Mute air-cooled generating set

A technology for generator sets and generators, applied in engine components, machines/engines, air cooling, etc., can solve the problems of poor cooling effect of engines and generators, limiting the upgrading of generator sets, and reducing the reliability of generator sets. The effect of reducing temperature and noise, unaffected output power, and stable reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

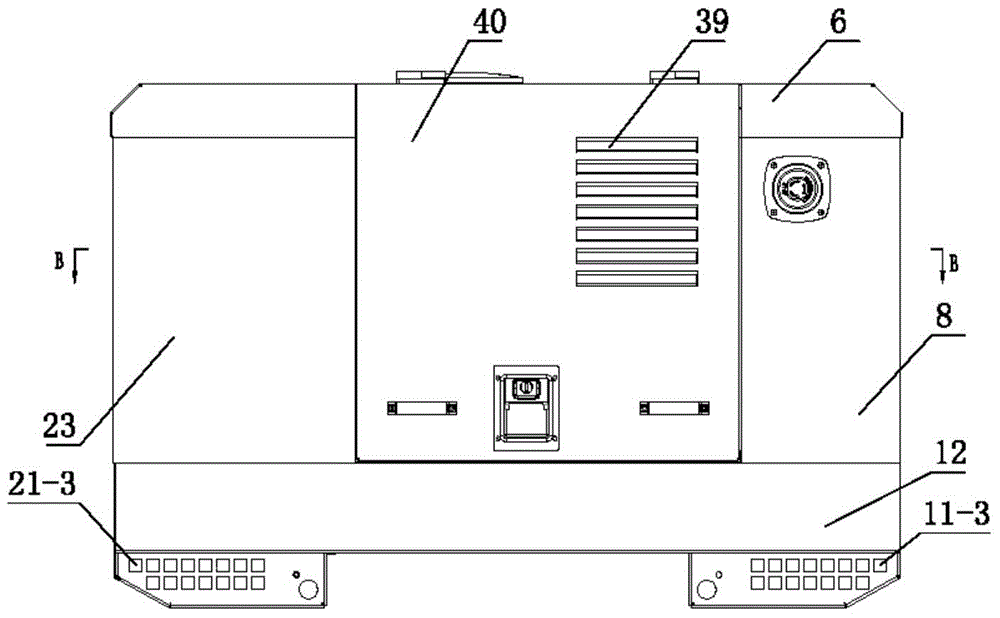

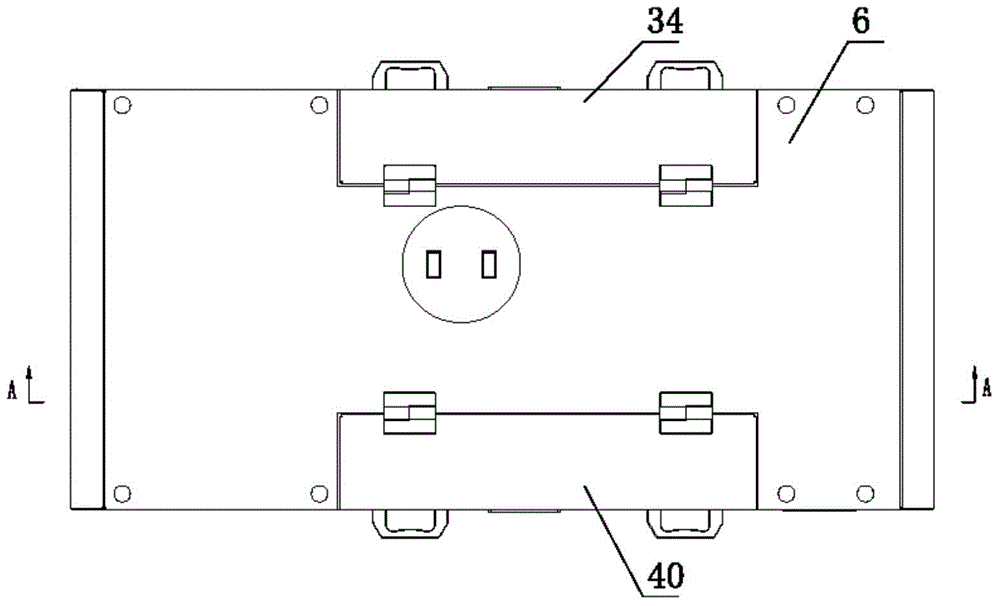

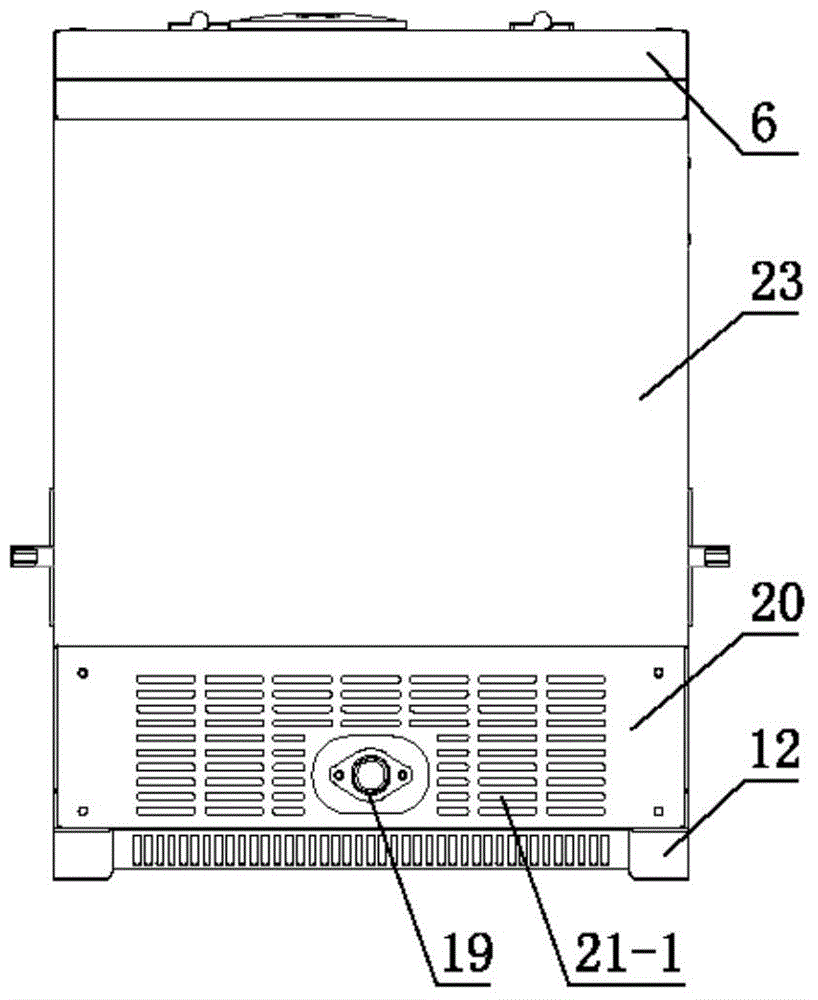

[0028] Such as Figure 1-9As shown, the soundproof box 3 of the present invention includes a top cover 6 , an engine side column 23 , a generator side column 8 , an engine exhaust valve 40 , a generator exhaust valve 34 , a panel 7 , and an air intake sealing plate 10 . The engine side column 23 is provided with an engine intake louver 31, and the engine exhaust valve 40 is provided with an engine exhaust passage louver 39; the chassis 12 is provided with a generator intake chamber air inlet 11 on the side close to the generator. -1, 11-2, 11-3; the chassis 12 is located at the lower part of the fuel tank 13 and is provided with a chassis air inlet 15; the chassis 12 is provided with an exhaust chamber peripheral exhaust port 21-2, 21-3; the exhaust heat shield 20 is provided with an exhaust port 21-1 around the exhaust chamber; the generator exhaust valve 34 is provided with a generator exhaust channel louver 37 .

[0029] The engine 1 and the generator 2 are coaxially conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com