Preparation method of flexible supercapacitor based on metal wires/cotton threads/polymer composite yarns

A supercapacitor and metal wire technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of complex carbon nanotube yarn preparation process, poor device weavable properties, and high cost of conductive substrates. The effect of reducing transmission resistance, low price, and increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

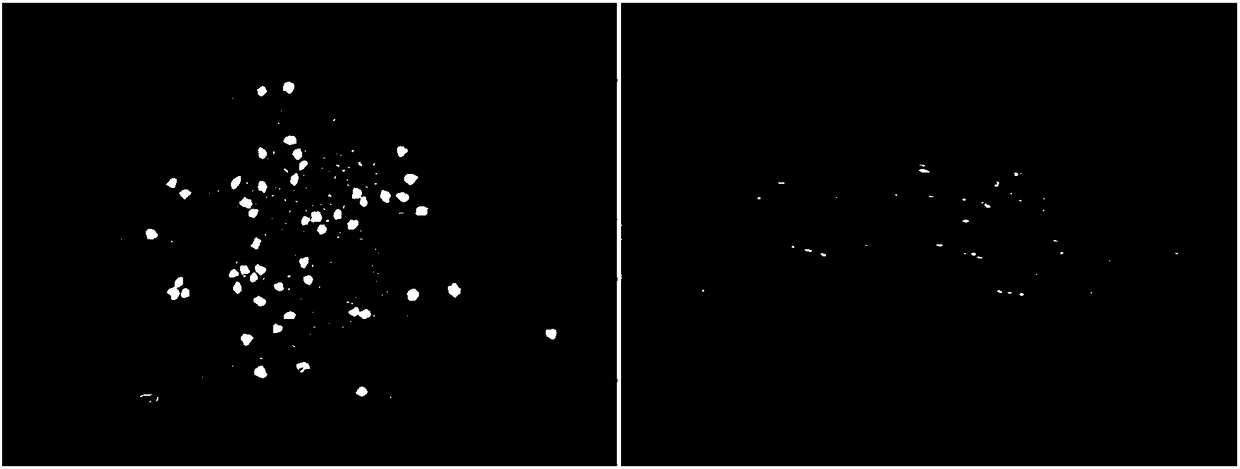

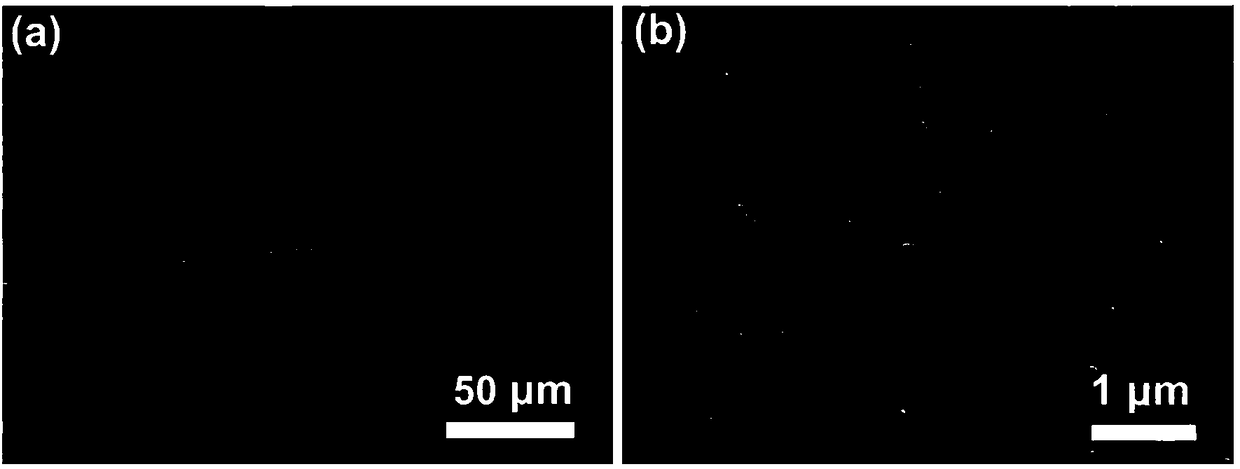

Image

Examples

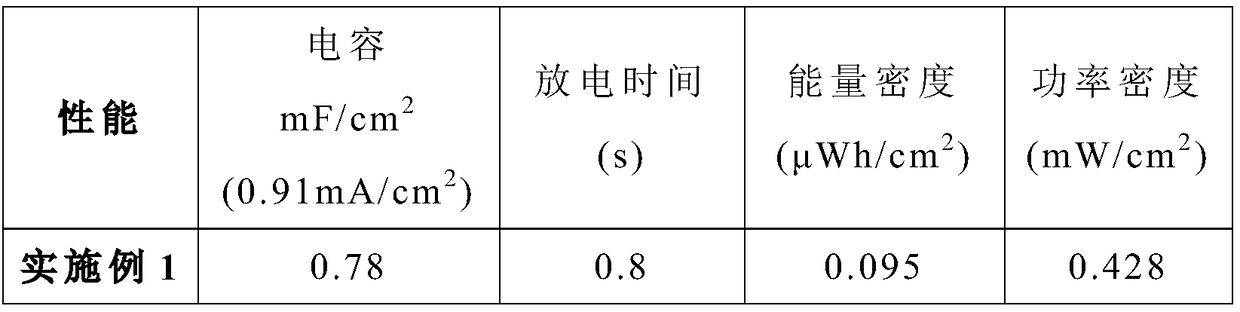

Embodiment 1

[0039] Embodiment 1 A method for preparing a flexible supercapacitor based on metal wire / cotton thread / polymer composite yarn, comprising the following steps in turn:

[0040] (1) Prepare steel wire / cotton composite yarn (SS / Cotton) by ring spinning method:

[0041] The mass ratio of raw steel wire / cotton thread is 10g:100g, the carbon content of the steel wire is 0.08%, the diameter is 6 microns, the cotton thread is pure cotton, and the diameter is 8 microns; the linear density of the obtained composite yarn is 50tex;

[0042] (2) Get two SS / Cotton composite yarns with a length of 1 cm and put them into the mixed solution of dimethyl sulfoxide, fluorocarbon surfactant, PEDOT:PSS and water and soak them for 1 minute, take them out, rinse them with deionized water, And vacuum-dried at 60°C for 6 hours to obtain SS / Cotton-PEDOT:PSS composite yarns applied to supercapacitors, and their resistivity is 760Ω / cm; wherein dimethyl sulfoxide, fluorocarbon surfactant, PEDOT : The mass...

Embodiment 2

[0046] Embodiment 2 A method for preparing a flexible supercapacitor based on metal wire / cotton thread / polymer composite yarn, comprising the following steps in turn:

[0047] (1) Prepare steel wire / cotton composite yarn (SS / Cotton) by ring spinning method:

[0048] The mass ratio of raw material steel wire / cotton thread is 5g:100g, the carbon content of steel wire is 0.08%, and diameter is 10 microns, and cotton thread is all cotton, and diameter is 15 microns; Gained composite yarn linear density is 50tex;

[0049] (2) Get a length of 1 cm and another SS / Cotton composite yarn with a length of 2 cm and put them into the mixed solution of dimethyl sulfoxide, fluorocarbon surfactant, PEDOT:PSS and water for 5 Take it out in minutes, rinse it with deionized water, and dry it under vacuum at 60°C for 6 hours to obtain two SS / Cotton-PEDOT:PSS composite yarns for supercapacitors; dimethyl sulfoxide, fluorocarbon surfactant , The mass ratio of PEDOT:PSS to water is 1.5g:7g:3g:98.5g...

Embodiment 3

[0054] Embodiment 3 A method for preparing a flexible supercapacitor based on metal wire / cotton thread / polymer composite yarn, comprising the following steps in turn:

[0055] (1) Prepare steel wire / cotton composite yarn (SS / Cotton) by ring spinning method:

[0056] The mass ratio of raw material steel wire / cotton thread is 25g:100g, the carbon content of steel wire is 0.08%, and diameter is 6 microns, and cotton thread is all cotton, and diameter is 15 microns; Gained composite yarn linear density is 50tex;

[0057] (2) Take a length of 1 cm and another SS / Cotton composite yarn with a length of 4 cm and put them into the mixed solution of dimethyl sulfoxide, fluorocarbon surfactant, PEDOT:PSS and water for 5 Take it out in minutes, rinse it with deionized water, and dry it in vacuum at 60°C for 6 hours to obtain the SS / Cotton-PEDOT:PSS composite yarn used in supercapacitors; wherein dimethyl sulfoxide, fluorocarbon surfactant, PEDOT: The mass ratio of PSS to water is 1.5g:7g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com