A transformer case processing system and a transformer production system

A processing system and transformer technology, applied in the direction of metal processing equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of low precision, low efficiency, difficulty in meeting industrialization, batch production, etc., and achieve mechanization, processing efficiency and processing accuracy Improve and meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

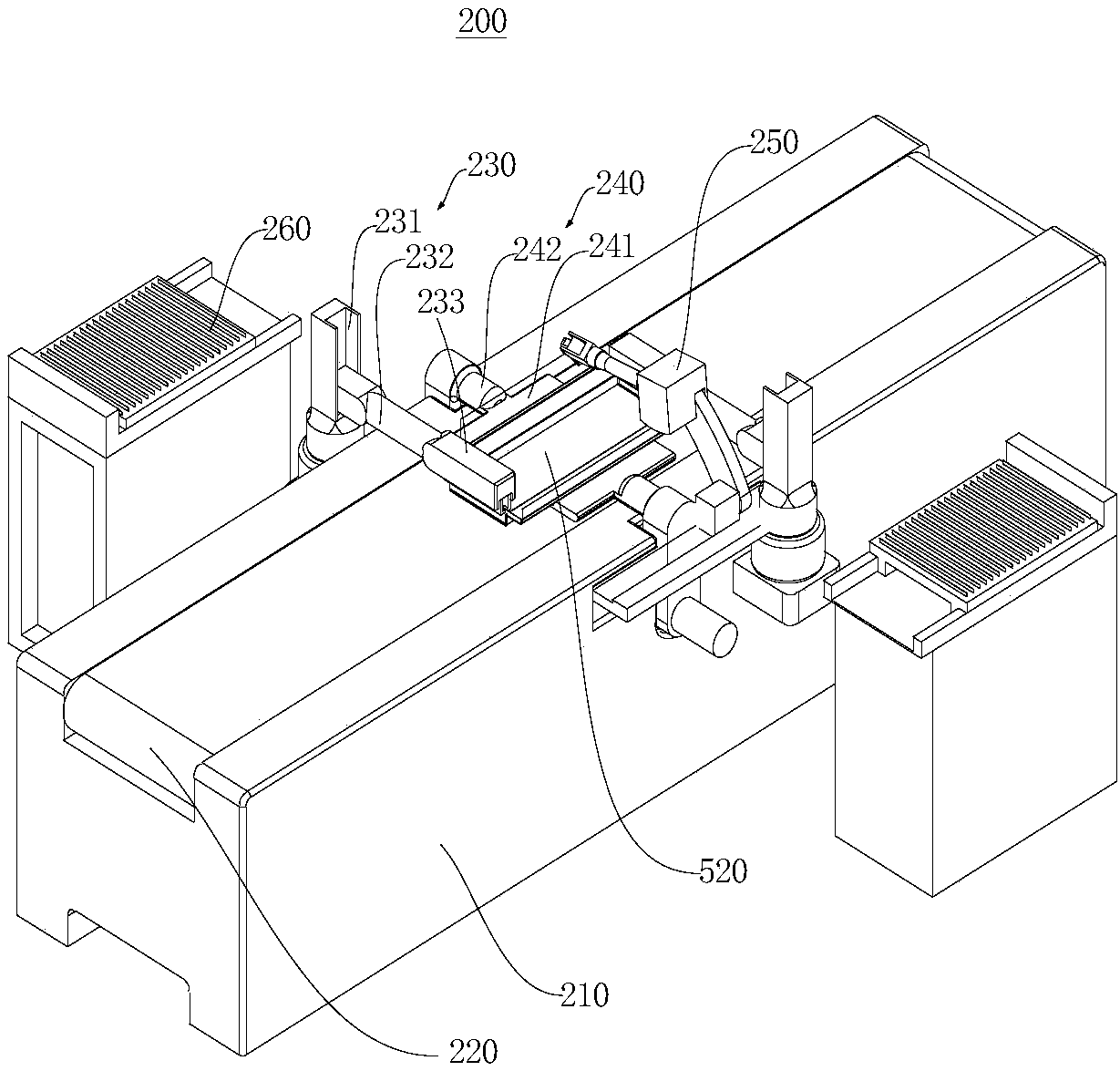

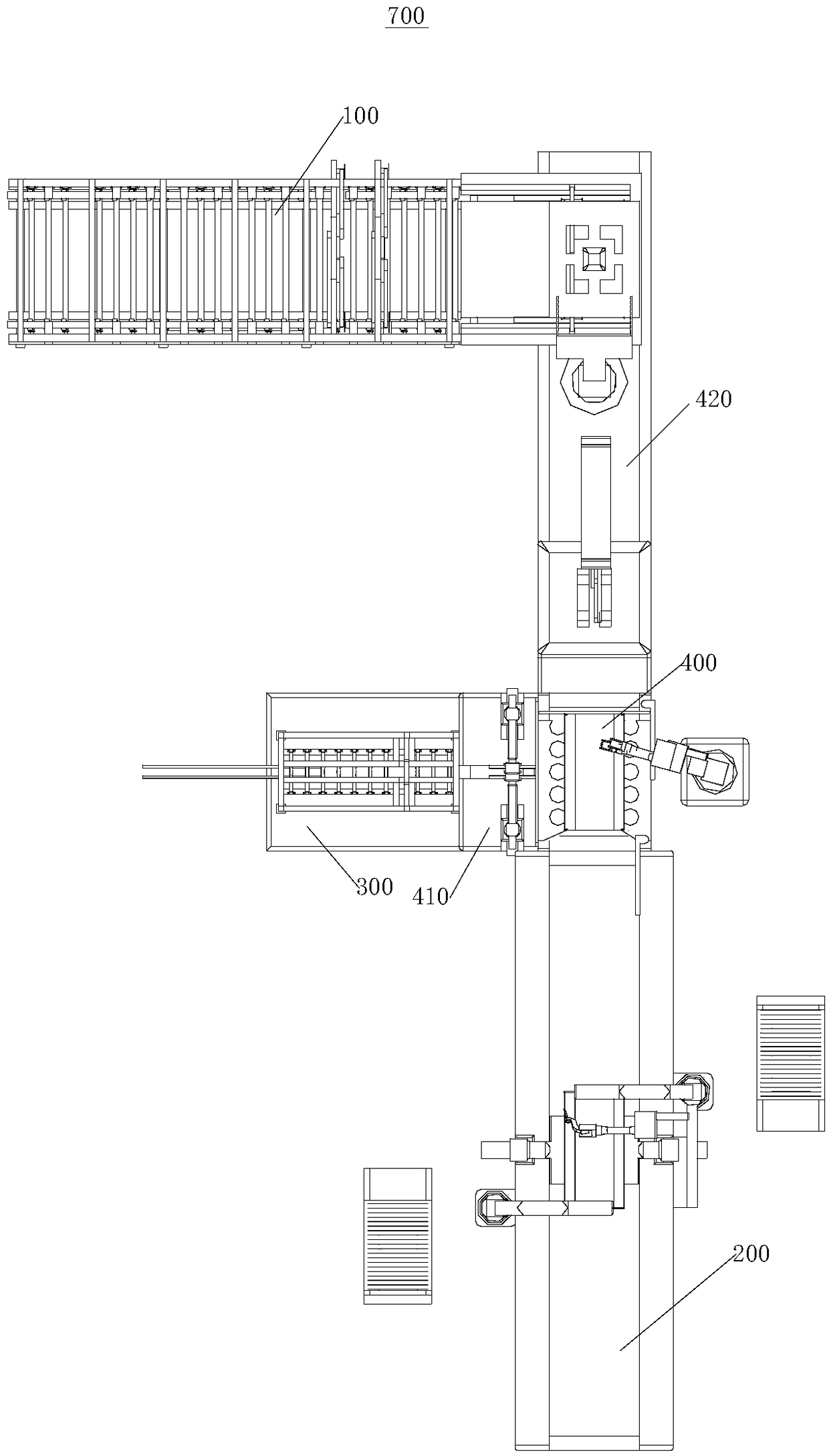

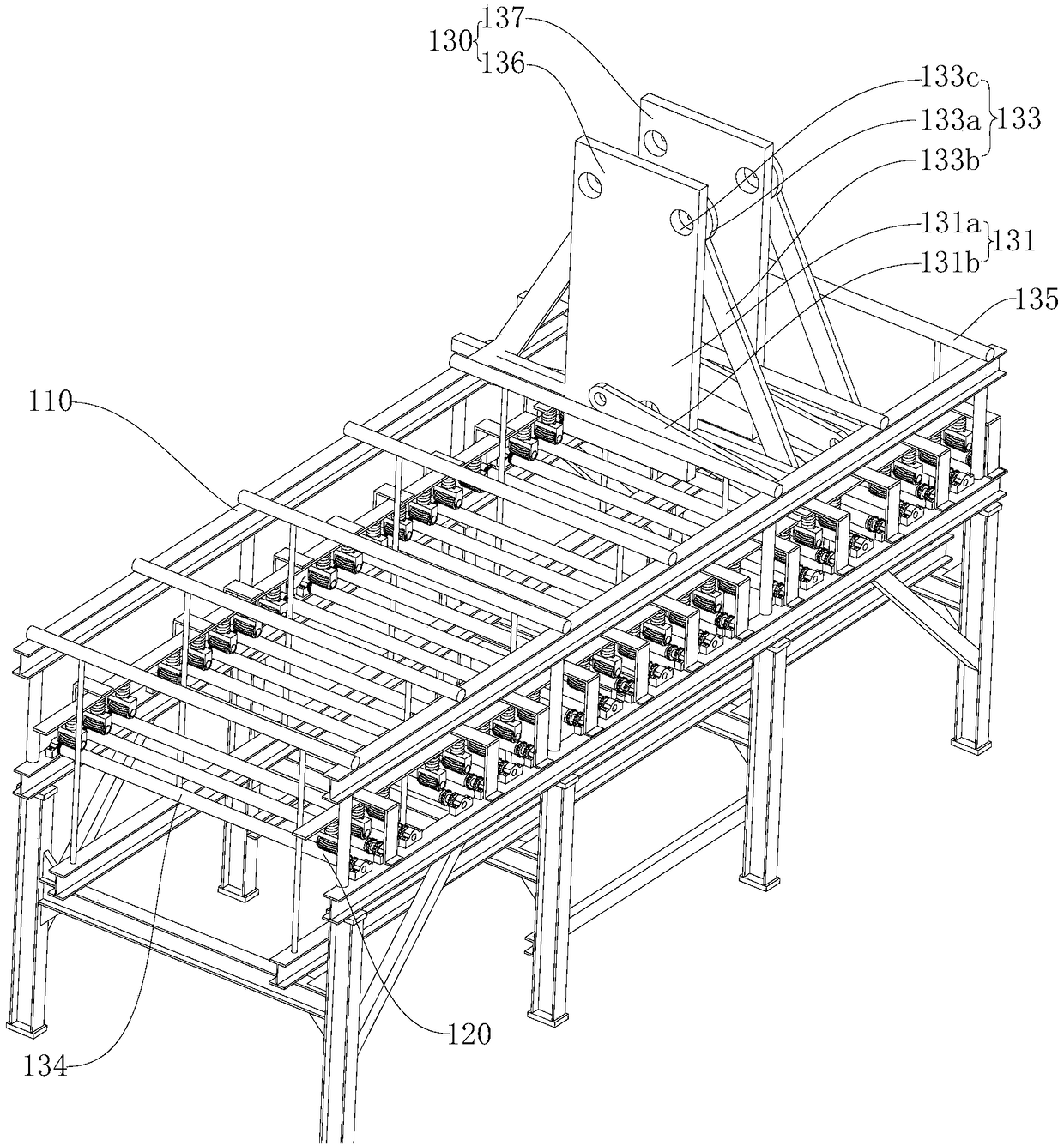

[0034] Please refer to figure 1 , the present embodiment provides a transformer box processing system 700 , including box edge processing equipment 100 , bottom plate processing equipment 200 , side column processing equipment 300 , first assembly equipment 400 and heat sink welding equipment 600 . The box edge processing equipment 100, the bottom plate processing equipment 200 and the side column processing equipment 300 are all independent of each other, and are respectively used for outputting the box edge, the bottom plate 520 and the side column, and the first assembly equipment 400 is connected with the box edge processing equipment 100 and the bottom plate processing equipment respectively. The equipment 200 is connected with the side column processing equipment 300, and is used to weld the base plate 520, the side column and the box along the edge to form a part of the chassis; the heat sink welding equipment 600 (see Figure 9 ) is connected to the first assembly devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com