Vacuum heat insulating low-temperature pipe joint

A technology of vacuum heat insulation and cryogenic pipes, which is applied in the direction of pipes/pipe joints/fittings, non-detachable pipe connections, and pipes protected by heat insulation, etc. It can solve the problems of large heat leakage, high cost, and difficult operation at the joints. Achieve low heat leakage, easy installation, simple and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

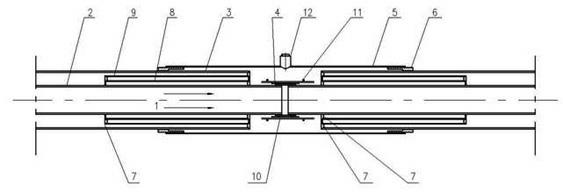

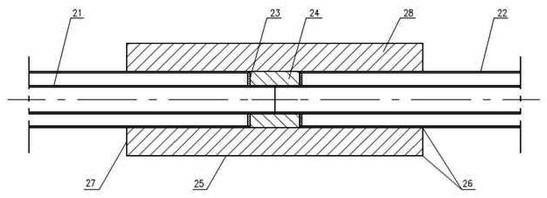

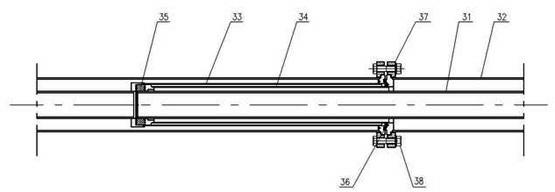

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: image 3 As shown, the present invention includes an inner tube 2 for cryogenic liquid 1 to pass through, and two outer tubes 3 that are sleeved outside the inner tube 2 and connected together, and a vacuum space is formed between the inner and outer tubes; The joints of the two inner tubes 2 are welded together by a sleeve 4; the two outer tubes 3 are sleeved with a thermal insulation tube 5 at the joint, and two ends of the thermal insulation tube 5 are respectively provided with a 3 Welding ring 6 for outer wall welding.

[0016] image 3 Between the ends of the joints of the two outer pipes 3 shown and the walls of the inner pipe 2 are respectively provided with a section of inner heat-insulating pipe 8 and an outer heat-insulating pipe 9 that are nested with each other and extend to the two outer sides through the flange ring 7 to form the inner pipe 2 and the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com