Test device and test method for testing heat leakage of low-temperature fluid transmission pipeline

A technology for transmission pipelines and cryogenic fluids, applied in the field of heat leakage test devices for low temperature fluid transmission pipelines, can solve problems affecting heat leakage testing, poor test accuracy, small volume of low temperature fluid transmission pipelines, etc., and achieve good test versatility and wide temperature range range, the effect of low critical temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

[0023] For the sake of convenience and brevity, in this application, the former refers to the same direction of fluid flow, and the latter refers to the reverse direction of fluid flow.

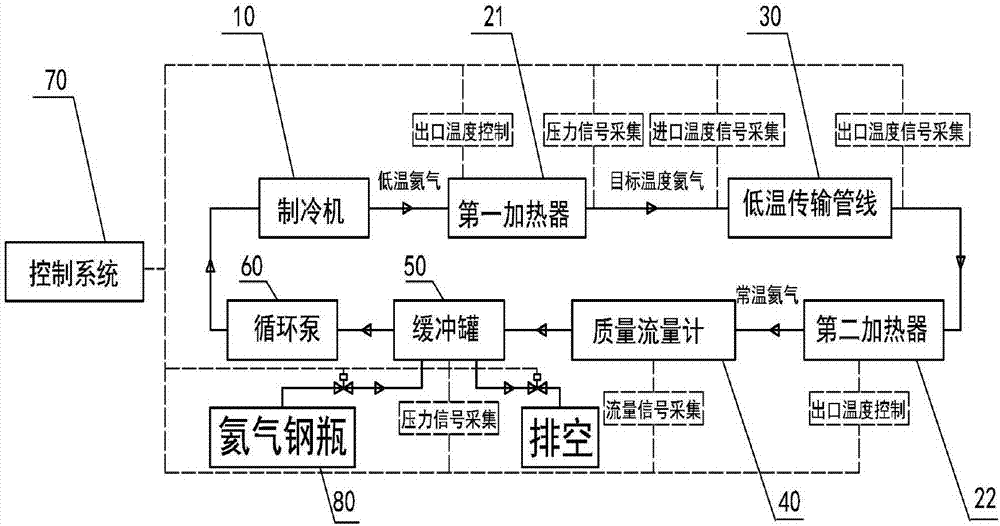

[0024] The low-temperature fluid transmission pipeline heat leakage testing device in this embodiment includes a refrigerator 10, a first heater 21, a second heater 22, a tested low-temperature transmission pipeline 30, a mass flow meter 40, a buffer tank 50, and a circulation pump 60 , control system 70. Along the fluid transmission direction, the refrigerator 10 , the first heater 21 , the second heater 22 , the tested low-temperature transmission pipeline 30 , the mass flow meter 40 , the buffer tank 50 and the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com