Novel LNG (Liquefied Natural Gas) vehicle-mounted gas bottle liner support structure

A technology for supporting structure and vehicle-mounted gas cylinder, which is applied in gas/liquid distribution and storage, container discharge method, container filling method, etc., can solve the problems of large heat leakage of support pipe, complex device structure, and large number of welding seams, etc. Achieve the effect of reducing heat leakage, low thermal conductivity, and reducing the number of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

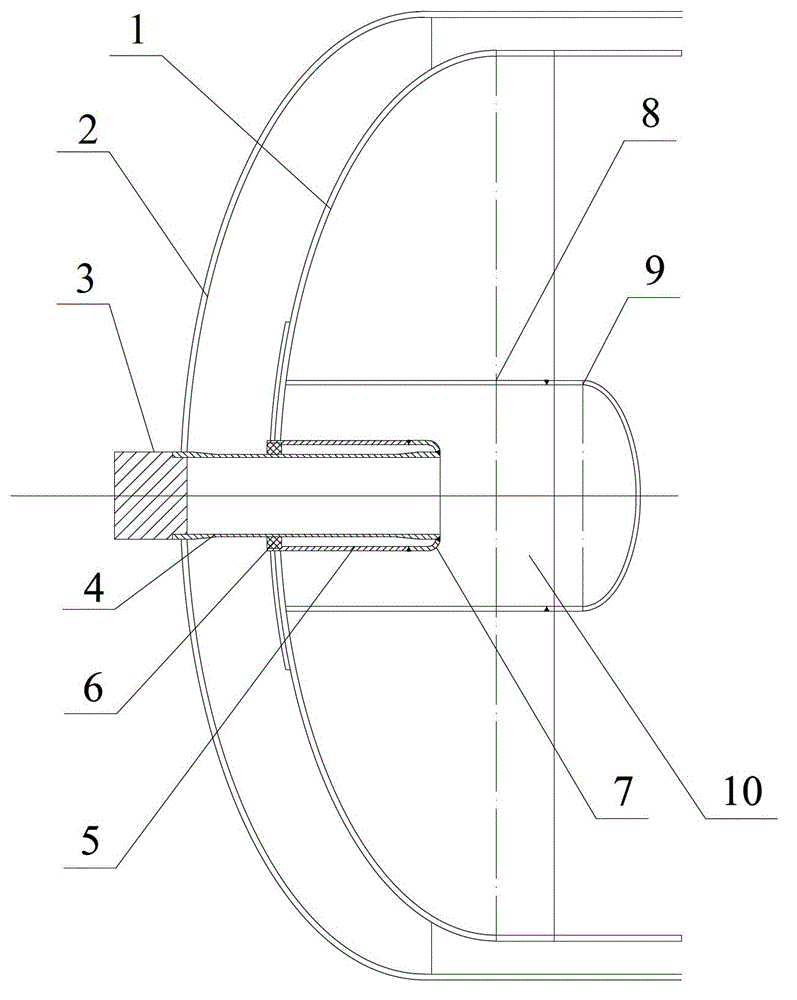

[0015] refer to figure 1 , the support structure is mainly composed of inner tank head 1, shell head 2, header 3, support neck 4, extension pipe 5 and glass steel ring 6, one end of header 3 is fixedly installed on the top of shell head 2, and the other One end is exposed outside the shell, one end of the extension tube 5 is fixedly connected with the inner tank head 1, and the other end extends into the inner tank, and the end of the extension tube 5 extending into the inner tank part is connected with a first cap 7 to support one end of the neck tube 4 It is connected with the header 3, and the other end extends into the bottom of the extension tube 5 and is welded with the first cap 7. The support neck tube 4 and the extension tube 5 are supported by the glass fiber reinforced plastic ring 6 arranged on the inner tank head 1, extending There is a reinforcing tube 8 on the outside of the tube 5, one end of the reinforcing tube 8 is fixedly connected to the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com