Dyeing device for cotton thread

A dyeing device and cotton thread technology, which can be used in the processing of textile materials, equipment configuration, textiles and papermaking, liquid/gas/steam textile material processing, etc., can solve the problems of dye deterioration, improper storage, waste, etc., to save dyes and improve efficiency , the effect of reducing expenditure costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

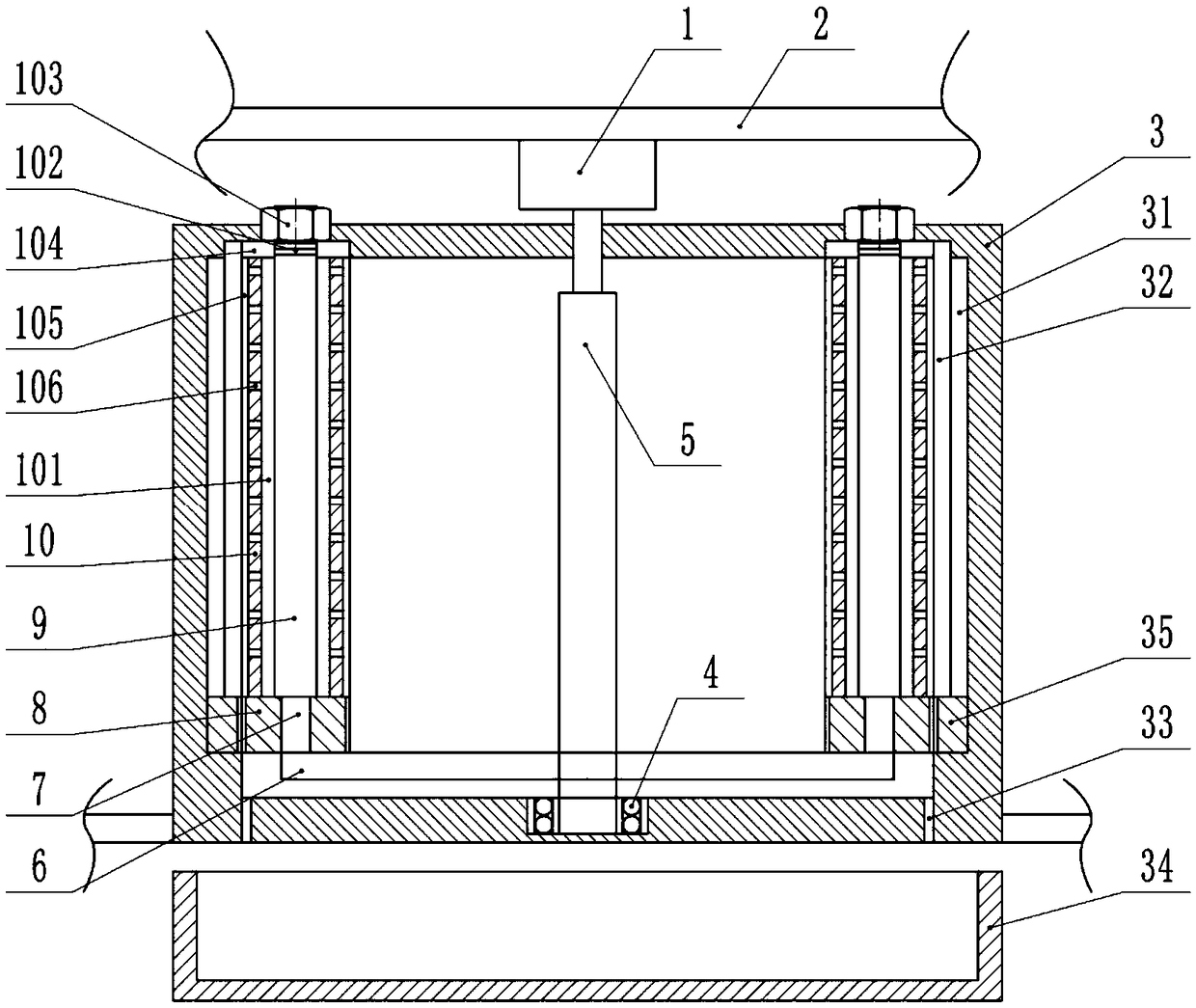

[0032] Cotton thread dyeing apparatus, such as figure 1 As shown, it includes servo motor 1, frame 2 and dyeing barrel 3, dyeing barrel 3 is installed under the frame 2, servo motor 1 is fixedly connected to frame 2, and servo motor 1 is fixedly connected with output shaft; dyeing barrel 3 is an opening structure with the opening facing upwards. A concave groove is processed in the center of the bottom wall of the dyeing barrel 3. A ball bearing 4 is fixedly connected in the concave groove. The inner ring of the ball bearing 4 is fixedly connected with a center rod 5. The upper end is fixedly connected on the output shaft of the servo motor 1 .

[0033] Two radial rods 6 are fixedly connected to the center rod 5 at three centimeters from the bottom wall of the dyeing barrel 3, and the right end of the radial rod 6 is connected with an axial rod 7, and the length of the axial rod 7 is the height of the dyeing barrel 3 One-sixth of that; the axial rod 7 is also fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com