Complete equipment for flow-line production of Maofeng tea (produced in Huangshan Mountain, Anhui, China)

A complete set of equipment and technology for Maofeng tea, which is applied in the field of complete sets of equipment for the production of Maofeng tea, can solve the problems of uneven quality, scattered processing, waste of equipment resources, etc. Effects of Sexual Injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

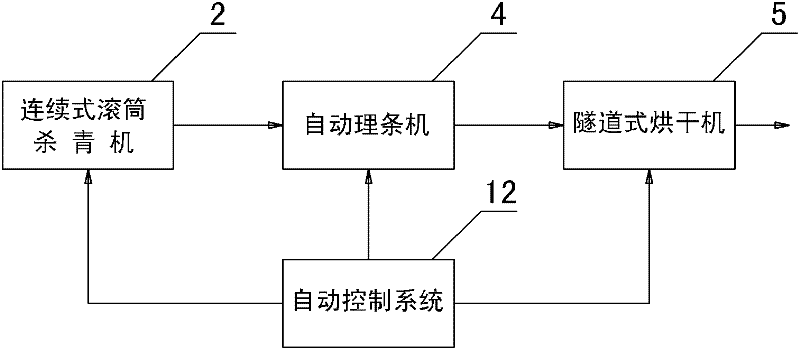

[0031] exist figure 1 In the shown embodiment 1, a kind of Maofeng tea streamlined production complete set of equipment comprises the deenzyming, stripping and drying equipment of Maofeng tea. machine connected to the automatic trimmer 4 (see Figure 5 ), the automatic trimmer is connected to the tunnel dryer 5 (see Figure 6 ), the tunnel dryer includes a frame 6 and a drying tunnel 7 arranged on the frame, the top of the drying tunnel is provided with a heating device, the heating device is a hot air device, including a heat sink Infrared heating tube 17 and blower fan 18, described infrared heating tube is arranged on the same horizontal plane, blower fan is arranged on the top of infrared heating tube, and the top of drying tunnel is also provided with air outlet 19, and air outlet is provided with air outlet adjusting device The bottom of the drying tunnel is provided with a tea conveyor belt 8, and several supporting plates 9 close to the tea conveyor belt are arranged...

Embodiment 2

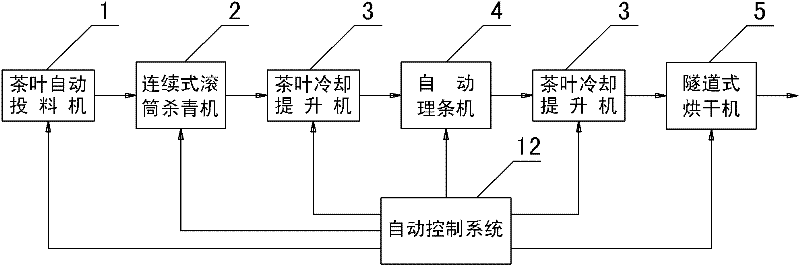

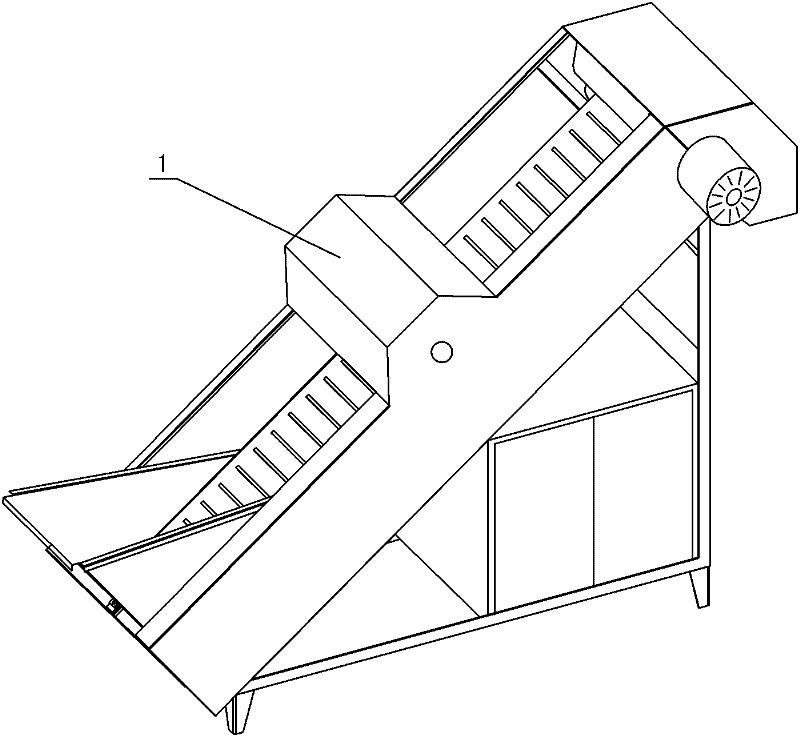

[0033] exist figure 2 In the shown embodiment 2, an automatic tea feeder 1 is provided before the continuous roller greening machine of the Maofeng tea streamlined production complete set of equipment (see image 3 ), there is a tea cooling hoist 3 between the continuous drum fixing machine and the automatic strip machine, the automatic strip machine and the tunnel dryer (see Figure 4 ), and the rest are the same as in Example 1.

Embodiment 3

[0035] The tea conveyor belt of the tunnel dryer of embodiment 3 is a polytetrafluoroethylene flat wire braided belt, and the aspect ratio of its cross section of the polytetrafluoroethylene flat wire is 7 to 1, and the tea conveyor belt is provided with a rectangular mesh. The area of the hole is 2 square millimeters, and two tea powder collection tanks 13 are arranged directly below the plucking device. The cross section of the tea powder collection tank is U-shaped, and the opening edge of the U-shaped structure is connected with the supporting plates on both sides ( See Figure 7 ), and the rest are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com