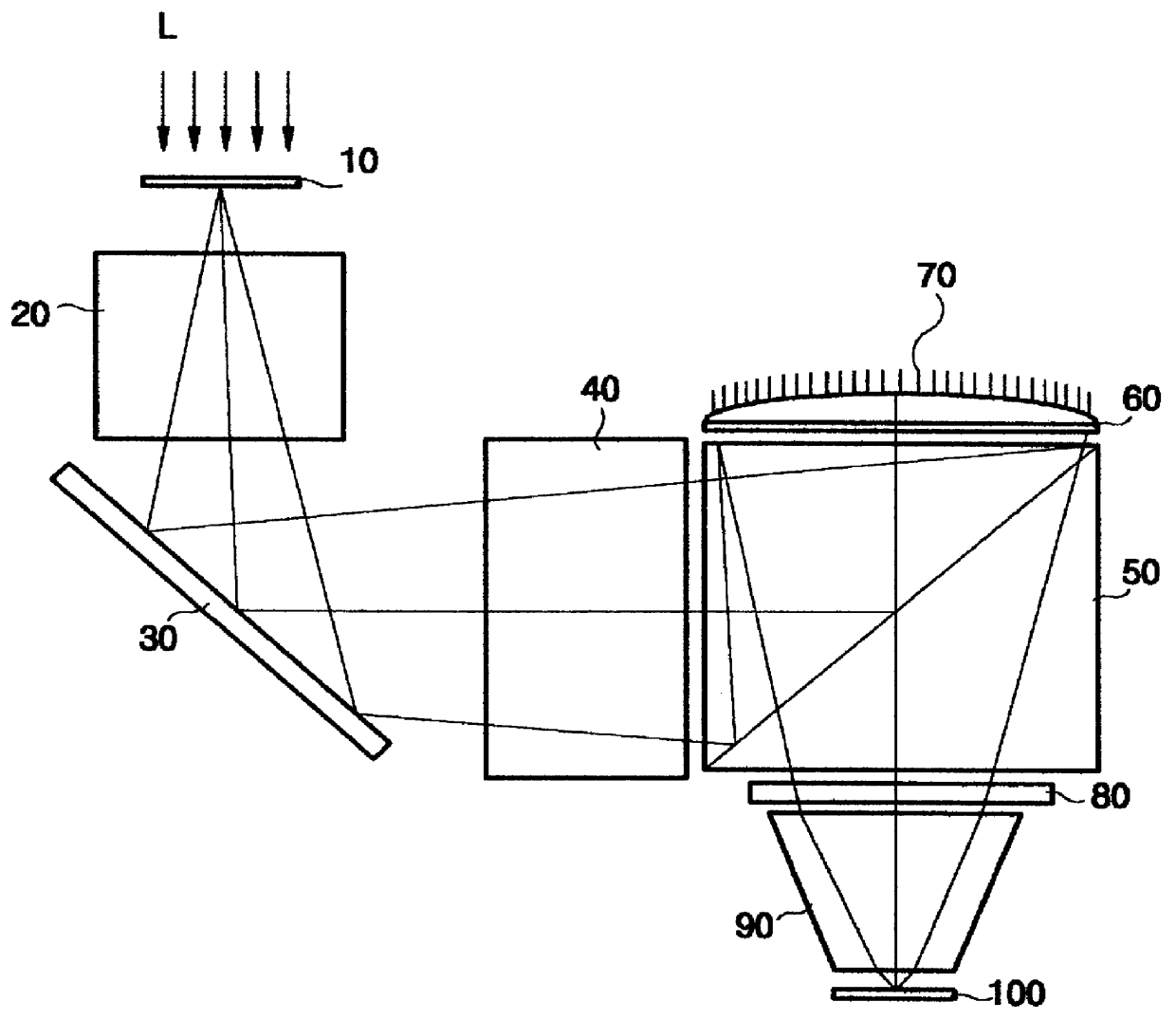

Conductor pattern and electronic component having the same

InactiveUS20130049917A1Improve connectivityHigh resolutionMultiple-port networksTransformers/inductances detailsFine lineElectrical conductor

Disclosed herein are a conductor pattern of an electronic component formed in an oval coil shape on a magnetic substrate, the conductor pattern including: a straight part; and a curved part connected to the straight part at both sides thereof, wherein a line width of the curved part is smaller than that of the straight part, and an electronic component including the same. With the conductor pattern and the electronic component including the same according to the present invention, the high precision fine line width and the high resolution conductor pattern may be implemented to improve connectivity, thereby improving characteristics and reliability of the electronic component.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

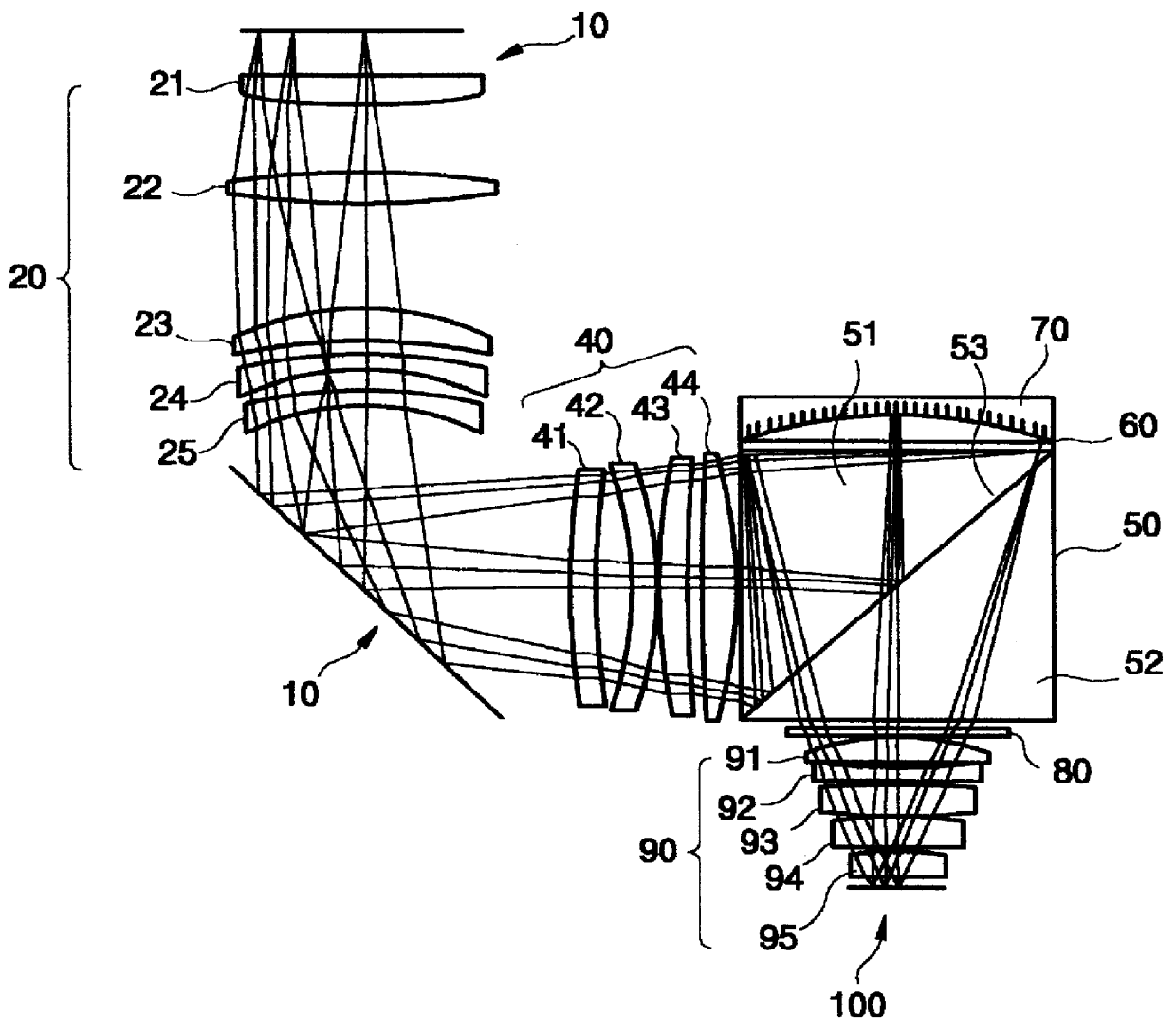

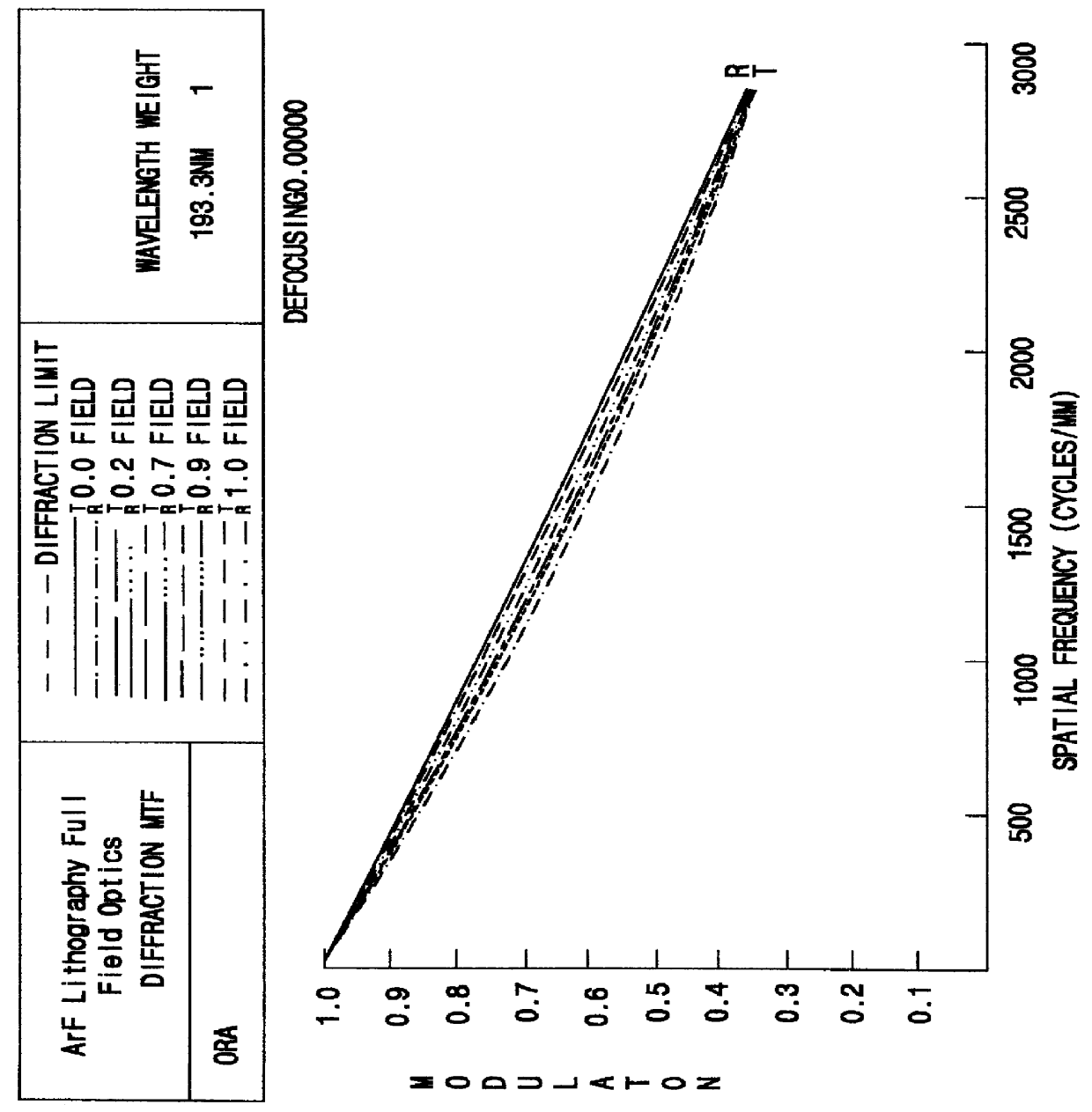

Catadioptric optical system for lithography

InactiveUS6101047AThin line widthPhotomechanical exposure apparatusMicrolithography exposure apparatusAstigmatismBroadband

Provided with an optical system which is applicable to an exposure apparatus used in the manufacture of semiconductors and includes a combination of a spherical mirror having a function of refraction and lenses for astigmation control, using a CaF2 lens as the last lens, thereby making it possible to use a light source operating at a short wavelength and a wide bandwidth, enhance the life of the optical system, and transfer the enlarge pattern of a mask onto the wafer for realizing fine line width.

Owner:ELECTRONICS & TELECOMM RES INST

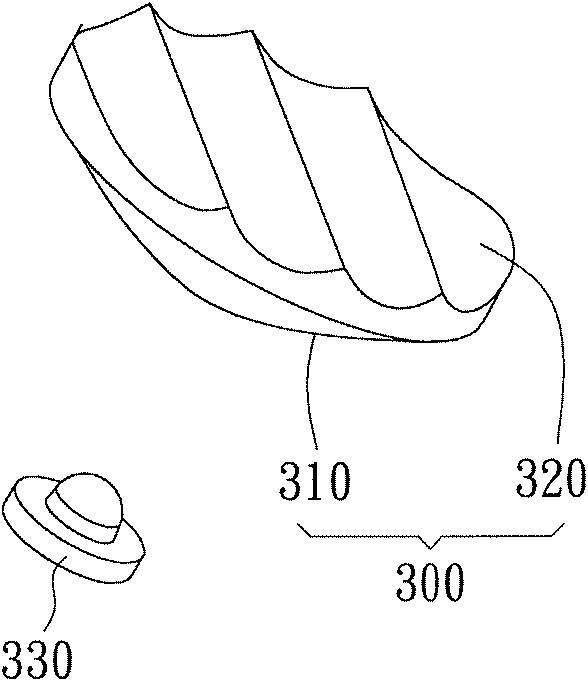

Light source module and optical lens thereof

The invention relates to a light source module and an optical lens of the light source module. The light source module comprises lighting bodies from a light source side to an object side in sequence and an optical lens, wherein the lighting bodies are used for generating light rays towards the direction of the object side; the optical lens is provided with a collimation plane, a first plane, a corrugated surface and a second plane which are sequenced from the light source side to the object side, so that the light rays generated by the lighting bodies enter the optical lens from the collimation plane and shoot out from the first plane, then enter the optical lens again through the corrugated surface, and finally shoot out from the second plane to form the collimated and linear illumination.

Owner:ASIA OPTICAL CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com