A kind of hard suitcase and its manufacturing method

A production method and technology of suitcases, which are applied to suitcases, travel goods, and other household appliances, etc., can solve the problems of difficult temperature balance control, structural adjustment, and low barrel temperature of injection molding machines, so as to reduce preparation time, The thickness of the box is uniform and the effect of ensuring the degree of fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

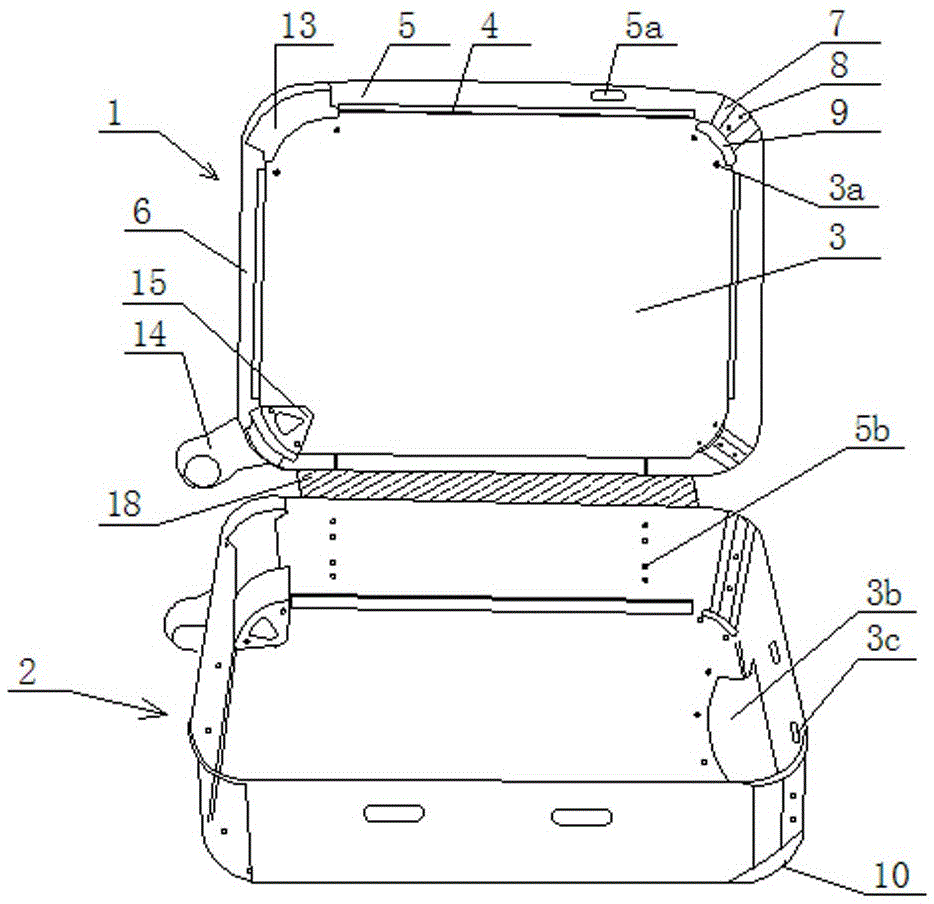

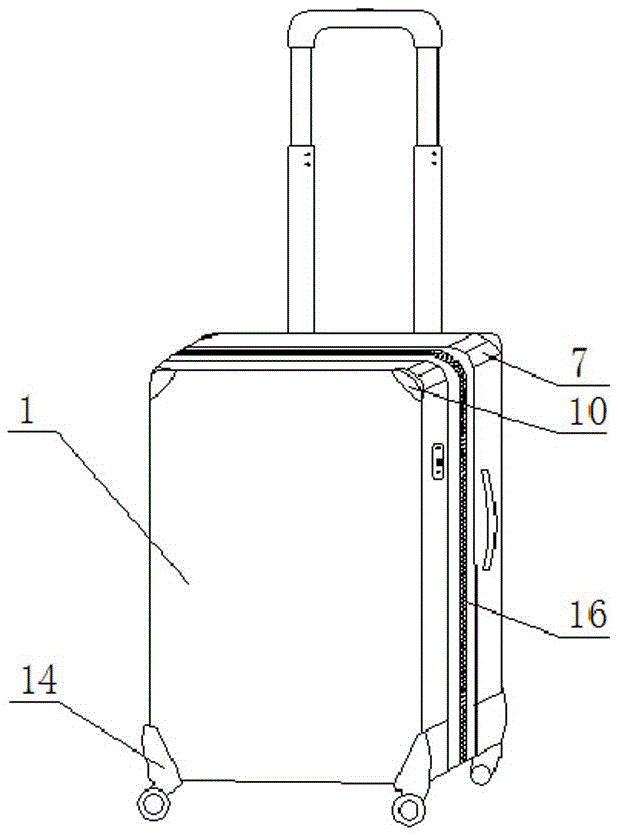

[0059] A hard suitcase, comprising an upper case body 1 and a lower case body 2, the upper case body 1 and the lower case body 2 are connected through a lining 18.

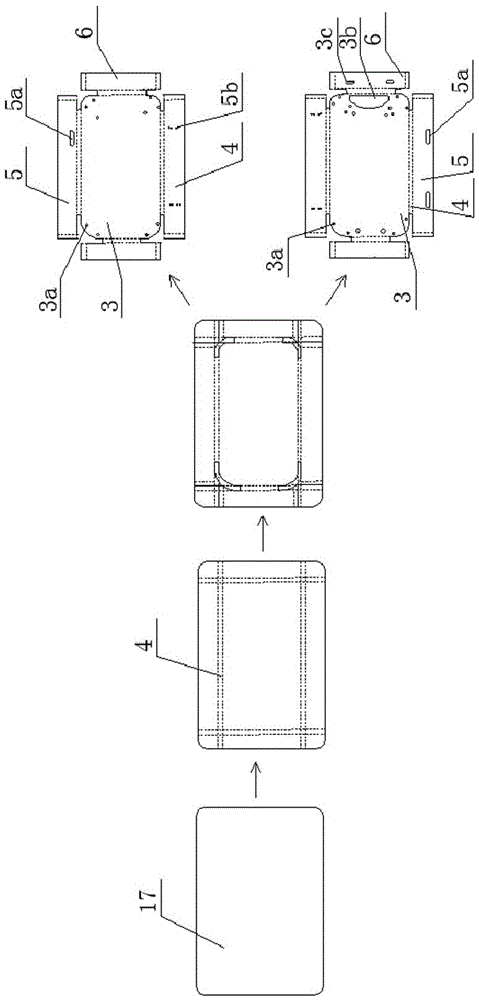

[0060] Both the upper box body 1 and the lower box body 2 include a bottom plate 3, an indentation belt 4 and a surrounding frame; the surrounding frame is vertically connected to the bottom plate 3 through the indentation belt 4; the cross section of the indentation belt 4 is arranged in an arc shape The surrounding frame includes a long frame 5 and a short frame 6; the long frame 5, the short frame 6 and the bottom plate 3 are surrounded to form an accommodation space; the long frame 5 and the short frame 6 are overlapped and fixed at the four corners of the box ; Both sides of the top of the base plate 3 are provided with top arc holes 9; both sides of the bottom of the base plate 3 are provided with bottom arc holes 13; Matching bottom support 14; the bottom support 14 is provided with a roller 14e; the inner ...

Embodiment 2

[0081]In this embodiment, a hard suitcase, the outer side of the top arc-shaped hole 9 is provided with a top support 12 that is plugged and fitted with the top arc-shaped hole 9; the inner side of the top arc-shaped hole 9 is provided with a The top support member 12 is plug-fitted and the top connector 11 is screwed; the top support member 12 and the top connector 11 close the top arc hole 9;

[0082] The top connector 11 includes a fan-shaped top connection base plate 11a and a top connection insert plate 11c perpendicular to the top connection base plate 11a; the top connection base plate 11a is provided with a top connection threaded hole 11b adapted to the corner hole 3a; The top connection board 11c is connected to the arc edge of the top connection base plate 11a; the top connection board 11c is provided with a top connection plug 11d; the top support member 12 includes a fan-shaped top support base plate 12a and a The top support plate 12c of the top support base plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com