Thermoelectric cooling systems

a technology of thermal insulation and cooling system, applied in the direction of refrigerating machines, machines using electric/magnetic effects, tubular elements, etc., can solve the problems of lowering the thermal resistance inside the heat pipe, and achieve the effect of high coefficient of performance and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Before describing the embodiments in detail, in accordance with the present invention, it should be observed that these embodiments reside primarily in the method and apparatus for cooling of fluids. Accordingly, the steps involved in the method and the system components have been represented to show only those specific details that are pertinent for understanding the embodiments of the present invention, and not the details that will be apparent to those with ordinary skill in the art.

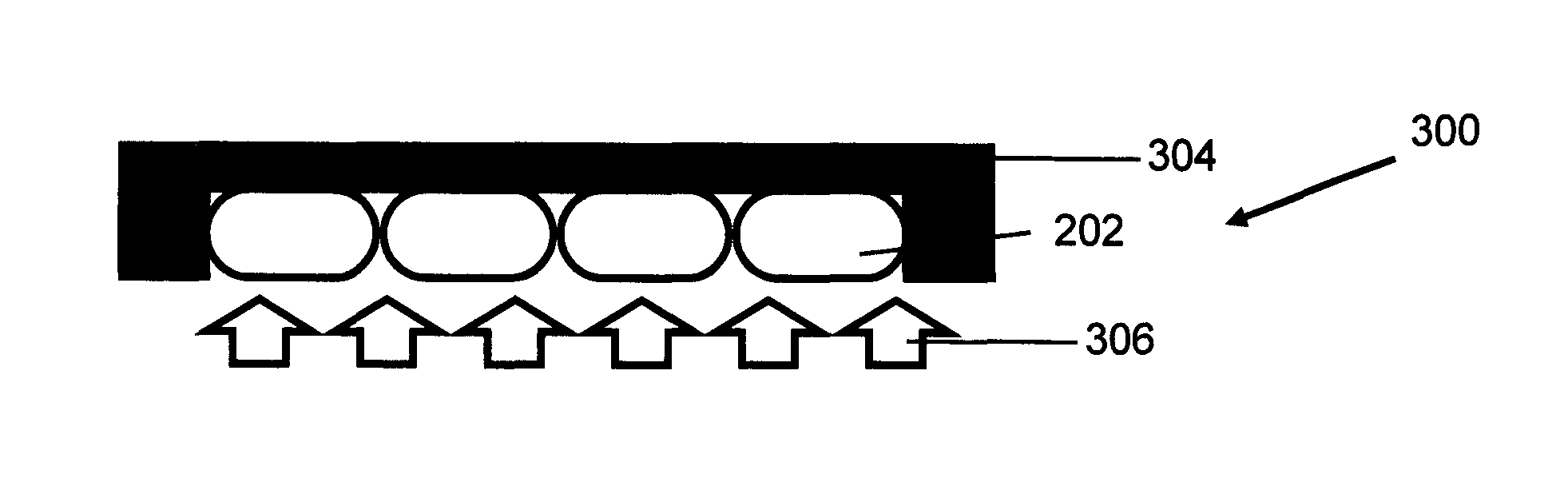

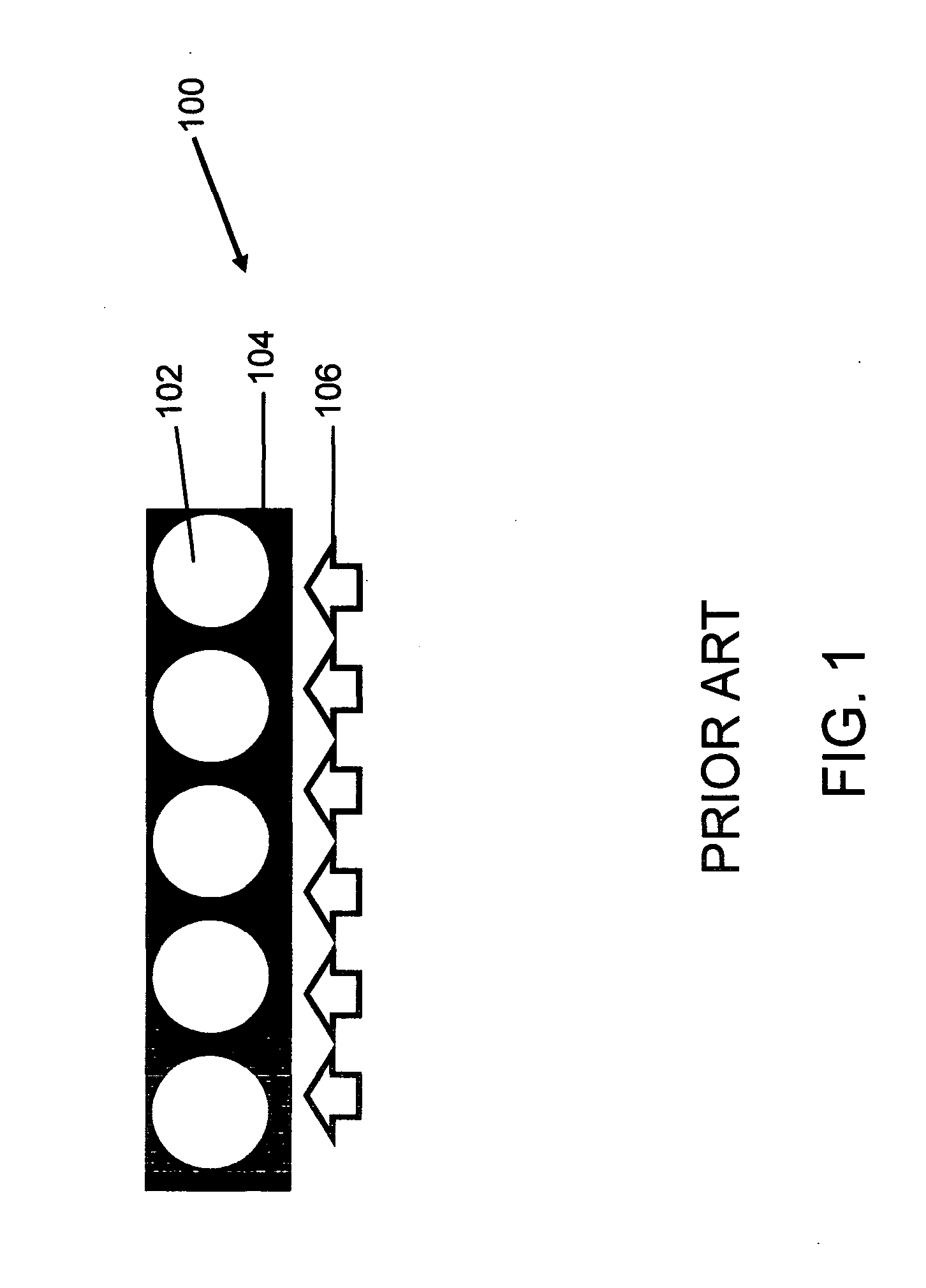

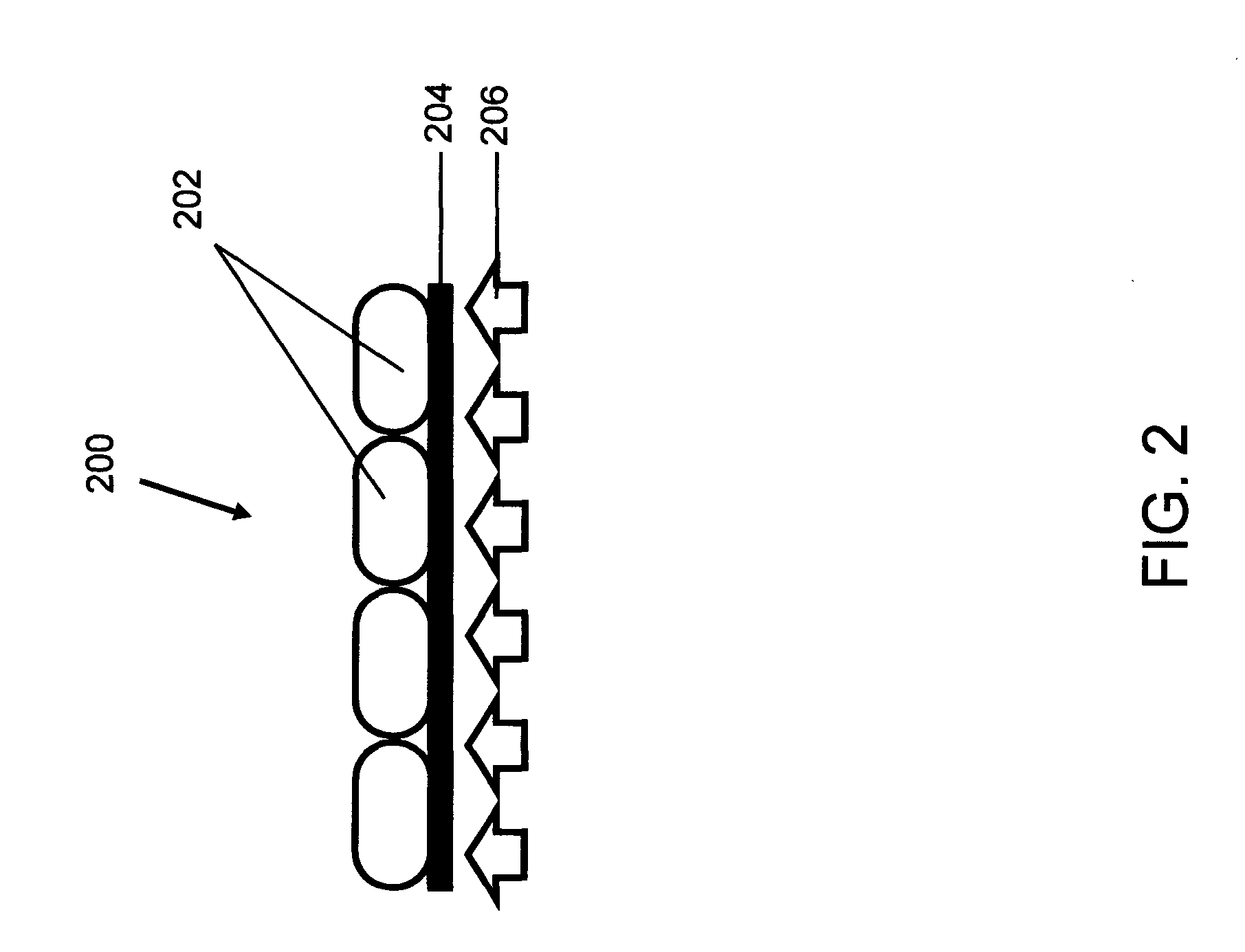

[0035]FIG. 1 illustrates a conventional assembly of heat pipes. FIGS. 2 to 4 illustrate heat pipes, in accordance with various embodiments of the present disclosure.

[0036]FIG. 1 is a schematic cross-sectional diagram of a conventional assembly of heat pipes 100.

[0037]The assembly of heat pipes 100 comprises heat pipes 102 having a circular cross sectional area embedded in a metal block 104. Metal block 104 comprises circular cavities in which heat pipes 102 are embedded. Preferably, heat pipes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com