High-power flat evaporator resistant to positive pressure, processing method of flat evaporator and flat-plate loop heat pipe based on evaporator

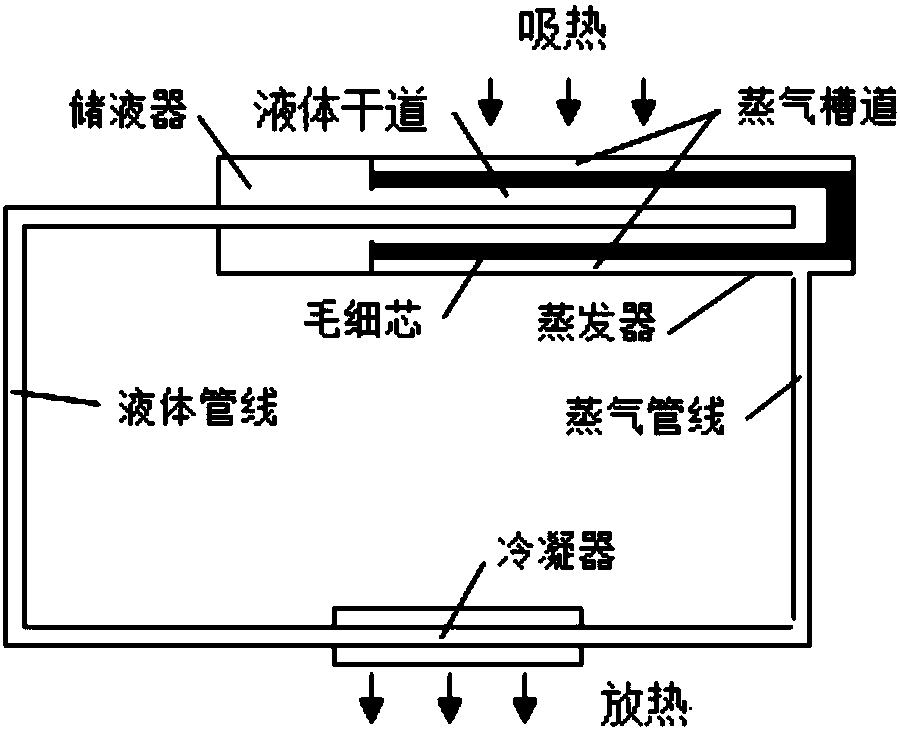

A flat-plate loop, high-power technology, used in lighting and heating equipment, indirect heat exchangers, etc., to achieve the effect of improving heat transfer capacity, good permeability, and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a high-power flat-plate loop heat pipe evaporator with a positive-pressure-resistant structure, which uses a composite capillary structure to improve heat transfer capacity, solves the problem of compressive strength when the evaporator uses positive-pressure working fluid, and can be used in Improve heat transfer capability without increasing thickness.

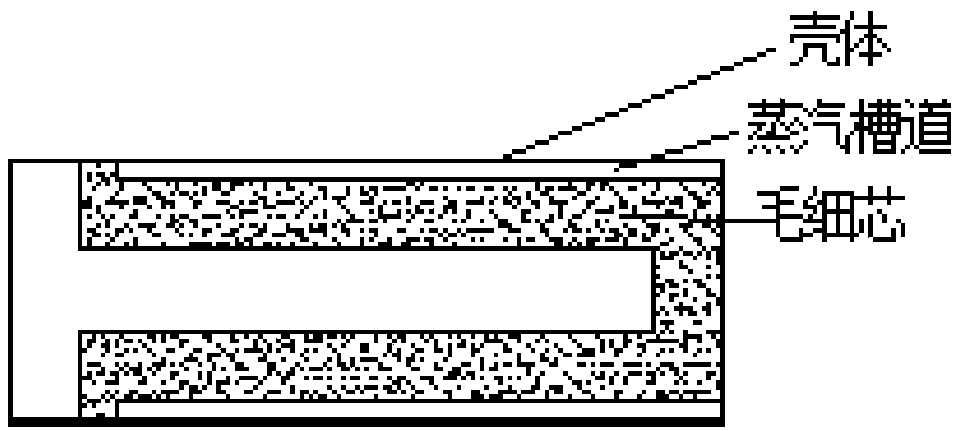

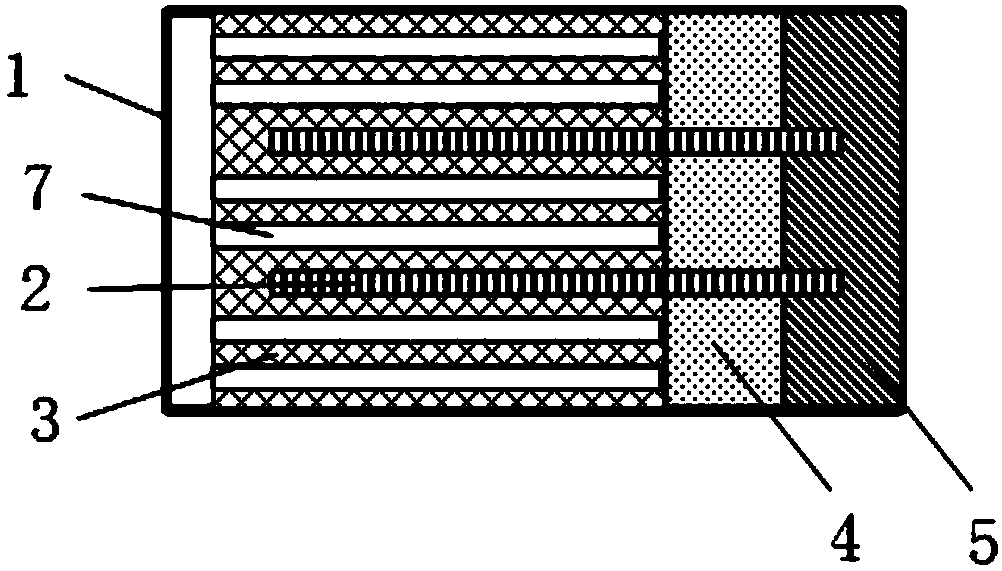

[0053] The structure of the evaporator is as image 3 As shown, it includes: a housing 1 and a capillary core disposed inside the housing 1 .

[0054] The structure of the housing 1 takes into account both the strength required for positive pressure resistance and the uniform liquid supply function. The housing 1 is a rectangular structure with openings at both ends and reinforcing ribs 2 inside. Specifically, two reinforcing ribs 2 are arranged in parallel along the height direction inside the housing 1 , and the width of the reinforcing ribs 2 is consistent with the width of the housing 1 ....

Embodiment 2

[0060] This embodiment provides a processing method for a high-power flat-plate loop heat pipe evaporator with a positive-pressure-resistant structure. The transmission core 6 in the evaporator is made of metal sintered felt or wire mesh.

[0061] Raw materials include shell, wire mesh or sintered felt, powder required for heat insulation core, powder required for evaporation core, powder required for sealing core, limit tooling, steam channel tooling.

[0062] (1) Vertically place the steam channel tooling (wire) on the boss on the upper surface of the limiting tooling, and then install the shell (the rib and the shell as an integrated structure) on the boss on the upper surface of the limiting tooling (After the evaporator is processed, the space inside the shell occupied by the boss is the air accumulation chamber), so that the steam channel tooling is located inside the shell, and the steam channel tooling is attached to the end surface of one side of the shell, Such as ...

Embodiment 3

[0071] This embodiment provides a processing method for a high-power flat-plate loop heat pipe evaporator with a positive pressure-resistant structure. The transmission core 6 in the evaporator is formed by powder sintering or pressing.

[0072] Raw materials include the shell, the powder required for the transmission core, the powder required for the heat insulation core, the powder required for the evaporation core, the limit tooling, the placeholder tooling, and the steam channel tooling.

[0073] (1) Combine the limiting tooling with the steam channel tooling (that is, place the steam channel tooling vertically on the boss on the upper surface of the limiting tooling), and then install the shell on the boss on the upper surface of the limiting tooling, The steam channel tooling is located inside the shell, and the steam channel tooling is attached to the end face of one side of the shell, such as Figure 9 As shown in A;

[0074] (2) Fill the powder required for the evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com