Production line for producing sausage product

A production line and product technology, which is applied in sausage production, equipment for ligating sausage casings, sausage stuffing machines, etc., can solve the problems of increasing the production cost of sausage products, complicated operation and maintenance, uneven sausage products, etc. Low production cost and labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0056] preferred embodiment

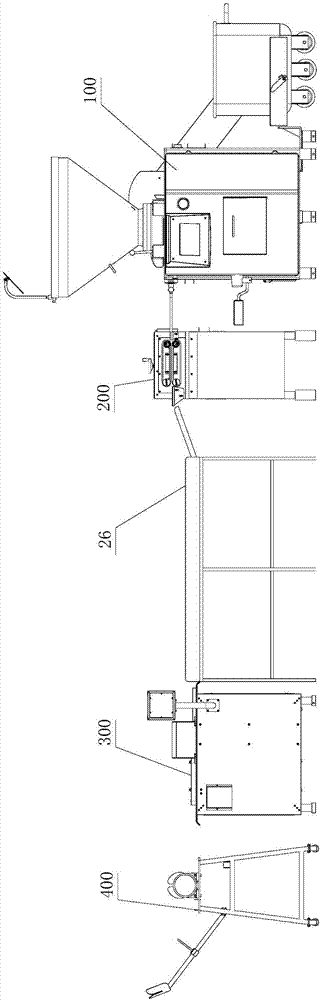

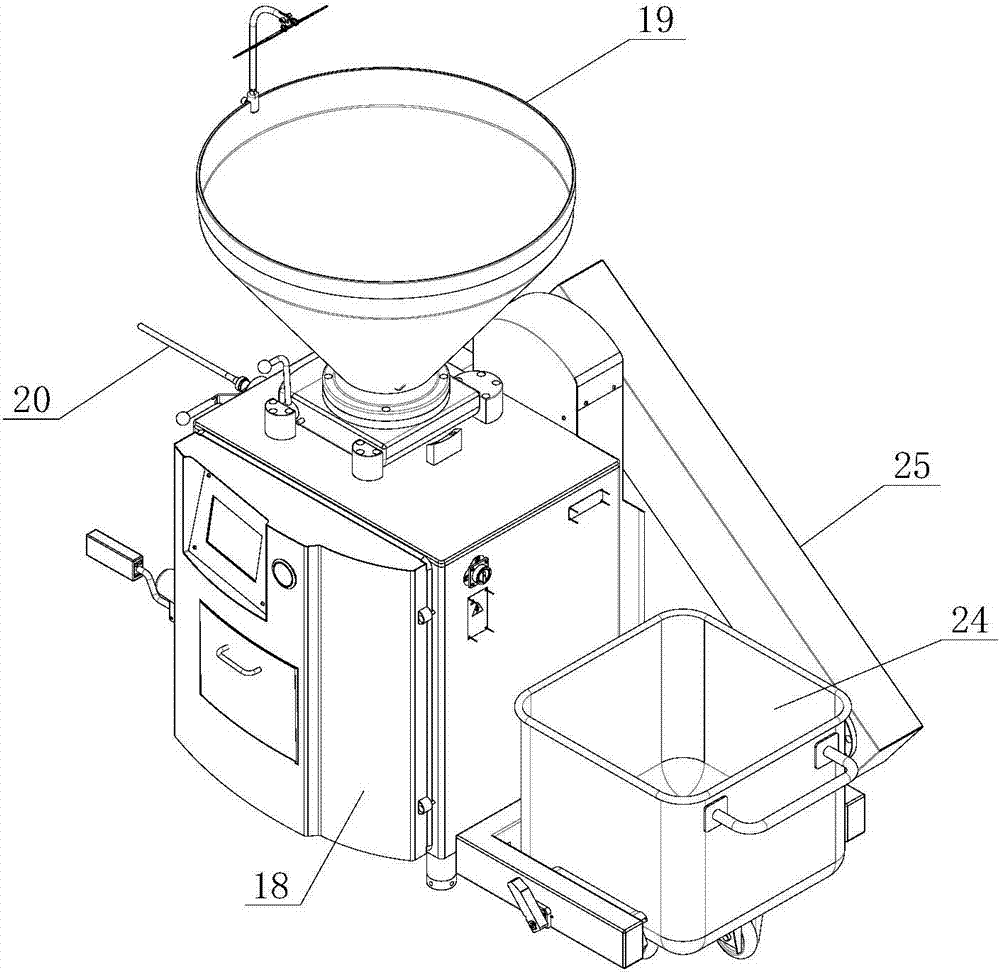

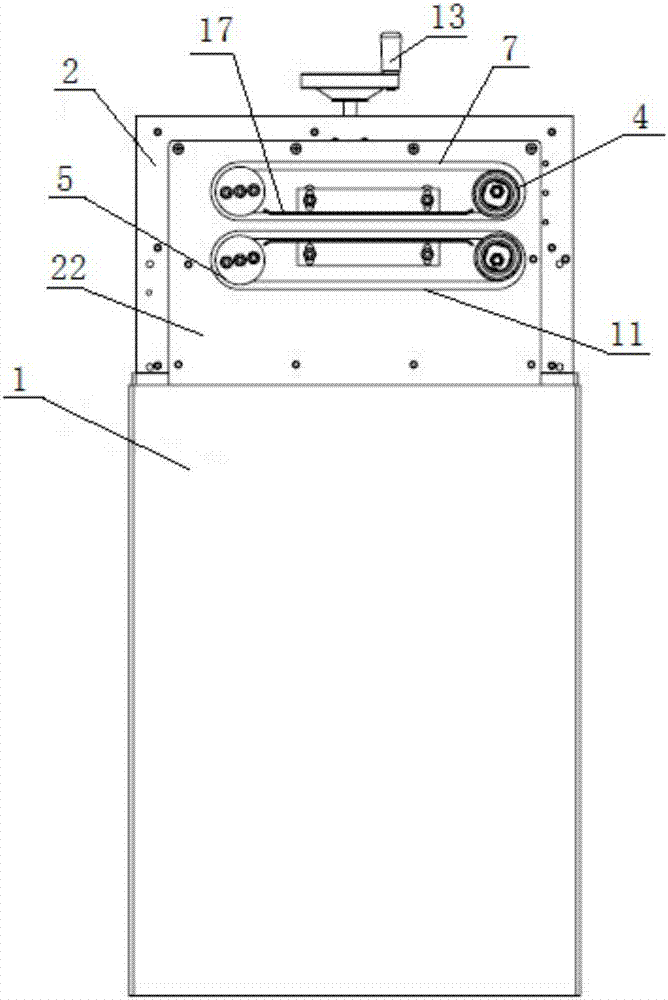

[0057] see figure 1As shown, this embodiment discloses a preferred production line for producing sausage products. The production line includes a filling device 100, a traction device 200, a workbench 26, a thread binding device 300 and a thread removal device 400 arranged in sequence. Wherein, the filling device 100 can automatically fill casings. The traction device 200 can guide and forwardly transport the casing filled with sauce. The working table can temporarily store the sausage products to be tied. The thread binding device 300 can perform lengthening, sectioning and thread binding on the sausage products. The thread removal device 400 can remove the sectioned cotton thread on the fumigated or steamed sausage product af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com