Flow control valve of large-sized low temperature device

A low-temperature device and flow control technology, applied in valve devices, lift valves, valve details, etc., can solve the problems of lack of liquid helium in low-temperature devices, large valve heat leakage, waste of helium, etc., and reduce radiation heat transfer. and radial heat conduction, solve heat leakage and leakage, reduce the effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

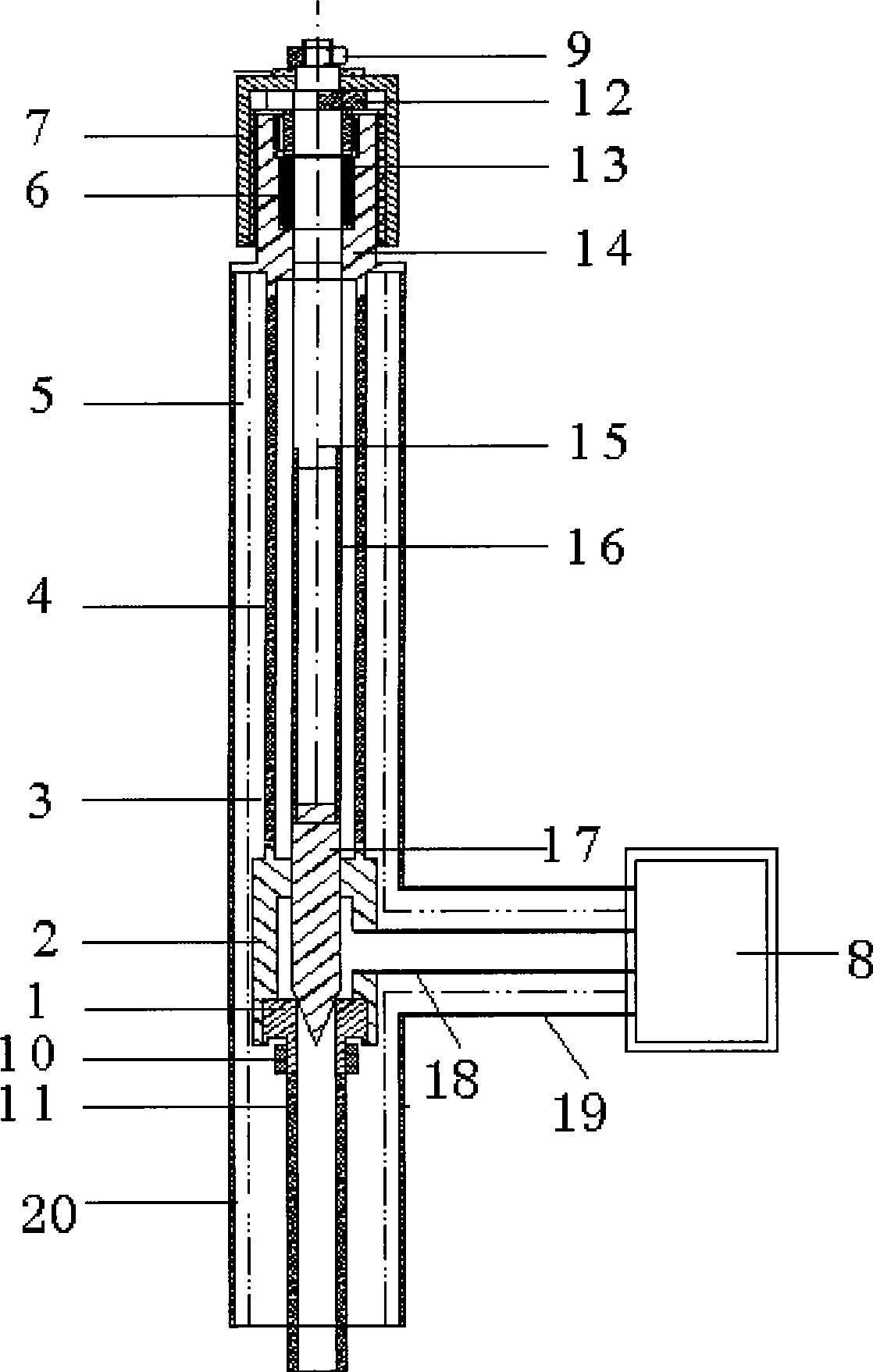

[0015] A flow control valve for a large cryogenic device, including a valve seat 1, a valve core 17 and a valve body 2, and a vacuum valve sleeve outer tube 5, the upper ends of the vacuum valve sleeve outer tube 5 and the vacuum valve sleeve inner tube 4 are connected with a valve cover 14. There is a stepped hole in the middle of the bonnet 14, and a valve stem 15 is slidingly fitted in the stepped hole, and there is a Teflon material between the outer wall of the valve stem 15 and the wall of the stepped hole of the bonnet 14. The sealing ring 6, the sealing ring 6 is located in the sealing groove 13 on the step hole, the upper end of the step hole has an internal thread, the sealing ring pre-tightening bolt 12 with a middle opening is set outside the valve stem 15, the sealing ring pre-tightening bolt 12 Screwed with the internal thread on the stepped hole, the sealing ring pre-tightening bolt 12 is pressed on the sealing ring 6; the upper end of the valve stem 15 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com