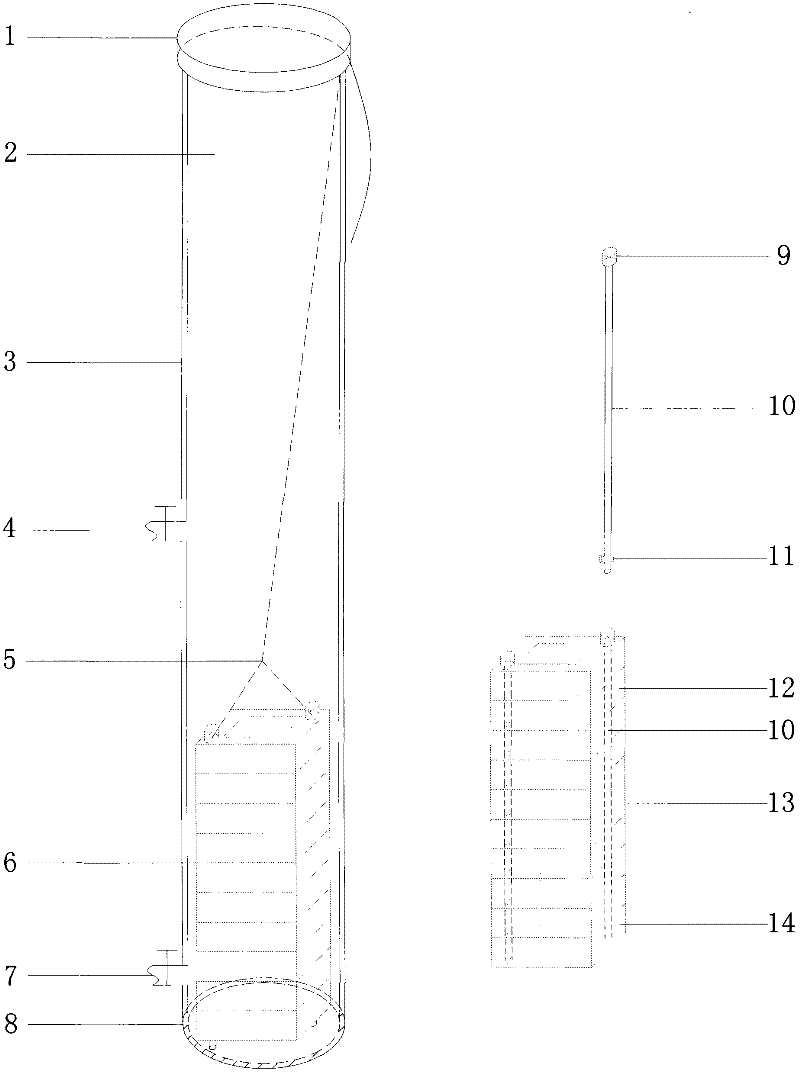

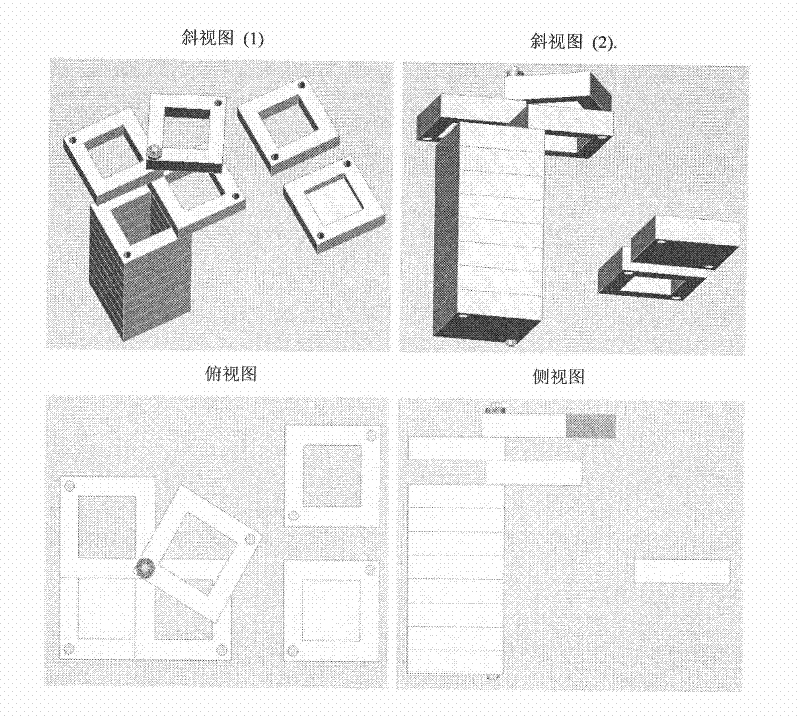

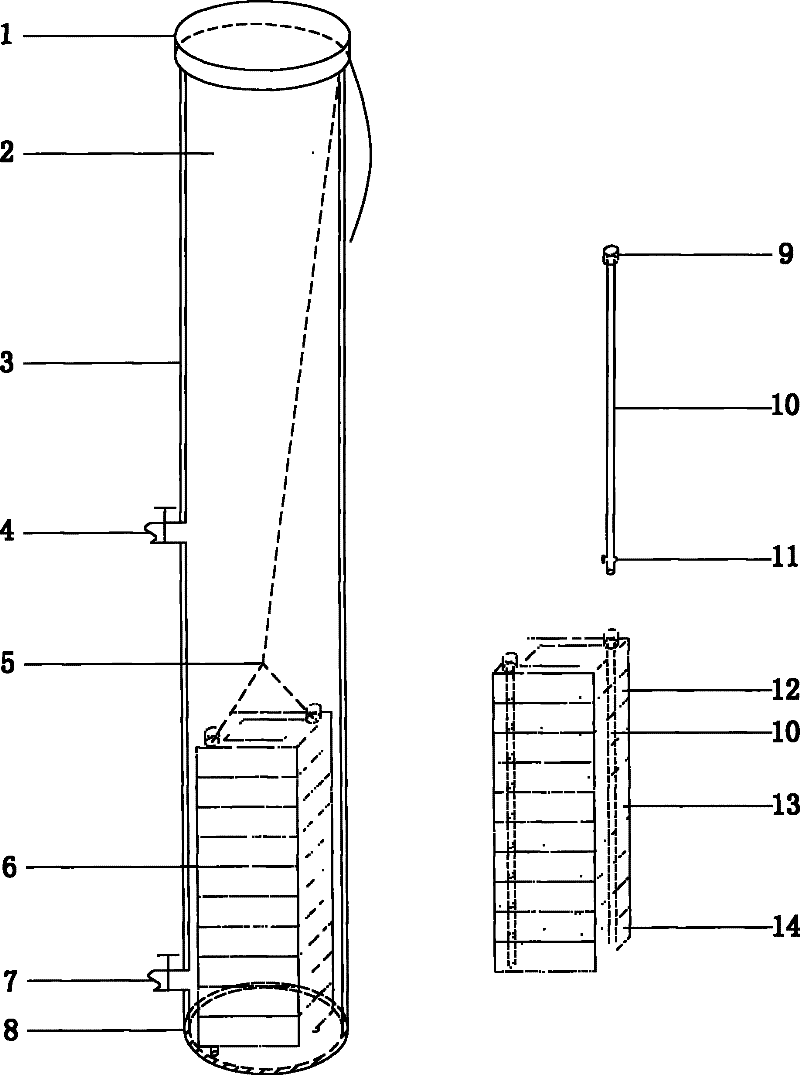

Water-sediment compound simulation test device for accurately layering and collecting sediment

A technology of composite simulation and test device, applied in sampling devices and other directions, can solve the problems of water-sediment interface disturbance, layered collection of difficult sediments, small pipe diameter, etc., and achieves simple structure, convenient operation, convenient and accurate layered collection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] When the test is started, the inner cylinder is filled with uniformly mixed lake sediment layer by layer. During the filling process, sediment passivation agents can be added at a fixed depth according to needs, and then continue to cover the sediment until the inner cylinder is filled (30cm height ). After that, you can hand-hold the 80cm-long thin line tied to the nut, lower the inner cylinder steadily to the inner bottom of the outer cylinder, and hang the 10cm cotton thread higher than the outer cylinder on the outer wall of the outer cylinder to facilitate the sampling of the entire inner cylinder. propose. After placing the inner cylinder, slowly inject the lake water collected in the field along the inner wall of the outer cylinder to the height of 90cm of the outer cylinder. At this time, the overlying water depth in the test system is 60cm. Cover the upper end of the outer cylinder with a light-transmitting plexiglass cover, and the test can be started outdoor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com