Complete equipment for continuous laser welding

A technology of laser welding and complete sets of equipment, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of automatic welding of unfavorable parts, worker's hand injury, vulnerability to injury, etc., to achieve simple and convenient operation and reduce injury , to ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

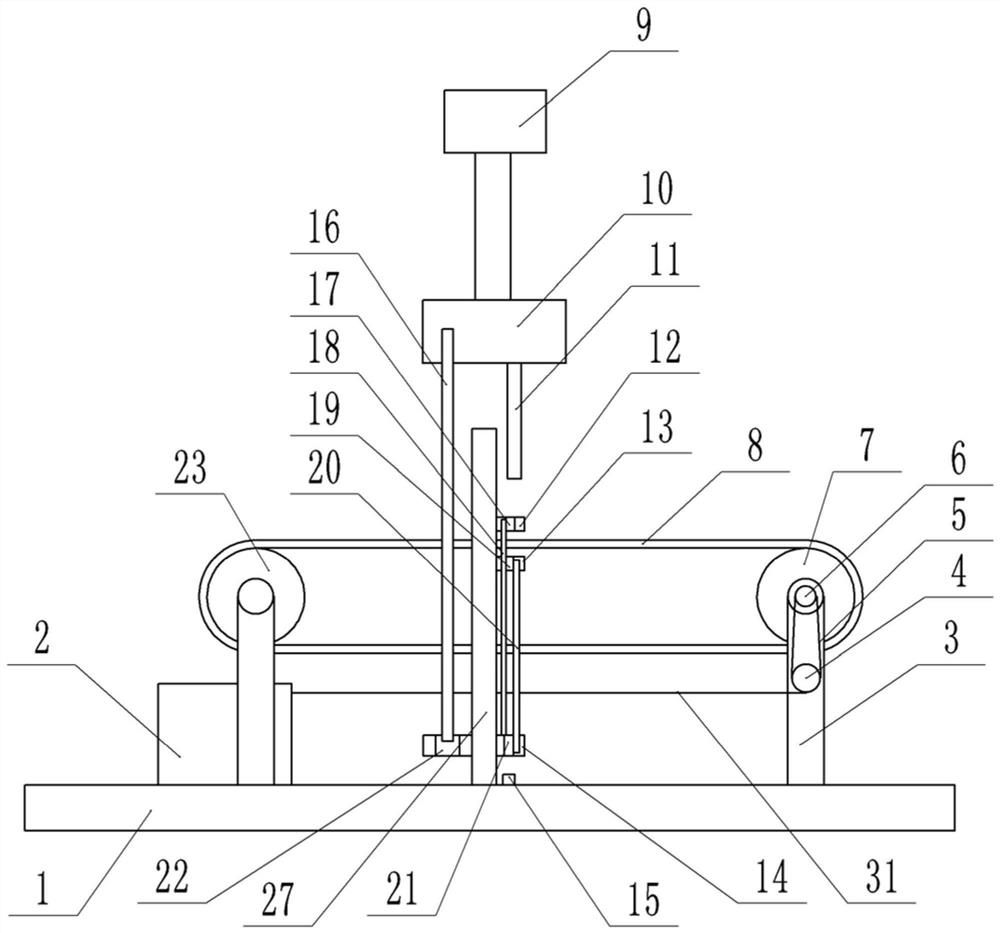

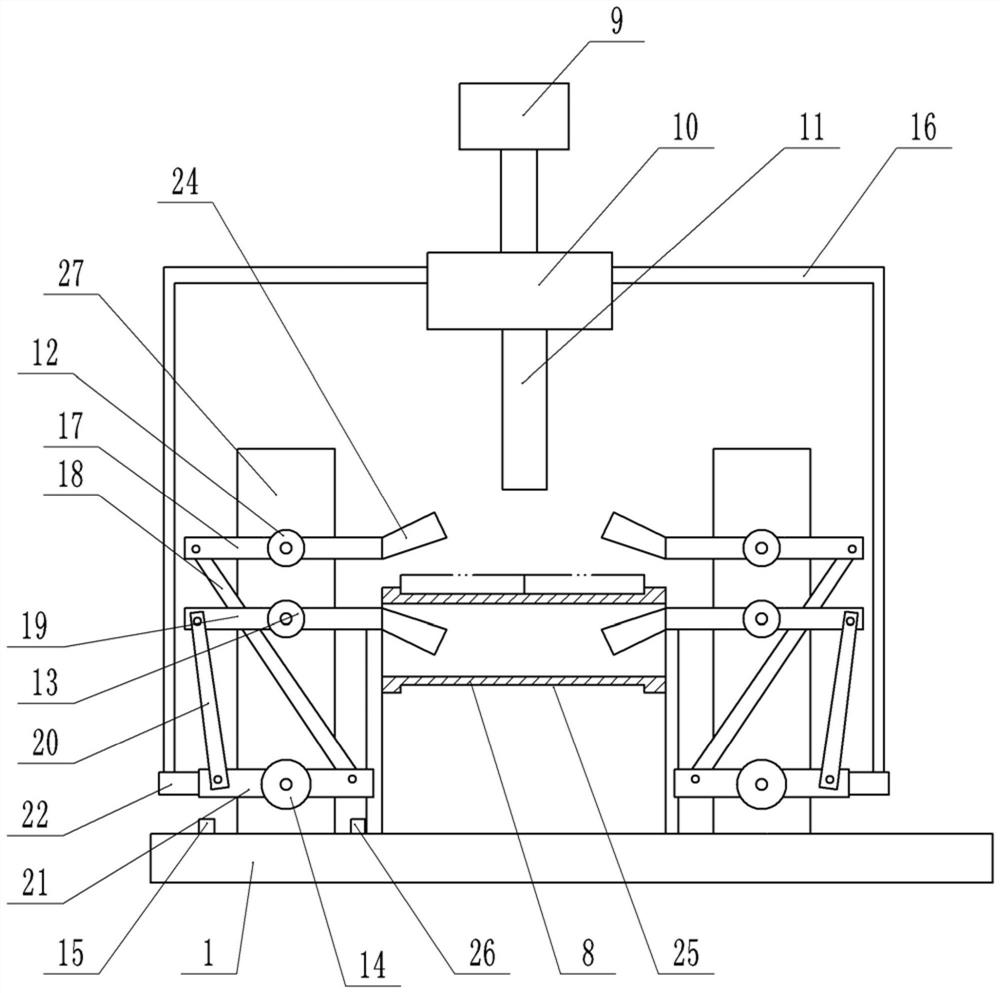

[0024] Basic as attached figure 1 Shown: a complete set of equipment for continuous laser welding, including a frame, a base 1 is welded on the frame, two support frames 3 are welded on the base 1, and a driven roller 23 is connected to the support frame 3 on the left through shaft rotation. A driving roller 7 is connected to the support frame 3 on the right side through shaft rotation, and a conveyor belt 8 is connected between the driving roller 7 and the driven roller 23 . On the support frame 3 on the right side, a motor (not shown) is fixed by screws, and a belt pulley 6 is coaxially welded on the drive roller 7 , and a belt 5 is connected between the output shaft 4 of the motor and the pulley 6 . combine figure 2 As shown, the thickness of the middle part of the conveyor belt 8 is less than the thickness of the two sides of the conveyor belt 8, so the middle part of the conveyor belt 8 forms a groove 25, thereby the parts can be limited to prevent the parts from figu...

Embodiment 2

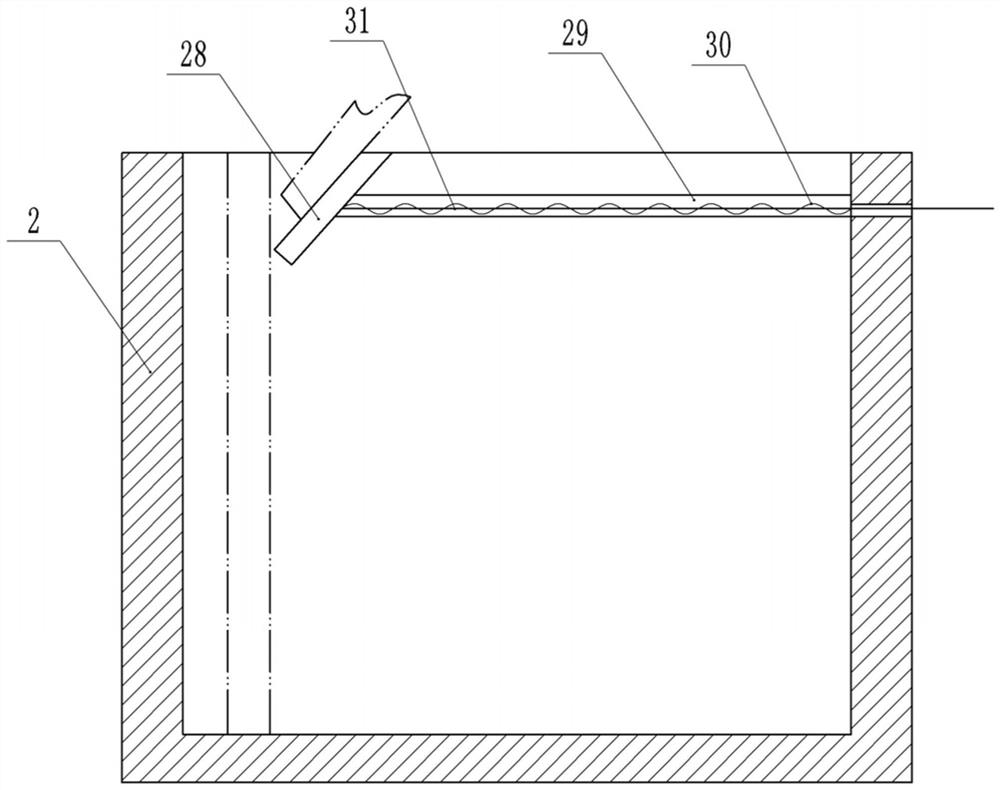

[0034] combine figure 1 As shown, a collection box 2 is provided below the driven roller 23, and the collection box 2 is slidably connected to the base 1 from left to right. bumps in slots. combine image 3 As shown, the top of the collection box 2 is slidably connected with an inclined guide plate 28. Specifically, the inner wall of the collection box 2 is provided with a laterally arranged chute 29, and the side of the guide plate 28 is integrally formed with a sliding connection on the chute. 29 inner bumps. The right side wall of collection box 2 is provided with rope hole, and one end of stay rope 31 is bolted on the support frame 3 where driving roller 7 is located, and stay rope 31 other ends pass rope hole and are bolted on the guide plate 28, and guide plate An elastic member is connected between 28 and the right inner wall of the collection box 2, and the elastic member is a compression spring 30 in this embodiment.

[0035] combine Figure 4 As shown, the base ...

Embodiment 3

[0039] In this embodiment, the laser 10 can slide on the cylinder rod, so that the laser 10 can be moved laterally to adapt to welding parts with different widths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com