A countercurrent solid-state distillation column with a spiral slide

A spiral slide and solid-state distillation technology, which is applied in distillation separation, fermentation liquid distillation/rectification, separation methods, etc., can solve the problems of insignificant improvement of heat and mass transfer effects, large differences in material particles, and short liquid residence time, etc. problems, to achieve the effect of avoiding energy consumption, controllable residence time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

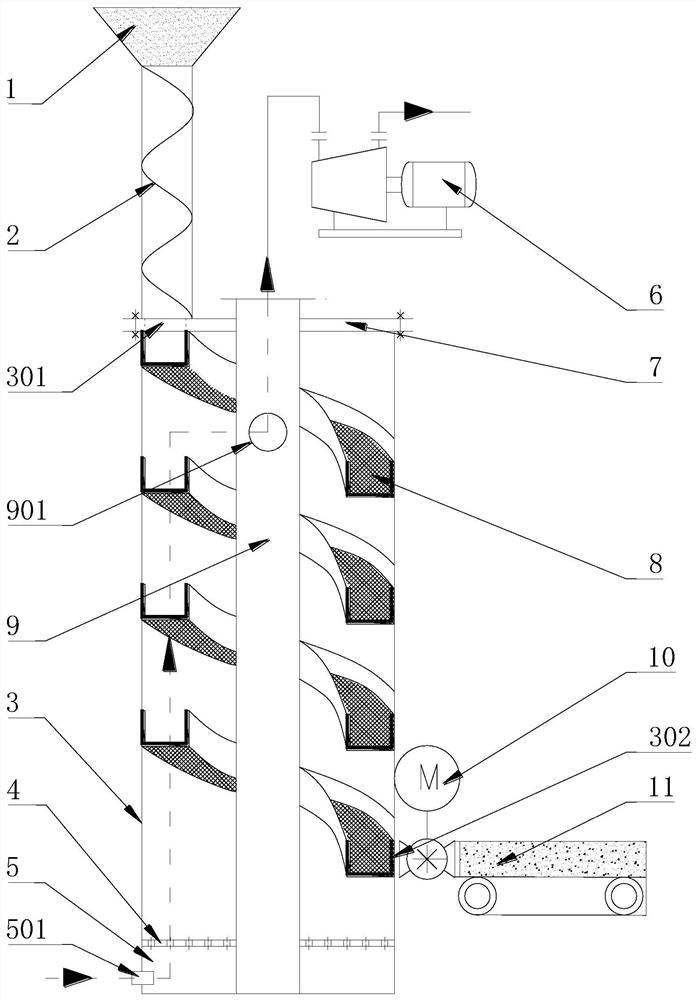

[0032] Such as figure 1 The illustrated embodiment of the present invention includes: a silo blanking machine 1, a feed conveying mechanism 2, a tower body 3, a steam chamber 5, a spiral slide 8, a central conduit 9, a discharge control valve 10 and a discharge device 11 , wherein the tower body 3 is vertically arranged on the tower bottom plate, the upper end of the tower body 3 is equipped with a distillation tower top plate 7, the steam chamber 5 is arranged at the bottom of the tower body 3, and the spiral slideway 8 is fixedly installed on the inside of the tower body 3 and Located above the steam chamber 5, a central conduit 9 is provided at the center of the tower body 3, and the central conduit 9 is directly inserted into the bottom of the tower, welded and fixed with the bottom plate of the tower, and isolated from the steam chamber 5; the gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com