Highly effective flat-type loop heat-pipe apparatus

A loop heat pipe, flat-plate technology, used in cooling/ventilation/heating transformation, instrument cooling, instrumentation, etc., can solve the problems of high operating temperature of loop heat pipe, high partial pressure of evaporator, and low maximum heat transfer, etc. Enhanced heat transfer capability, reduced heat leakage, and better performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

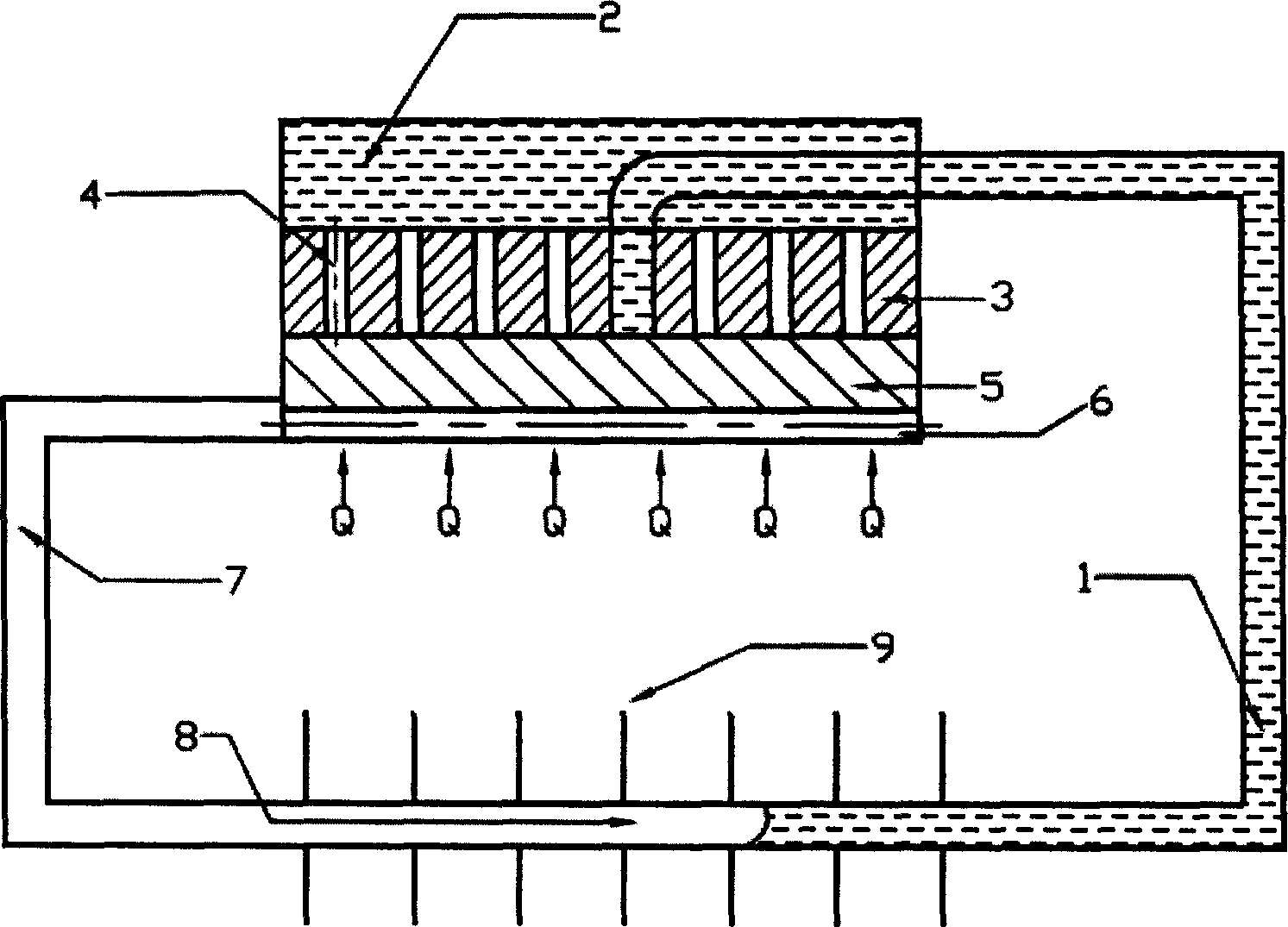

[0017] Embodiment 1 Use a high-efficiency loop heat pipe device to dissipate heat from a computer CPU

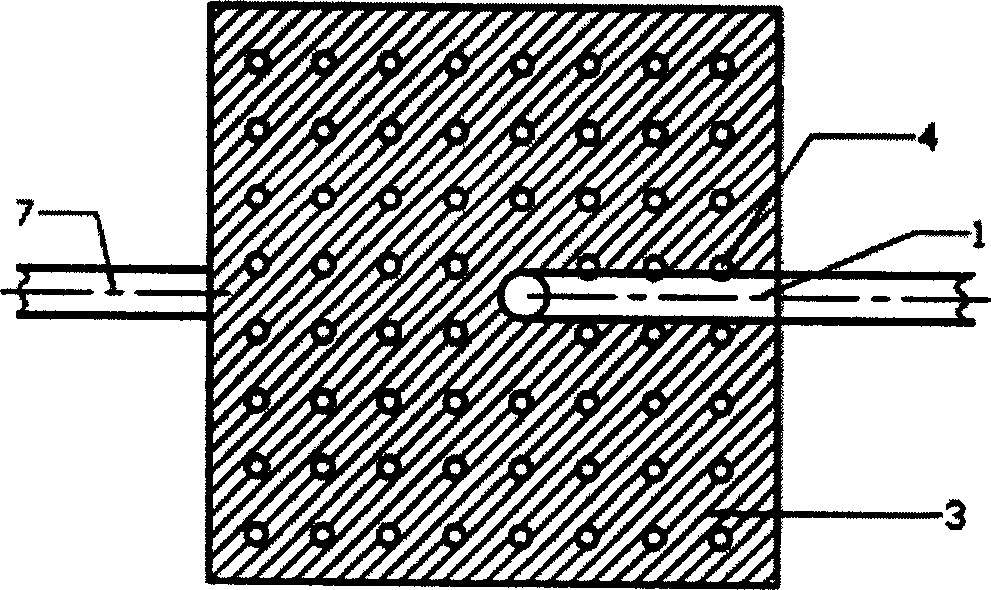

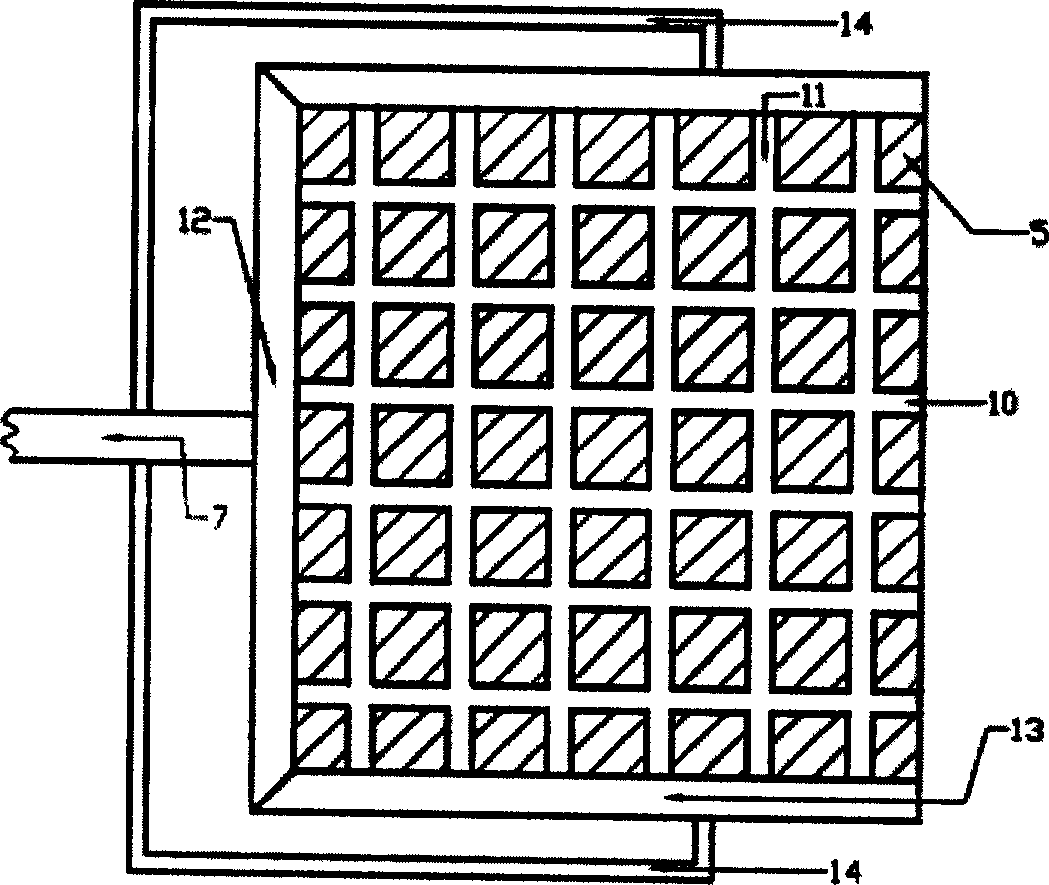

[0018] figure 1 Among them, the evaporator and the compensation chamber 2 are in one-piece structure. The bottom of the evaporator is in contact with the heat load end Q, that is, the CPU of the computer. Both the first liquid-absorbing core 5 and the second liquid-absorbing core 3 are located inside the evaporator, wherein the first liquid-absorbing core is close to the bottom of the evaporator, and the second liquid-absorbing core Then it is close to the first liquid-absorbent core. On the other side of the second liquid-absorbing core, there is a certain space inside the evaporator, which is the compensation chamber 2 . The liquid return pipe 1 ends at the second liquid-absorbent core 3 through the compensation chamber 2, and this pipe is mainly connected to the condensation section so that the liquid can return to the first liquid-absorbent core. There are many steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com