Empty bottle inspection method and empty bottle inspection machine thereof

A technology for inspection machines and empty bottles, applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of high cost, a large number of sensors, and low efficiency, and achieve the effect of reducing quantity and detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the embodiments of the present invention will be described below in conjunction with the accompanying drawings.

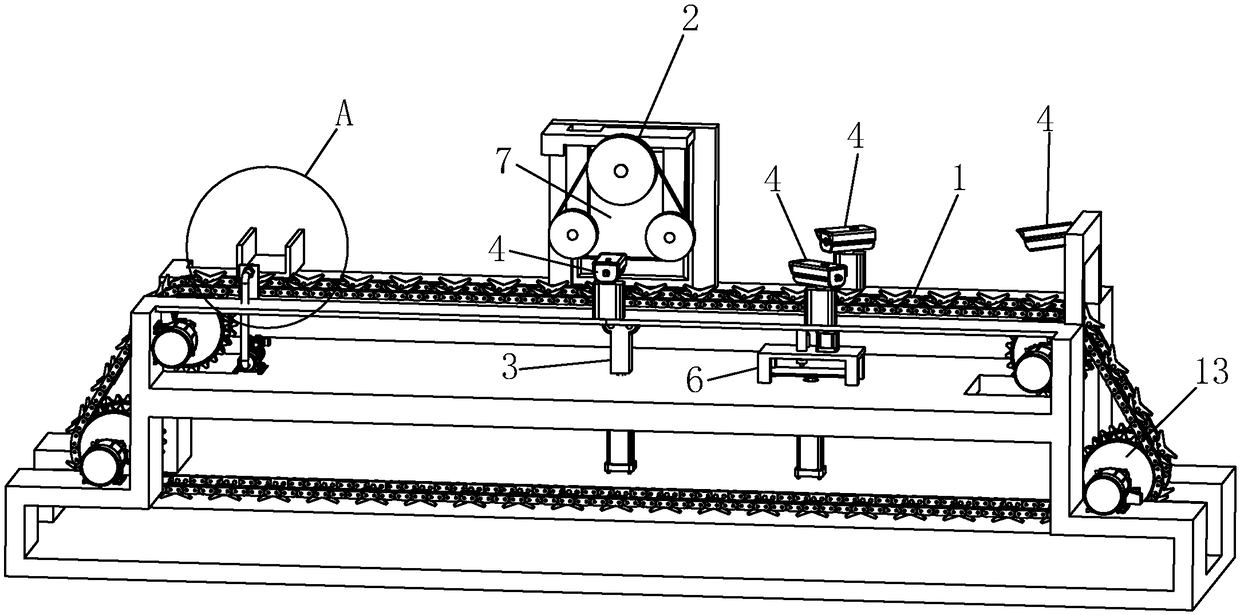

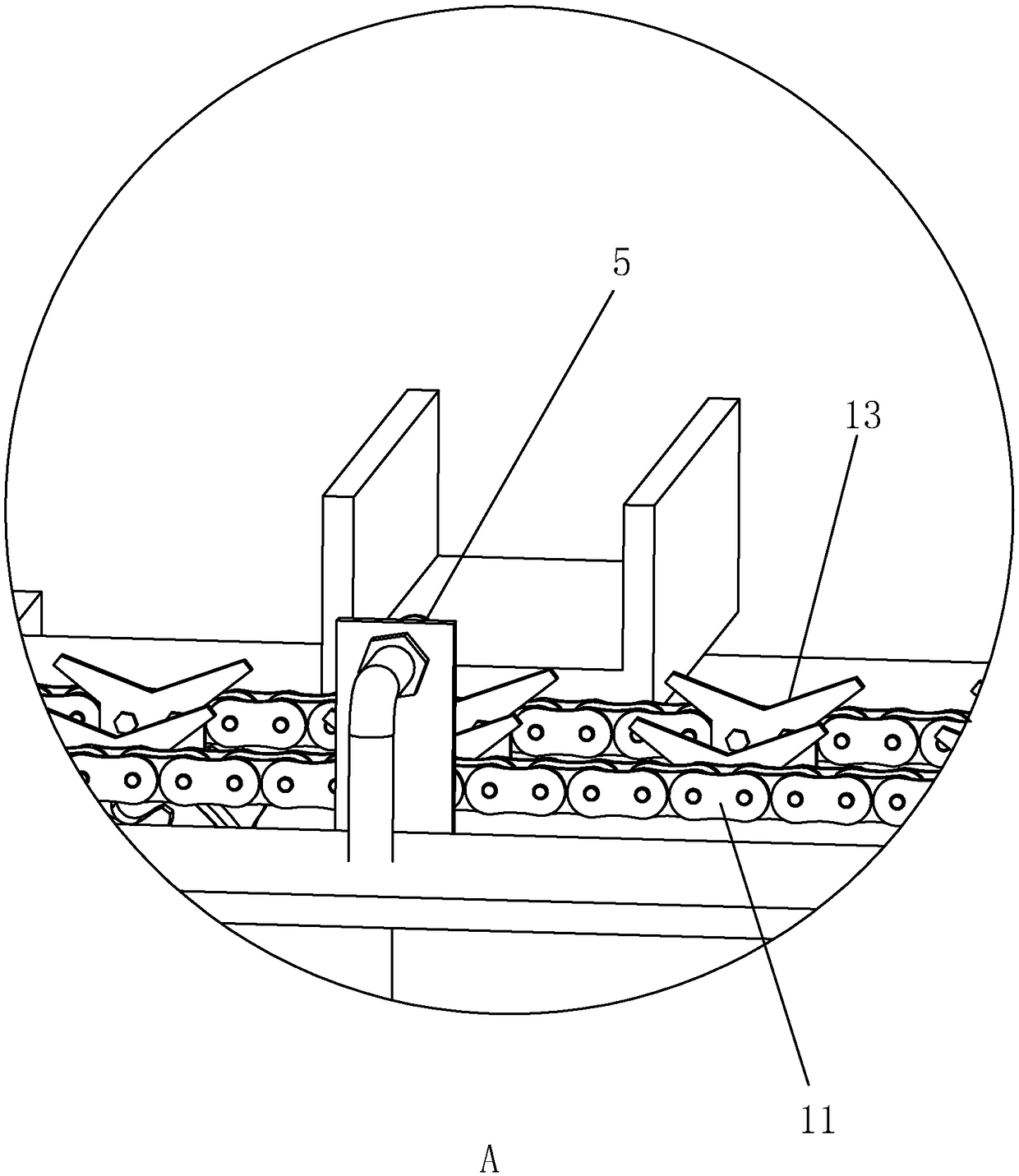

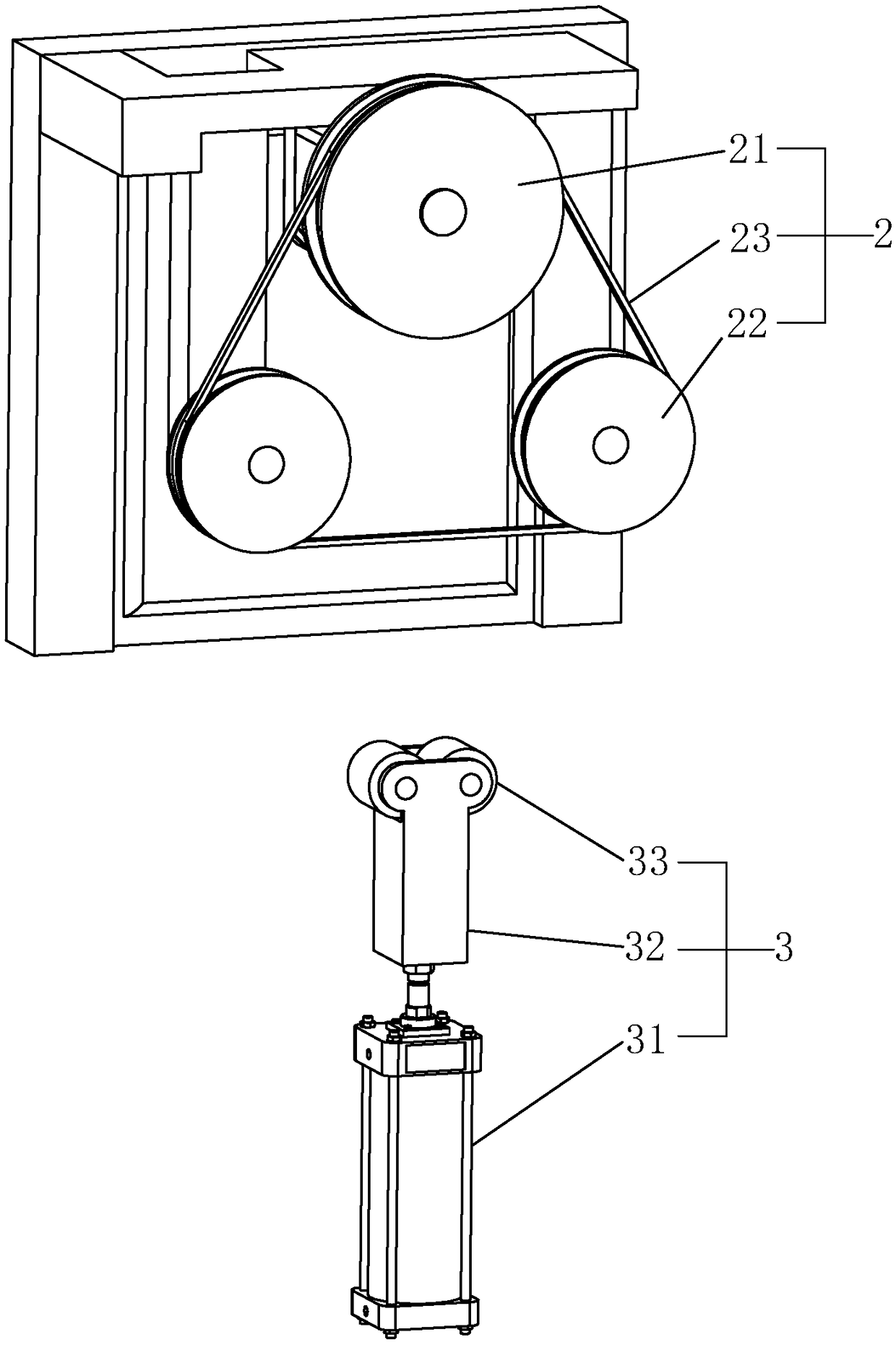

[0033] An empty bottle inspection machine, such as figure 1 As shown, it includes a conveyor belt 1, a rotating mechanism 2, an ejector mechanism 3, a camera 4, and a processor (not shown in the figure). The ejector mechanism 3 is located directly below the rotating mechanism 2, and the conveyor belt 23 is connected from the rotating mechanism 2 to The ejector mechanism 3 passes through for transmission. The conveyor belt 1 is provided with an opening for the ejector mechanism 3 to pass through. The ejector mechanism 3 pushes the empty bottle up until it contacts the rotating mechanism 2 to rotate the empty bottle axially, and the camera 4 Located at a position where the empty bottle can be photographed, the processor is connected to the camera 4 to obtain the image captured by the camera 4, and process the image to screen out unqualif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com