Patents

Literature

31results about How to "Streamlining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

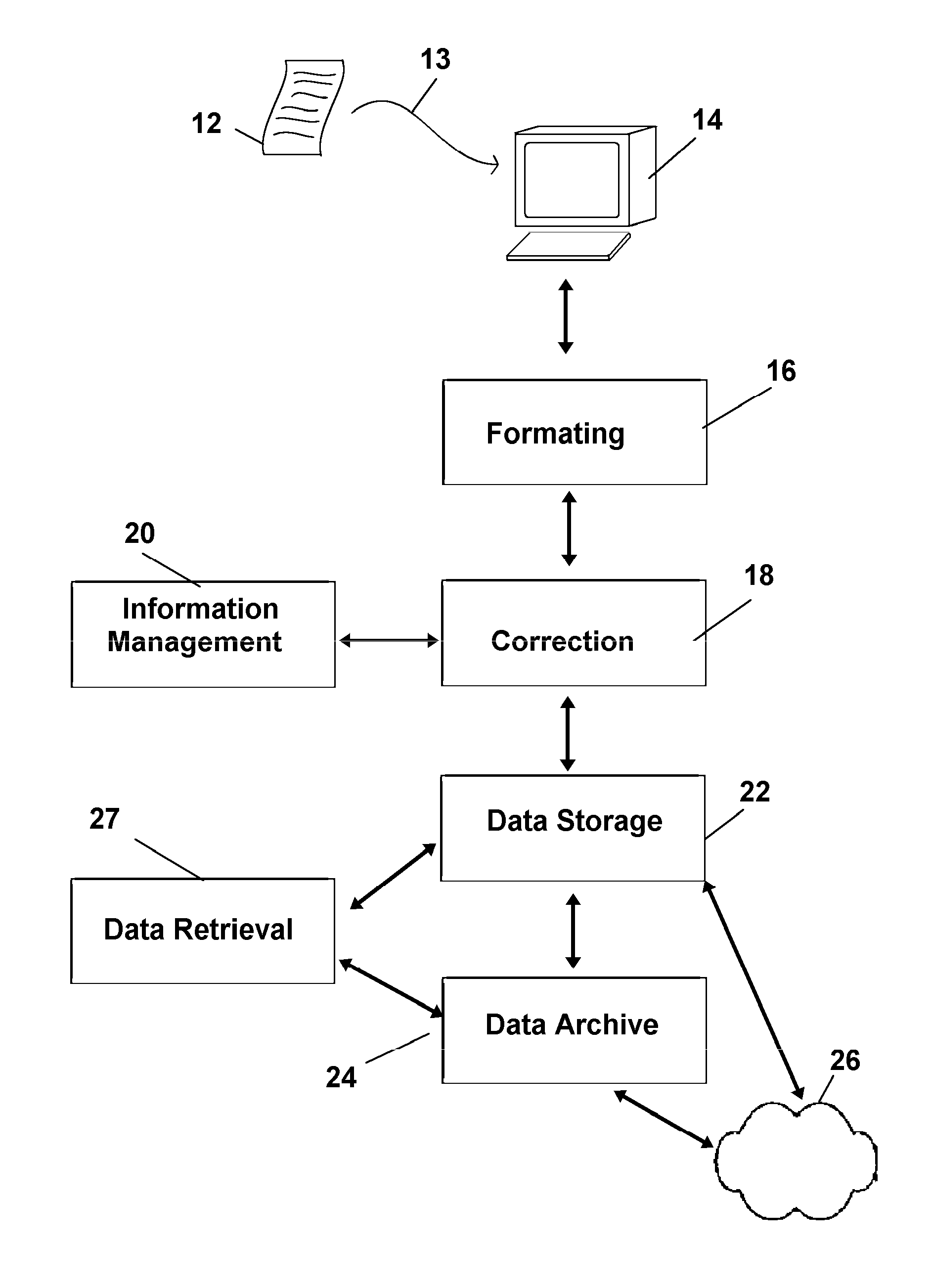

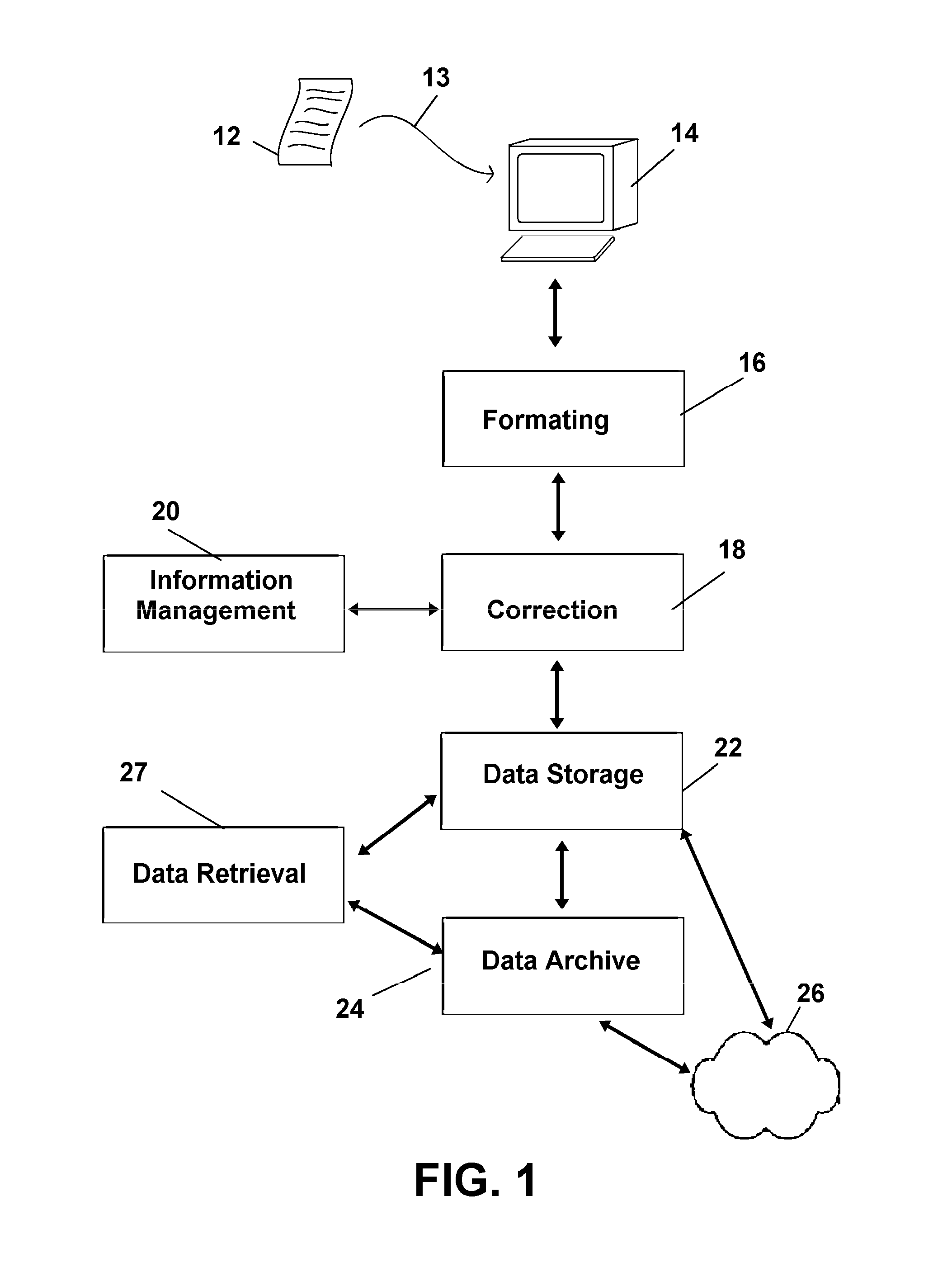

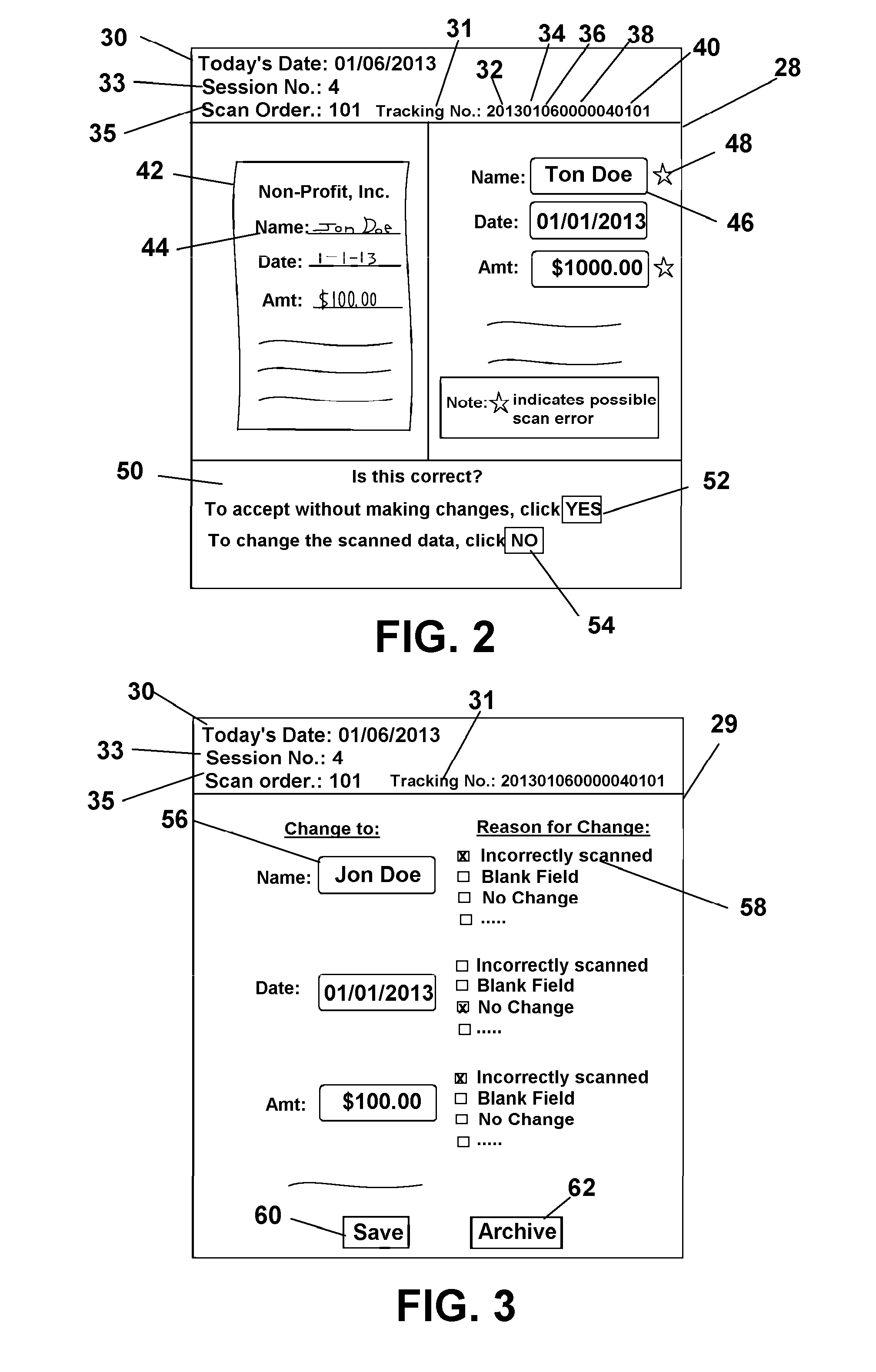

Device and Method for Contribution Accounting

InactiveUS20140198969A1Improve efficiencyStreamliningFinanceCharacter and pattern recognitionPaymentSoftware

A system or apparatus employing a multi-functional scanner and software running upon a computing device for capturing payment or donation data from indicia positioned upon scanned documents tendered with donations or payments and optionally, subsequent total compilation and entry of thereof directly into accounting software.

Owner:MCRAE KENYA

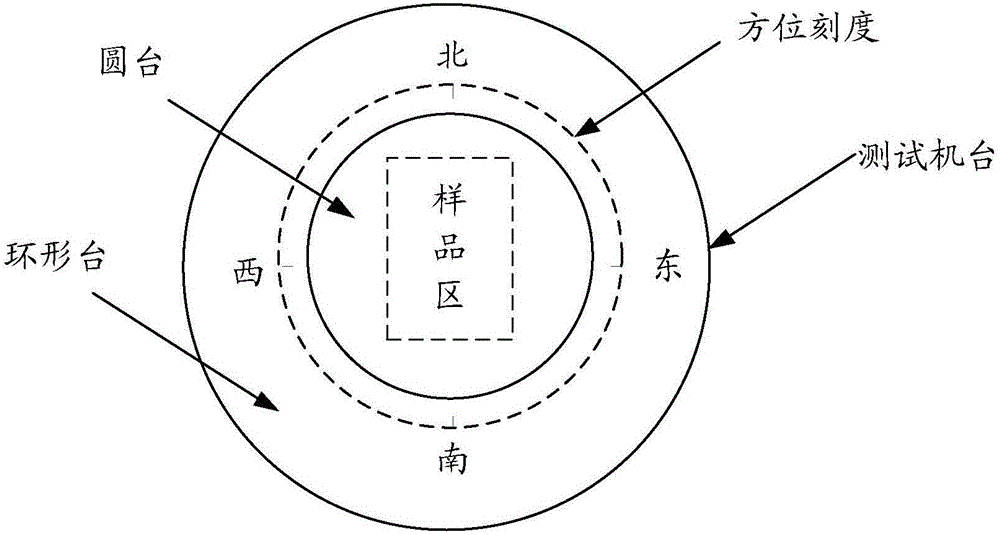

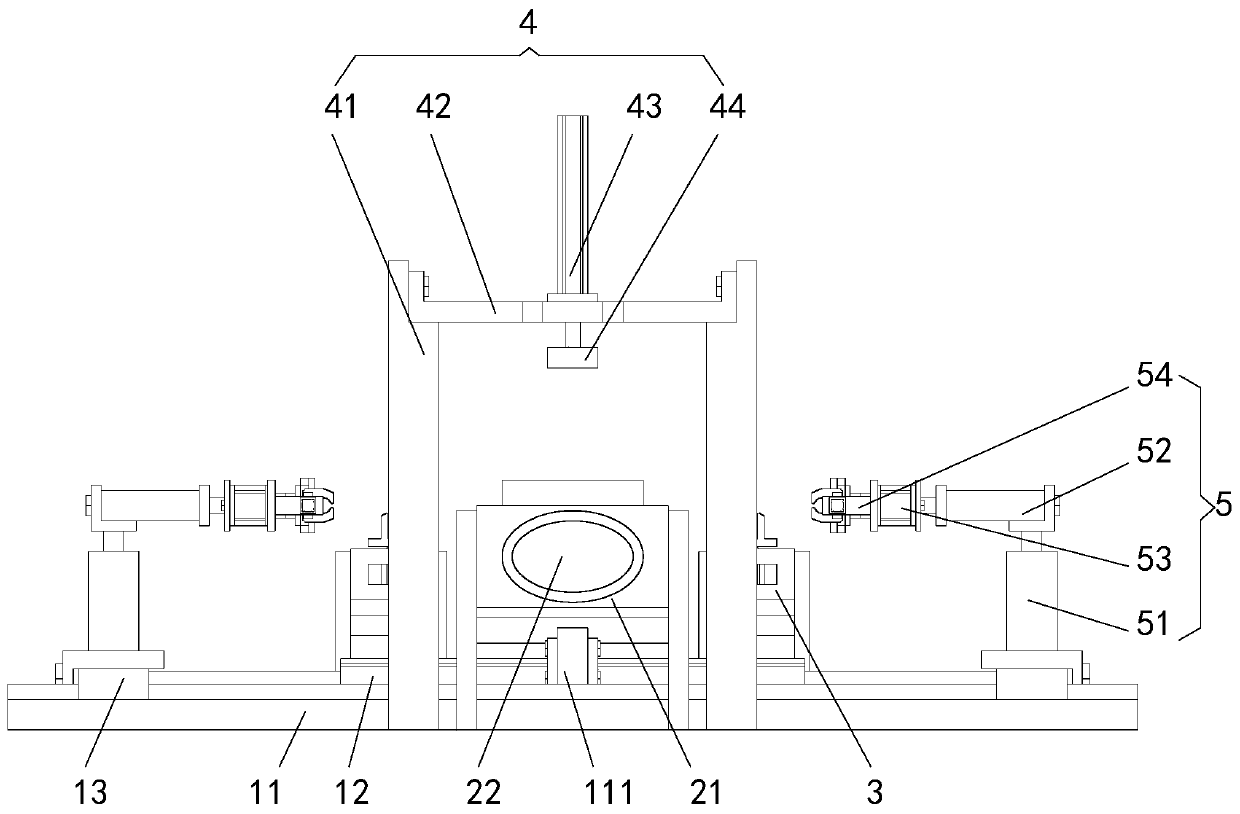

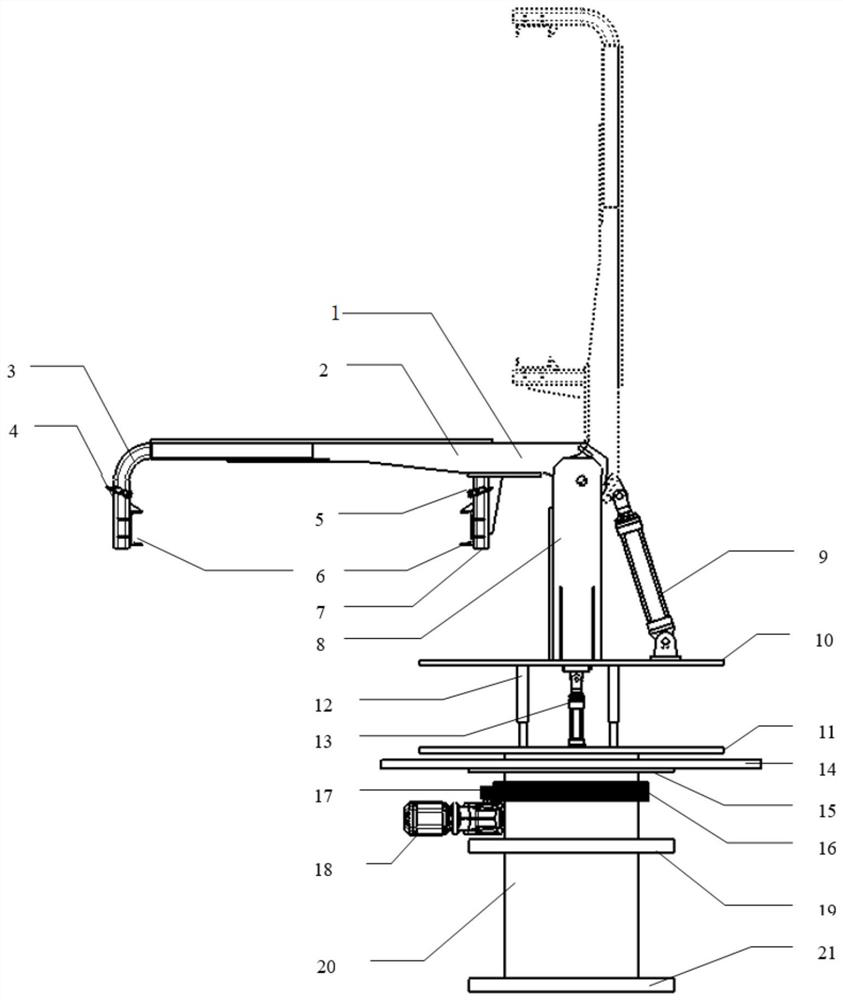

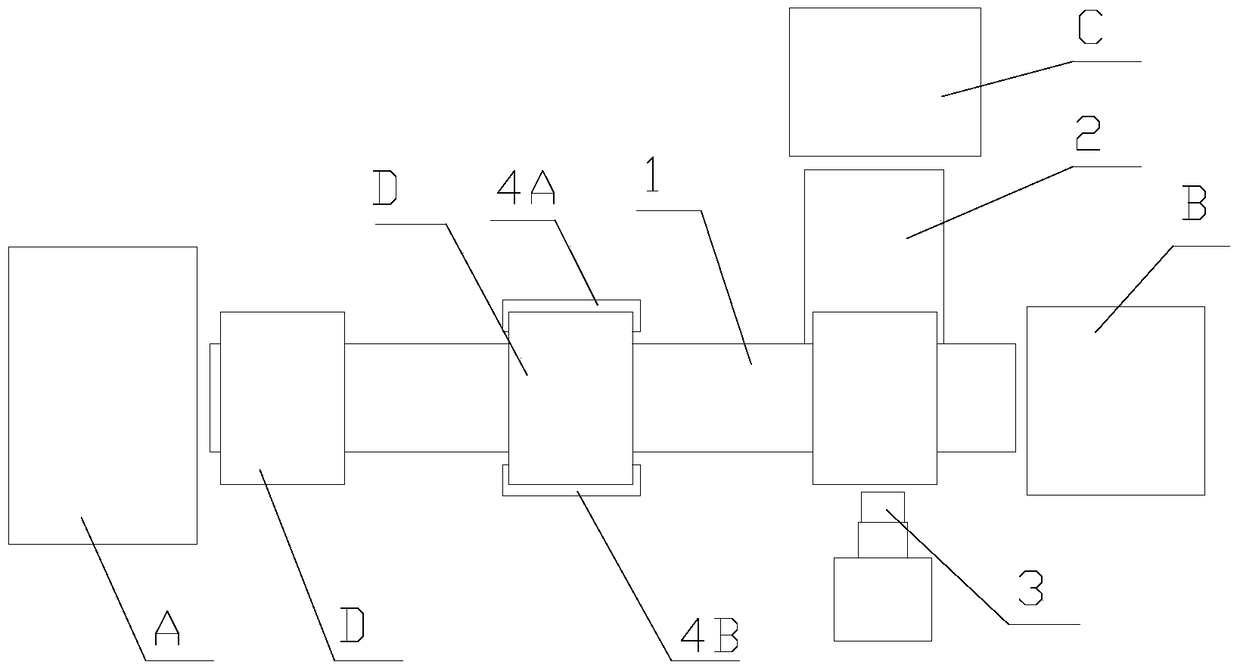

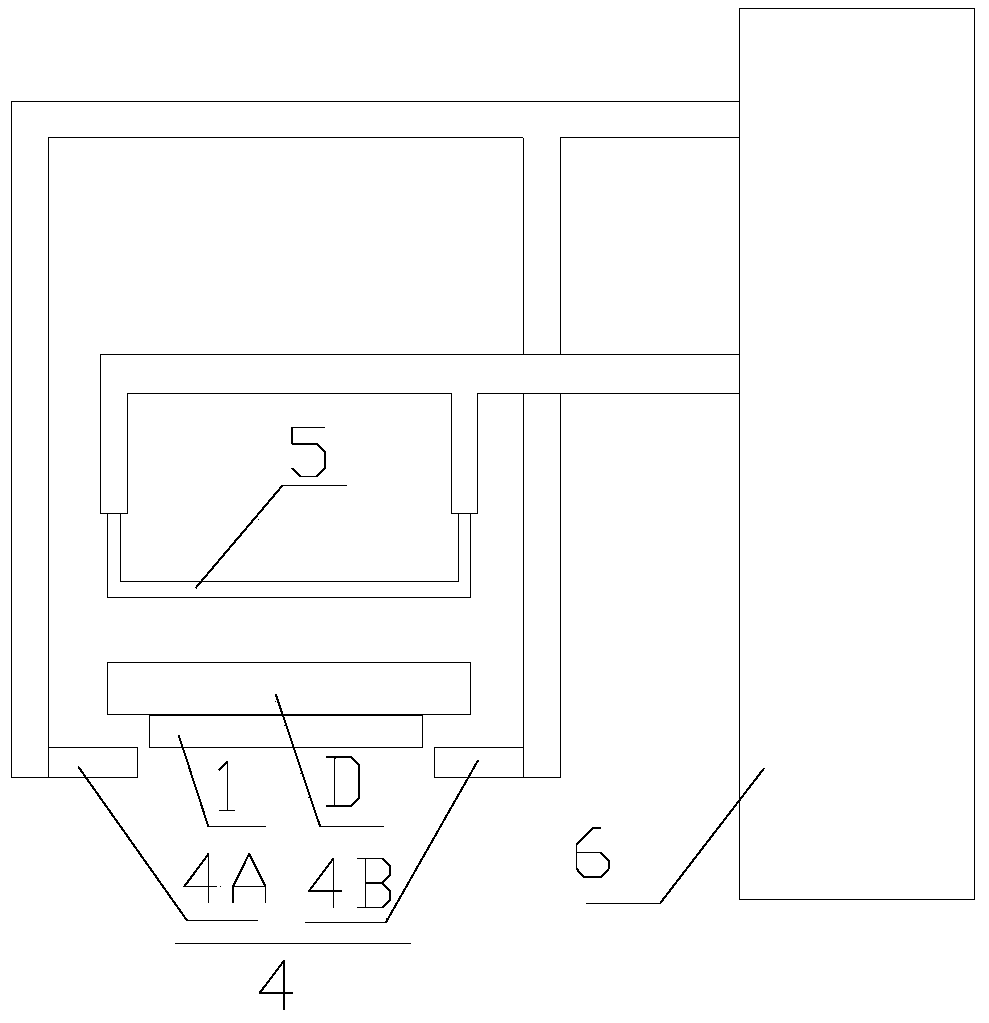

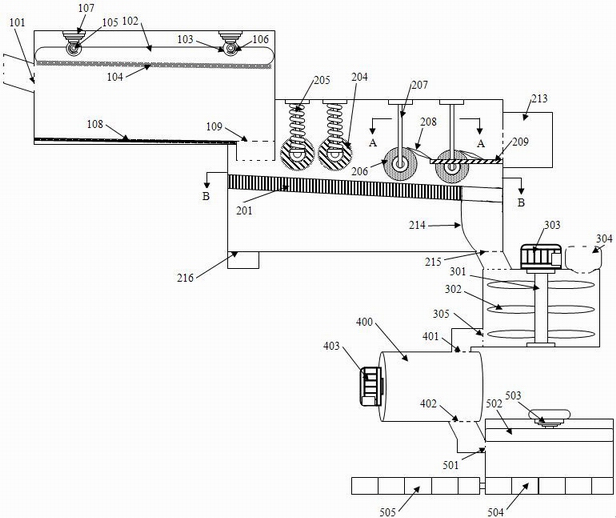

Automatic test method, device, equipment and system for intelligent terminal compass

InactiveCN106546268AEasy to controlFully automatedMeasurement devicesTest efficiencyAutomatic test equipment

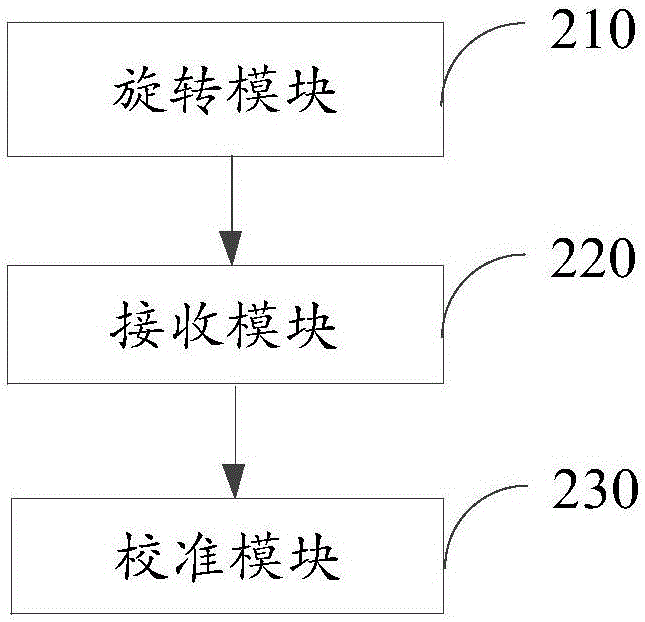

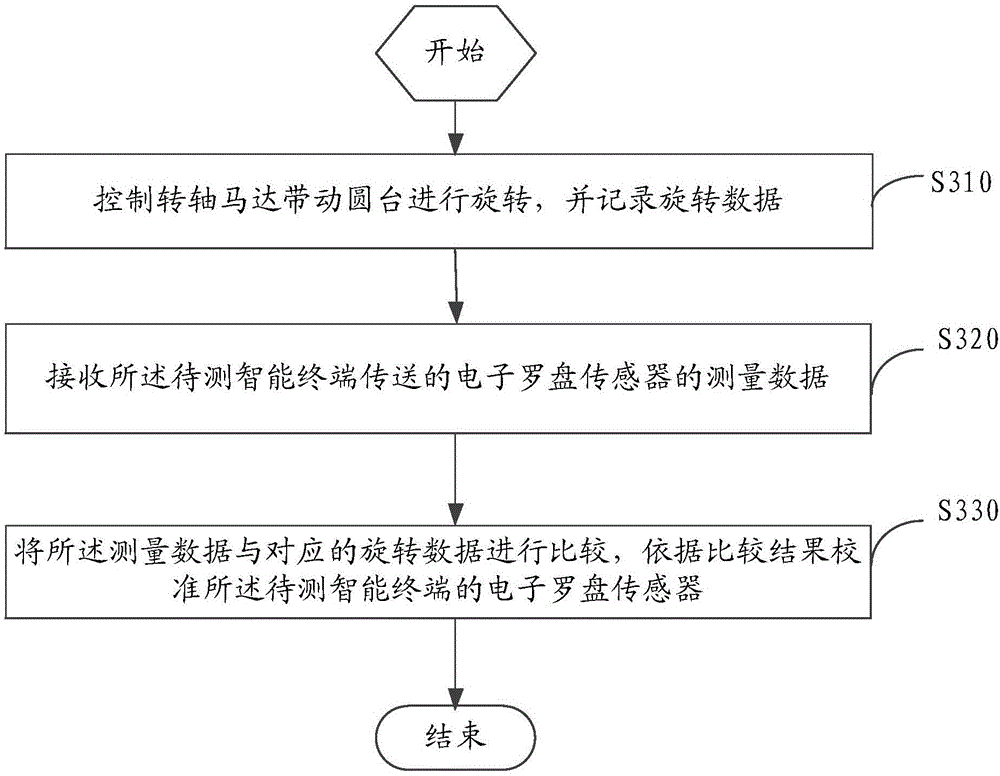

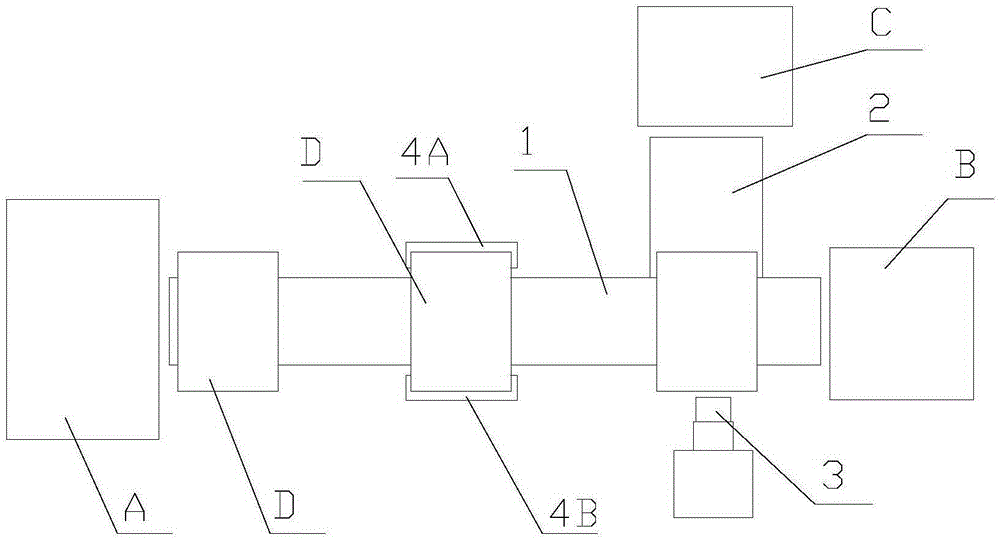

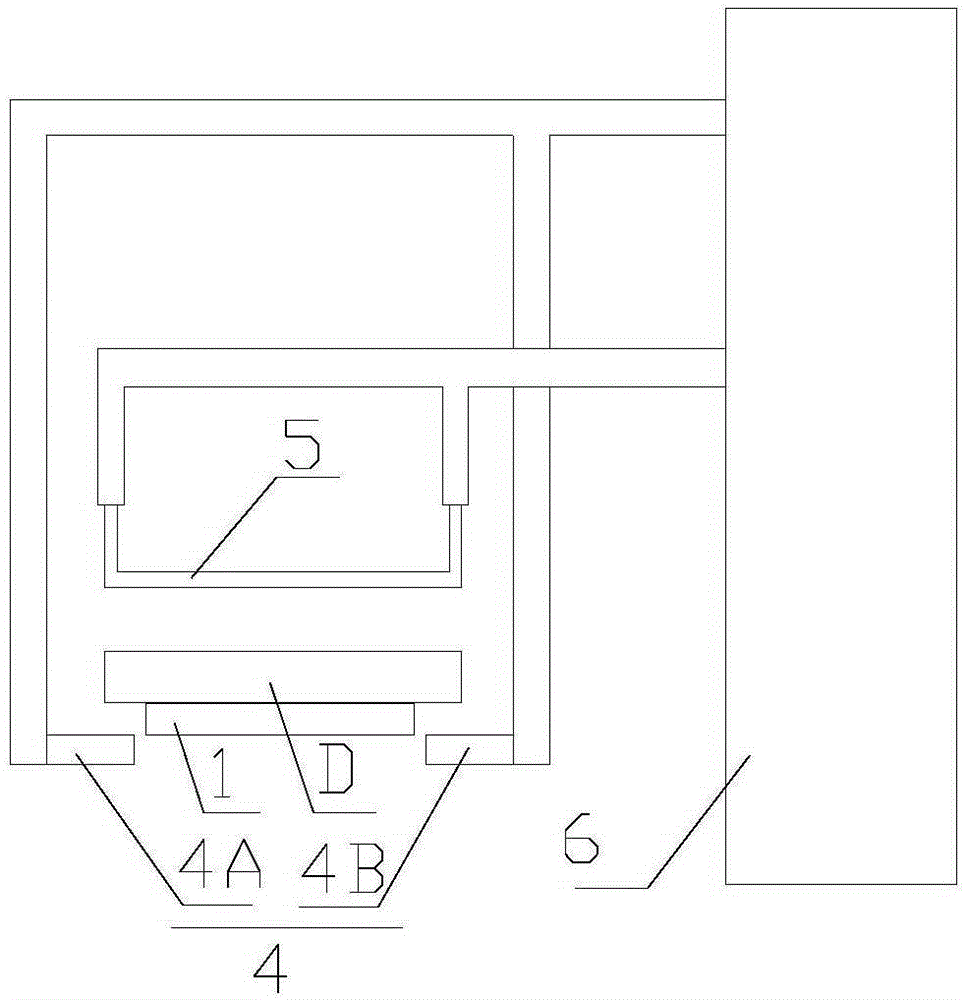

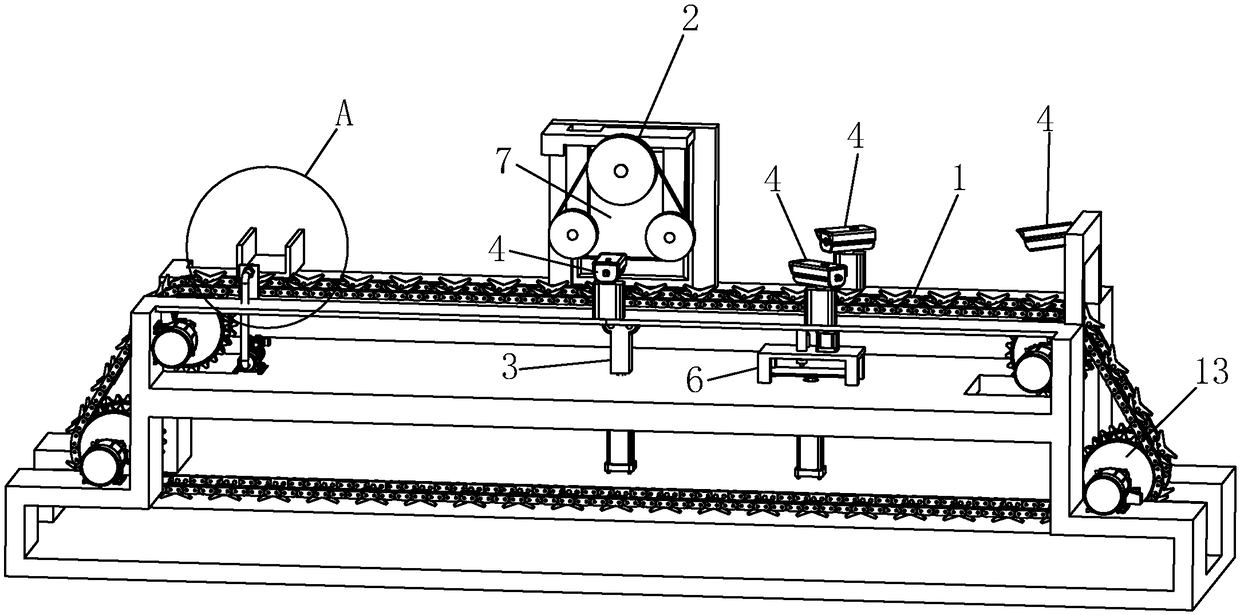

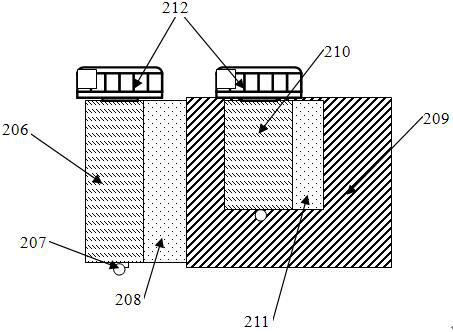

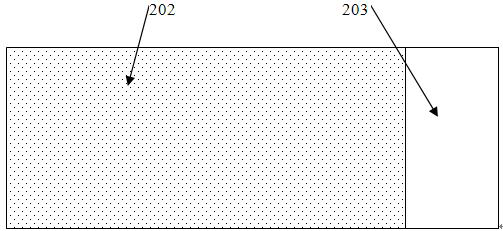

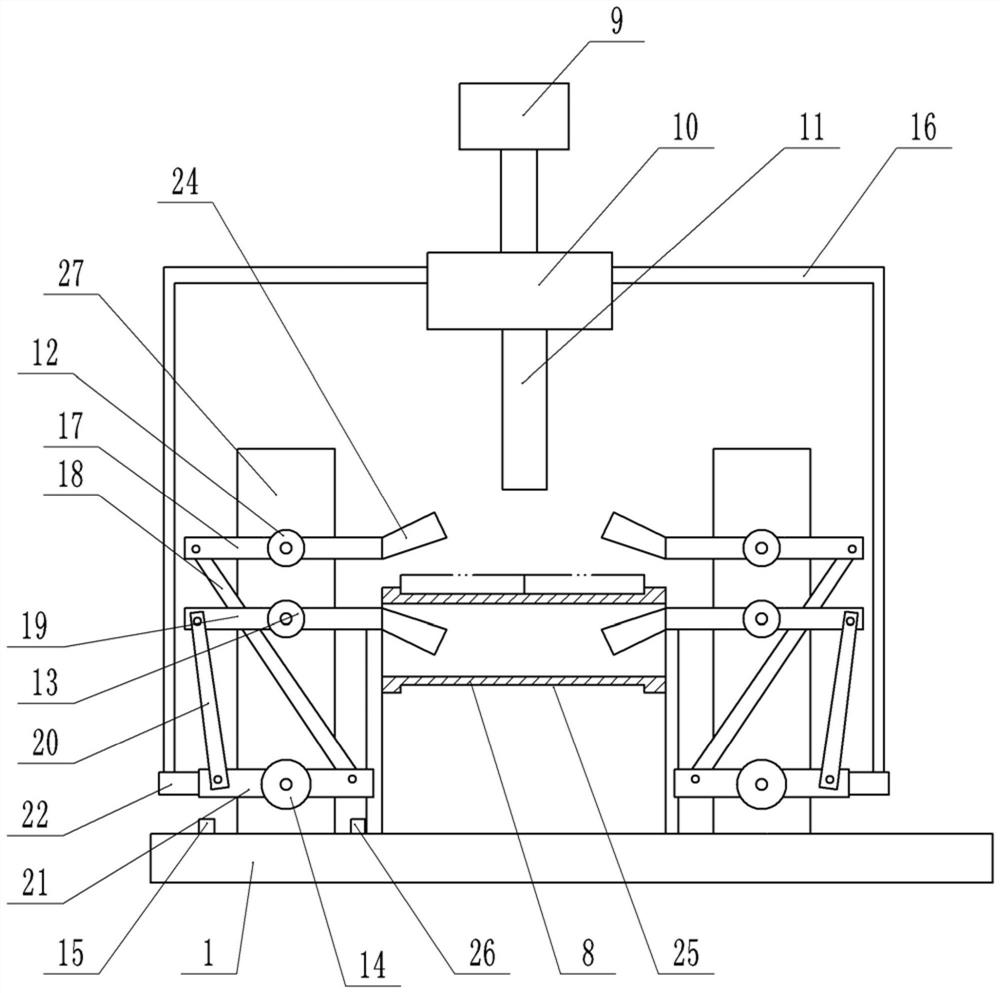

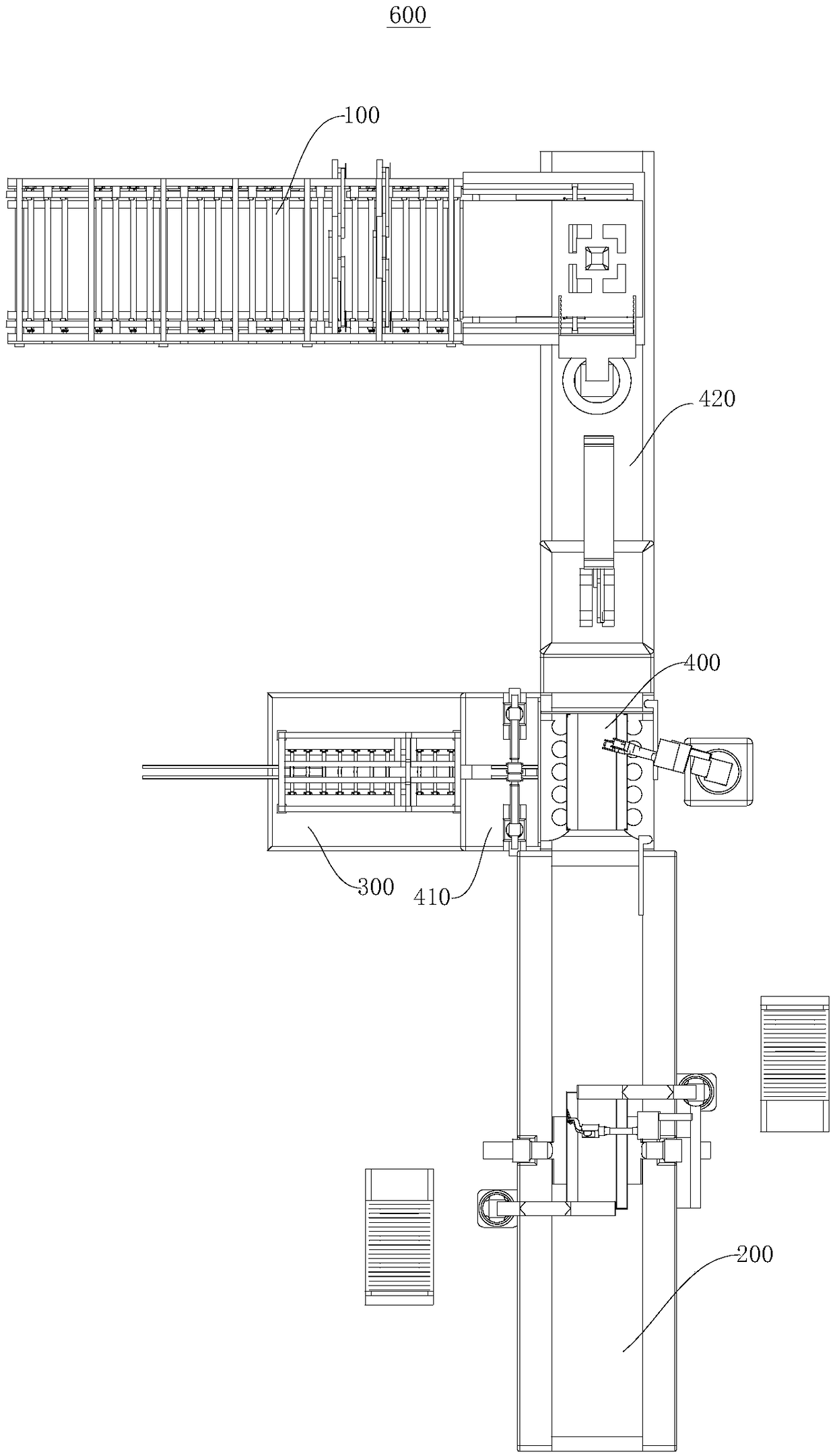

The invention discloses an automatic test method, device, equipment and system for an intelligent terminal compass. The equipment comprises a conveying device, a testing machine and a spindle motor, wherein the testing machine comprises a rotatable circular platform located at the center, and the circular platform is driven to rotate by the spindle motor. The device comprises a rotating module, a receiving module and a calibrating module; the rotating module is used for controlling the spindle motor to drive the circular platform to rotate and recording the rotating data; the receiving module is used for receiving the measured data of an electronic compass sensor transmitted by a to-be-tested intelligent terminal; the calibrating module is used for comparing the measured data with the corresponding rotating data and calibrating the electronic compass sensor of the to-be-tested intelligent terminal according to a comparison result. Thus, mechanical test equipment is combined with automatic test software; the control on the rotating angle and the automation of calibration of the to-be-tested intelligent terminal are realized; the test error and the data inconsistency brought by a traditional manual clamp are reduced; the test efficiency is improved; the streamlined test is realized.

Owner:NUBIA TECHNOLOGY CO LTD

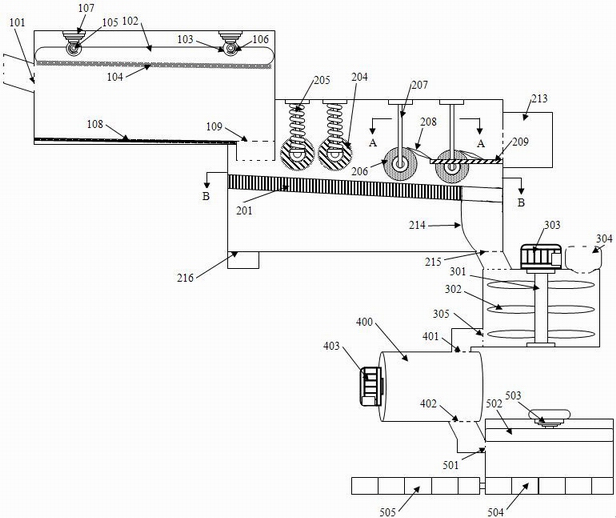

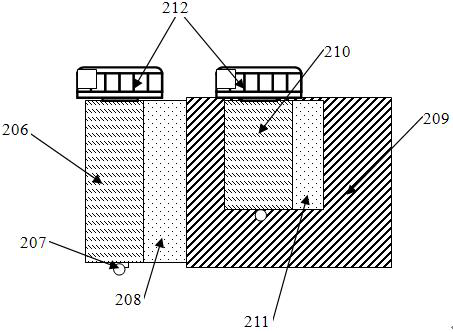

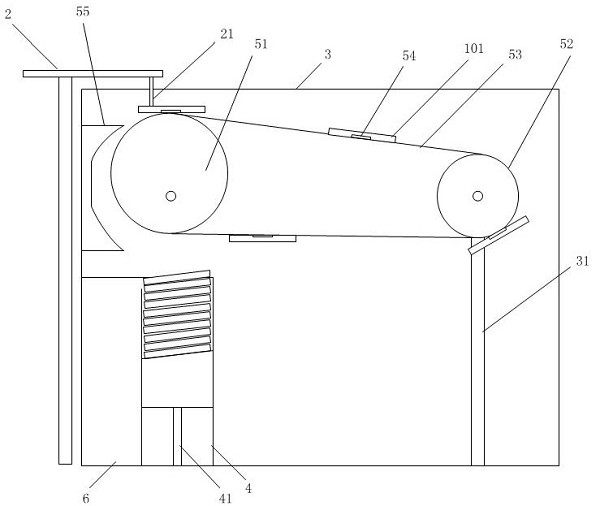

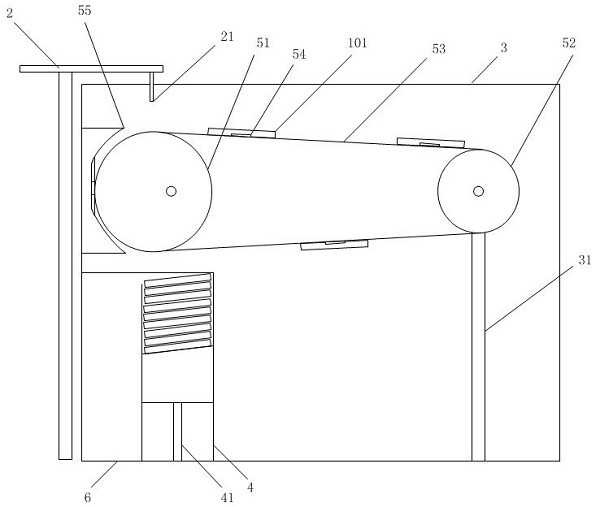

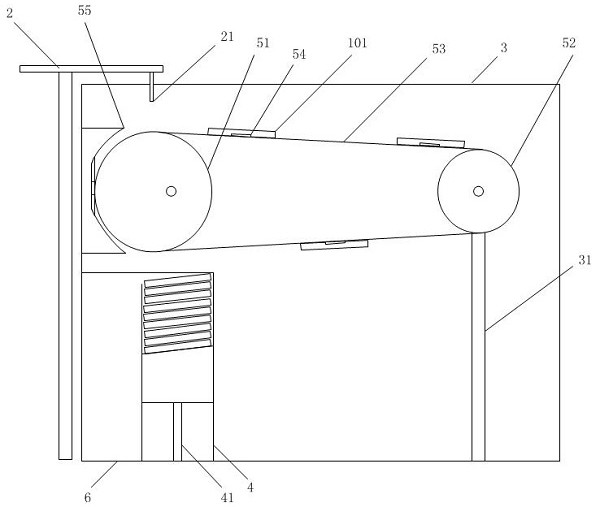

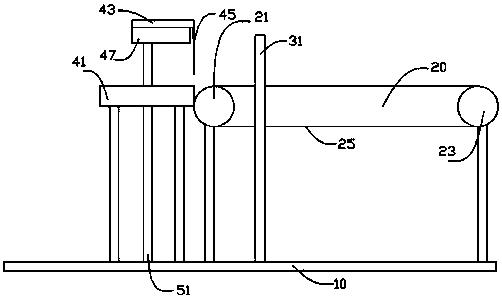

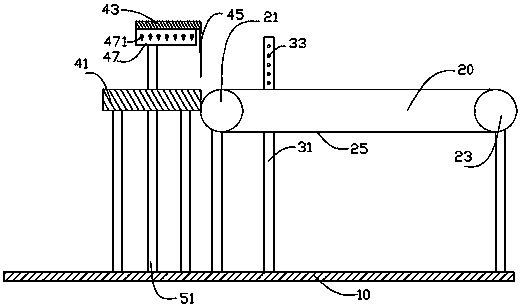

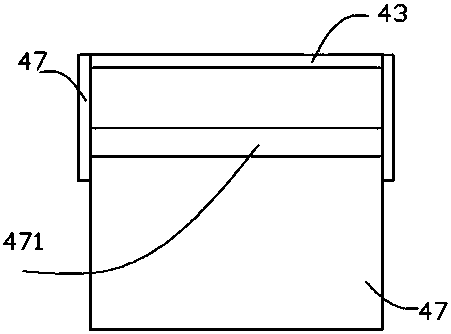

Liquid crystal display panel foreign matter detection system

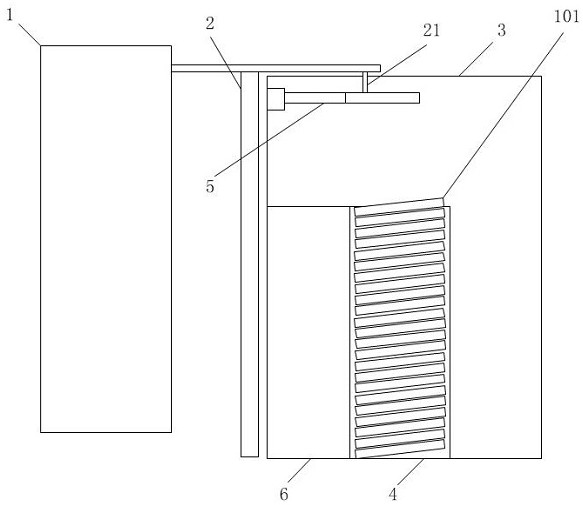

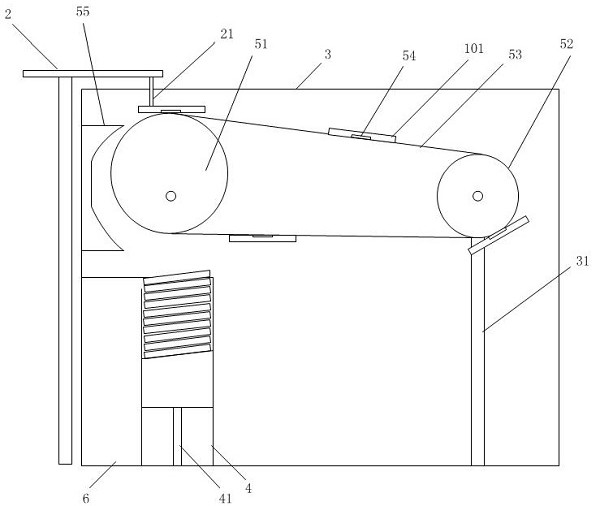

ActiveCN105388642AStreamliningRealize intelligenceNon-linear opticsForeign matterLiquid-crystal display

The invention discloses a liquid crystal display panel foreign matter detection system. The system comprises a feeding mechanism, a discharging mechanism, a scrap material discharging mechanism, a conveying mechanism, a pressing plate mechanism and a judgment module. According to the liquid crystal display panel foreign matter detection system, liquid crystal display panels to be detected are driven to flow through a first conveyor belt, thereby all the liquid crystal display panels to be detected are sequentially detected through the pressing plate mechanism and the judgment module, pipelining, intelligentization and automation of liquid crystal display panel detection work are achieved, the manpower demand is lowered, detection objectivity is improved, and it is helpful to improve detection efficiency and lower the risk that an inferior-quality product passes detection.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

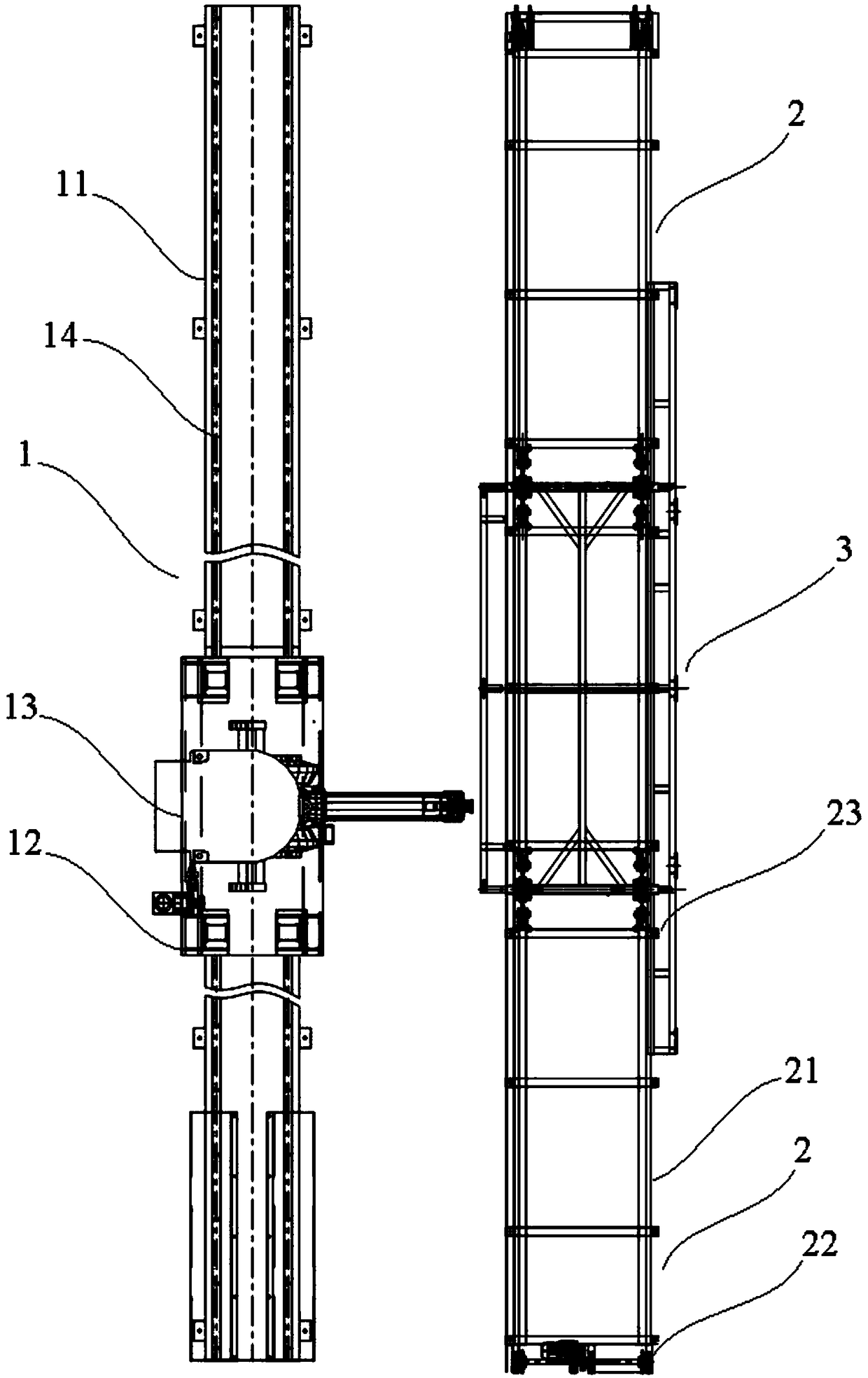

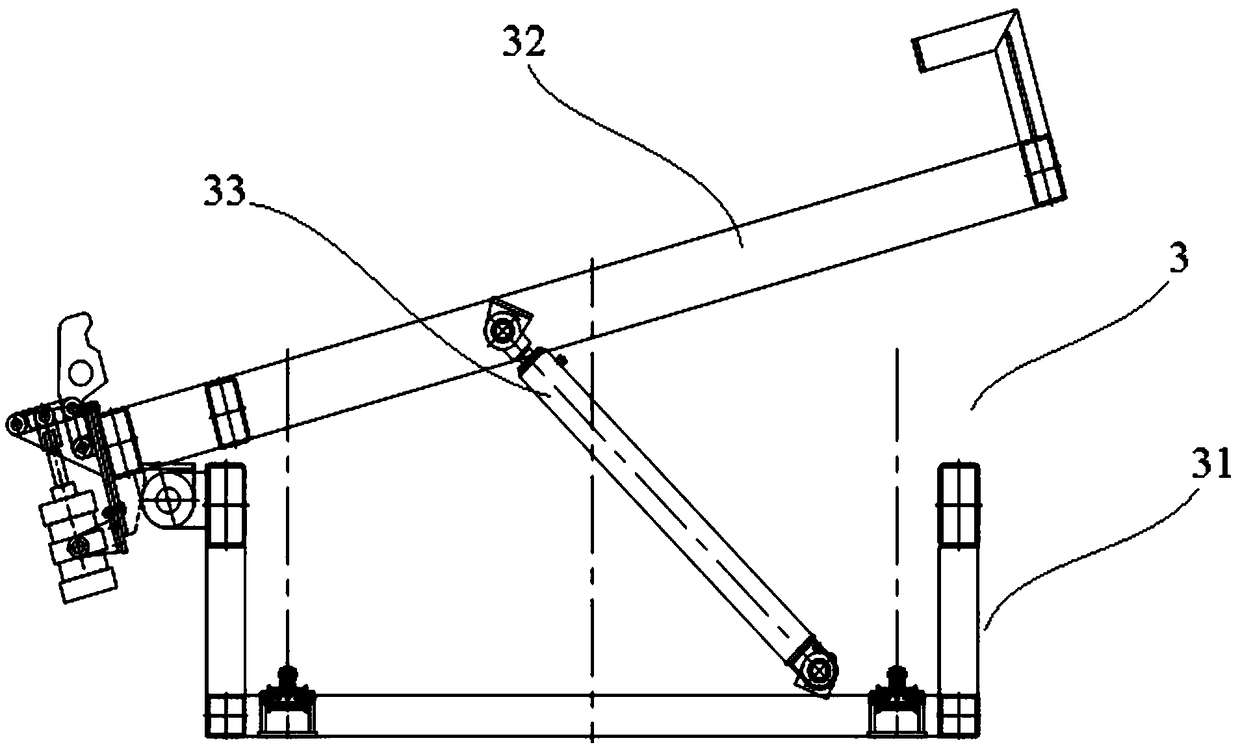

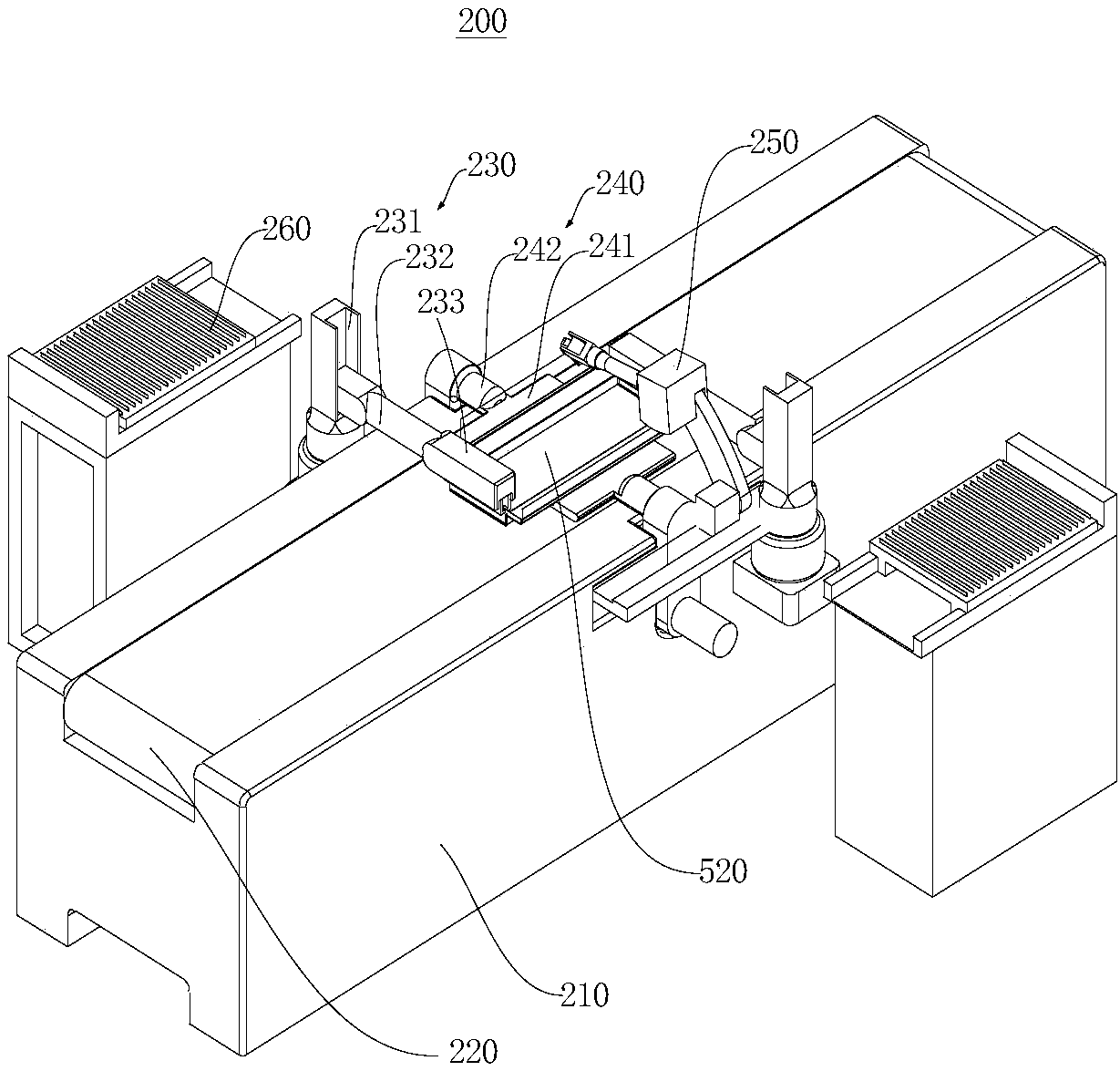

Container corrugated weld joint automatic welding tool and welding method used by same

InactiveCN109317872AFlipFully automatedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringProduction quality

The invention relates to a container corrugated weld joint automatic welding tool and a welding method used by the same. The welding tool comprises a welding device, two transporting machines and a turnover device, wherein the welding device comprises a bottom beam, a welding platform which is arranged on the bottom beam and can slide in the length direction of the bottom beam in a reciprocating mode, and a welding robot arranged on the welding platform, the turnover device is arranged between the two transporting machines, and the turnover device comprises a turnover frame body, a turnover frame and a driving oil cylinder, wherein the turnover frame is arranged on the turnover frame body, one end of the turnover frame is rotationally connected with the turnover frame body, and the two ends of the driving oil cylinder are correspondingly and rotationally connected to the turnover frame body and the turnover frame. In the container corrugated weld joint automatic welding tool, the turnover device is used for realizing turnover of sectional materials, moreover, welding of the sectional materials subjected to turnover is realized by the aid of the welding device, the welded sectionalmaterials can be conveyed to a next station through the transporting machines, so that the automation of welding and the streamlined production are realized, and the production efficiency and the production quality are greatly improved.

Owner:CRRC YANGTZE CO LTD

Brick making device for building garbage

ActiveCN111688014AUniform sizeWell mixedTransportation and packagingRotary stirring mixersBrickArchitectural engineering

The invention relates to a brick making device for building garbage. The brick making device comprises a hammer crushing cavity, a screening magnetic separation part, a river sand stirring cavity, a sand grinding cylinder and a brick forming chamber. After the building garbage is hammered and rolled, ferromagnetic metal in the building garbage is removed through a magnetic separation mechanism ofthe specific structure, river sand is uniformly mixed, the sand grinding cylinder of a transverse cylinder is rotated, the building waste particles are ground by using the river sand, and the mixtureis extruded into bricks, so that the efficient reuse of the building garbage is achieved.

Owner:FENGLIN ENVIRONMENTAL PROTECTION TECH CO LTD

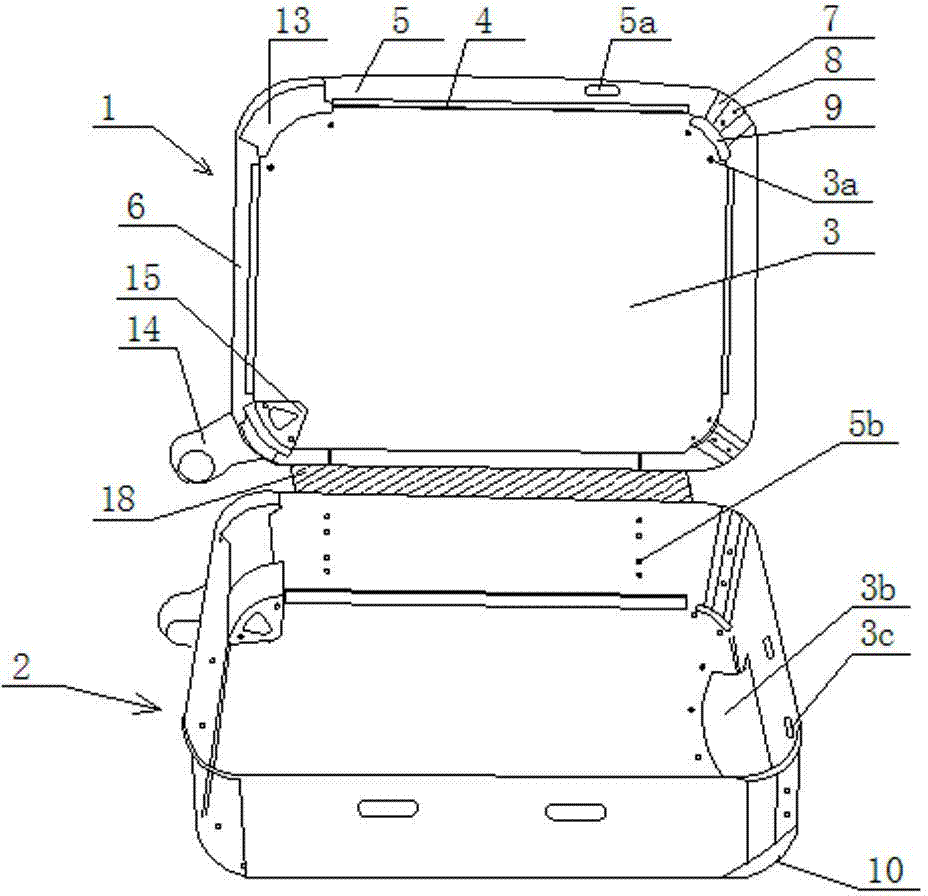

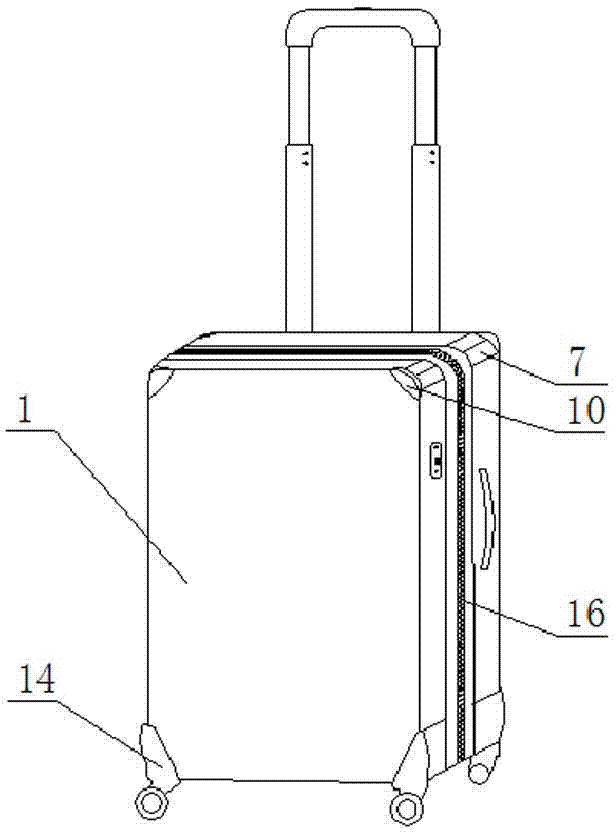

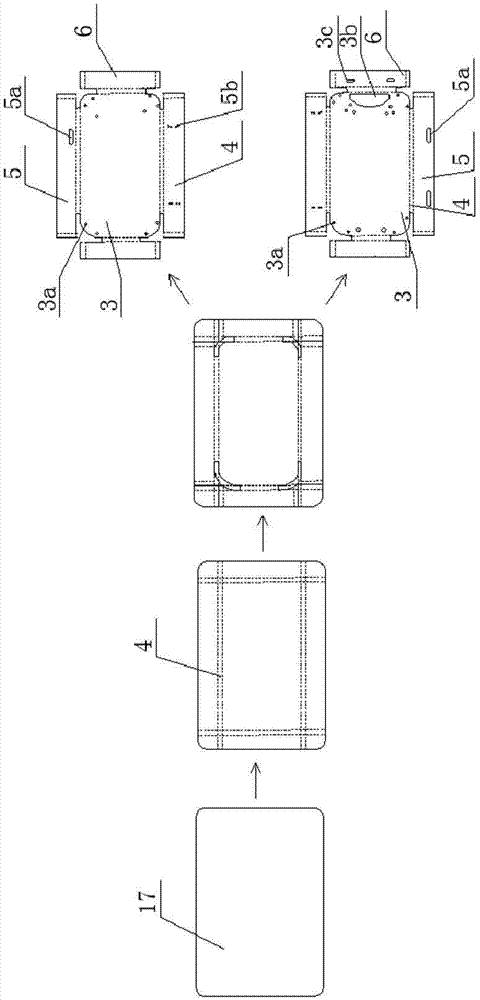

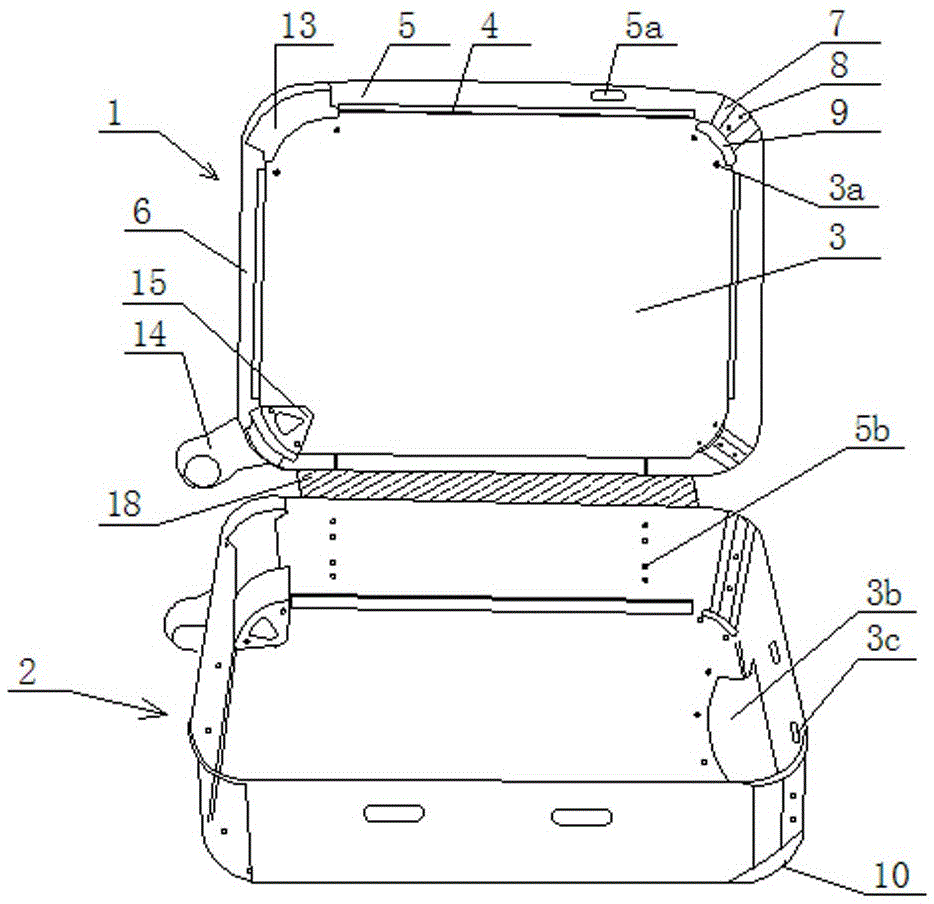

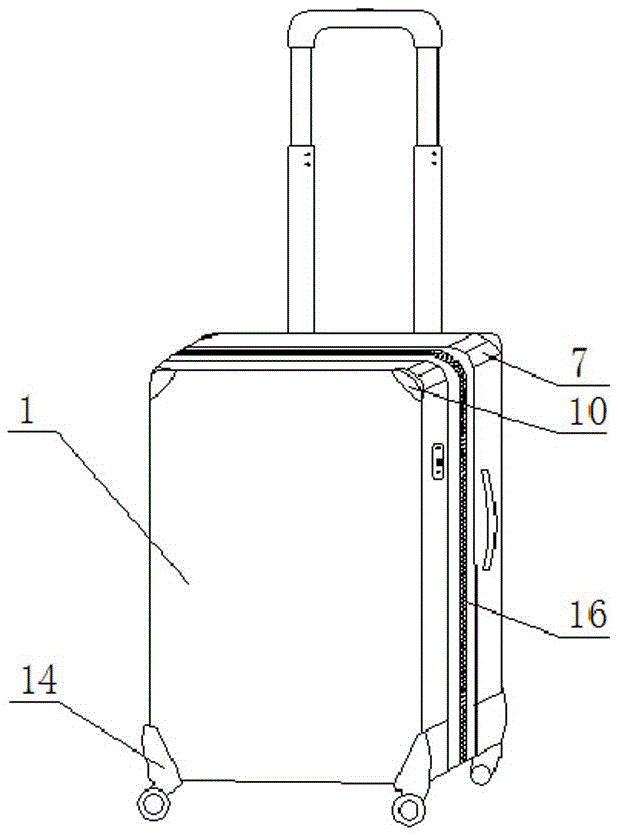

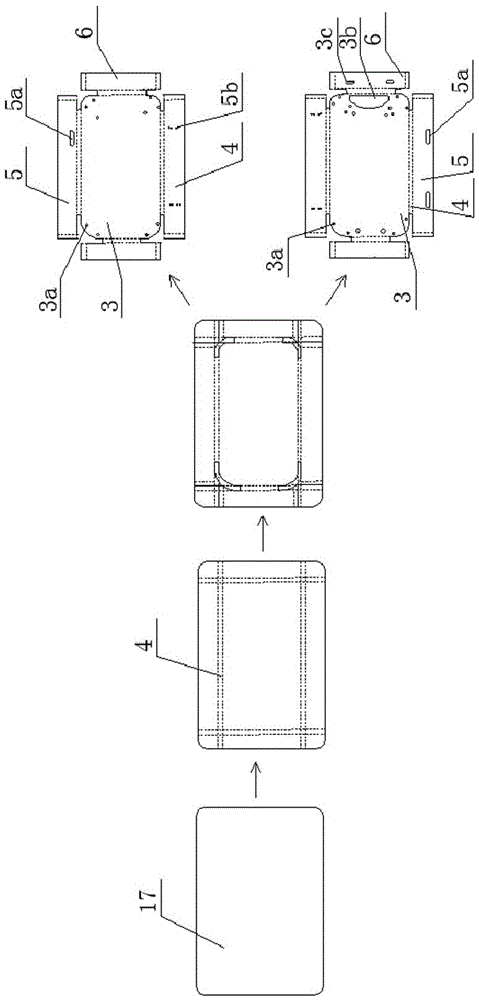

Hard traveling case and manufacturing method thereof

ActiveCN104490043AUniform thicknessGuaranteed degree of fastnessLuggageHollow articlesMechanical engineeringIndustrial engineering

The invention discloses a hard travelling case and a manufacturing method thereof, belonging to the technical field of travelling cases and manufacturing method thereof. The hard travelling case comprises an upper case body and a lower case body which are connected through lining, wherein each of the upper case body and the lower case body comprises a bottom plate, an impression belt and a surrounding frame which includes a long side frame and a short side frame, the long side frame and the short side frame are superposed and fixed on four corners of the case body; top arc-shaped holes are formed in the two sides of the top of the bottom plate; bottom arc-shaped holes are formed in two sides of the bottom of the bottom plate; bottom supporting parts which are in connected with the bottom arc-shaped holes are arranged at the outer sides of the bottom arc-shaped holes. According to the travelling case and the manufacturing method thereof disclosed by the invention, the conception is delicate and the structure design is reasonable; after being reasonably cut, rectangular plates are jointed in a thermoplastic manner to form the travelling case which is uniform in thickness, so that the defect that the plastic on a plastic-uptake molding corner is relatively thin is overcome, the firmness degree of the case is guaranteed. The whole production process can be streamlined, so that the production cost is lowered and the manufacturing time is shortened.

Owner:HANGZHOU GEMA SUITCASES & BAGS

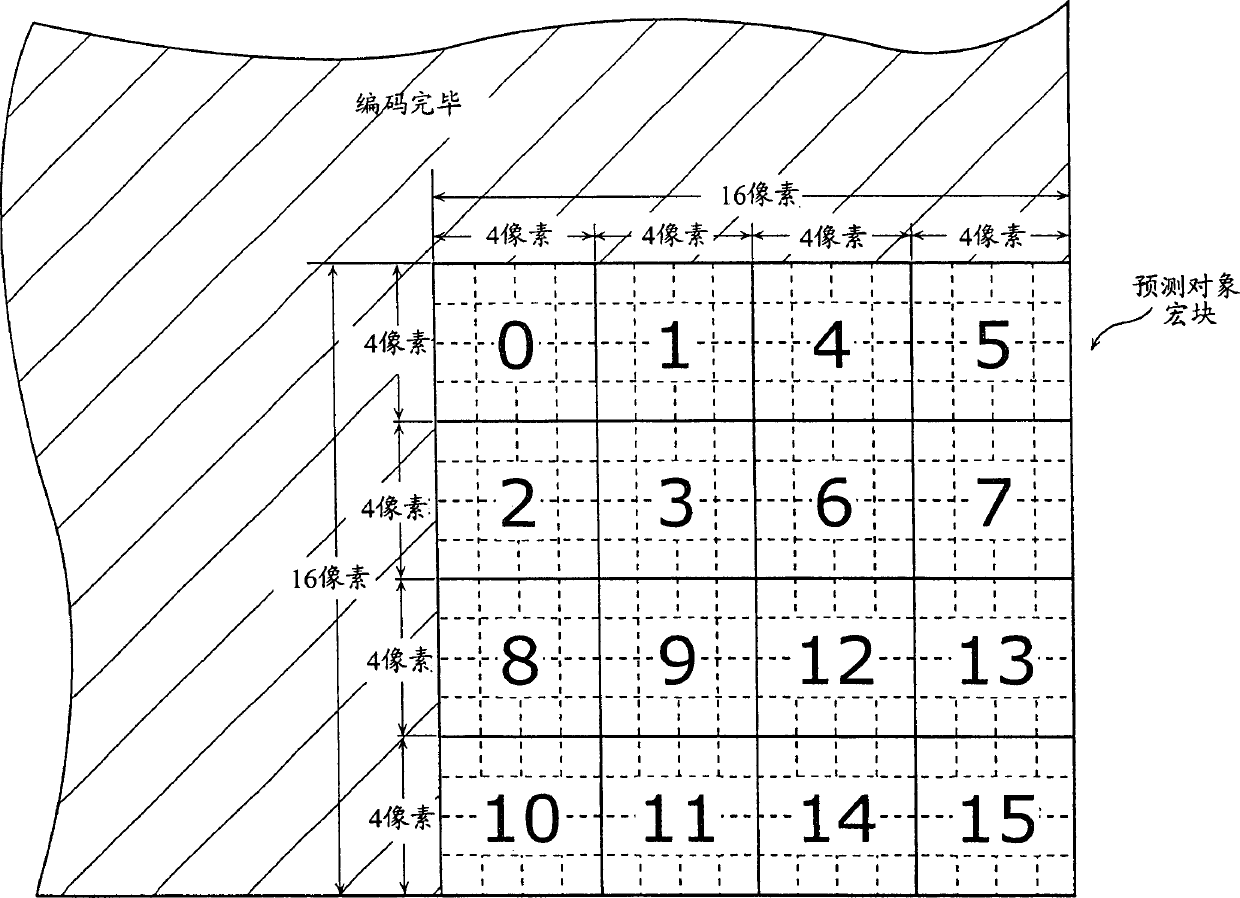

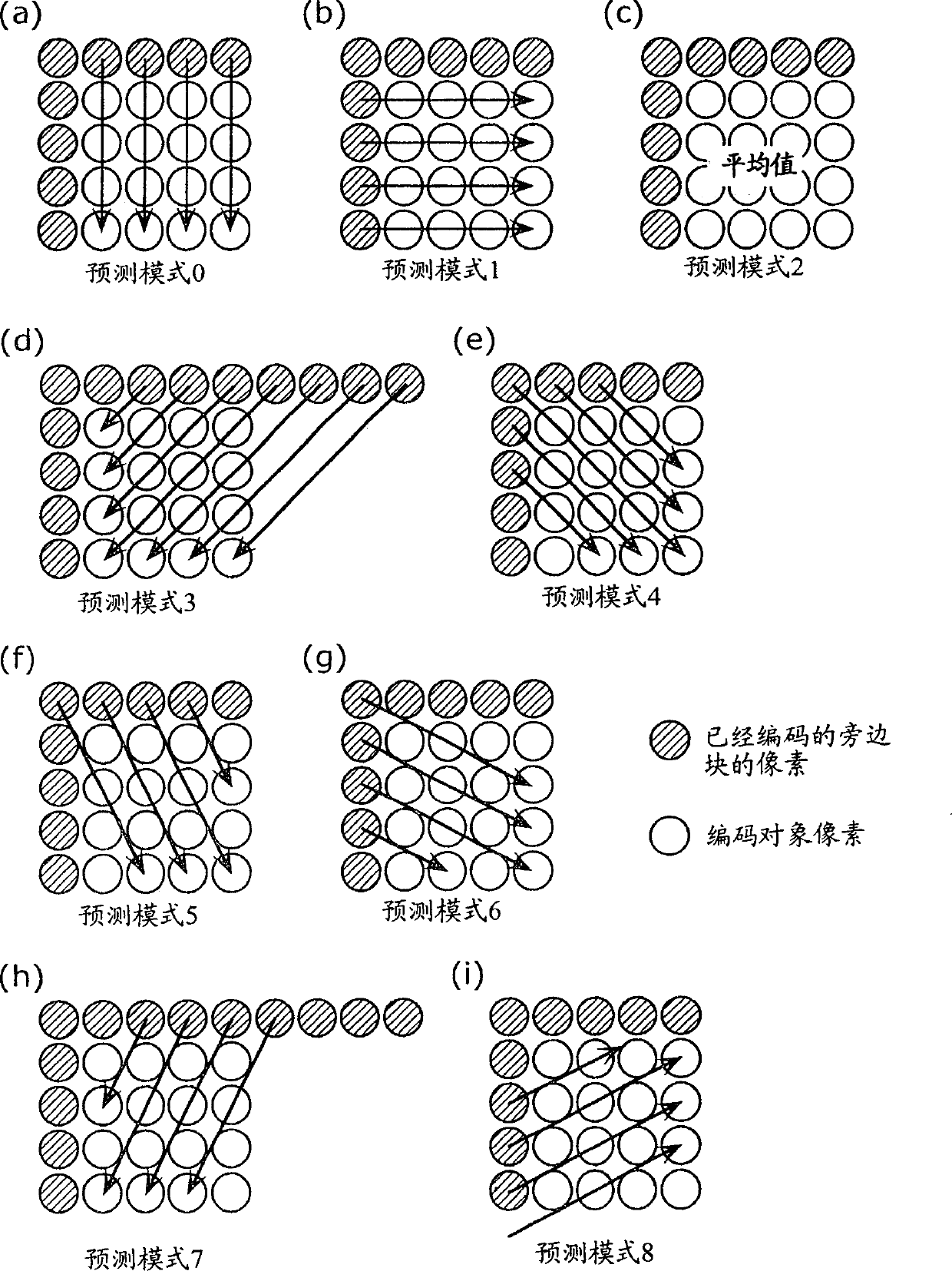

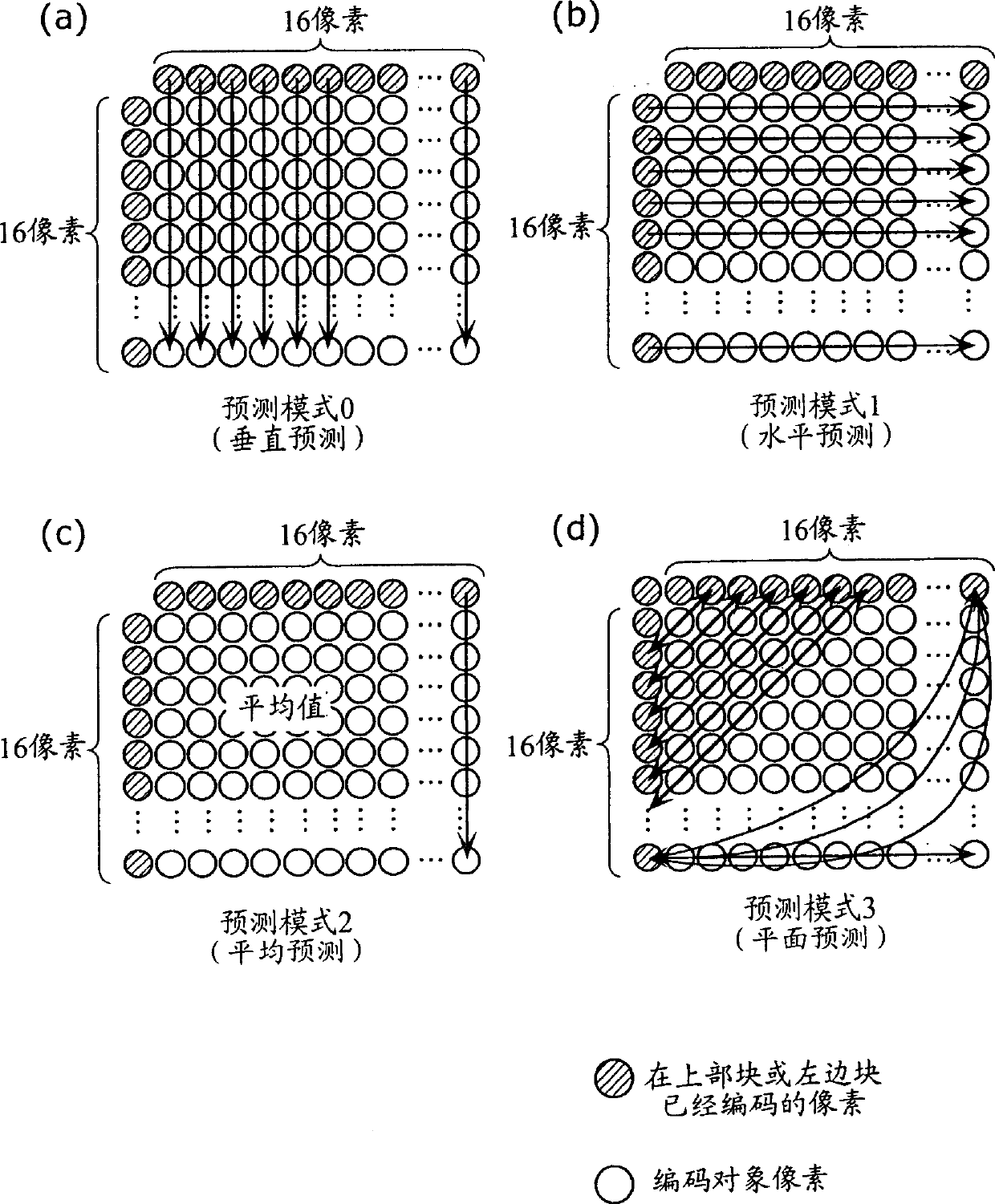

Intra prediction apparatus and intra prediction method

InactiveCN1791226AAvoid risky questionsImprove time shortening effectDigital video signal modificationIn planeOrthogonal transformation

The present invention provides an in-plane prediction device capable of avoiding the hazard problem and improving the effect of shortening the time. The in-plane prediction means (11) includes a method for performing in-plane prediction in units of second blocks (blocks) in which a first block (macroblock) constituting an image is divided into a plurality of second blocks (blocks), and at the same time performs plane prediction on the entire first block. Intra-prediction includes a prediction unit (113), an orthogonal transformation-quantization unit (115), an inverse-orthogonal transformation-inverse quantization unit (116), an adder (117) and an in-plane prediction device for controlling parallel execution of related predictions. unit (113), orthogonal transform and quantization unit (115), inverse orthogonal transform and inverse quantization unit (116), control unit for in-plane prediction of the block of the adder (117) and in-plane prediction of the whole macroblock (119 ).

Owner:PANASONIC CORP

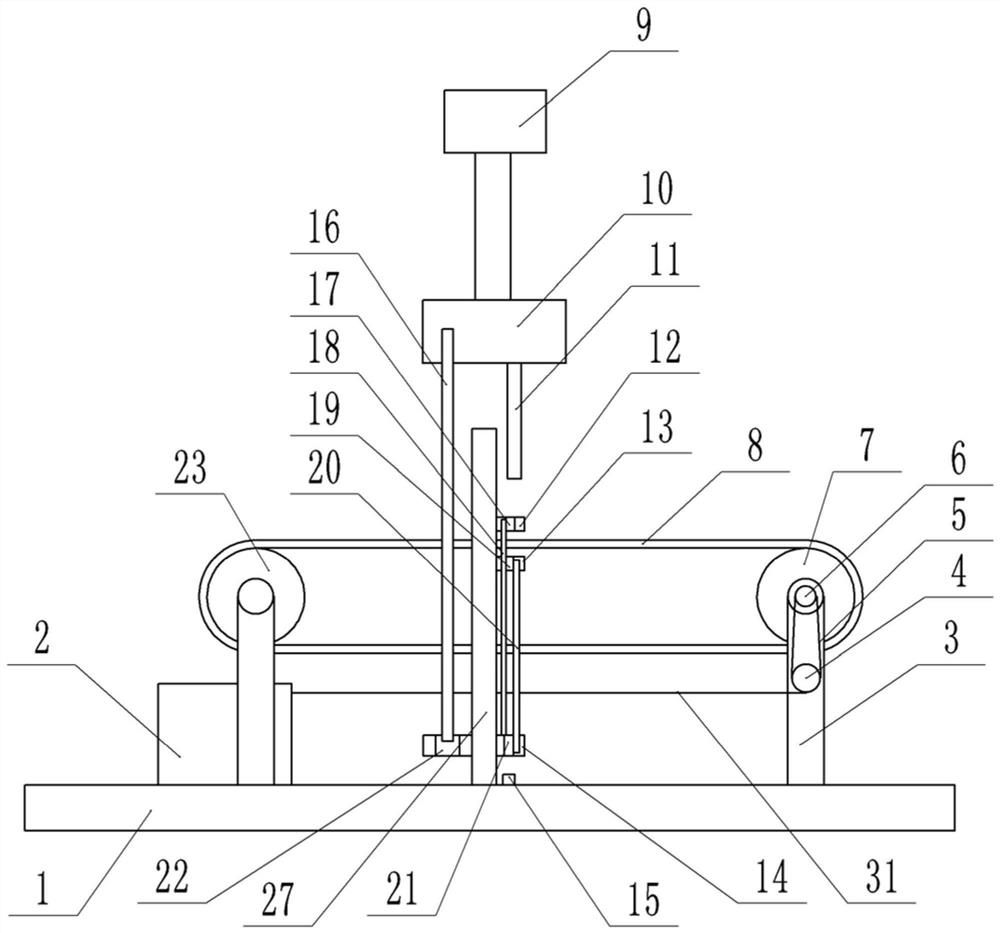

Empty bottle inspection method and empty bottle inspection machine thereof

InactiveCN108872258AShooting comprehensiveReduce in quantityOptically investigating flaws/contaminationEngineeringBottle

The invention discloses an empty bottle inspection machine, and relates to the technical field of manufacturing equipment. The empty bottle inspection machine has the advantage that while the disqualified empty bottle is found out, the cost of the equipment is reduced. The empty bottle inspection machine comprises a conveying belt, a rotary mechanism, an ejection mechanism, a camera and a processor, wherein the ejection mechanism is positioned just under the rotation mechanism; the conveying penetrates between the rotary mechanism and the ejection mechanism to convey; the conveying belt is provided with an opening for the ejection mechanism to penetrate through; the ejection mechanism is used for pushing the empty bottle up to be in contact with the rotary mechanism, and then the empty bottle is axially rotated; the camera is positioned at the location capable of photographing the empty bottle; the processor is connected with the camera, and is used for obtaining the images photographed by the camera, and processing the images so as to screen the disqualified products.

Owner:成都市金鼓药用包装有限公司

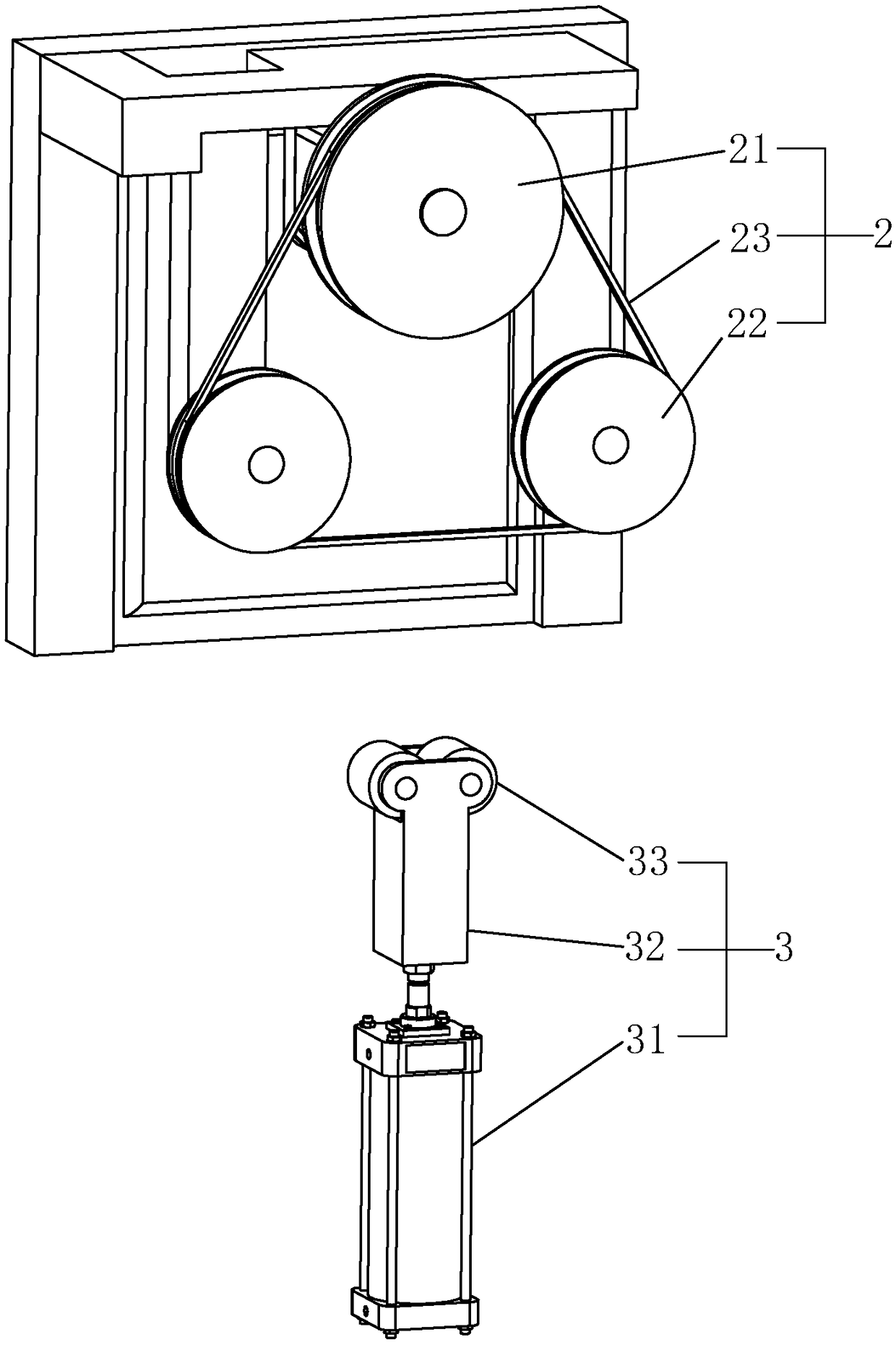

Lamp production assembly flow line

ActiveCN110394627AImprove assembly productivityInconvenient to change the assemblyMetal working apparatusEngineeringMechanical engineering

The invention relates to a lamp production assembly flow line. The lamp production assembly flow line comprises a moving mechanism, a down lamp conveying mechanism arranged perpendicular to the movingdirection of the moving mechanism, two snap spring conveying mechanisms symmetrically distributed on the two sides of the down lamp conveying mechanism, a pressing mechanism for pressing down lamps,and two snap spring mounting mechanisms mounted on the moving mechanism; and the snap spring mounting mechanisms comprise lifting cylinders vertically fixed on a sliding base, feeding cylinders horizontally fixed at output ends of the lifting cylinders, pneumatic clamps horizontally fixed at output ends of the feeding cylinders, and two mounting execution modules fixedly mounted at the front endsof the pneumatic clamps. The assembly flow line can realize full-automatic assembly of the down lamps and snap springs, can realize the batch flow operation, changes the problems of inconvenience to assemble, low efficiency and high cost in a traditional assembly mode, and greatly improves the down lamp assembly production efficiency.

Owner:TAIZHOU SRUITE IMP &EXP CO LTD

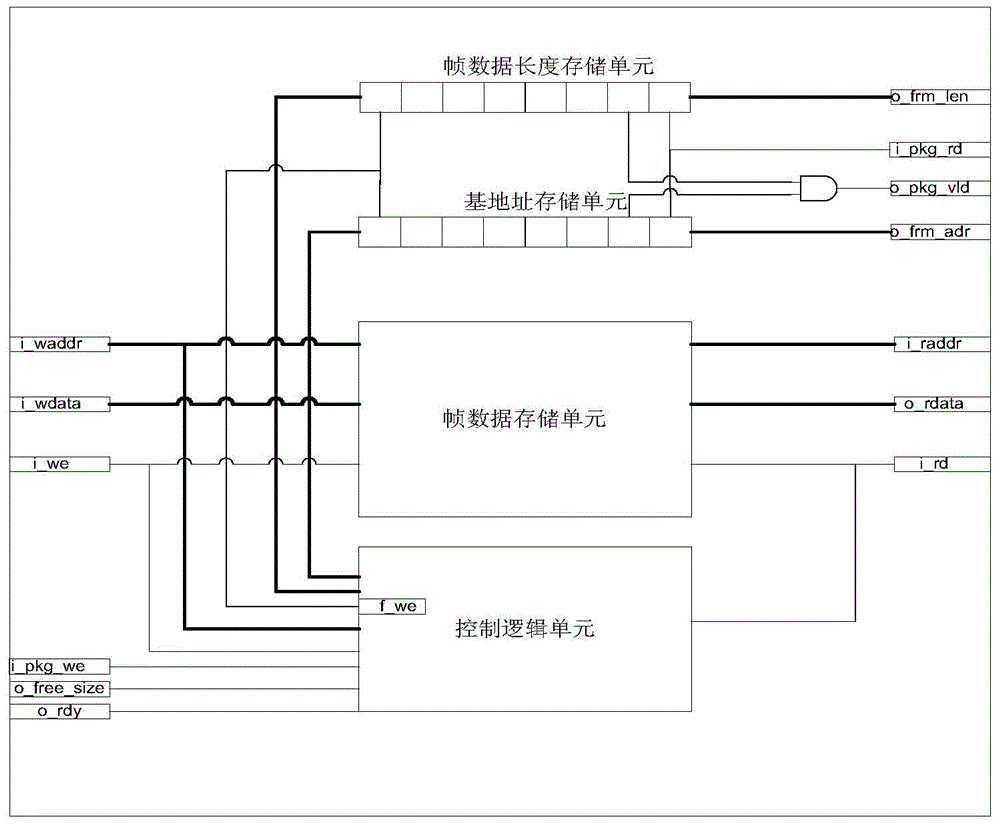

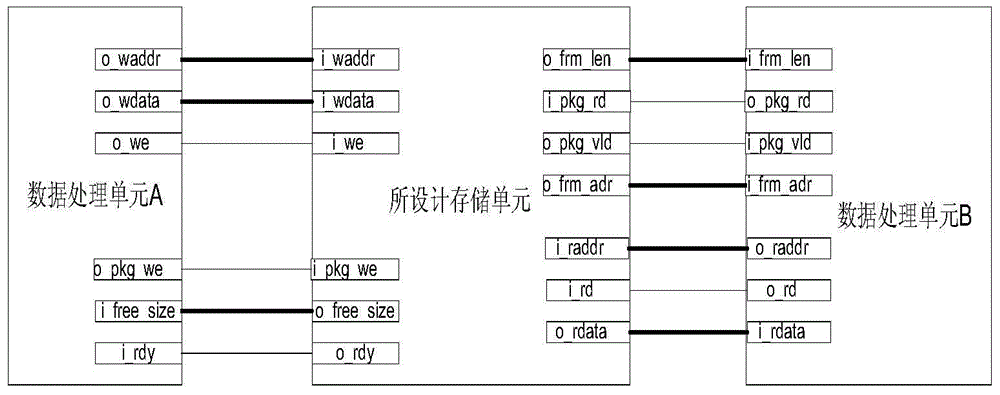

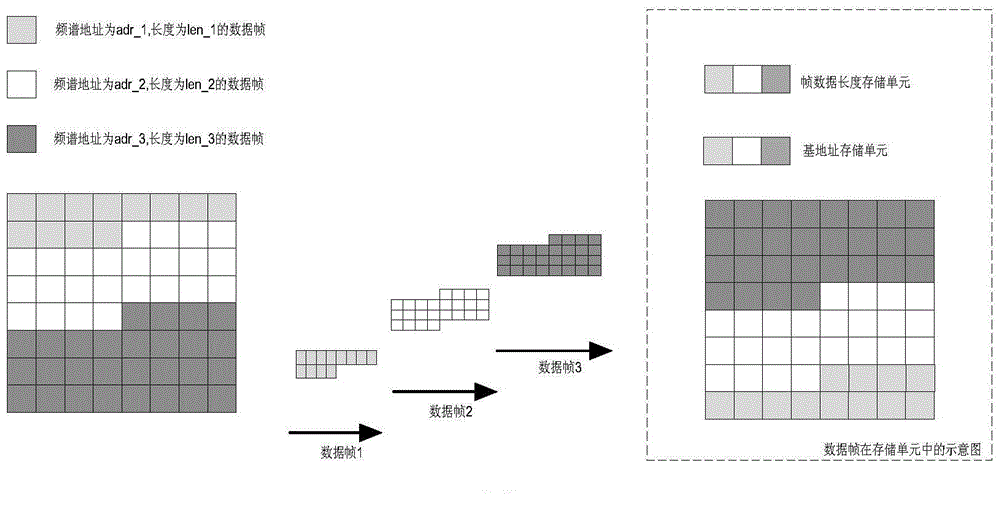

Device and method for improving baseband signal processing capacity of satellite navigation terminal receiver

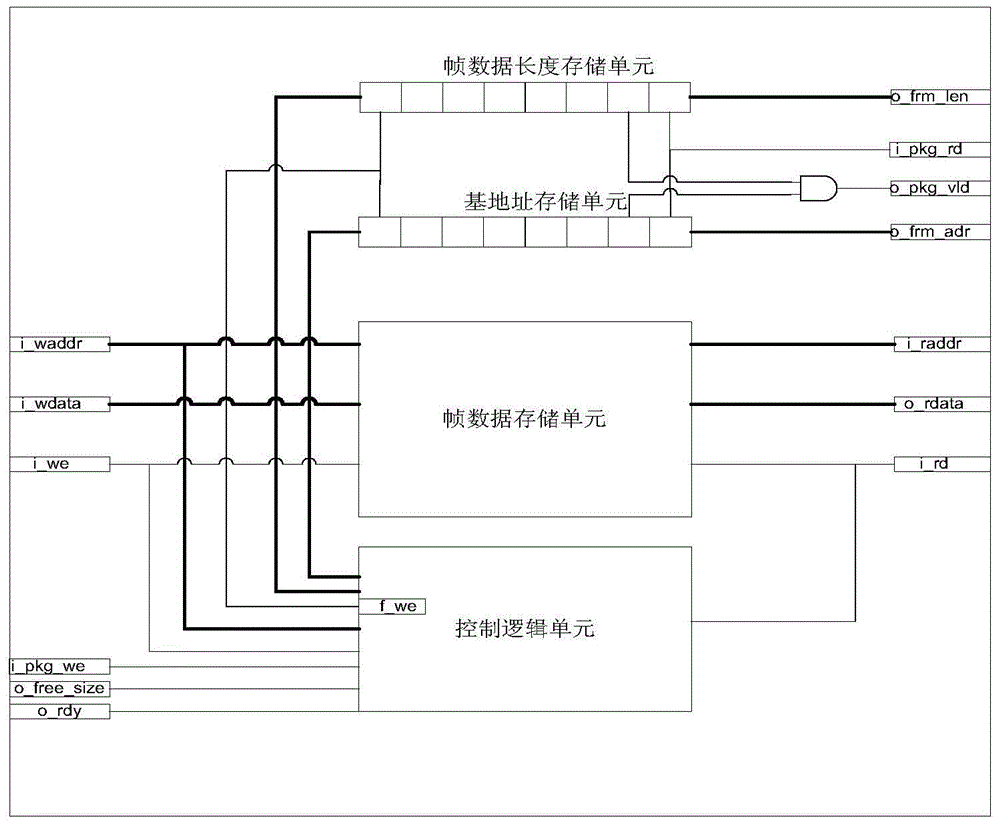

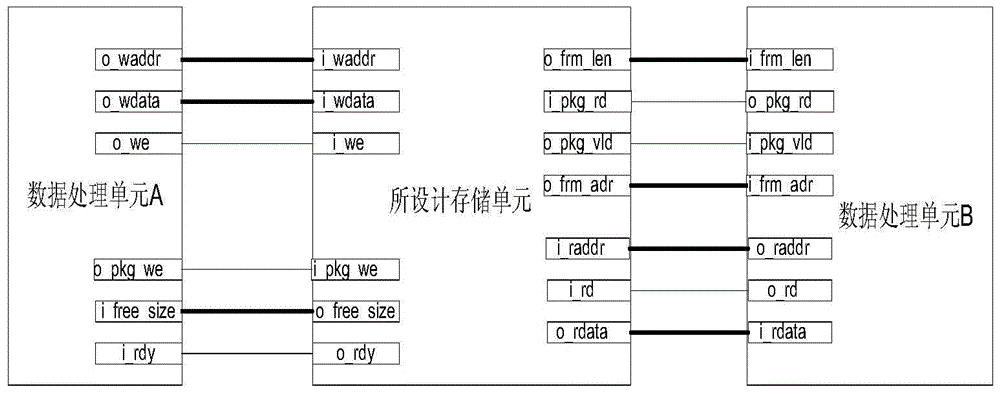

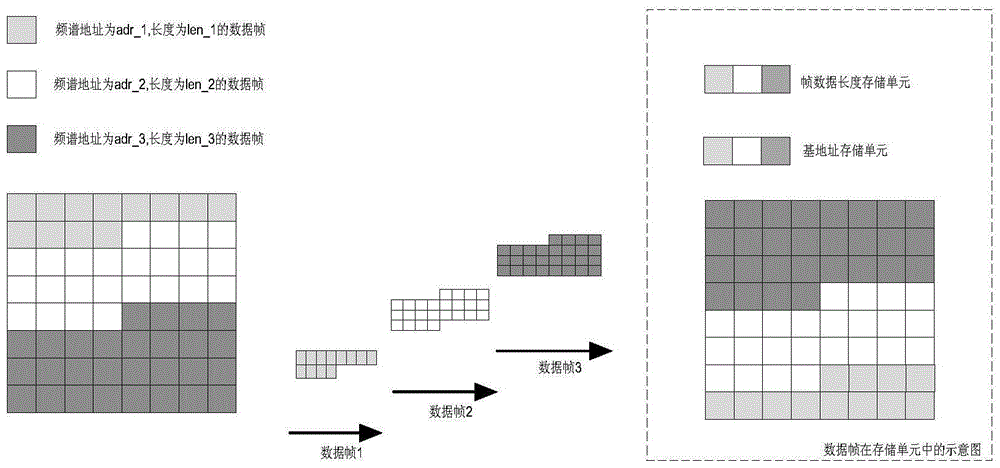

InactiveCN104407367ASave logic resourcesImprove processing powerSatellite radio beaconingData processingSatellite navigation

The invention discloses a device for improving the baseband signal processing capacity of a satellite navigation terminal receiver. The device comprises a frame data storage unit, a base address storage unit, a frame data length storage unit and a logic control unit, wherein the frame data storage unit is used for storing frame data information produced during baseband signal processing; the base address storage unit is used for storing base addresses of real physical space of data frames; the frame data length storage unit is used for storing the information of the length taking each byte of each data frame as a unit; and the logic control unit generates storage state information for an external port. The device is connected to a baseband signal processing system through the storage units in a cascading manner, signal processing data units in the system can process data without specific laws in the same manner for processing regular data, design complicity of logic circuits of the signal processing data units is simplified, and the data processing capability of the whole baseband processing system is improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

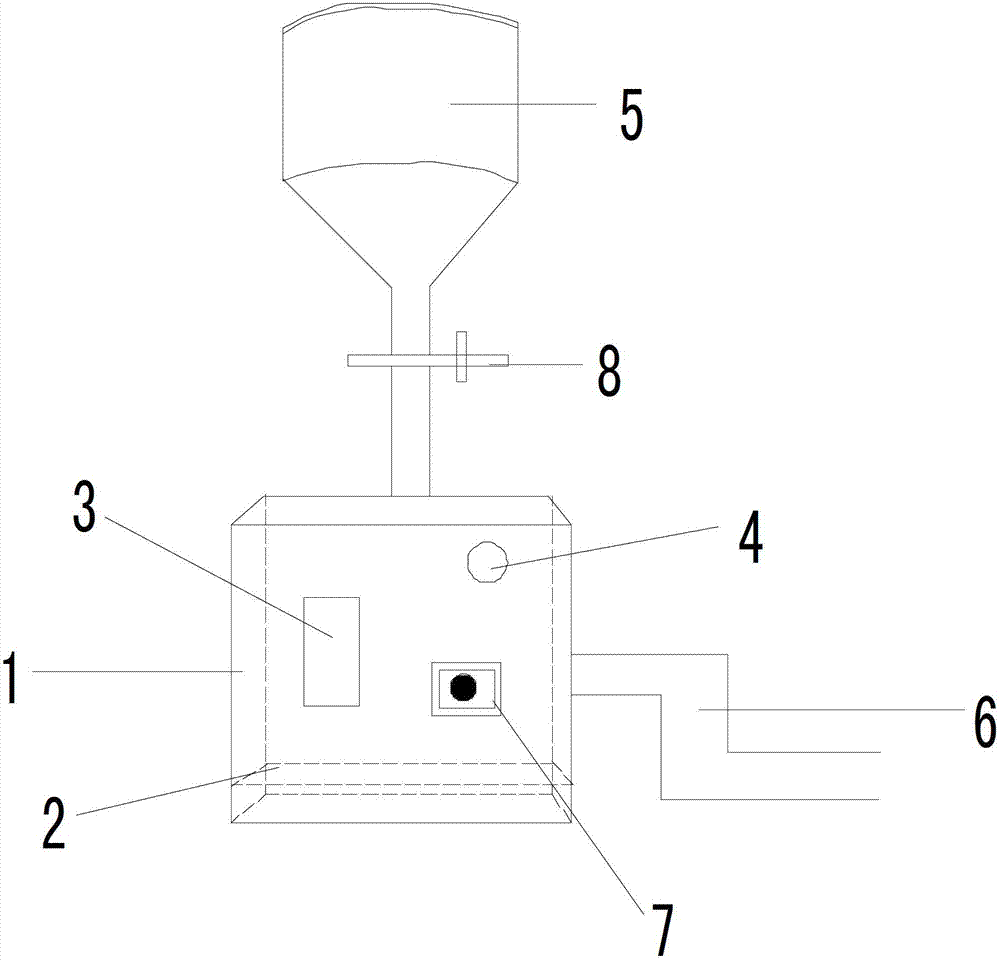

A metering weighing apparatus

InactiveCN103592012AEasy to useSave human effortSpecial purpose weighing apparatusLiquid crystalMaterial resources

The invention discloses a metering weighing apparatus comprising a stocker. A baffle plate is arranged inside the stocker. A weighing sensor is arranged in a cavity formed between the baffle plate and the lower surface of the stocker. The weighing sensor is connected with a processor. The external surface of the stocker is provided with an LCD liquid crystal screen and a unit conversion button. The upper end of the stocker is provided with a feeding cylinder. The lower end of the stocker is provided with a discharging cylinder. The beneficial effects of the present invention are that: the weighing sensor is arranged inside the stock, so that the stocker is integrated with the weighing structure; the usage is convenient; manpower and material resources are saved; the efficiency is high; the upper end of the stocker is provided with the feeding cylinder and the lower end of the stocker is provided with the discharging cylinder, so that streamline production of the whole production is realized; and the external surface of the stocker is provided with the LCD liquid crystal screen and the unit conversion button which are respectively used for displaying correlated parameters and unit conversion; so that the calculating is convenient and the observation is easy.

Owner:西安秦昊电子技术有限责任公司

Silicon carbide dynamic detection equipment

ActiveCN113253087AMeet testing needsImprove performanceConveyorsControl devices for conveyorsCarbide siliconEngineering

The invention belongs to the technical field of semiconductor detection equipment, and particularly relates to silicon carbide dynamic detection equipment which comprises a detection equipment main body and a sample introduction device, the sample introduction device comprises a vertical frame and a shell, a wire connected with a silicon carbide device port and a wiring port of the detection equipment main body is laid on the vertical frame, and the shell is connected with the silicon carbide device port. One end of the wire, which is used for being inserted into the port, adopts a conductive metal column; a penetrating port is formed in the top of the shell; and a sample storage box, a sample conveying device, a sample collection box and a controller are arranged in the shell, the sample conveying device is located between the conductive metal column and the sample storage box, and the sample conveying device is used for conveying a silicon carbide device to a proper position. The silicon carbide dynamic detection equipment develops a sample introduction device which is matched with silicon carbide detection equipment and can be used for continuous detection, all silicon carbide devices to be detected can be continuously tested, and compared with the traditional process of testing the devices one by one, the speed is greatly improved, and the manpower is saved.

Owner:陕西开尔文测控技术有限公司

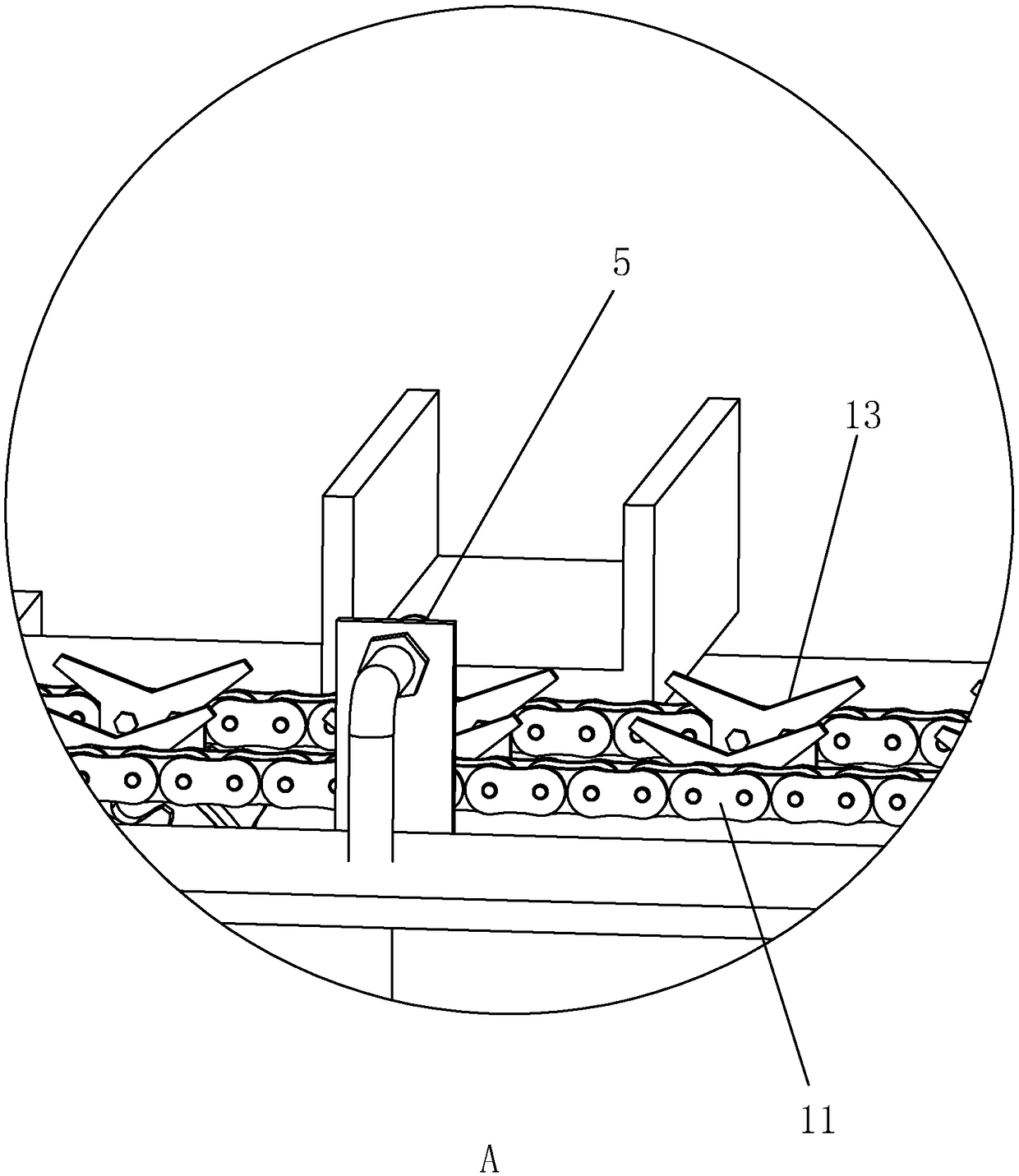

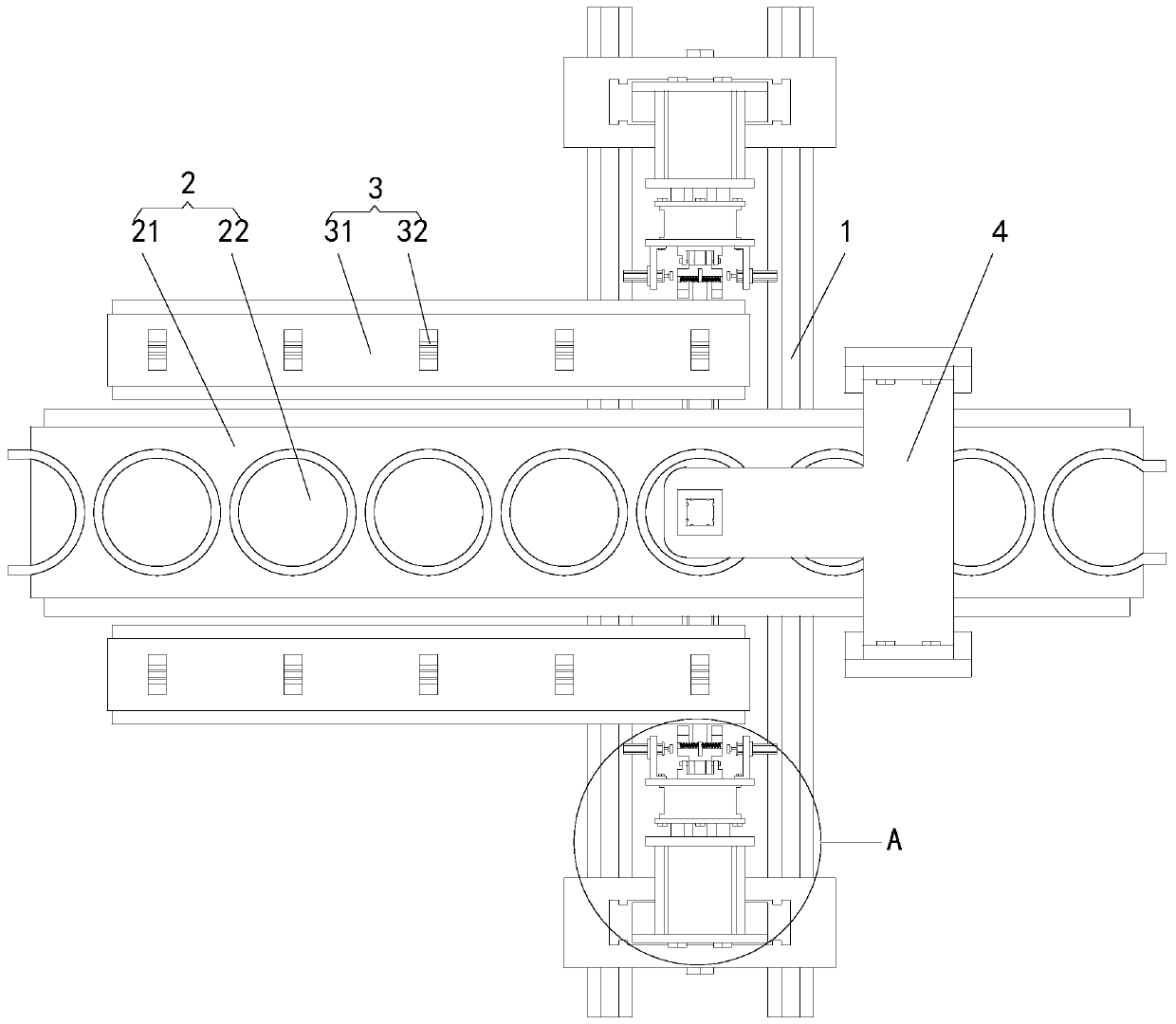

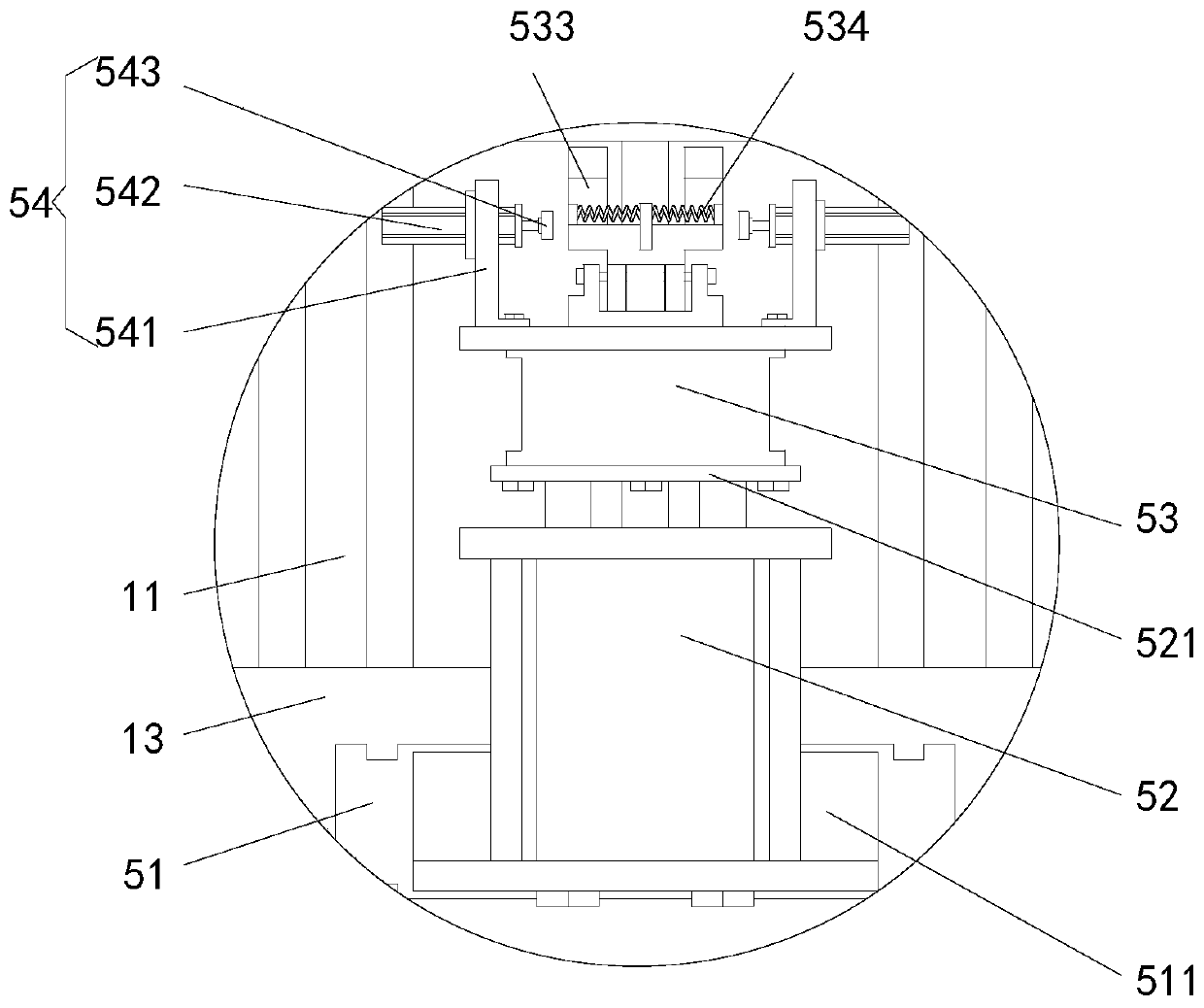

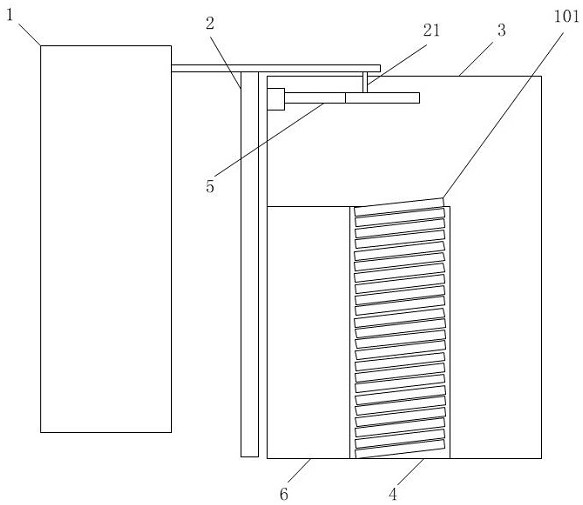

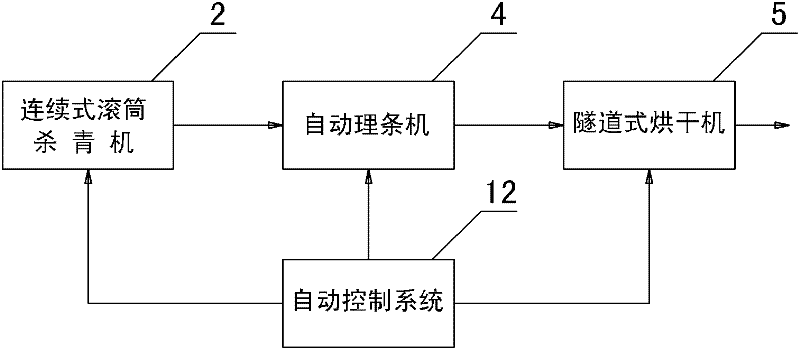

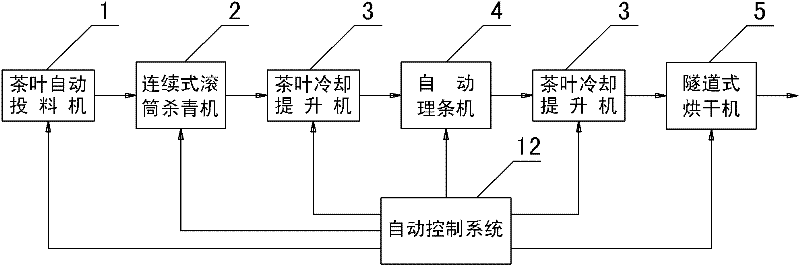

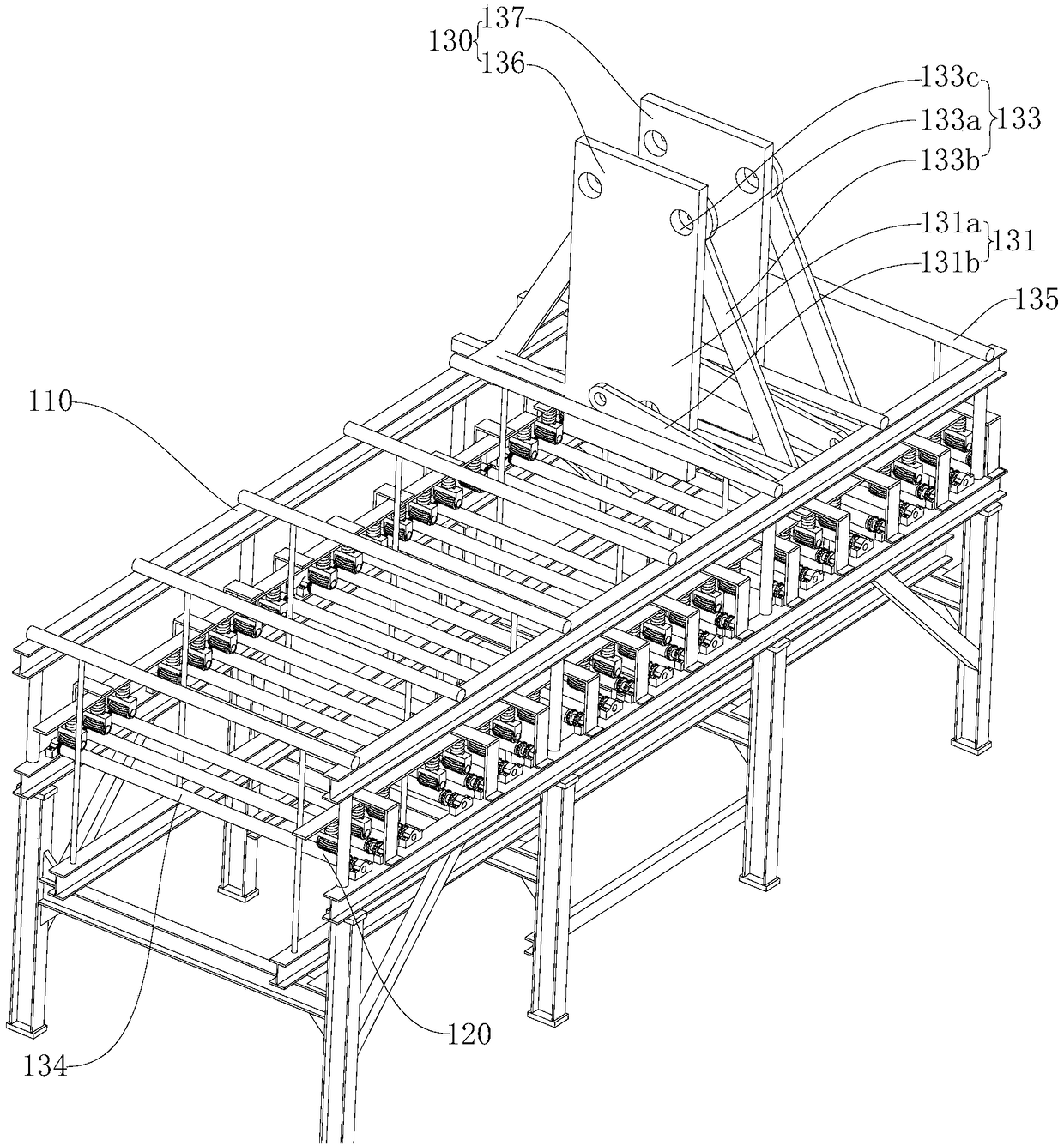

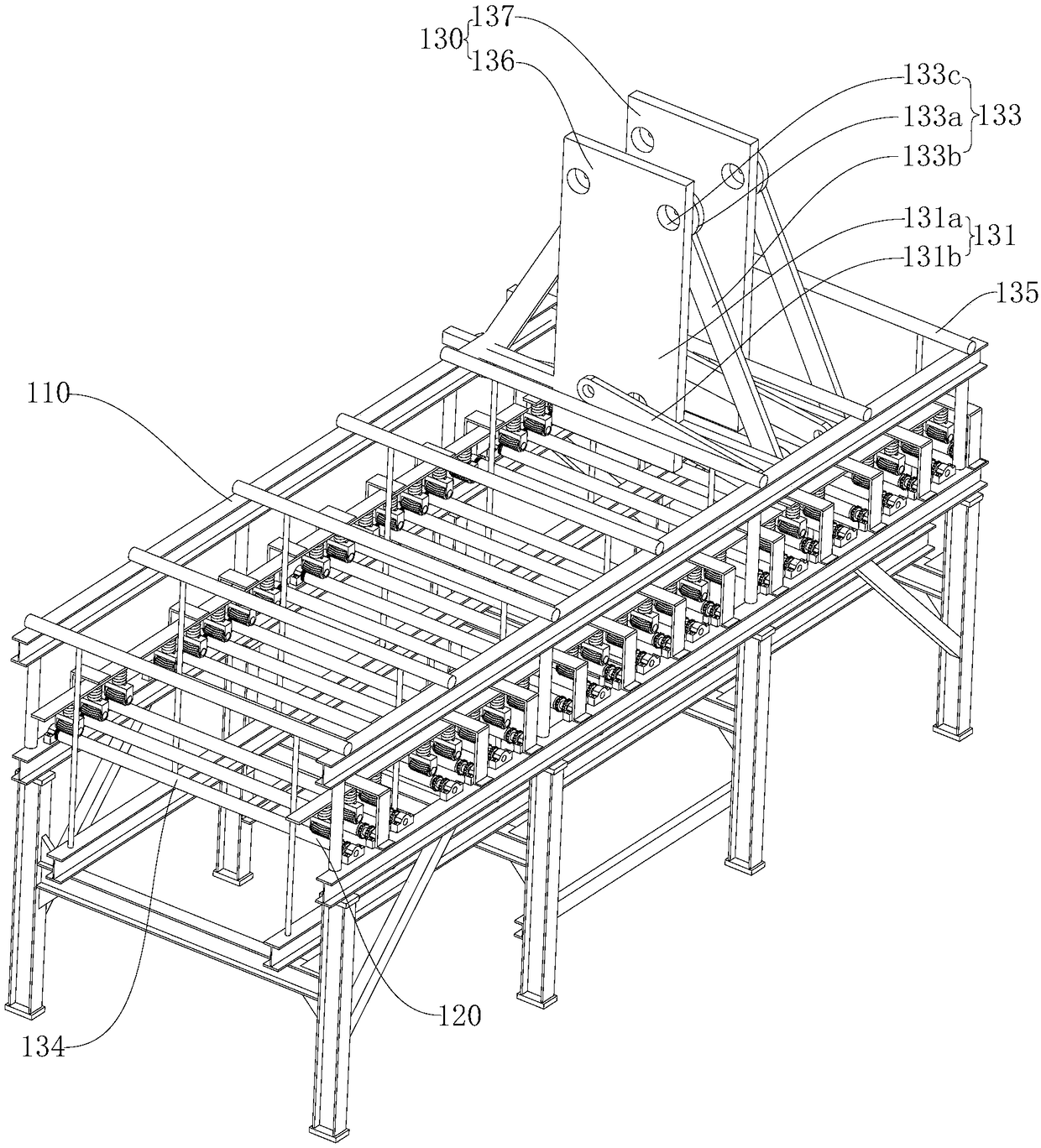

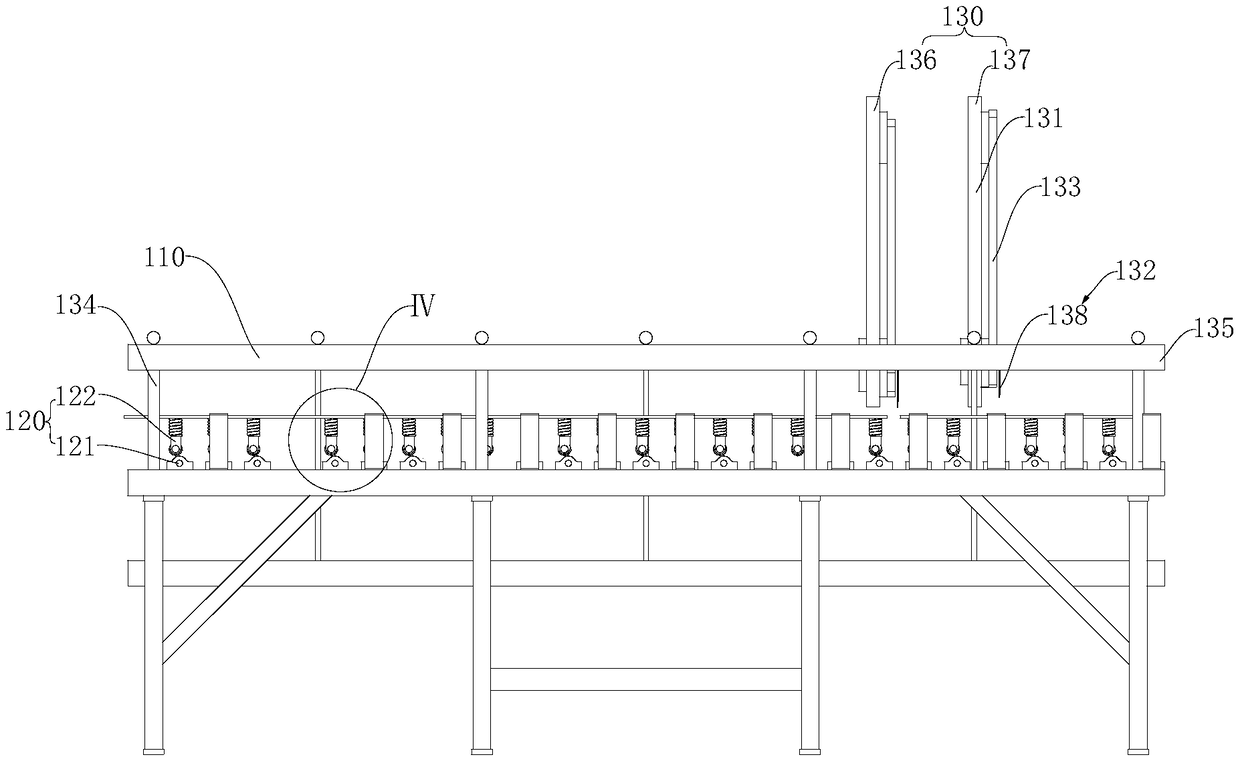

Complete equipment for flow-line production of Maofeng tea (produced in Huangshan Mountain, Anhui, China)

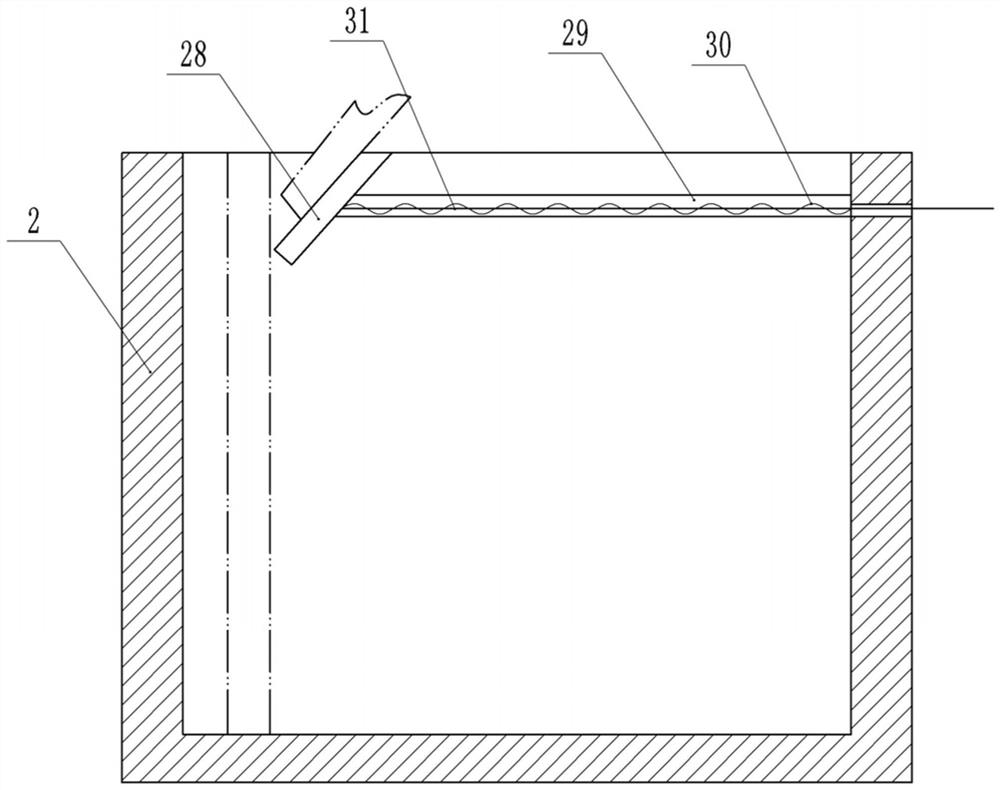

ActiveCN102640811AAchieve continuous flowStreamliningPre-extraction tea treatmentQuality levelAutomatic control

The invention discloses complete equipment for flow-line production of Maofeng tea (produced in Huangshan Mountain, Anhui, China). The complete equipment comprises a continuous cylinder inactivating machine, an automatic tea carding machine, a tunnel type dryer and an automatic control system, wherein the continuous cylinder inactivating machine, the automatic tea carding machine and the tunnel type dryer are connected with one another; the tunnel type dryer comprises a rack and a drying tunnel arranged on the rack; a heating device is arranged at the top of the drying tunnel; a tea leaf conveying belt and supporting flat plates adhered to the tea leaf conveying belt are arranged at the bottom of the drying tunnel; a stripped plucking device perpendicular to the movement direction of the tea leaf conveying belt is arranged between the supporting flat plates; and the automatic control system is connected with all processing equipment and is used for controlling all the processing equipment on the complete equipment for the flow-line production of the Maofeng tea. The complete equipment for the flow-line production of the Maofeng tea has high automation degree, stability and safety in operation and small dust pollution and does not damage tea leaves; and a finished product of the Maofeng tea has aromatic flavor, high quality level and very high popularization value.

Owner:浙江丰凯机械股份有限公司

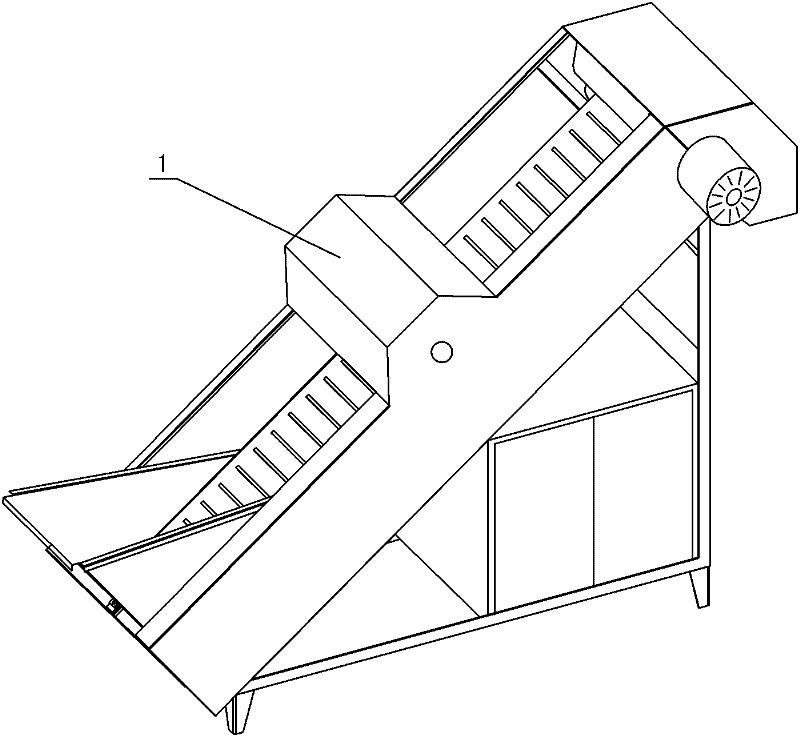

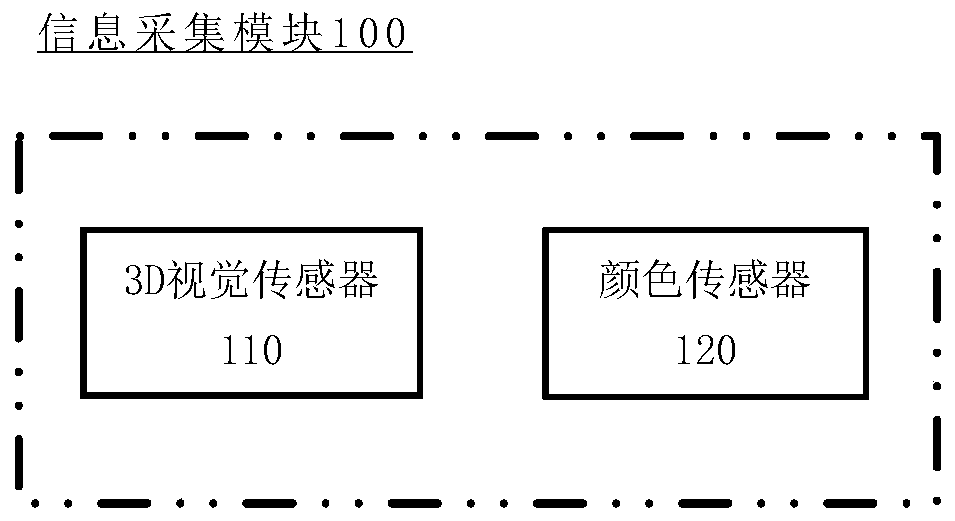

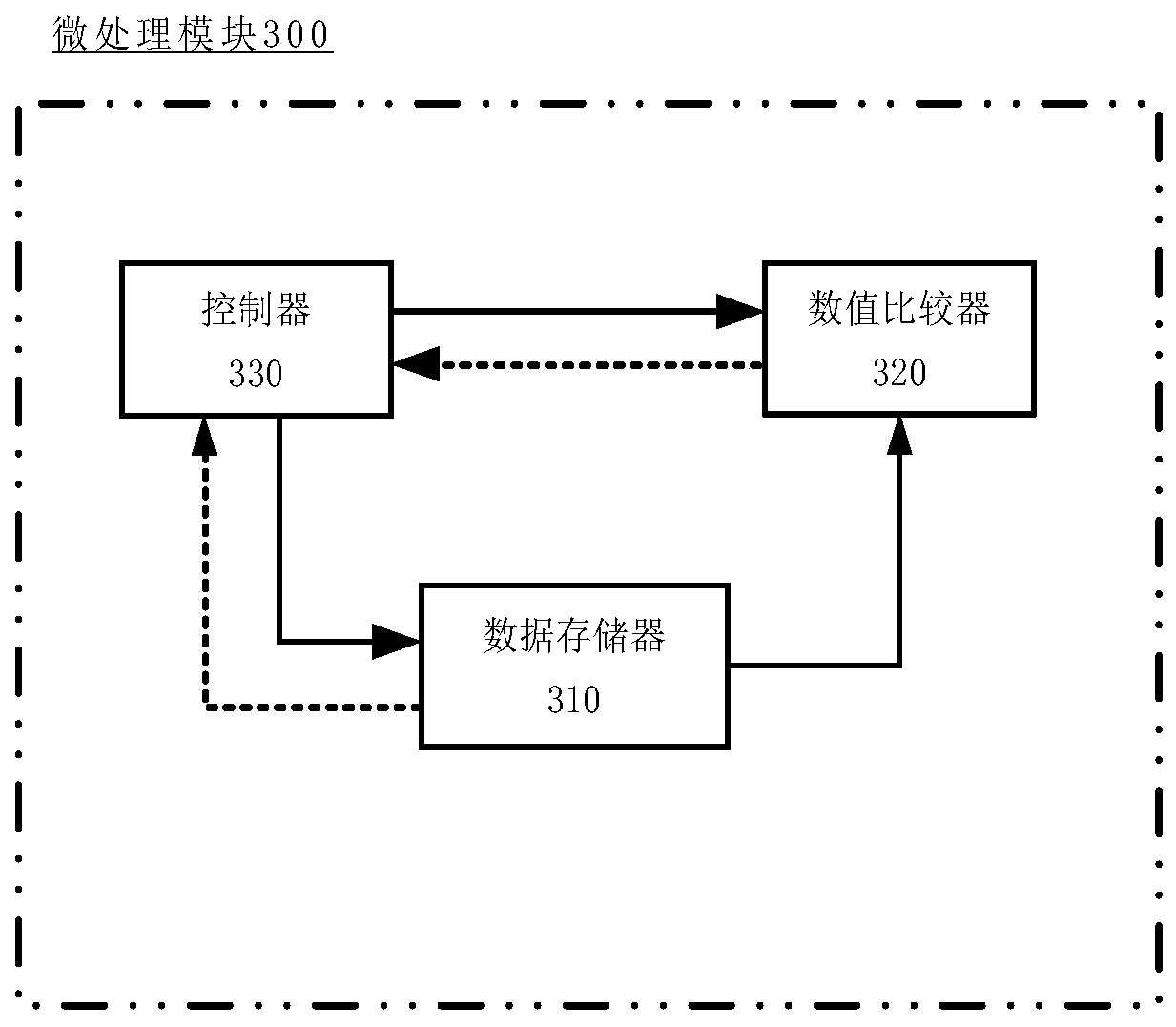

Industrial 3D visual inspection system

InactiveCN111504458AEasy to viewEasy to recordColor measuring devicesSteroscopic systemsVisual inspectionData memory

The invention discloses an industrial 3D visual detection system. The system comprises an information acquisition module, an A / D converter, a micro-processing module, a display screen, an alarm and amulti-dimensional manipulator; the information acquisition module comprises a 3D visual sensor and a color sensor; the input end of the A / D converter is connected with the output end of the information acquisition module; the output end of the A / D converter is connected with the input end of the micro-processing module; the micro-processing module comprises a data memory, a numerical value comparator and a controller; the input end of the numerical value comparator is in one-way connection with the output end of the data memory; the controller is in two-way connection with the data memory; thecontroller is in two-way connection with the numerical value comparator; the display screen and the alarm are connected with the output end of the micro-processing module; and the 3D visual sensor and the color sensor are both arranged on the multi-dimensional manipulator. According to the system, X-axis, Y-axis and Z-axis linkage omnibearing data detection can be achieved, and automatic, streamlined and large-scale operation of data detection and data analysis is achieved.

Owner:沈阳祥宝科技有限公司

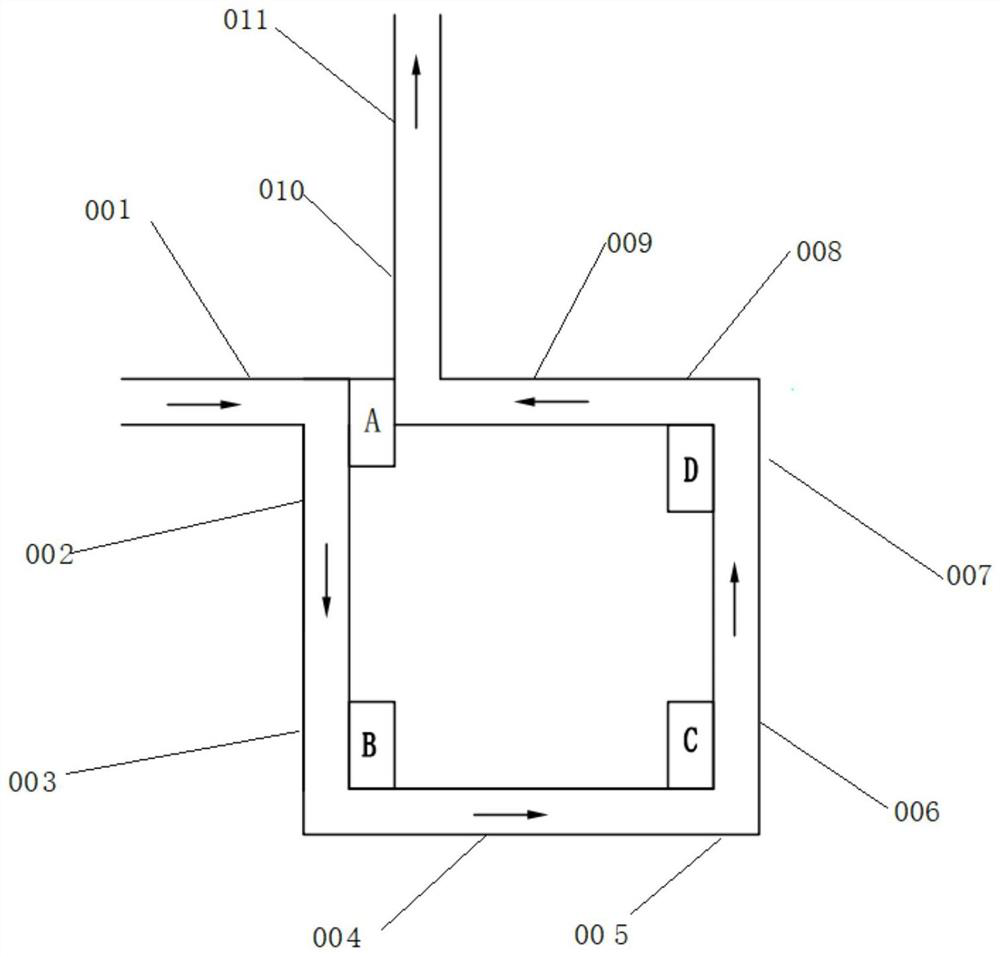

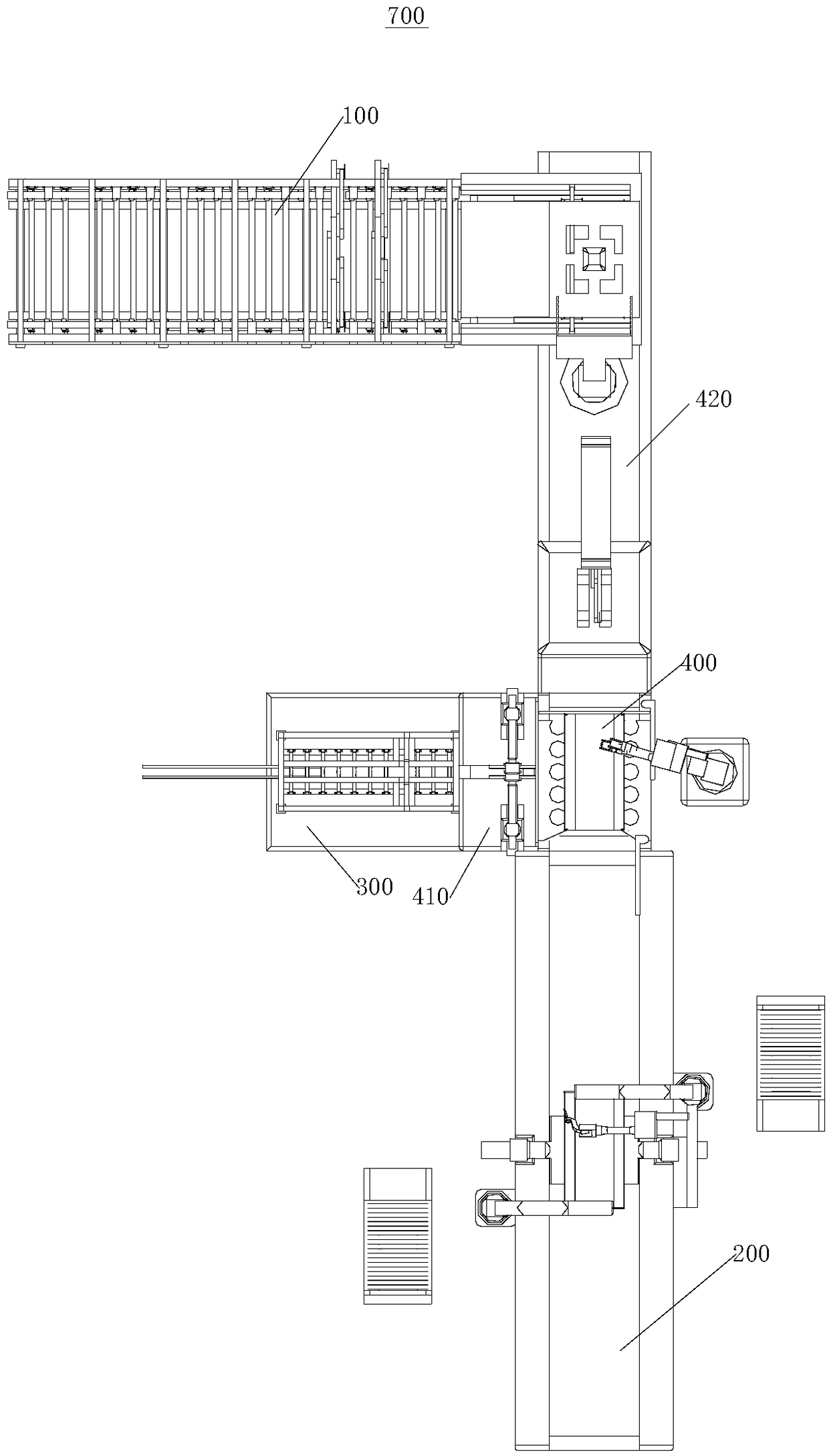

Closed-loop old automobile disassembling assembly line matching remanufacturing and disassembling process of closed-loop old automobile disassembling assembly line

InactiveCN111891262ARealize multi-station disassemblyRealize collinear dismantlingVehicle dissasembly recoverySolid waste disposalNew energyAssembly line

The invention discloses a closed-loop old automobile disassembling assembly line matching remanufacturing. The assembly line is provided with a closed-loop assembly line with a square-shaped structureand a special inlet and outlet station, and two disassembling stations are arranged around the assembly line with the square-shaped structure; double rails are laid on the ground around the assemblyline; different disassembling devices are installed on the inner sides or the outer sides of the rails and matching the disassembling stations, a waste automobile linearly walks and stays on the stations through a plurality of trolleys matching the double rails, lifting disassembling or station transferring is conducted at the corners through intelligent clamps, and waste automobile assembly linedisassembling is conducted in a closed-loop operation transmission mode. According to the reverse process of vehicle production, disassembly stations are flexibly and reasonably arranged for fuel vehicles and new energy vehicles in the current market, and collinear disassembly is achieved; and a plurality of disassembling stations are flexibly arranged, so that the disassembling requirements of waste automobiles with different types, different sizes, different shapes and different devices are met, and automatic, streamlined and comprehensive disassembling is realized.

Owner:JIANGSU UNIV OF TECH

Local area network dual-channel device discovery method

ActiveCN109361551AFlexible cuttingIncrease success rateData switching networksNetwork data managementTerminal equipmentClient-side

The invention relates to a local area network dual-channel device discovery method. In order to solve a technical problem of a device discovery technology purely based on Alljoyn, the local area network dual-channel device discovery method is provided. The method comprises the following steps: a server side device or a client side device starts device discovery through a broadcast or multicast mode; the device discovery is simultaneously transmitted through a first channel and the second channel through the broadcast or multicast mode, a first channel underlying layer uses an Alljoyn protocol,and a second channel underlying layer uses a UDP discovery protocol; the target device selects the first channel and / or the second channel to receive information according to a protocol type supported by the target device, and sends a connection establishment request; according to the connection establishment request, the server side device or the client side device establishes a connection withthe target discovery device. Such design can guarantee high discovery success rate of a local area network device, and is compatible to a strong terminal and a weak terminal.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Analysis method for vertical migration transformation rule of elements in soil

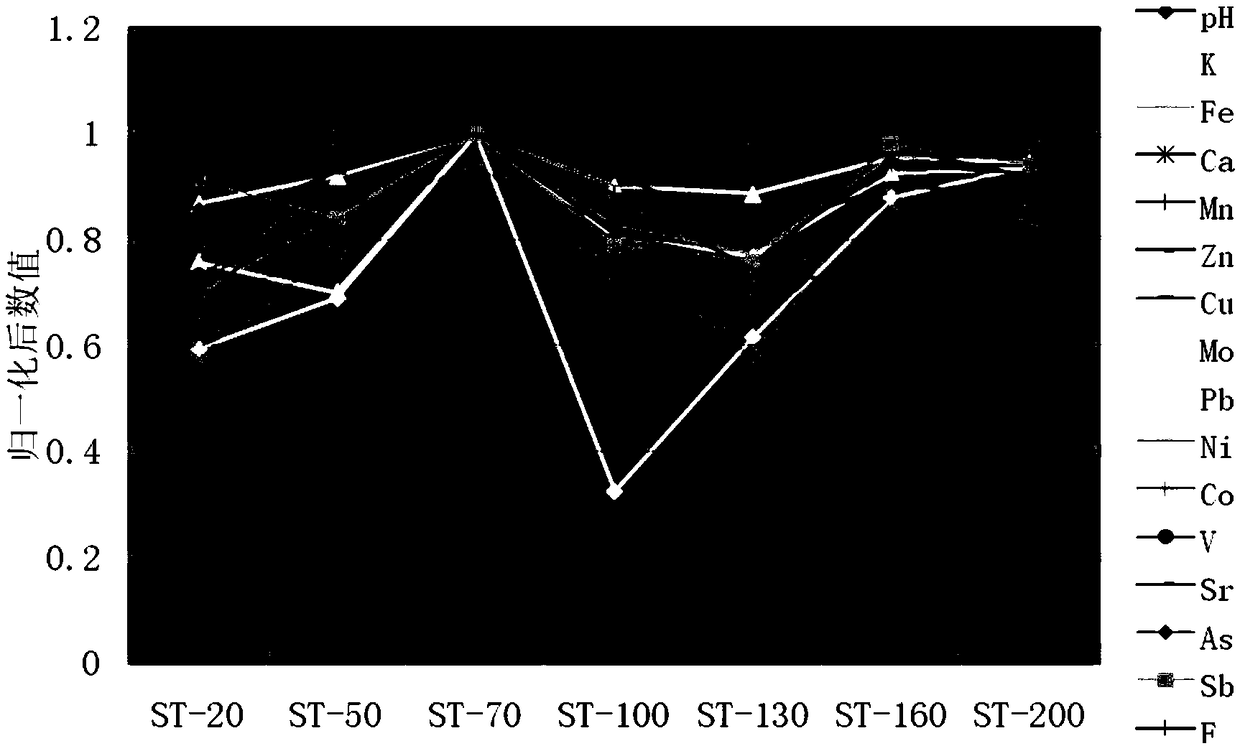

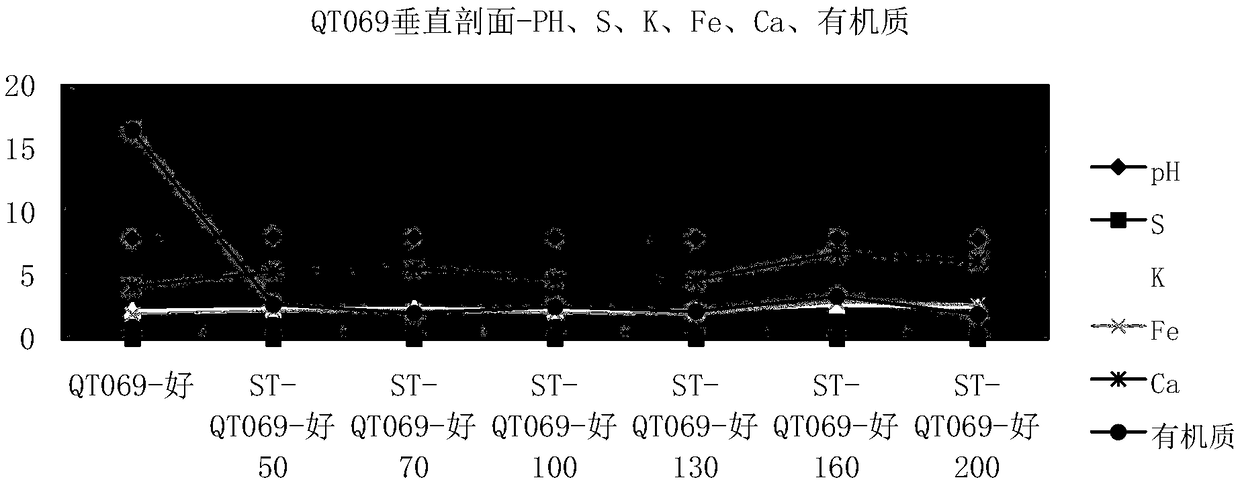

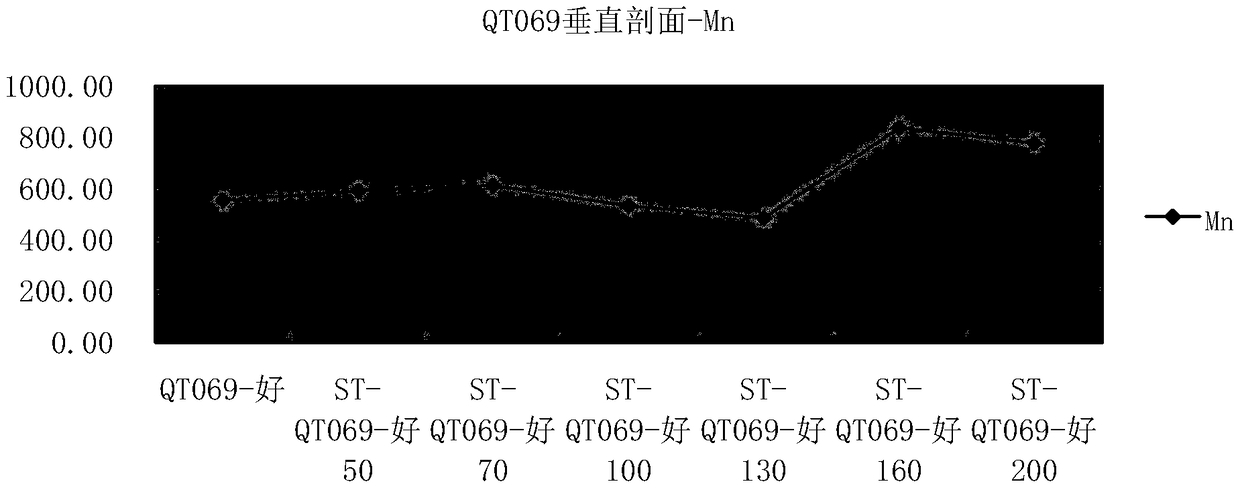

InactiveCN109444381ANot easy to compareSimple contentEarth material testingPattern recognitionOriginal data

The invention relates to an analysis method for a vertical migration transformation rule of elements in soil and belongs to the field of environment monitoring. The analysis method specifically comprises the following steps: choosing the maximum value of different elements and different depths of sampling results of all sampling points as a normalization denominator and respectively performing normalization treatment on all the elements; then calculating an arithmetical mean of the same element at the same depth of all the sampling points; based on the arithmetical mean, utilizing the maximumvalue at the depth as the denominator to perform normalization treatment again to achieve final basic data; then putting a change rule on a picture to perform contrastive analysis to find the verticalmigration rule of the elements in the vertical direction and the similarity of different elements. According to the method, a normalization method is utilized to process original data, so that the vertical migration rule of the elements and the similarity of the different elements can be more visually demonstrated, and time and the picture amount are remarkably reduced; furthermore, the similarity of element gathering rules is favorable for being found.

Owner:山东省地质矿产勘查开发局第一地质大队 +1

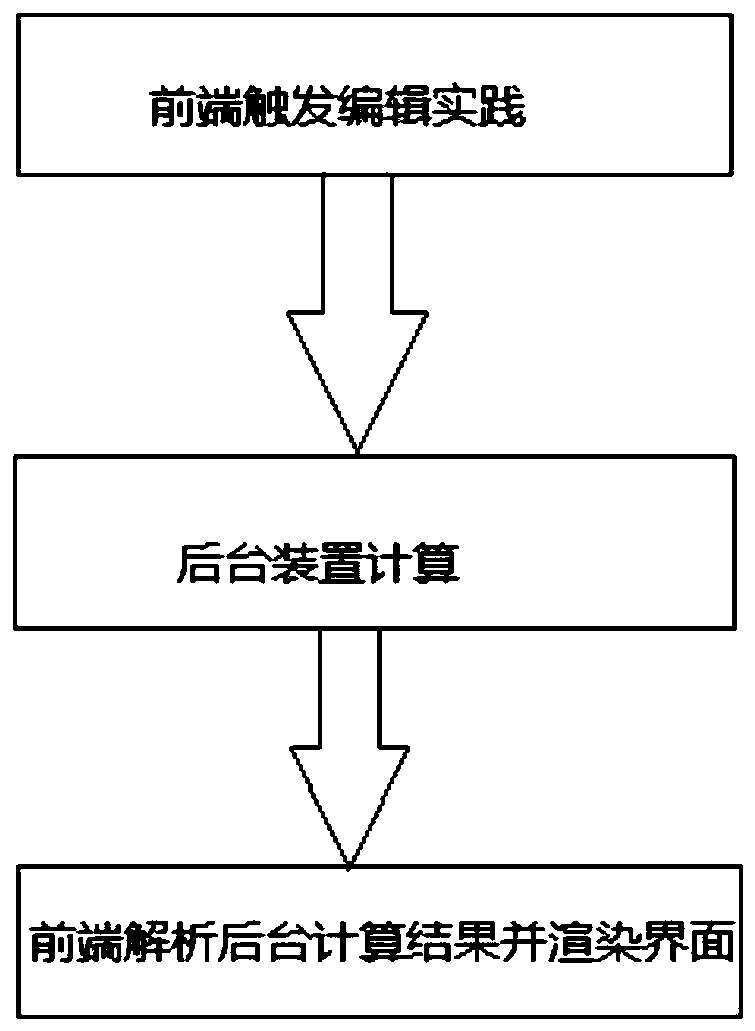

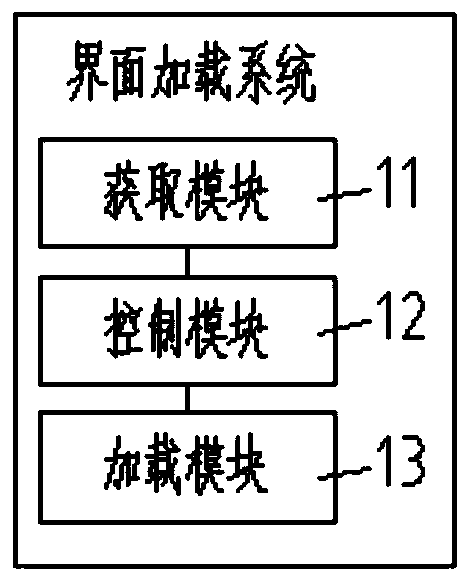

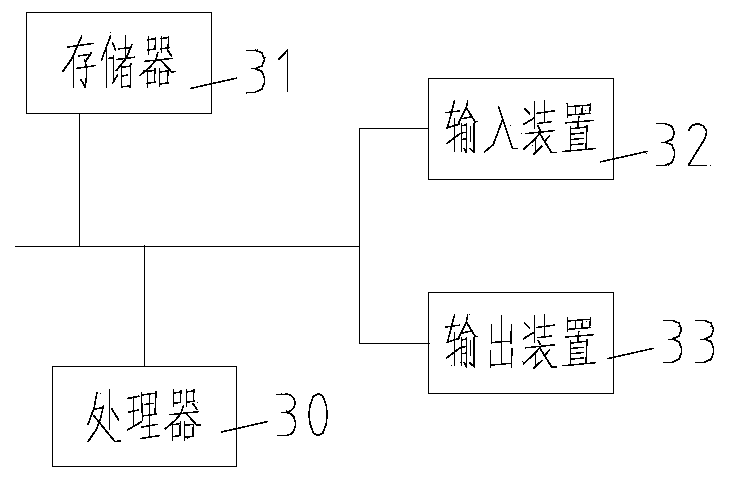

Interface loading method and system and computing device

PendingCN111401020AStreamliningEasy to maintainText processingProgram loading/initiatingPlug-inService control

The invention relates to an interface loading method and system and computing equipment, and the method comprises the steps: obtaining and processing to-be-loaded resource information on an interface,and obtaining the to-be-loaded resource information of a needed target type; determining to-be-loaded resource information of a target type, and processing the to-be-loaded resource information by utilizing the analysis plug-in to obtain loaded resource information; and returning the loaded resource information to the interface. According to the invention, unified processing is carried out by therear end, and a control result is informed to the front end, so that form control can be realized, the coding quantity of the front end is reduced, and unified maintenance is facilitated; as all control logics come from the judgment of the background on the original data, the problem that the form is incorrect due to logic judgment errors caused by front-end error data or too high scene complexity does not exist, and the accuracy of service control is improved.

Owner:YONYOU NETWORK TECH

A liquid crystal panel foreign object inspection system

ActiveCN105388642BStreamliningRealize intelligenceNon-linear opticsForeign matterLiquid-crystal display

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

Device and method for improving baseband signal processing capability of satellite navigation terminal receiver

InactiveCN104407367BSave logic resourcesReduce power consumptionSatellite radio beaconingPhysical spaceData information

The invention discloses a device for improving the baseband signal processing capacity of a satellite navigation terminal receiver. The device comprises a frame data storage unit, a base address storage unit, a frame data length storage unit and a logic control unit, wherein the frame data storage unit is used for storing frame data information produced during baseband signal processing; the base address storage unit is used for storing base addresses of real physical space of data frames; the frame data length storage unit is used for storing the information of the length taking each byte of each data frame as a unit; and the logic control unit generates storage state information for an external port. The device is connected to a baseband signal processing system through the storage units in a cascading manner, signal processing data units in the system can process data without specific laws in the same manner for processing regular data, design complicity of logic circuits of the signal processing data units is simplified, and the data processing capability of the whole baseband processing system is improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

A construction waste brick making device

ActiveCN111688014BUniform sizeWell mixedRotary stirring mixersTransportation and packagingBrickArchitectural engineering

The invention relates to a construction waste brick making device, which comprises a hammer crushing chamber, a screening and magnetic separation part, a river sand mixing chamber, a sand mill cylinder and a brick forming chamber. After hammering and rolling the construction waste, the ferromagnetic metal in it is removed by a magnetic separation mechanism with a specific structure, and after being evenly mixed with the river sand, the construction waste particles are processed by the rotating horizontal drum sand mill. After the sand is further ground, the mixture is extruded into bricks, thus realizing the efficient reuse of construction waste.

Owner:FENGLIN ENVIRONMENTAL PROTECTION TECH CO LTD

A silicon carbide dynamic detection equipment

ActiveCN113253087BMeet testing needsImprove performanceConveyorsControl devices for conveyorsCarbide siliconMechanical engineering

The invention belongs to the technical field of semiconductor testing equipment, and in particular relates to a silicon carbide dynamic testing equipment. The equipment includes a testing equipment main body and a sample feeding device. The wire connected to the port of the silicon device and the wiring port of the main body of the detection equipment, one end of the wire used to be inserted into the port adopts a conductive metal column, and the top of the shell is provided with a piercing port; the shell is provided with a sample storage box, a sample A transfer device, a sample collection box and a controller, the sample transfer device is located between the conductive metal column and the sample storage box, the sample transfer device is used to transfer the silicon carbide device to a suitable position. The invention develops a continuously detectable sampling device used in conjunction with silicon carbide testing equipment, which can continuously test all silicon carbide devices to be tested, which greatly improves the speed and saves manpower compared with the traditional device-by-device testing process.

Owner:陕西开尔文测控技术有限公司

A transformer case processing system and a transformer production system

ActiveCN106736188BMechanizationStreamliningWelding/cutting auxillary devicesAuxillary welding devicesTransformerMachining system

The invention relates to the field of equipment machining, and provides a transformer case machining system and a transformer production system. The transformer case machining system comprises case edge machining equipment, bottom plate machining equipment, side column machining equipment, first assembling equipment and cooing fin welding equipment. The first assembling equipment is connected with the case edge machining equipment, the bottom plate machining equipment and the side column machining equipment. The cooling fin welding equipment comprises a cooling fin conveying mechanism for receiving cooling fins, a cooling fin placing mechanism for placing the cooling fins, a cooling fin welding mechanism for welding the cooling fins and a cooling fin operation table where the cooling fins are placed. The cooling fin operation table comprises a stand column and a transformer support arranged on the stand column. According to the transformer case machining system, components in different working procedures can be spliced and welded, case streamline and mechanical machining is achieved on one workbench, and working efficiency is greatly improved.

Owner:江苏连变电气有限公司

soy product cutting machine

InactiveCN106695985BCutting operation omittedEasy to operateMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of cutting involving a plurality of linear cutting elements and discloses a bean product cutting machine. The bean product cutting machine comprises a base, a conveying mechanism, a first cutting device and a second cutting device, wherein the conveying mechanism is used for conveying bean products. The first cutting device is fixed on the base and positioned on one side of the second cutting device and is used for cutting the passing bean products on the conveying mechanism horizontally. The second cutting device comprises a supporting mechanism, a cutting mechanism and a driving mechanism, wherein the supporting mechanism is connected on the base and is provided with a supporting plate positioned on the same horizontal plane of a conveying belt, and the cutting mechanism comprises a connecting plate and a cutter group connected on the lower end face of the connecting plate. The bean product cutting machine is simple to operate and solves the problem that existing cutting equipment is complex to operate.

Owner:CHONGQING SHUNTAI FOOD

Complete equipment for continuous laser welding

The invention relates to the field of automatic welding, in particular to complete equipment for continuous laser welding. The complete equipment for continuous laser welding comprises a clamping mechanism, a laser welding mechanism is slidably connected above the clamping mechanism, the clamping mechanism comprises a vertical frame, the vertical frame is rotatably connected with a first rotating column, a second rotating column and a third rotating column, the first rotating column, the second rotating column and the third rotating column are fixedly connected with a first cross bar, a second cross bar and a third cross bar respectively, clamping heads are arranged at the end parts of the first cross bar and the second cross bar, the other ends of the first cross bar and the second cross bar are rotatably connected with a first connecting rod and a second connecting rod respectively, one end of the first connecting rod and one end of the second connecting rod are rotatably connected with the two ends of the third cross bar correspondingly, the third rotating column is fixedly connected with a driving handle, and a driving rod is connected between the laser welding mechanism and the driving handle; and the equipment further comprises a conveying mechanism, and the lower parts of the two ends of the third cross bar are provided with a first button and a second button correspondingly. According to the scheme, parts are automatically clamped and loosened, and the whole welding efficiency is improved.

Owner:RICH HIGH TECH CO LTD

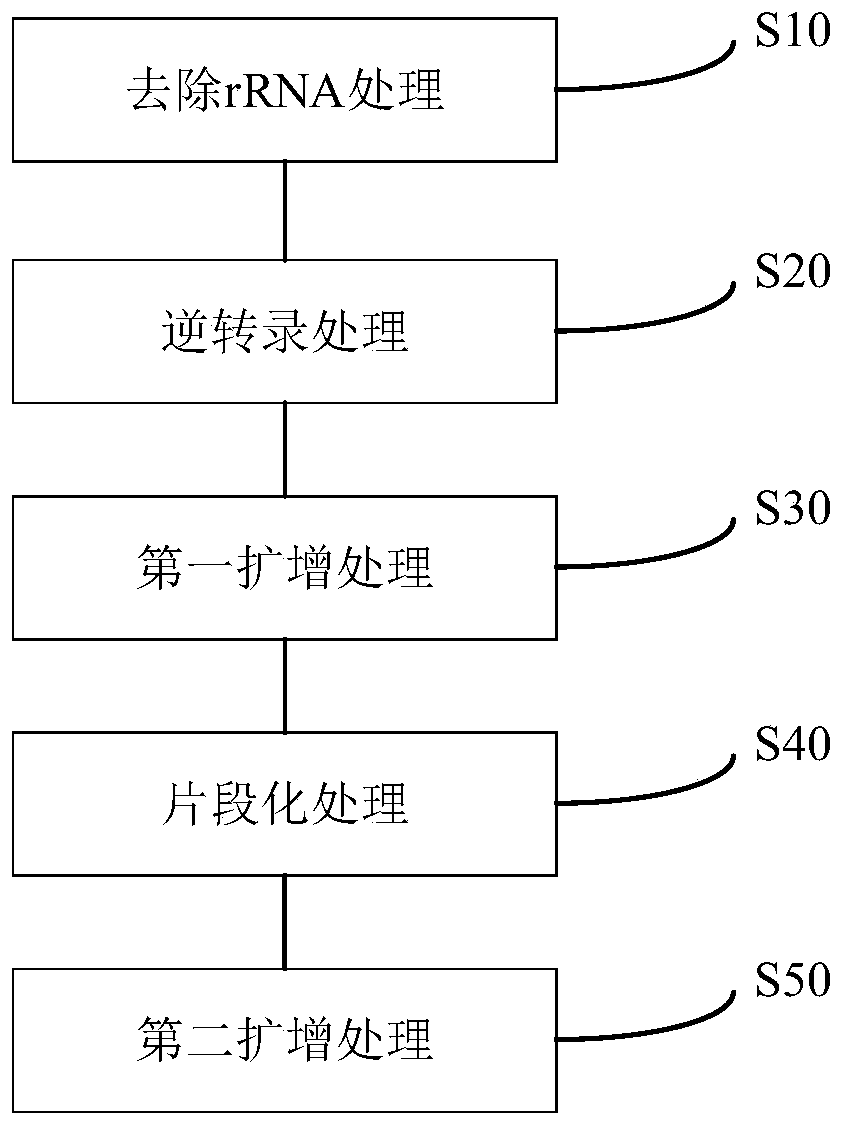

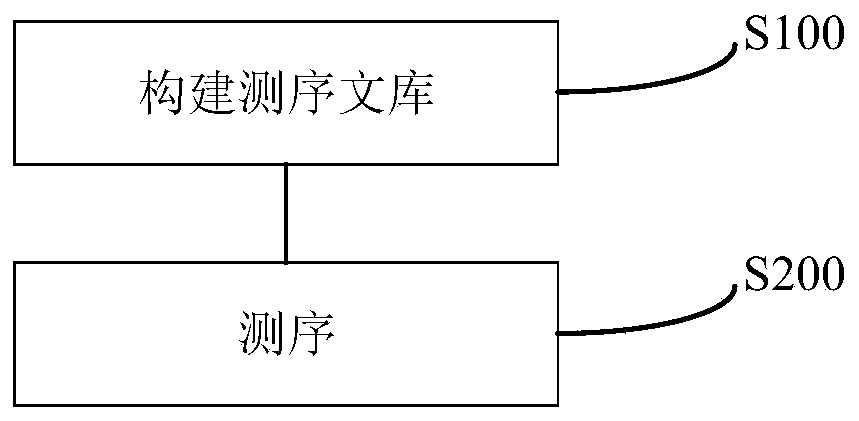

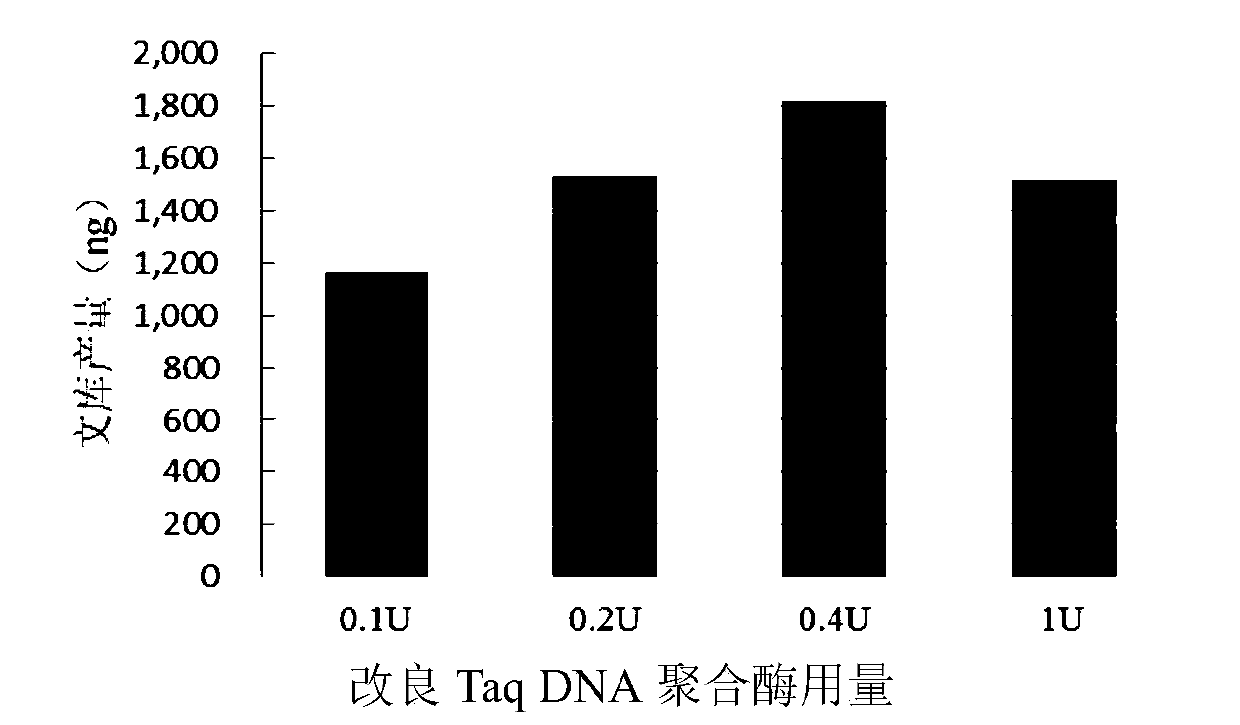

Method for constructing a DNA library and application thereof

ActiveCN111073952AImprove efficiencyLower preferenceMicrobiological testing/measurementLibrary creationEngineeringA-DNA

The invention discloses a method for constructing a DNA library and application thereof. The method comprises the following steps: carrying out terminal repairing on a DNA sample, and carrying out adenine nucleotide tailing treatment on the DNA sample by using high-temperature-resistant polymerase so as to obtain a tailed DNA under the condition of performing the terminal repairing and the adeninenucleotide tailing treatment continuously; and performing linker ligation treatment on the tailed DNA so as to obtain a linking product. In the DNA library, the conditions of terminal repairing and adenine nucleotide tailing treatment are as follows: the temperature is 27-37 DEG C and the time is 5-30 minutes; and the temperature is 70-75 DEG C, and the time is 10-20 minutes. According to the method, tail end repairing and adenine nucleotide tail adding treatment are continuously carried out, purification treatment is not needed in the process, stability is good; meanwhile, reaction time is remarkably shortened, and the reaction process is remarkably simplified.

Owner:ZHEJIANG ANNOROAD BIO TECH CO LTD +1

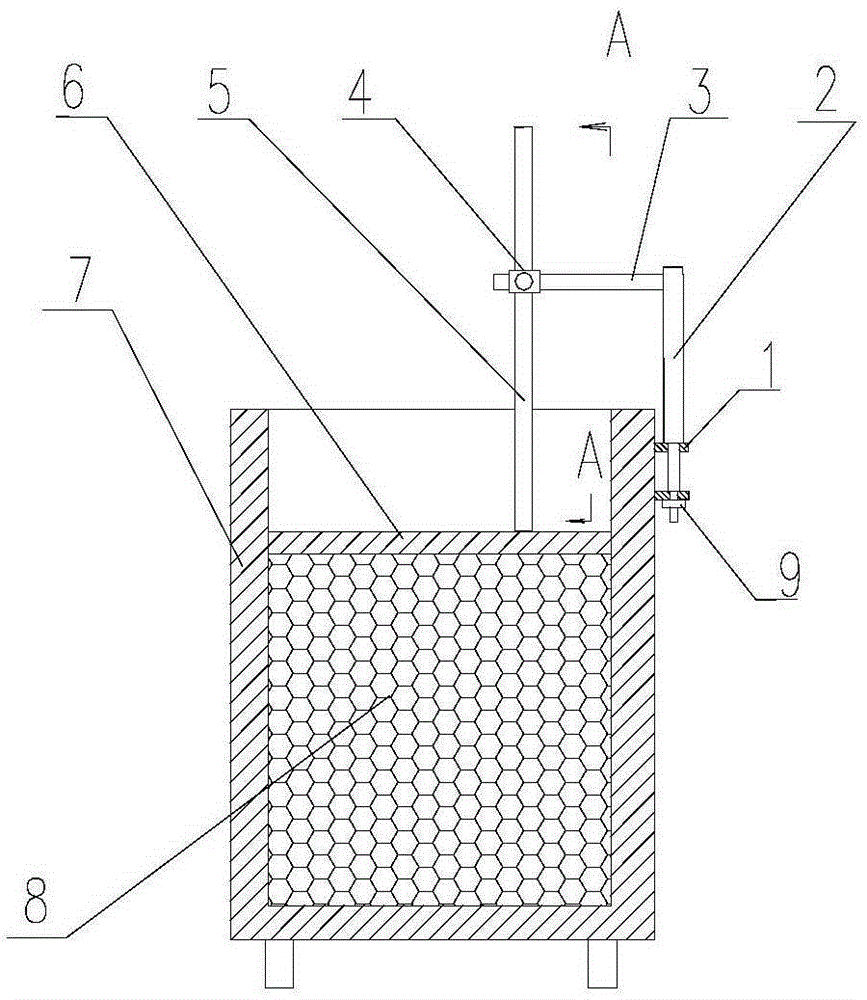

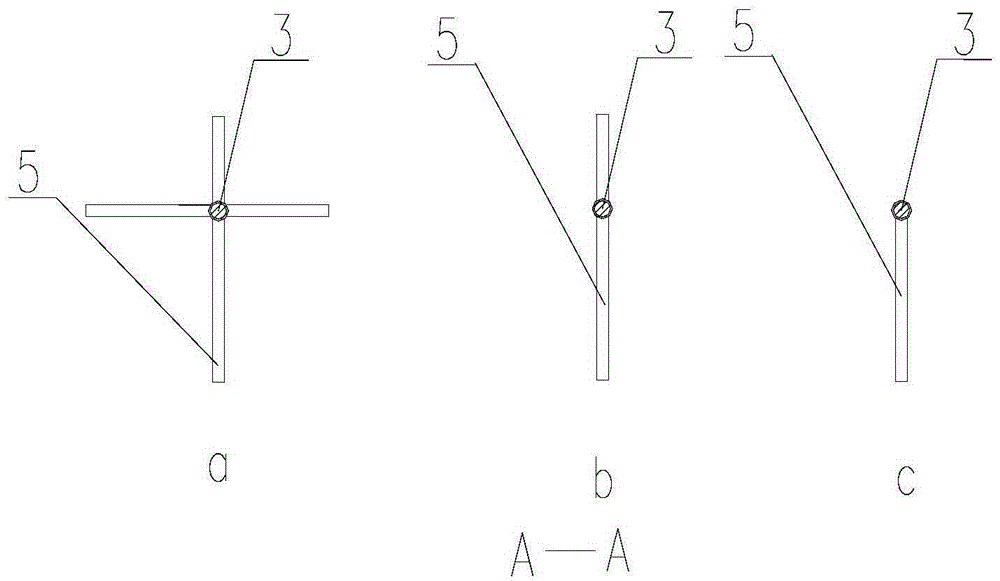

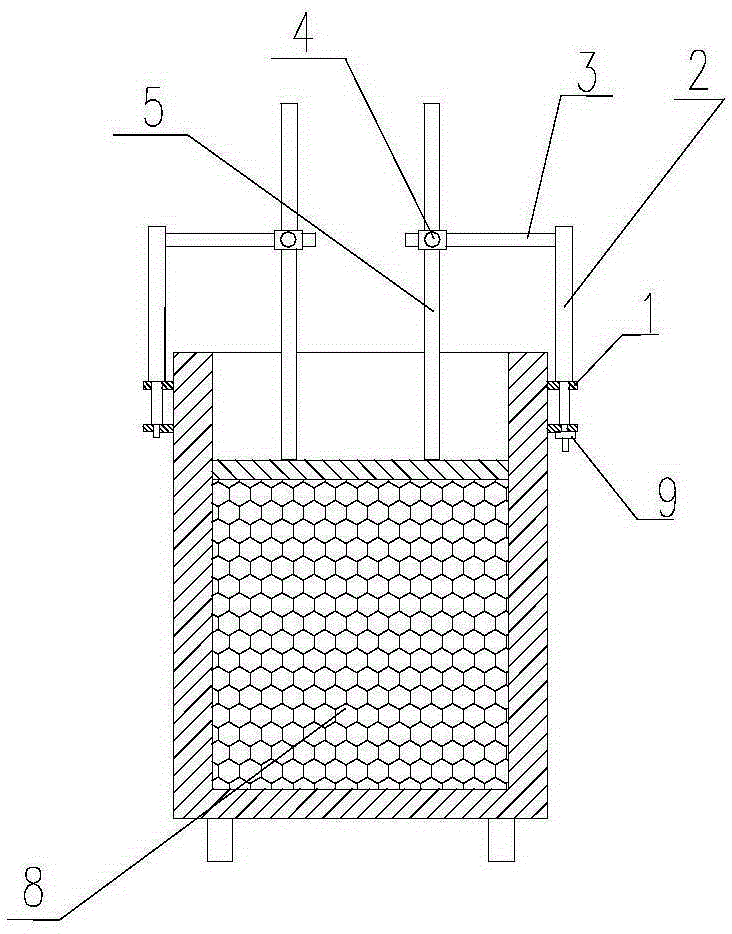

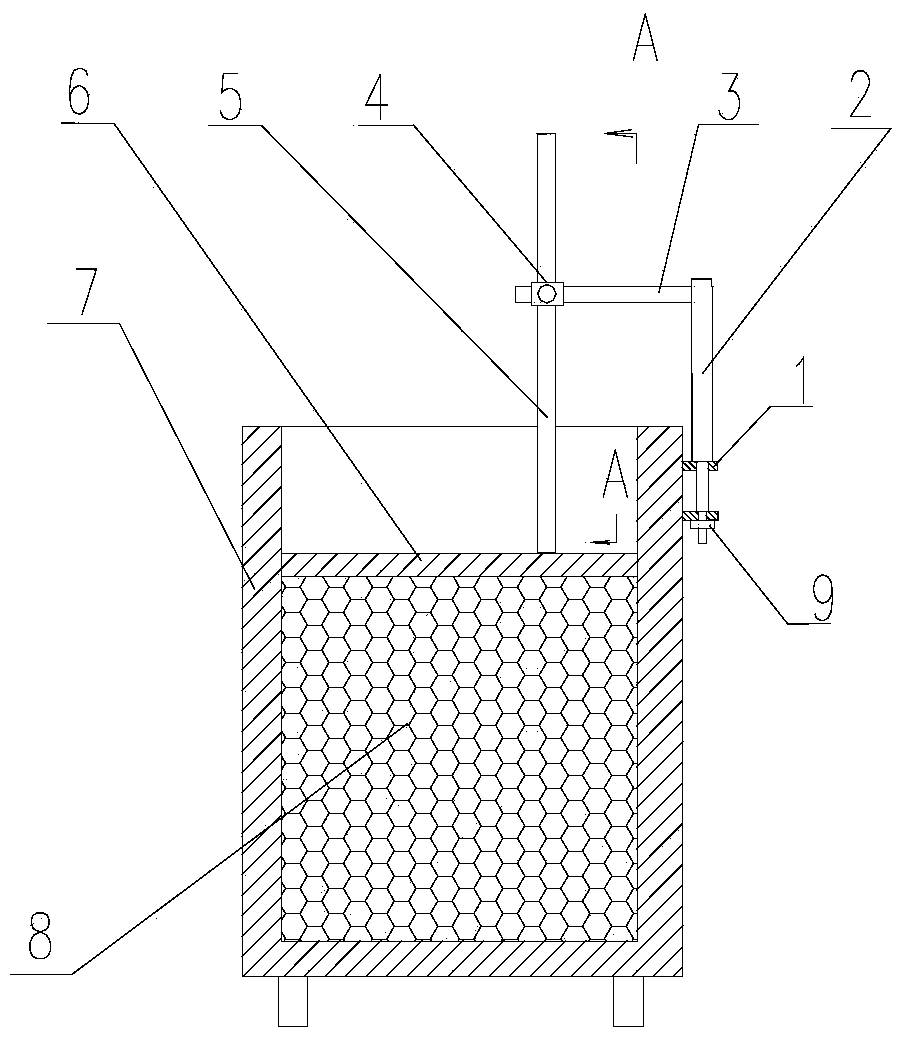

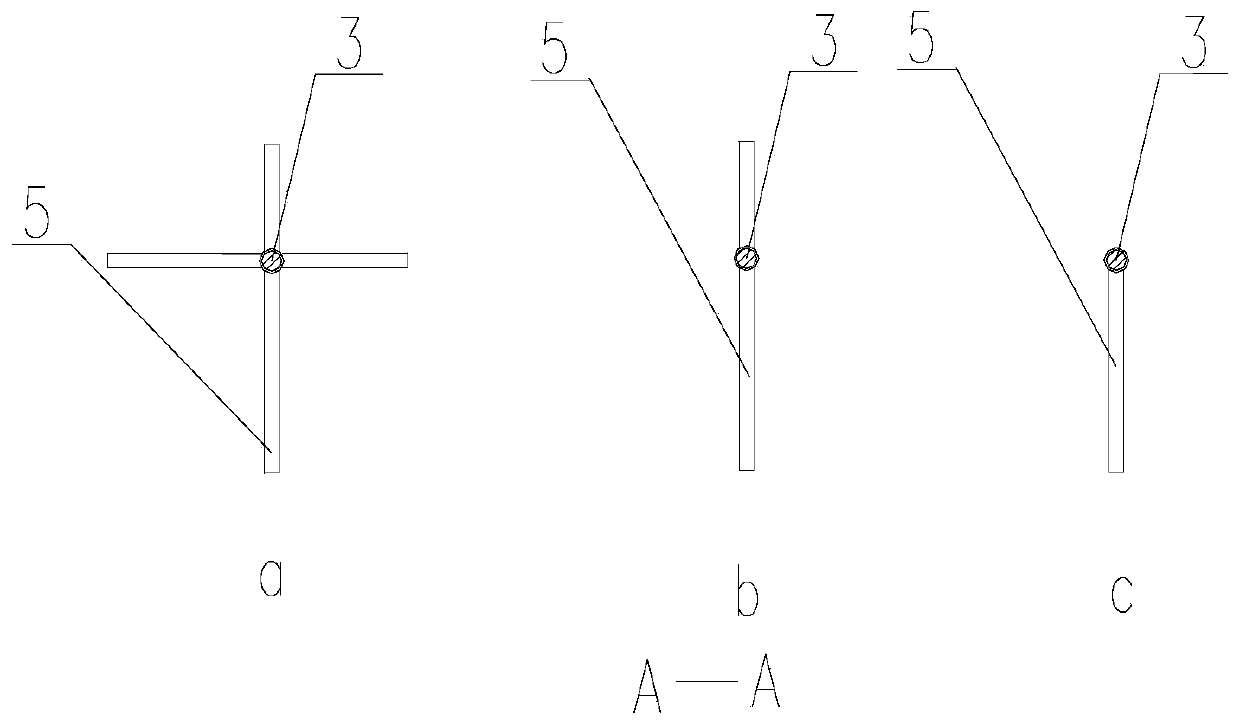

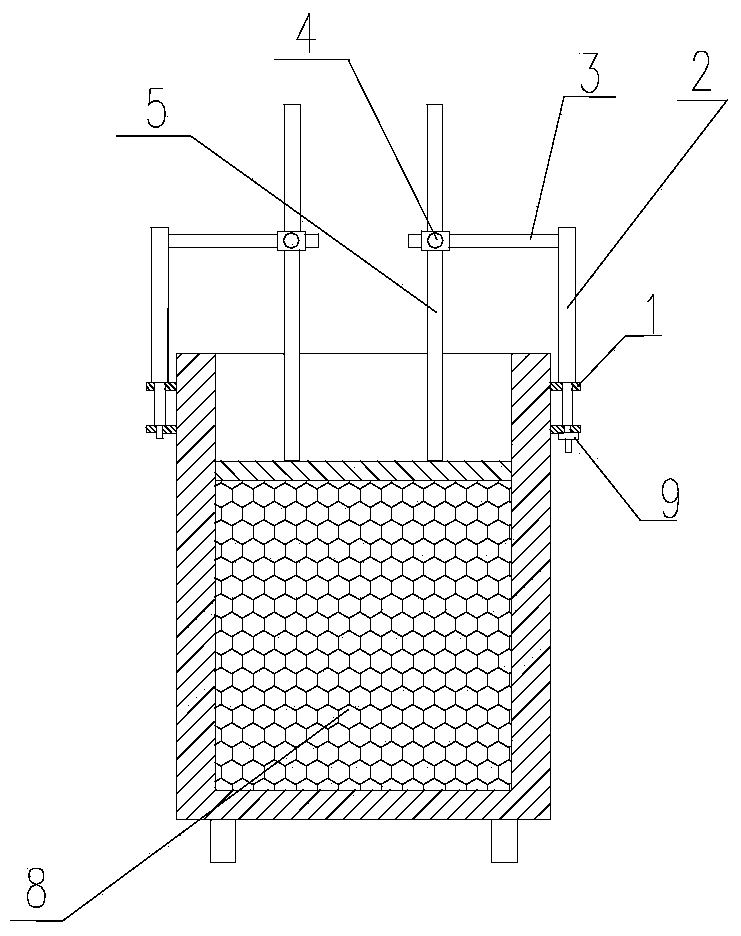

Insulation material foaming and shaping device

The invention relates to a shaping device of a heat-insulation material foaming box. The heat-insulation material shaping device is mainly characterized by comprising a foaming box body, wherein a plurality of supporting lugs are arranged on the lateral wall of the foaming box body; supporting rotation shafts are movably arranged inside the supporting lugs in a sleeved manner; locking pieces are arranged at the lower ends of the supporting rotation shafts; the supporting rotation shafts can be locked through the locking pieces; one end of a transverse arm is fixedly connected with the supporting rotation shafts, and sliding sleeves are arranged at the other end of the transverse arm; shaping columns are fixedly connected with the sliding sleeves; the end parts of the shaping columns are pressed on a pressing board. The heat-insulation material shaping device provided by the invention has the advantages of simple structure and convenience in use. When a hydraulic top of a press machine is pushed and pressed to a shaping position of a product, the press machine is replaced by the shaping device, and the streamline production of products can be realized.

Owner:LANZHOU XUNMEI PAINT IND TECH

A kind of hard suitcase and its manufacturing method

ActiveCN104490043BUniform thicknessGuaranteed degree of fastnessLuggageHollow articlesMechanical engineeringIndustrial engineering

The invention discloses a hard travelling case and a manufacturing method thereof, belonging to the technical field of travelling cases and manufacturing method thereof. The hard travelling case comprises an upper case body and a lower case body which are connected through lining, wherein each of the upper case body and the lower case body comprises a bottom plate, an impression belt and a surrounding frame which includes a long side frame and a short side frame, the long side frame and the short side frame are superposed and fixed on four corners of the case body; top arc-shaped holes are formed in the two sides of the top of the bottom plate; bottom arc-shaped holes are formed in two sides of the bottom of the bottom plate; bottom supporting parts which are in connected with the bottom arc-shaped holes are arranged at the outer sides of the bottom arc-shaped holes. According to the travelling case and the manufacturing method thereof disclosed by the invention, the conception is delicate and the structure design is reasonable; after being reasonably cut, rectangular plates are jointed in a thermoplastic manner to form the travelling case which is uniform in thickness, so that the defect that the plastic on a plastic-uptake molding corner is relatively thin is overcome, the firmness degree of the case is guaranteed. The whole production process can be streamlined, so that the production cost is lowered and the manufacturing time is shortened.

Owner:HANGZHOU GEMA SUITCASES & BAGS

Transformer case processing system and transformer automatic processing system

ActiveCN106584118BMechanizationStreamliningOther manufacturing equipments/toolsMetal working apparatusTransformerEngineering

The invention provides a crate machining system and automatic machining system for a transformer and belongs to the field of transformer machining. The crate machining system for the transformer comprises crate edge machining equipment, bottom plate machining equipment, side vertical column machining equipment and first assembling equipment. The first assembling equipment is connected with the crate edge machining equipment, the bottom plate machining equipment and the side vertical column machining equipment and comprises a side vertical column grabbing mechanism, a crate edge grabbing mechanism, an assembly welding mechanism and an assembly supporting mechanism, and the assembly supporting mechanism is used for installing the side vertical column grabbing mechanism, the crate edge grabbing mechanism and the assembly welding mechanism. According to the crate machining system for the transformer, components in different processes can be spliced and welded, streamlined and mechanized machining of a crate can be achieved on a same workbench, and the working efficiency is greatly improved. The automatic machining system for the transformer comprises the crate machining system for the transformer. According to the automatic machining system for the transformer, the transformer can be machined in a mechanized and streamlined mode.

Owner:江苏连变电气有限公司

Heat-insulation material foaming and shaping device

The invention relates to a shaping device of a heat-insulation material foaming box. The heat-insulation material shaping device is mainly characterized by comprising a foaming box body, wherein a plurality of supporting lugs are arranged on the lateral wall of the foaming box body; supporting rotation shafts are movably arranged inside the supporting lugs in a sleeved manner; locking pieces are arranged at the lower ends of the supporting rotation shafts; the supporting rotation shafts can be locked through the locking pieces; one end of a transverse arm is fixedly connected with the supporting rotation shafts, and sliding sleeves are arranged at the other end of the transverse arm; shaping columns are fixedly connected with the sliding sleeves; the end parts of the shaping columns are pressed on a pressing board. The heat-insulation material shaping device provided by the invention has the advantages of simple structure and convenience in use. When a hydraulic top of a press machine is pushed and pressed to a shaping position of a product, the press machine is replaced by the shaping device, and the streamline production of products can be realized.

Owner:LANZHOU XUNMEI PAINT IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com