Cotton-thread-based passive micro-fluid fuel cell

A fuel cell and microfluidic technology, applied in the direction of fuel cell additives, fuel cell parts, electrolyte flow processing, etc., can solve the limitation of miniaturization and practical application, reduce the net output power of microfluidic fuel cells, increase the fuel cell Problems such as system size and cost, to achieve the effect of high cost performance, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

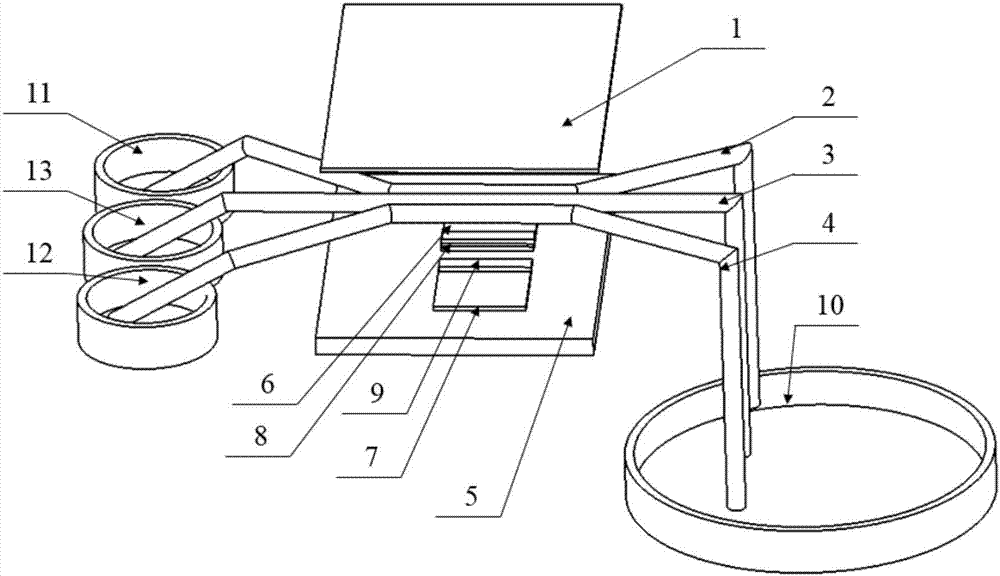

[0011] see figure 1 and figure 2 , a passive microfluidic fuel cell based on cotton thread, comprising anode carbon paper 6 and cathode carbon paper 7; anode carbon paper 6 and cathode carbon paper 7 are respectively provided with cotton thread one 2 and cotton thread two 4, cotton thread one 2 and cotton thread two 4 is isolated by cotton thread three 3; one end of cotton thread one 2 is inserted into entrance petri dish one 11, and anolyte is stored in entrance petri dish one 11; one end of cotton thread two 4 is inserted into entrance petri dish two 12, and entrance petri dish two Catholyte is stored in 12; one end of cotton thread 3 3 is inserted into inlet petri dish 3 13, and spacer is stored in inlet petri dish 3 13; the other ends of cotton thread 1 2, cotton thread 2 4 and cotton thread 3 3 are all inserted into outlet culture dish Inside the dish 10 ; the anode carbon paper 6 and the cathode carbon paper 7 are coated with the anode catalyst layer 8 and the cathode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com