A tower bag forming device

A forming device and bag forming technology, applied in the field of tower bag forming devices, can solve problems such as insufficient product quality consistency, and achieve the effects of good product consistency, improved efficacy, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

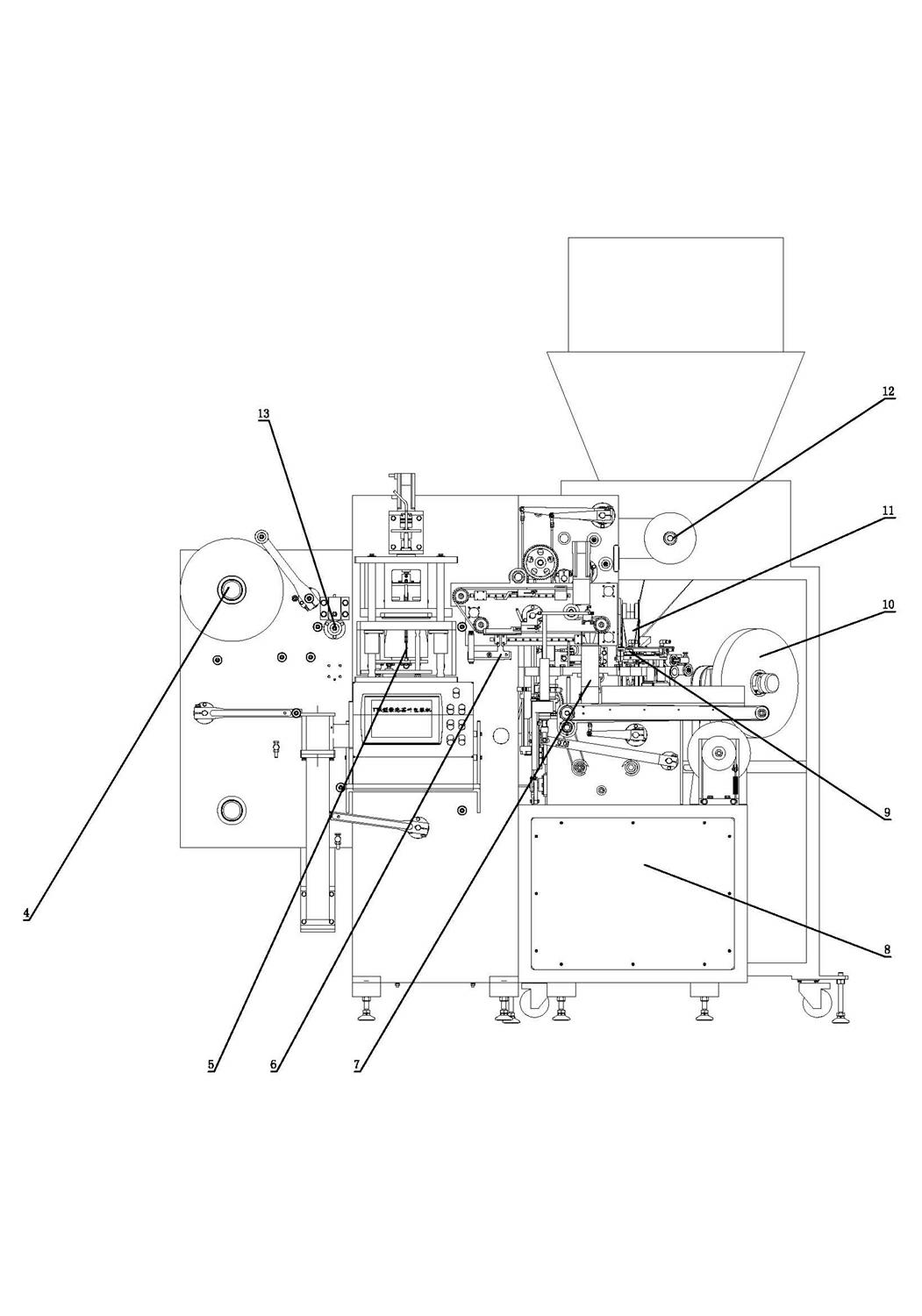

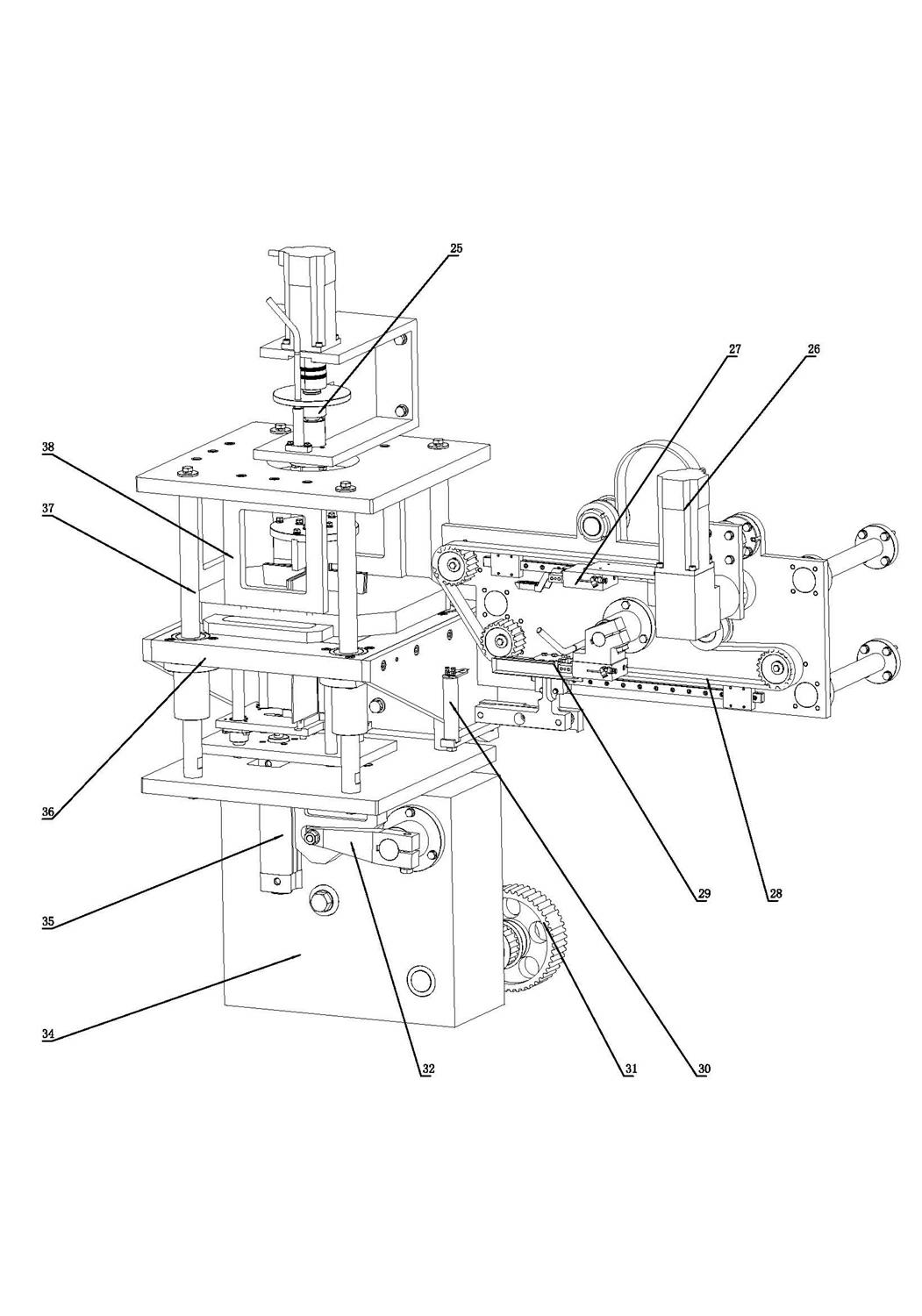

[0023] Example: such as figure 1 , this tower type bag forming device includes a box body 8, the box body 8 is respectively provided with an inner bag film material feeding and winding device 4, a tea bag shape punching and blanking device 5, a tea bag side welding device 6, a tea bag output Device 7, tea bag forming transposition mechanism 9, label feeding and forming device 10, metering feeding device 11, cotton thread feeding and forming device 12, inner bag film material pulling mechanism 13. Through the above 10 parts, the functions of material supply, tea bag forming, tea metering and filling, and tea bag output are completed. The structure and function of each part are detailed as follows:

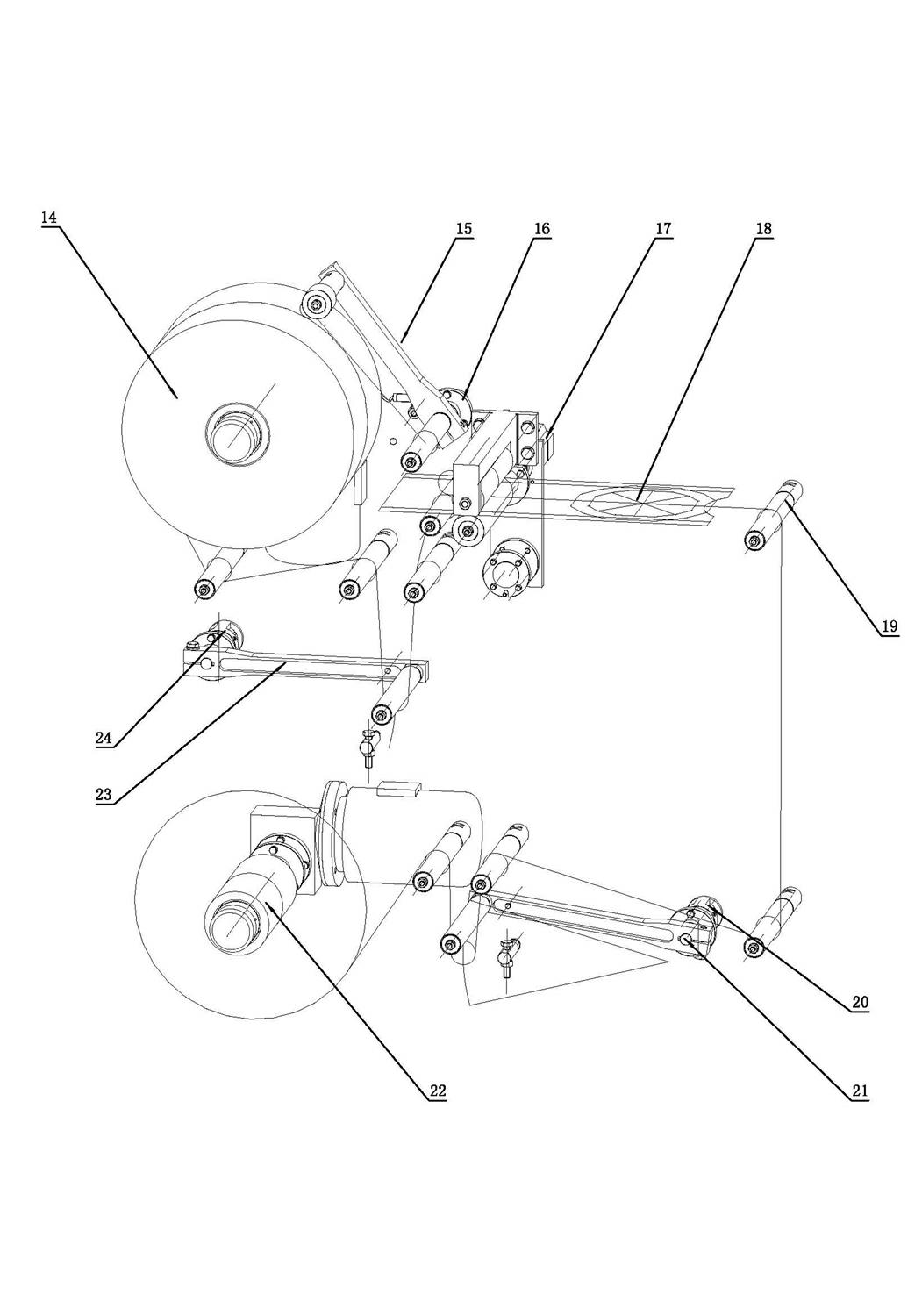

[0024] Such as figure 2 Shown is the inner bag film material feeding and winding device 4, which includes a film reel equipped with a tea bag film roll 14 and whose rear end is connected to a frequency conversion motor with a reducer, driven by a servo motor, and fixed-length fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com