Closed-loop old automobile disassembling assembly line matching remanufacturing and disassembling process of closed-loop old automobile disassembling assembly line

An assembly line and old car technology, applied in the direction of motor vehicles, vehicle scrap recycling, solid waste removal, etc., can solve the problems that affect the efficiency of disassembly, time-consuming, laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

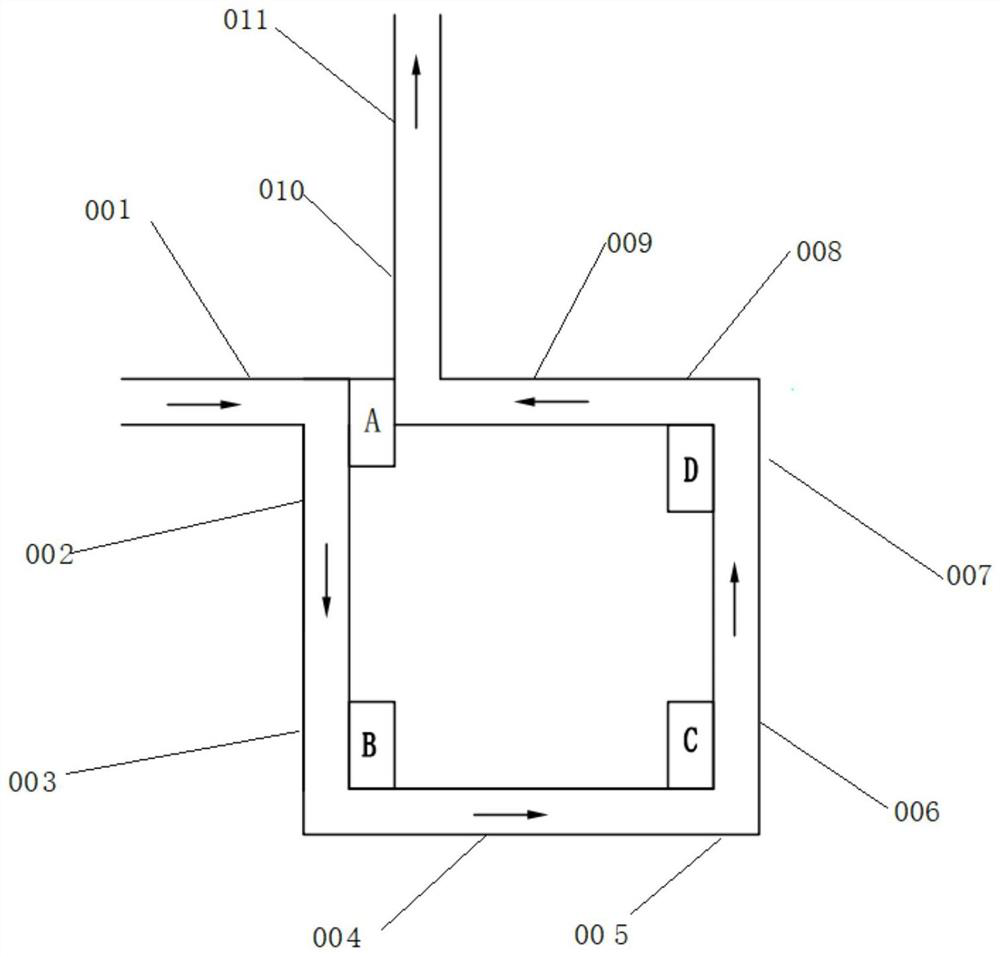

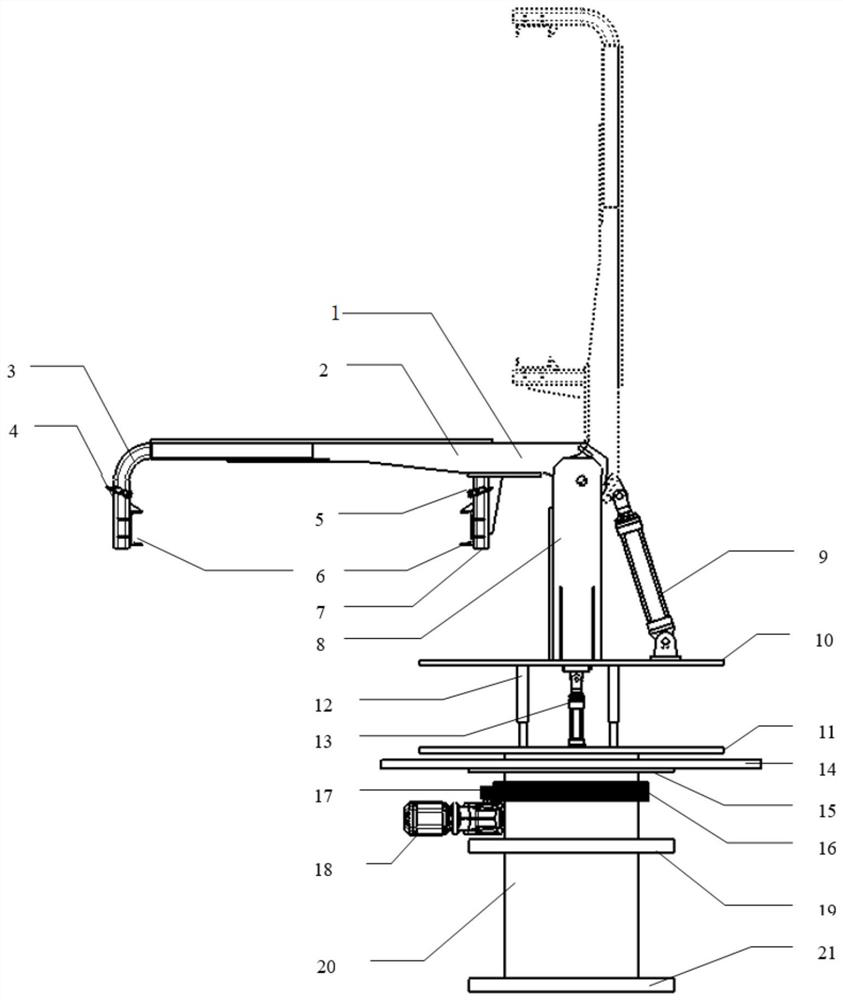

[0131] A closed-loop old car dismantling line matching remanufacturing. The closed-loop old car dismantling line has a "□" structure and is equipped with special import and export stations. There are 2 stations around the "□" structure line Dismantling stations; there are 2 dismantling stations for each straight line around the periphery, a total of 11 dismantling stations, the length of each dismantling station is set to 6 meters, and the length of the straight line is 15 meters. The untwisted length is 78 meters. Double tracks are laid on the ground around the straight line. The width of the double track is 1.5 meters. Different dismantling equipment is installed on the inner or outer side of the track and the dismantling station. The smart fixture is used for lifting and dismantling or station transfer, and the closed-loop transmission mode is used for dismantling of waste cars.

[0132]After cleaning the appearance of the vehicle, use a forklift to bring the external wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com