Production method of quantum well edge-emission semiconductor laser

A manufacturing method and quantum well technology, applied in the direction of semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., can solve the problems of laser active area becoming smaller and affecting laser output power, etc., to improve divergence angle and spot, and preparation process Simple, improve the effect of output spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

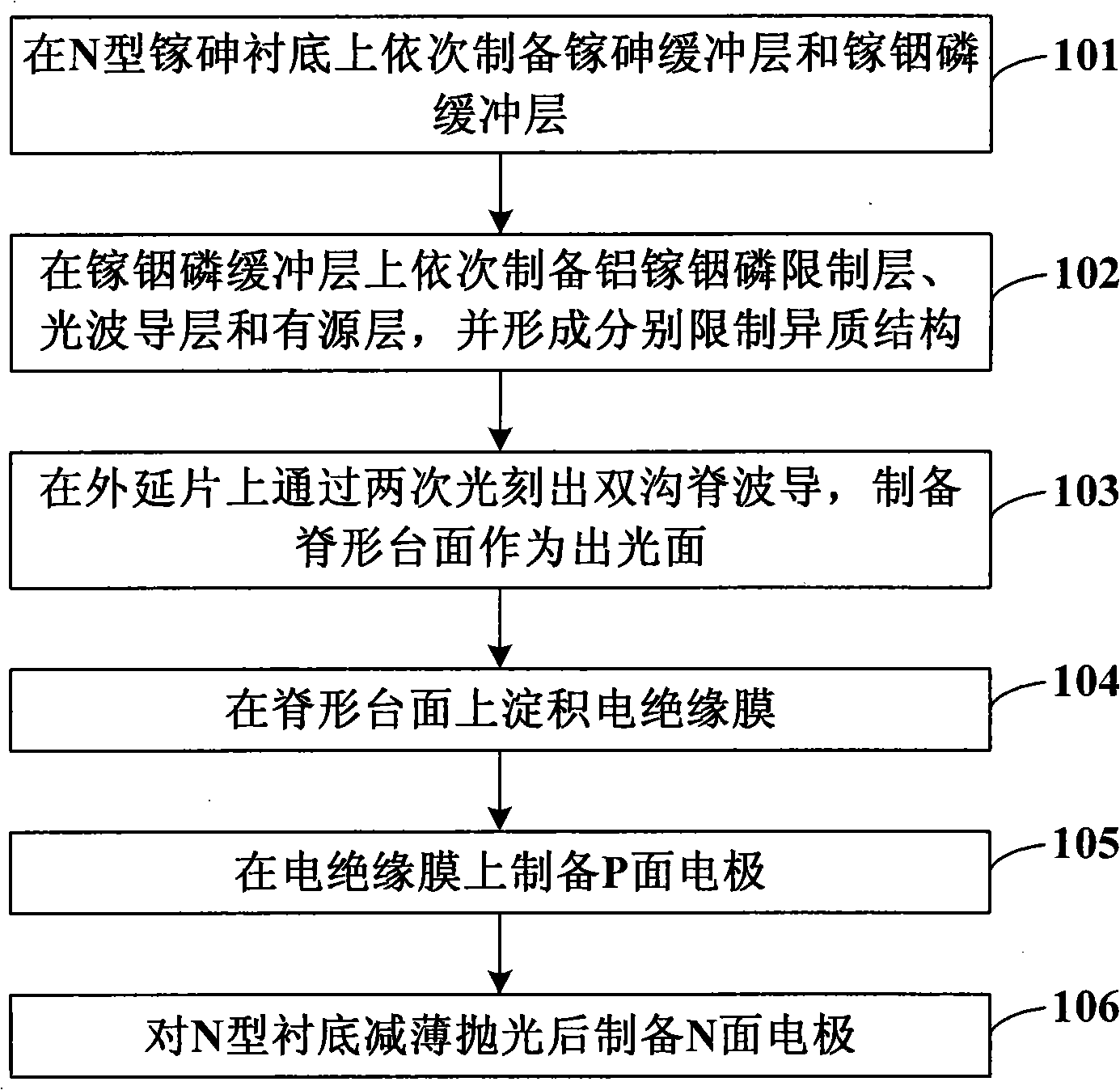

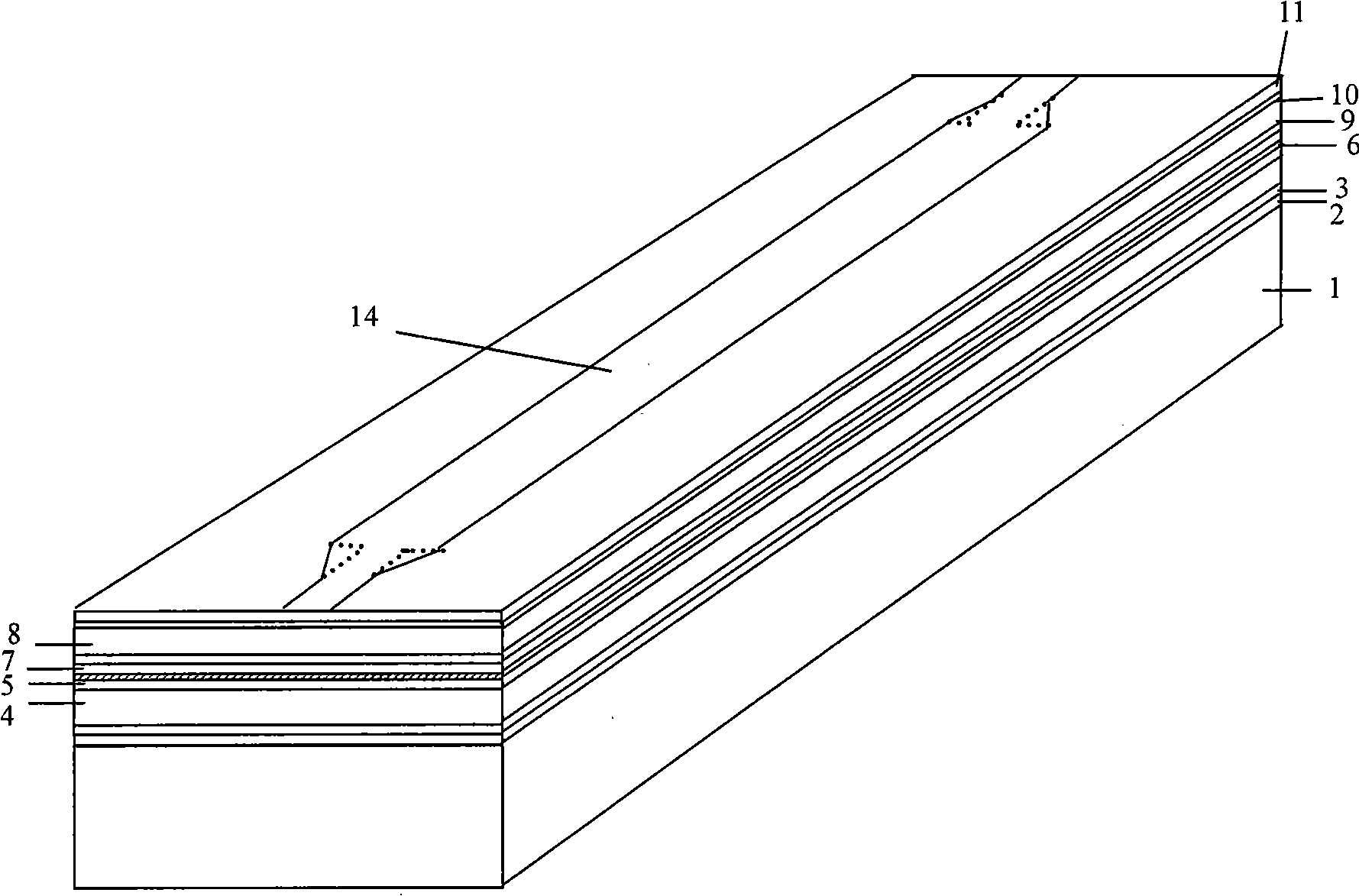

[0059] see Figure 2 to Figure 5 , the method for making quantum well edge-emitting semiconductor laser provided by the invention, the concrete structure of its device and preparation process comprise the following steps:

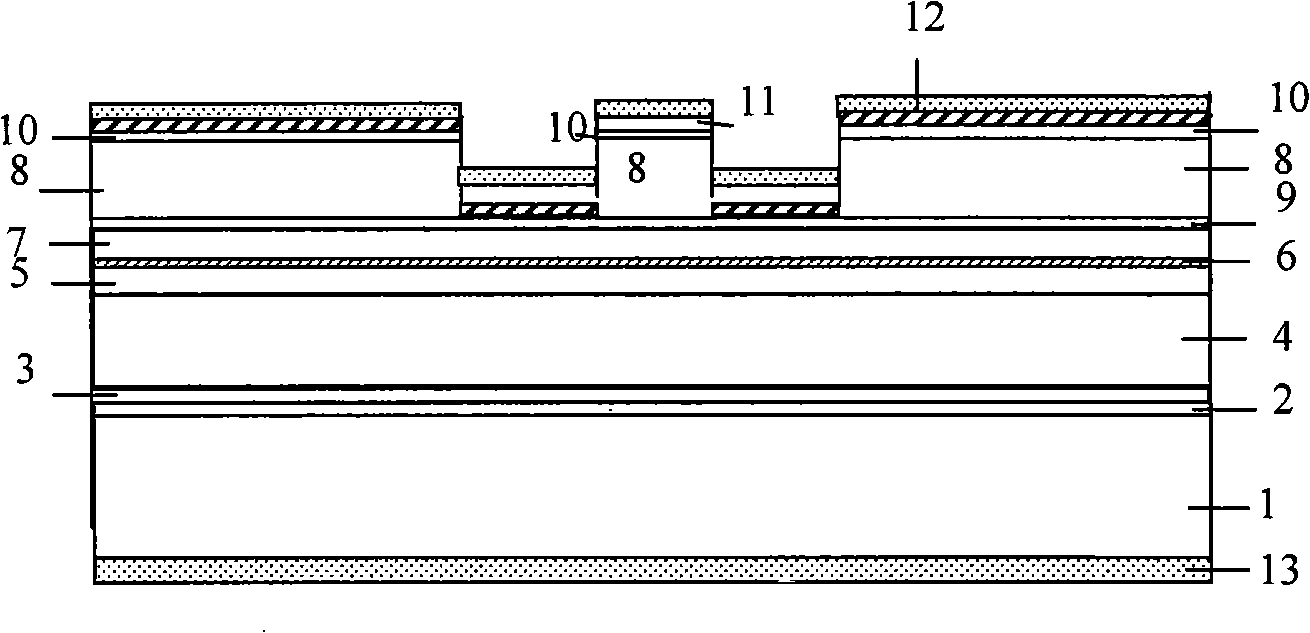

[0060] (1) Select an N-type GaAs substrate 1 at a temperature of 15 degrees, and epitaxially grow an N-type GaAs buffer layer 2 and an N-type GaInP buffer layer 3 on the N-type GaAs substrate 1 by metal-organic compound vapor deposition method.

[0061] (2) On the N-type GaInP buffer layer 3, epitaxially grow an N-type AlGaInP lower confinement layer 4 with a high aluminum composition, an AlGaInP lower optical waveguide layer 5 with a low aluminum composition, and an active region in sequence 6. Aluminum gallium indium phosphorus upper optical waveguide layer with low aluminum composition 7, P-type aluminum gallium indium phosphorus upper confinement layer with high aluminum composition 8, a thin layer of heavily doped gallium indium phosphorus corrosion st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com