Full-automatic line production packaging system

A packaging system, fully automatic technology, applied in the direction of transportation and packaging, continuous processing of textile materials, equipment configuration for processing textile materials, etc., can solve problems such as troublesome handling and waste of time, save time, improve dyeing effect, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

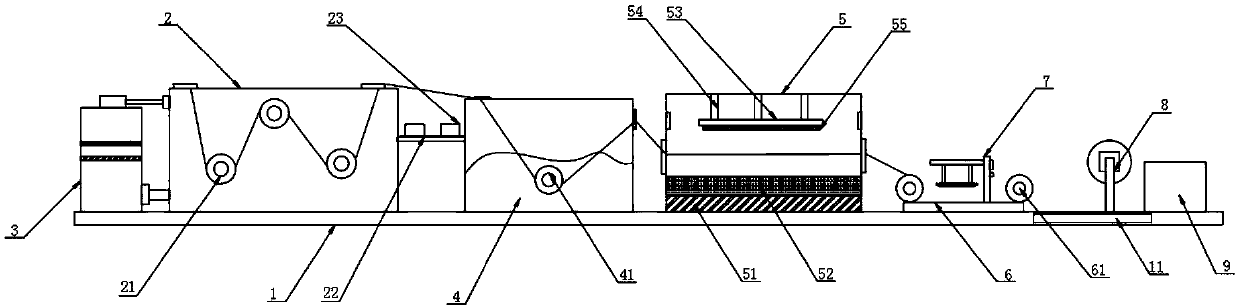

[0023] The present invention provides such as Figure 1-4 A kind of full-automatic line-making packaging system shown, comprises workbench 1, and the top of described workbench 1 is provided with dyeing room 2, and one side of described dyeing room 2 is connected with reflow chamber 3, and the other side of described dyeing room 2 An oil immersion chamber 4 is provided, a shaping chamber 5 is arranged on one side of the oil immersion chamber 4, a cutting table 6 is arranged on the outside of the shaping chamber 5, and a cutting device 7 is fixedly arranged on the top of the cutting table 6, and the cutting device 7 Both sides are provided with a third guide roller 61, the third guide roller 61 is arranged on the top of the cutting table 6, a winding device 8 is provided on one side of the cutting table 6, and a winding device 8 is provided on one side of the winding device 8. Collection chamber 9.

[0024] The interior of the oil immersion chamber 4 is filled with antibacteri...

Embodiment 2

[0028] The inside of the dyeing chamber 2 is evenly provided with a first guide roller 21 , a support plate 22 is provided between the dyeing chamber 2 and the oil immersion chamber 4 , and a hot air blower 23 is evenly provided on the top of the support plate 22 .

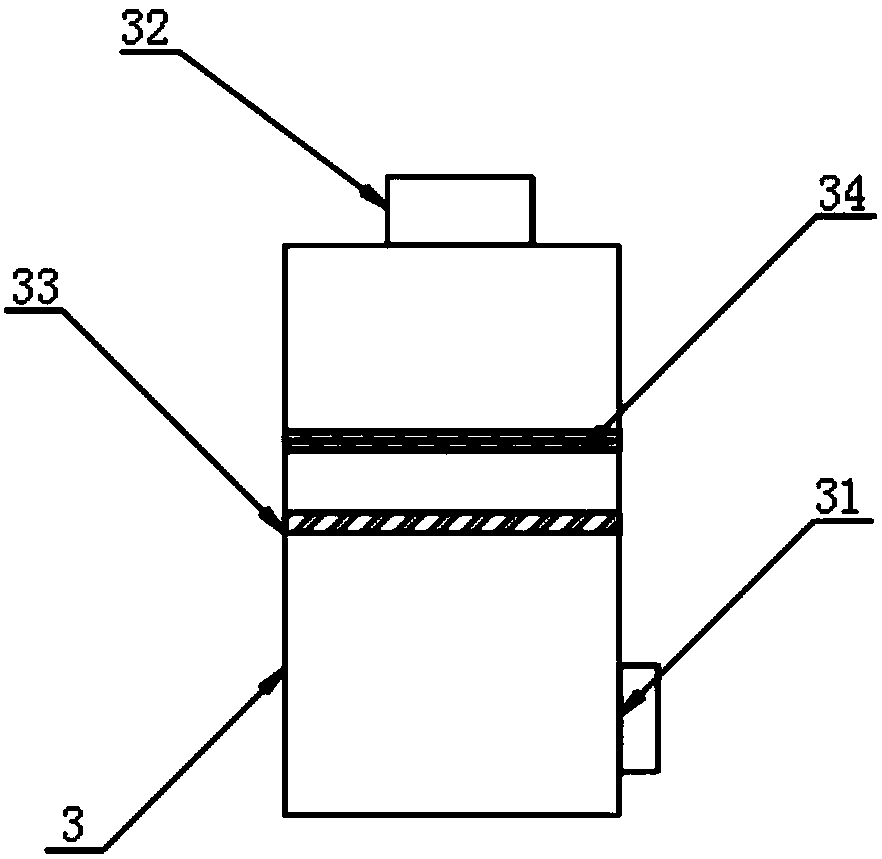

[0029] One side of the return chamber 3 is provided with a switch valve 31, and the top of the return chamber 3 is provided with a water pump 32. The switch valve 31 and the water pump 32 are all communicated with the dyeing chamber 2 through a water pipe, and the inside of the return chamber 3 is provided with A filter screen 33, the top of the filter screen 33 is provided with an activated carbon adsorption layer 34.

[0030] Beneficial effects of this embodiment: open the switch valve 31 and the dyeing solution in the dyeing chamber 2 flows into the return chamber 3, and the water pump 32 works to transfer the dyeing solution back to the dyeing chamber 2, so as to realize the continuous flow of the dyeing soluti...

Embodiment 3

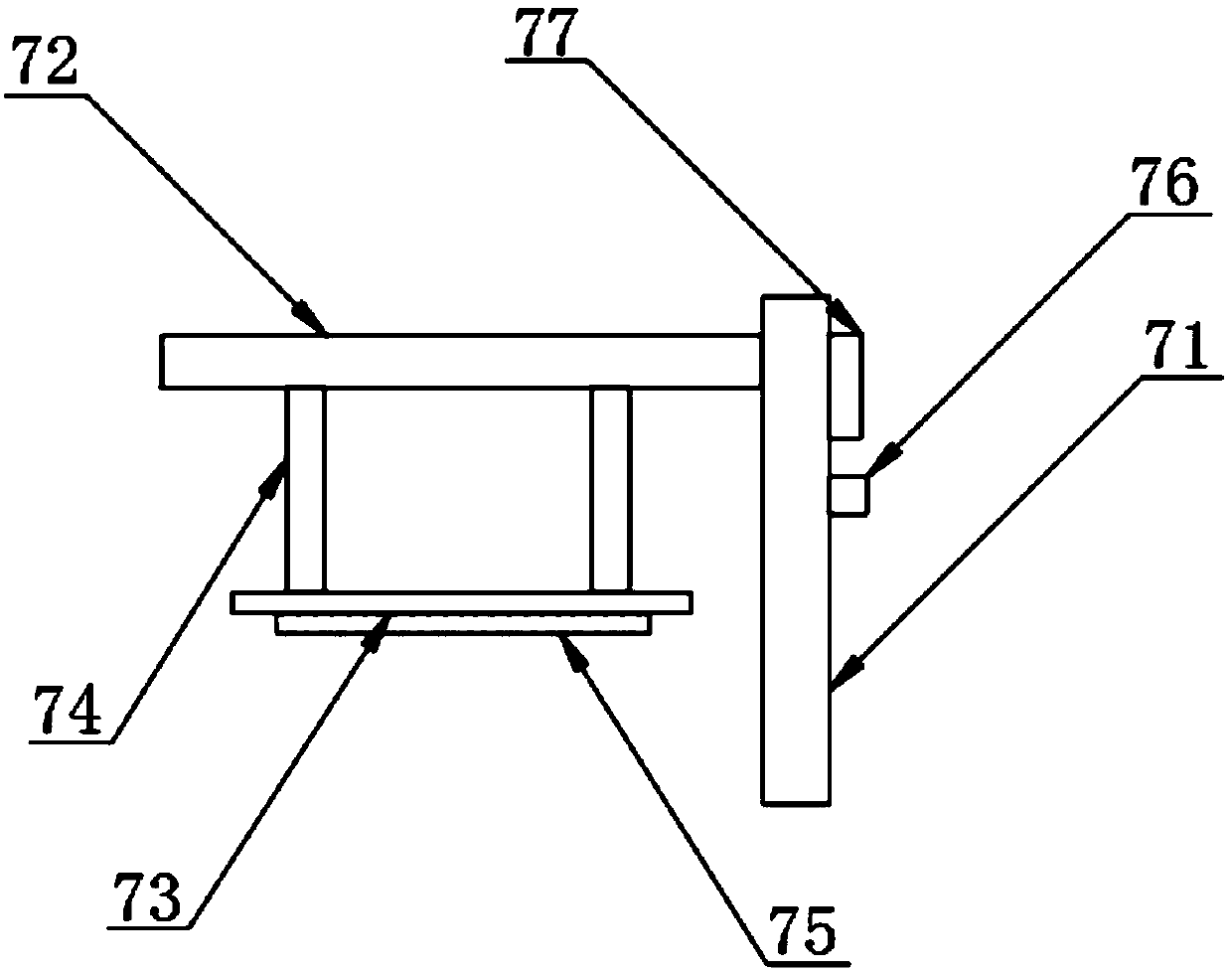

[0032] The cutting device 7 includes a cutting support column 71, a cutting top plate 72, a second lifting plate 73, a hydraulic lifting rod 74, a cutting tool 75, a laser sensor 76 and a buzzer 77, and the cutting support column 71 is arranged on the cutting table 6 At the top, a cutting top plate 72 is fixed on the front side of the cutting support column 71, and a second lifting plate 73 is provided at the bottom of the cutting top plate 72, and a hydraulic lift is evenly arranged between the second lifting plate 73 and the cutting support column 71. A rod 74, a cutting tool 75 is provided at the bottom of the second lifting plate 73, a laser sensor 76 is provided on one side surface of the cutting support column 71, and a buzzer 77 is provided at the top of the laser sensor 76.

[0033]The rewinding device 8 includes a rewinding support column 81, a motor 82, a rotating disc 83 and a rewinding roller 84. The rewinding support column 81 is arranged on the top of the workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com