Oil-water separation device and oily sludge drying system

A technology of oil-water separation device and separation zone, which is applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, separation methods, etc., and can solve problems such as large space occupation, low separation efficiency, and poor separation effect , to achieve the effect of saving space, improving separation efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

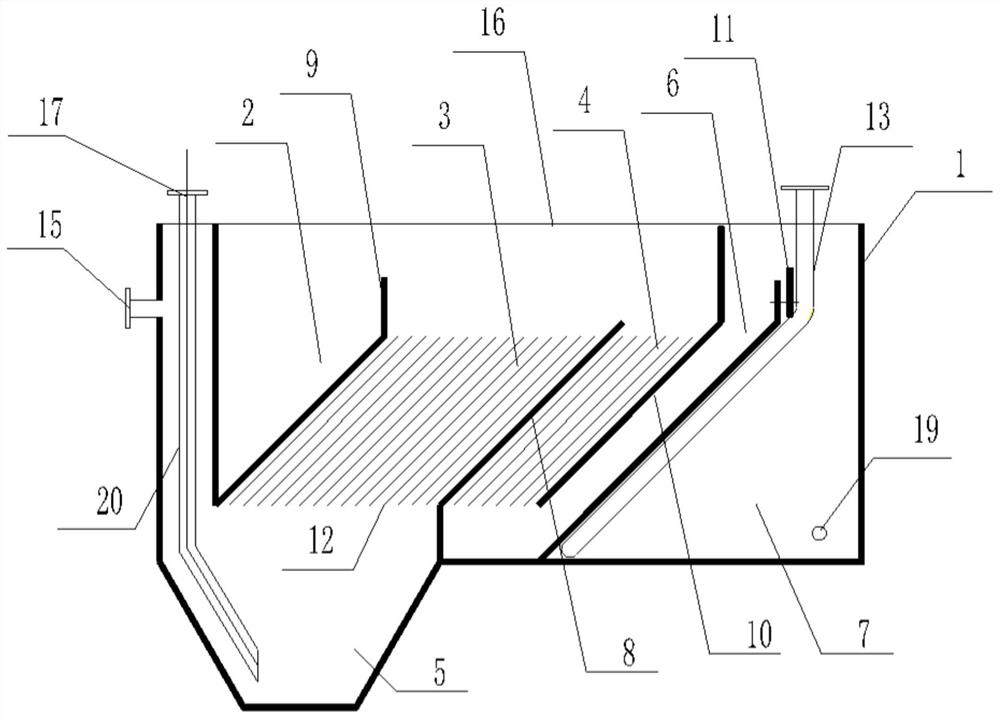

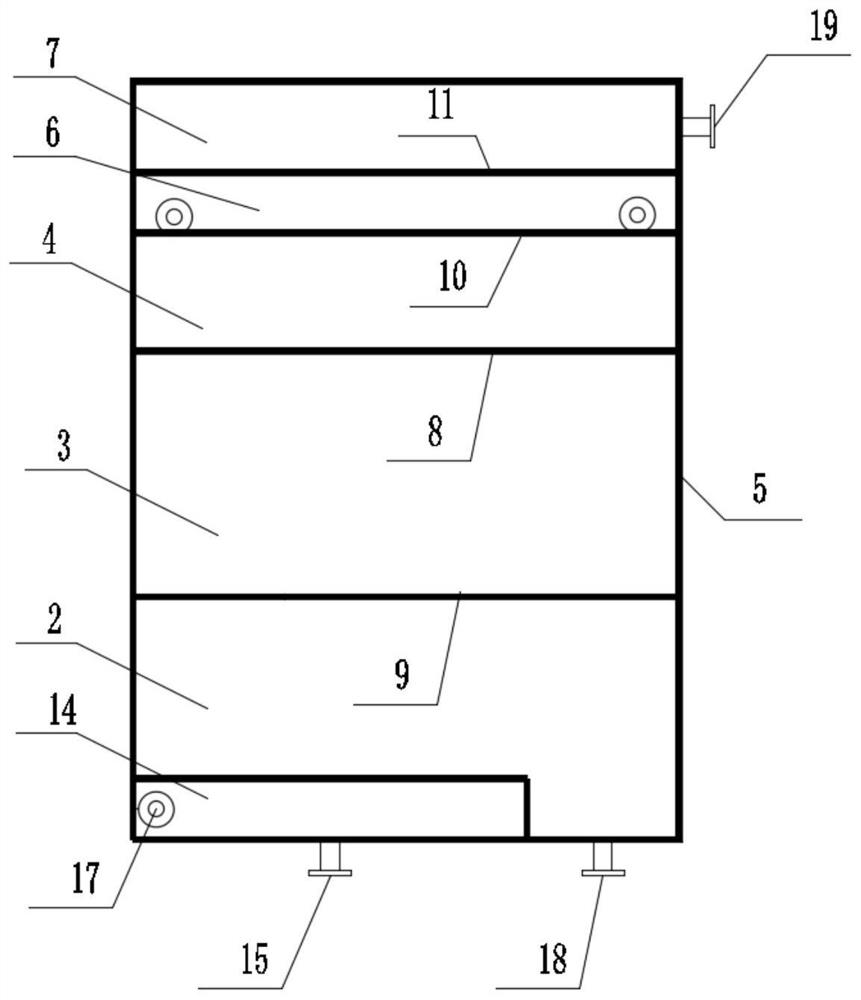

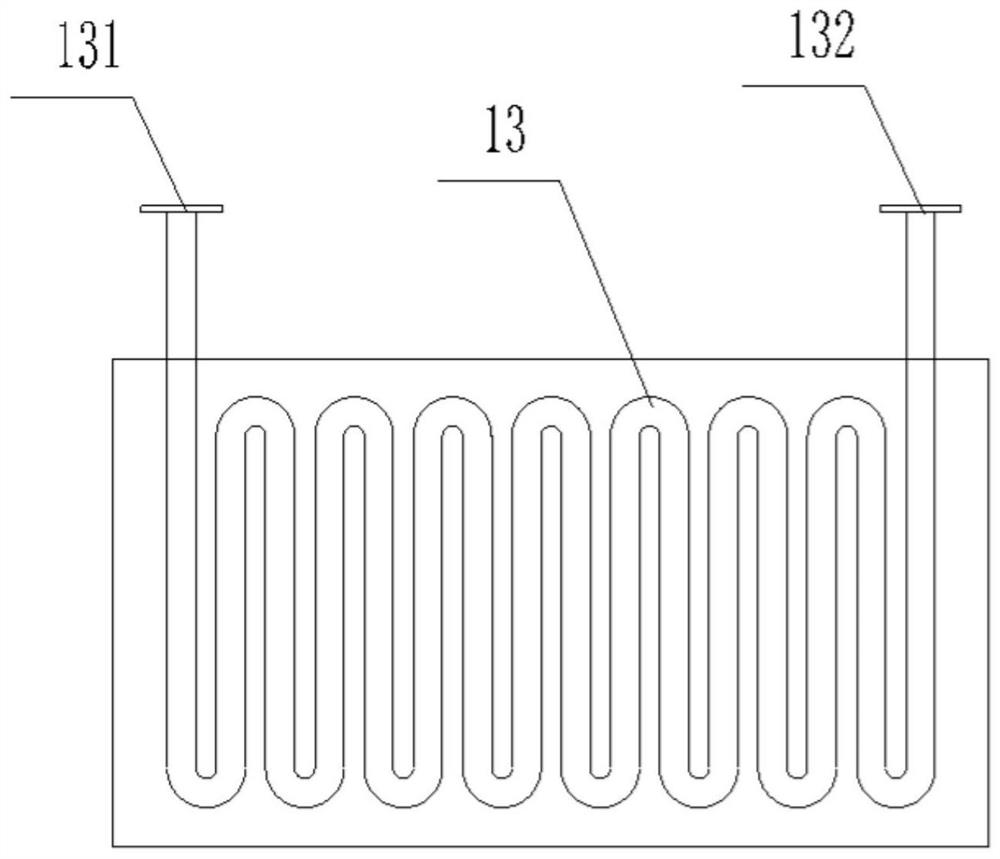

[0055] This embodiment provides an oil-water separation device, referring to figure 1 and figure 2 As shown, it includes: a box body 1, an oil storage area 2 arranged in the box body 1, a first separation area 3, a second separation area 4, a mud storage bucket 5, a water level adjustment area 6 and a water storage area 7; The mud storage hopper 5 communicates with the first separation area 3, and the second separation area 4 communicates with the water level adjustment area 6; a separation device is provided between the first separation area 3 and the second separation area 4 A partition 8; a first inner partition 9 is provided between the first separation area 3 and the oil storage area 2; a second inner partition 9 is provided between the second separation area 4 and the water level adjustment area 6 A partition 10, a water level adjustment weir plate 11 is provided between the water level adjustment area 6 and the water storage area 7; the separation partition 8, the fir...

Embodiment 2

[0087] Based on the same inventive concept, an embodiment of the present invention also provides an oily sludge drying system, including the oil-water separation device in the above embodiment.

[0088] In the embodiment of the present invention, the specific structure of the oil-water separation device of the oily sludge drying system can refer to the description of the first embodiment above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com