Heat pipes and thermoelectric cooling devices

A technology for thermoelectric cooling and thermoelectric devices, used in refrigerators, indirect heat exchangers, refrigeration and liquefaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Before describing in detail the embodiments according to the present invention, it should be noted that these embodiments pertain primarily to thermoelectric cooling systems with heat pipes. Accordingly, system components have been described to show only those specific details suitable for understanding the embodiments of the invention and not to show details that are obvious to those skilled in the art.

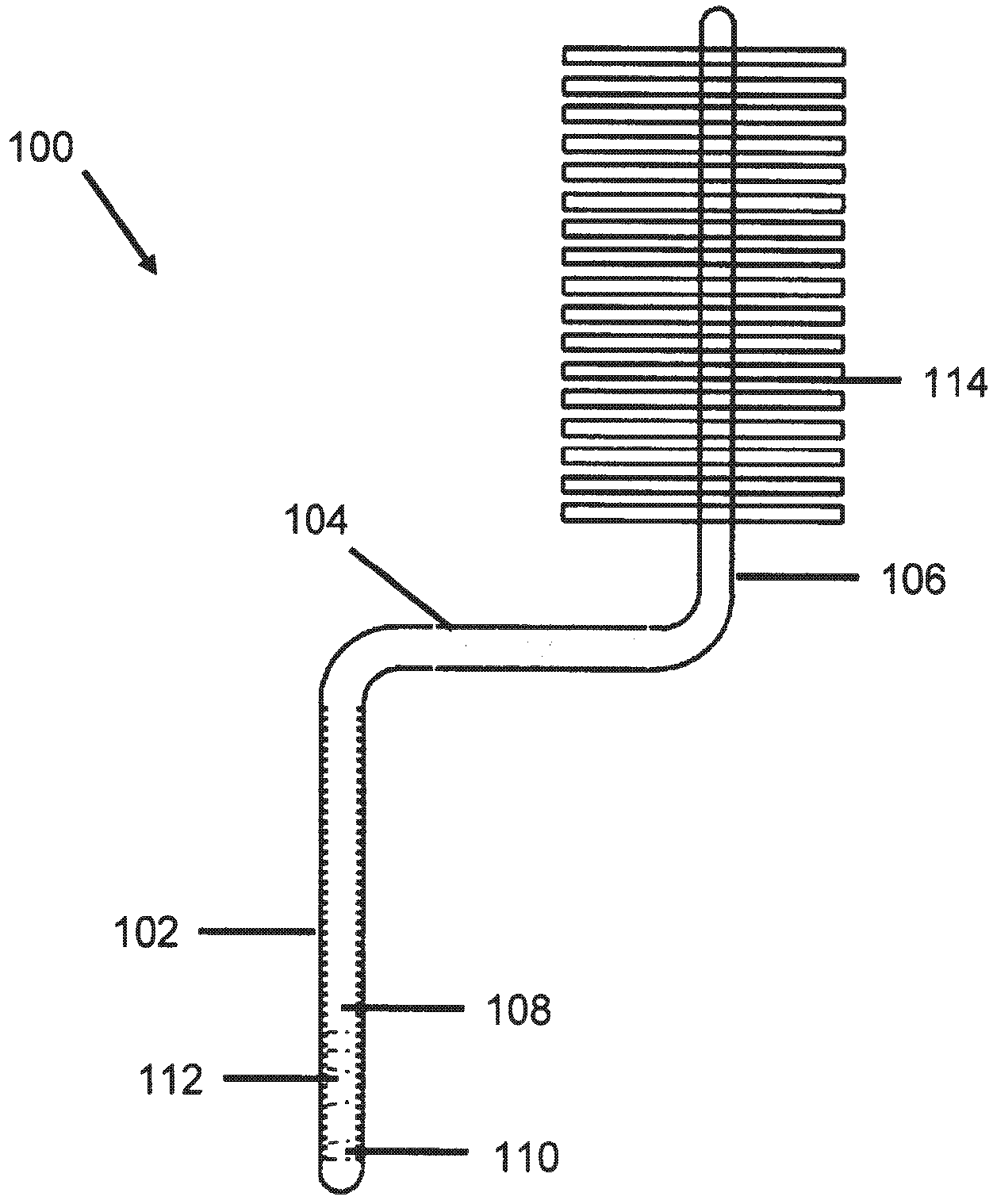

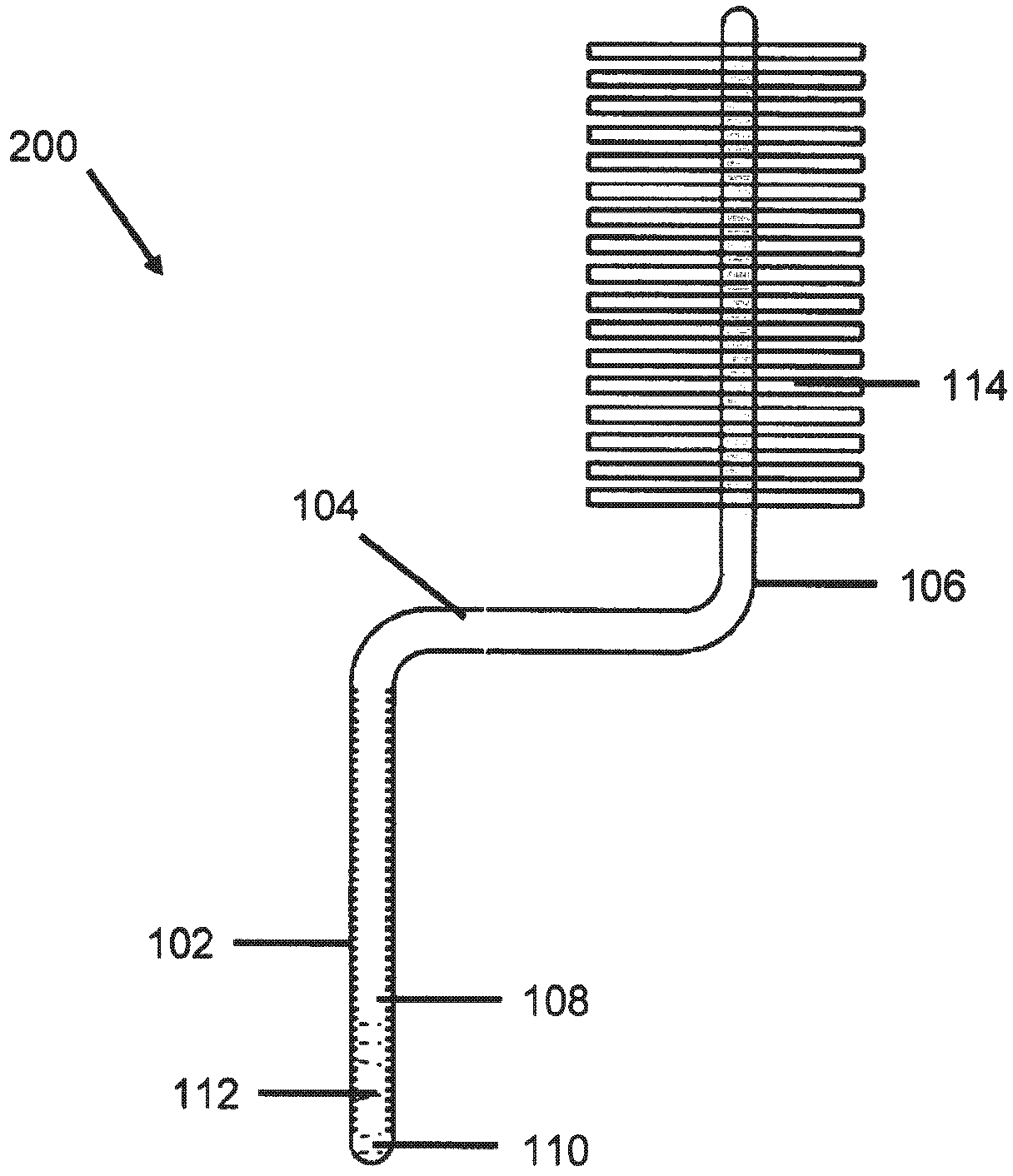

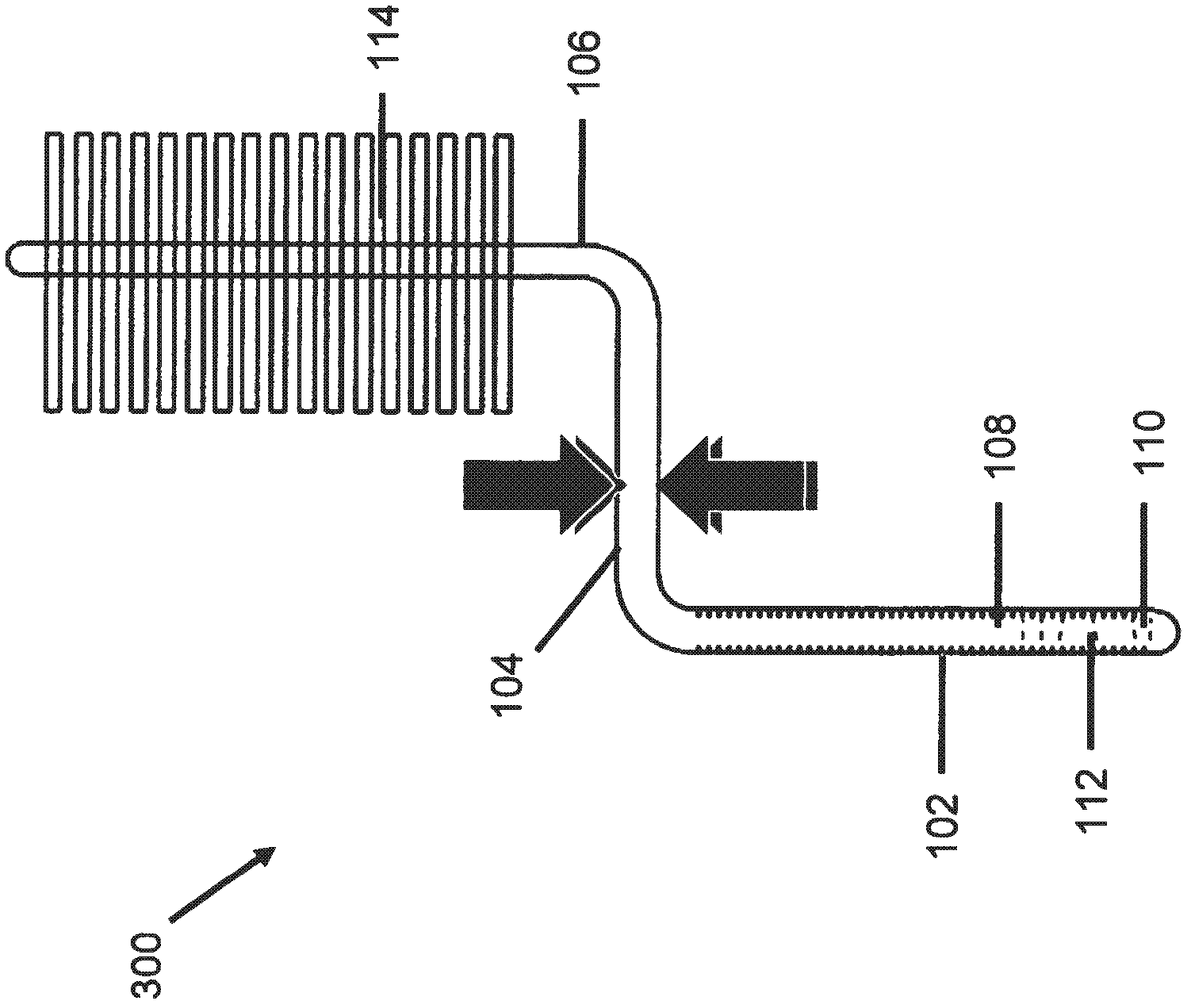

[0031] figure 1 A cross-sectional view of a heat pipe 100 according to an embodiment of the present invention is shown.

[0032] The heat pipe 100 includes three sections—an evaporating section 102 , an adiabatic section 104 , and a condensing section 106 . The evaporation section 102 includes a chamber 108 and a fluid reservoir 110 containing a working fluid 112 . In an embodiment of the present invention, the evaporation portion 102 is a sintered surface, a grooved surface, or a mesh surface to enhance evaporation.

[0033] The working fluid 112 is selected based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com