Heat-insulation material foaming and shaping device

A shaping device and thermal insulation material technology, which is applied in the field of thermal insulation material foaming and shaping devices, can solve the problems of long use time, high cost of presses, and a few days if it is long, and achieves simple structure, streamlined implementation, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

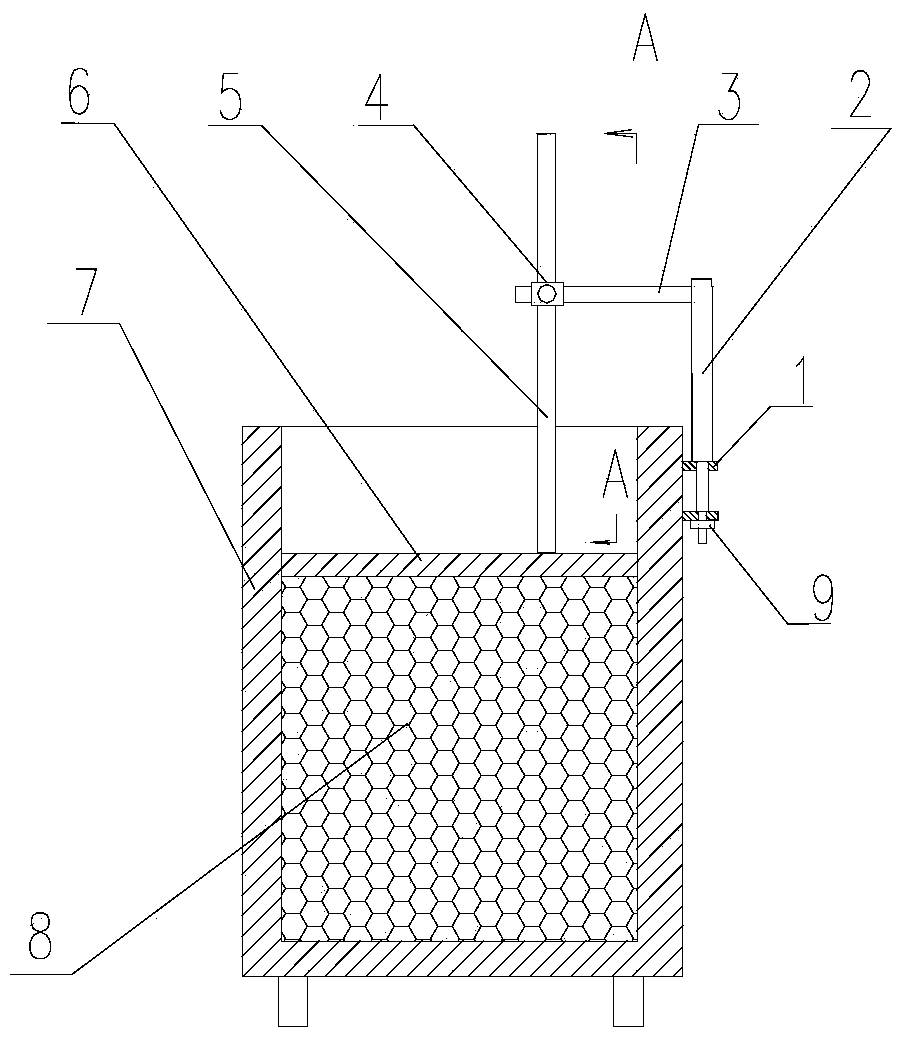

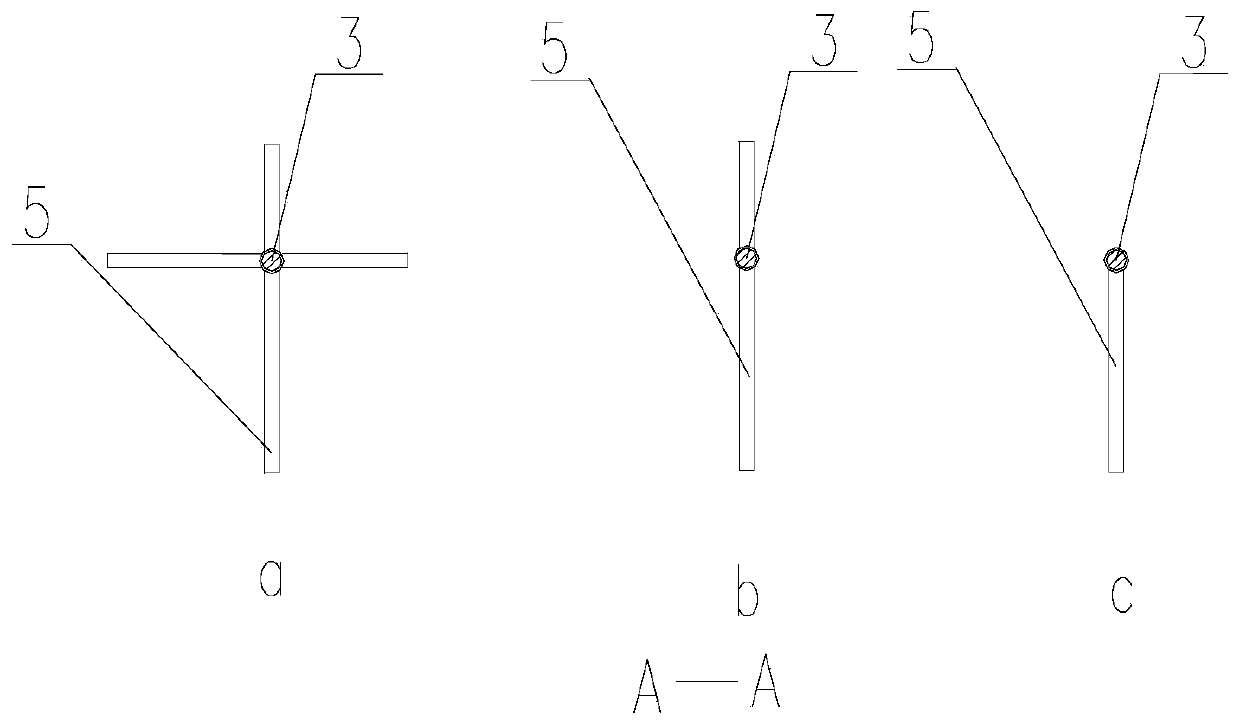

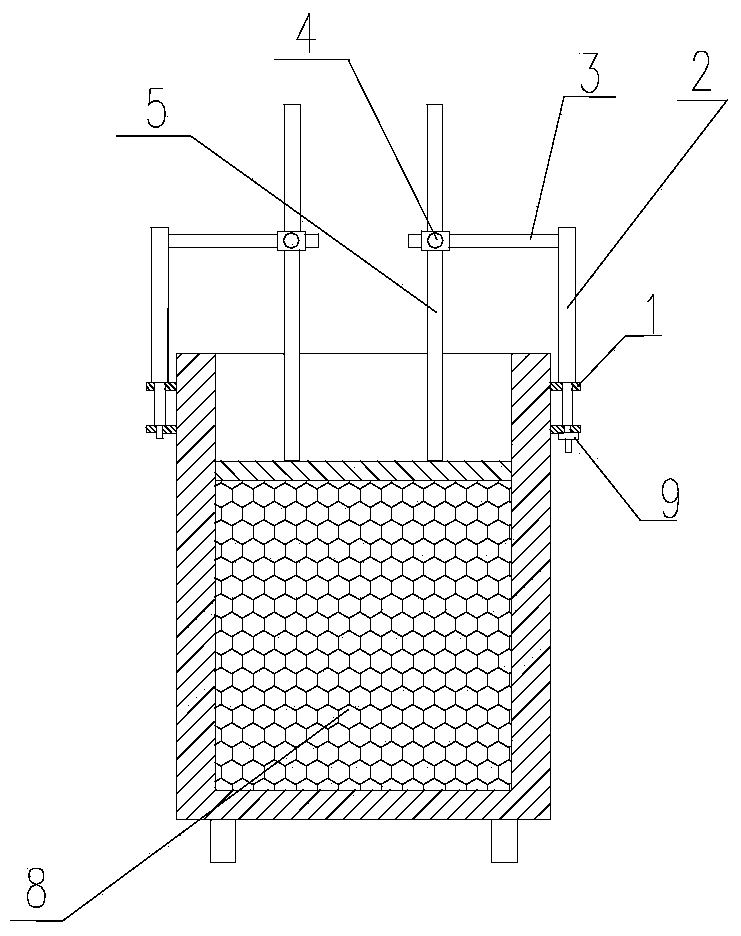

[0017] Example 1: see figure 1 , figure 2 (a), a shaping device for thermal insulation materials, including a foam box 7, a plurality of support ears 1 are arranged on the side wall of the foam box 7, and a support shaft 2 is looped in the support ears 1, The lower end of the supporting rotating shaft 2 has a locking plate 9, and the transverse arm can be rotated by supporting the rotating shaft. One end of the transverse arm 3 is fixedly connected with the supporting rotating shaft 2 , and the other end is provided with a sliding sleeve 4 .

[0018] The sizing column is cross-shaped or in-line.

[0019] The support ear 1 is arranged on one side wall of the foam box 7

Embodiment 2

[0020] Example 2: see figure 1 , figure 2 (b), a shaping device for thermal insulation materials, the shaping column is in the shape of a line. All the other structures are the same as in Example 1.

Embodiment 3

[0021] Embodiment 3: see figure 1 , figure 2 (c), a shaping device for thermal insulation materials, the shaping column is in the shape of a line. All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com