Brick making device for building garbage

A technology for waste production and construction, which is applied to supply devices, mixers with rotary stirring devices, and manufacturing tools, etc., can solve the problems of uneven mixing of raw materials and uneven particle size, and achieve the effect of uniform size and uniform mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

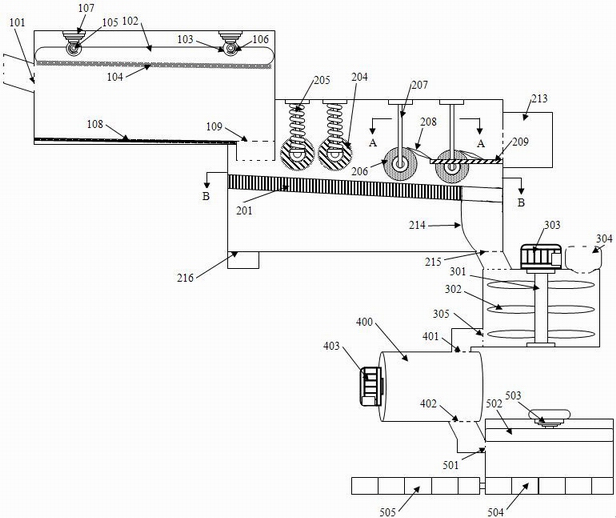

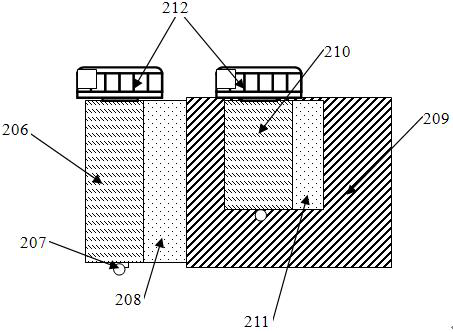

[0030] Further explanation in conjunction with accompanying drawings: Figure 1-Figure 3 The construction waste brick-making device of this embodiment includes a hammer crushing chamber, a sieving magnetic separation unit, a river sand mixing chamber, a sand mill drum and a brick-forming chamber.

[0031] Such as figure 1 As shown, the hammer crushing chamber includes a hammer crushing chamber casing, a construction waste inlet 101, a hammering pier 102, a rotating arc receiving plate 106, a telescopic rod 107, a bottom hammer bearing plate 108, and a hammer crushing chamber outlet 109; The garbage inlet is arranged on the left side wall of the hammer crushing cavity shell, and the hammering pier is placed horizontally in the hammer crushing cavity shell, and two or more than two top grooves 103 are arranged on the top of the hammering pier, and each The top groove is horizontally provided with a receiving shaft 105, and the hammering surface 104 at the bottom of the hammerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com