Method for measuring near field blast wave pressure of underwater explosion of explosive

A measurement method and shock wave technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of high test cost, many test data links, expensive instruments and equipment, etc., and achieve simple test components and test results. Simple process and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

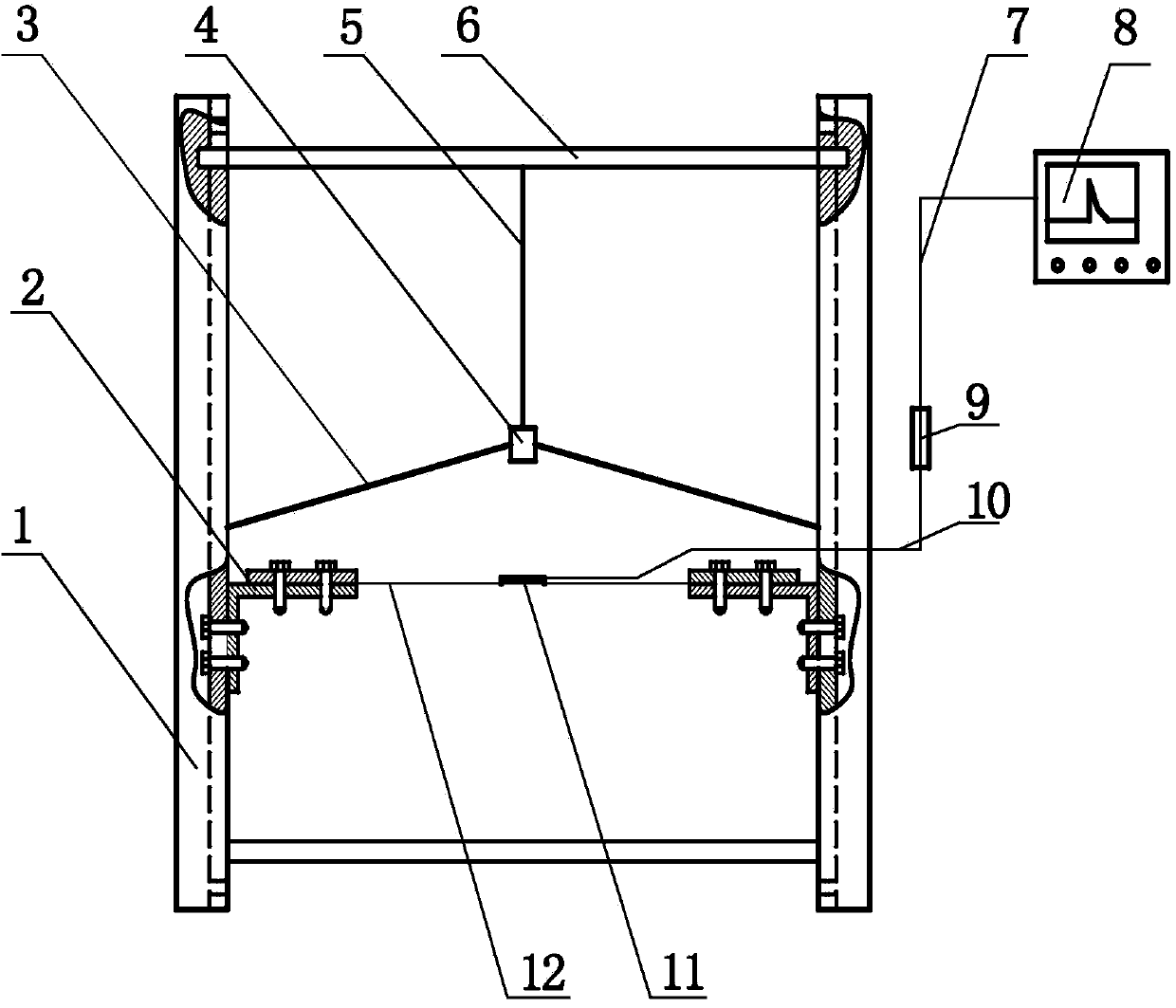

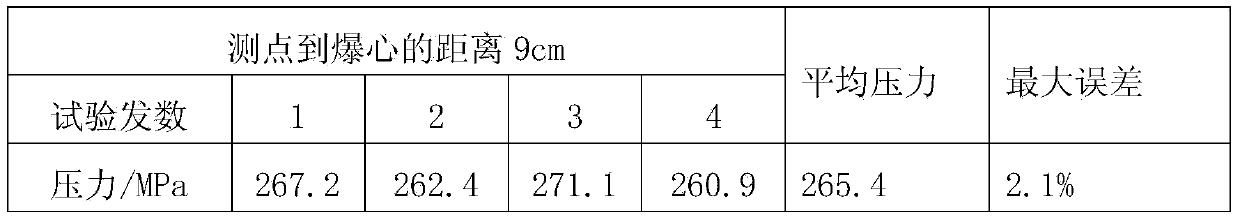

[0033] This embodiment is the near-field pressure measurement of B explosive underwater explosion. The B explosive is 25g, which is formed by melting and casting process. The charge size is φ25mm×30mm. The test method for an explosive pool with a diameter of 3.2 meters and a depth of 2.4 meters includes the following steps;

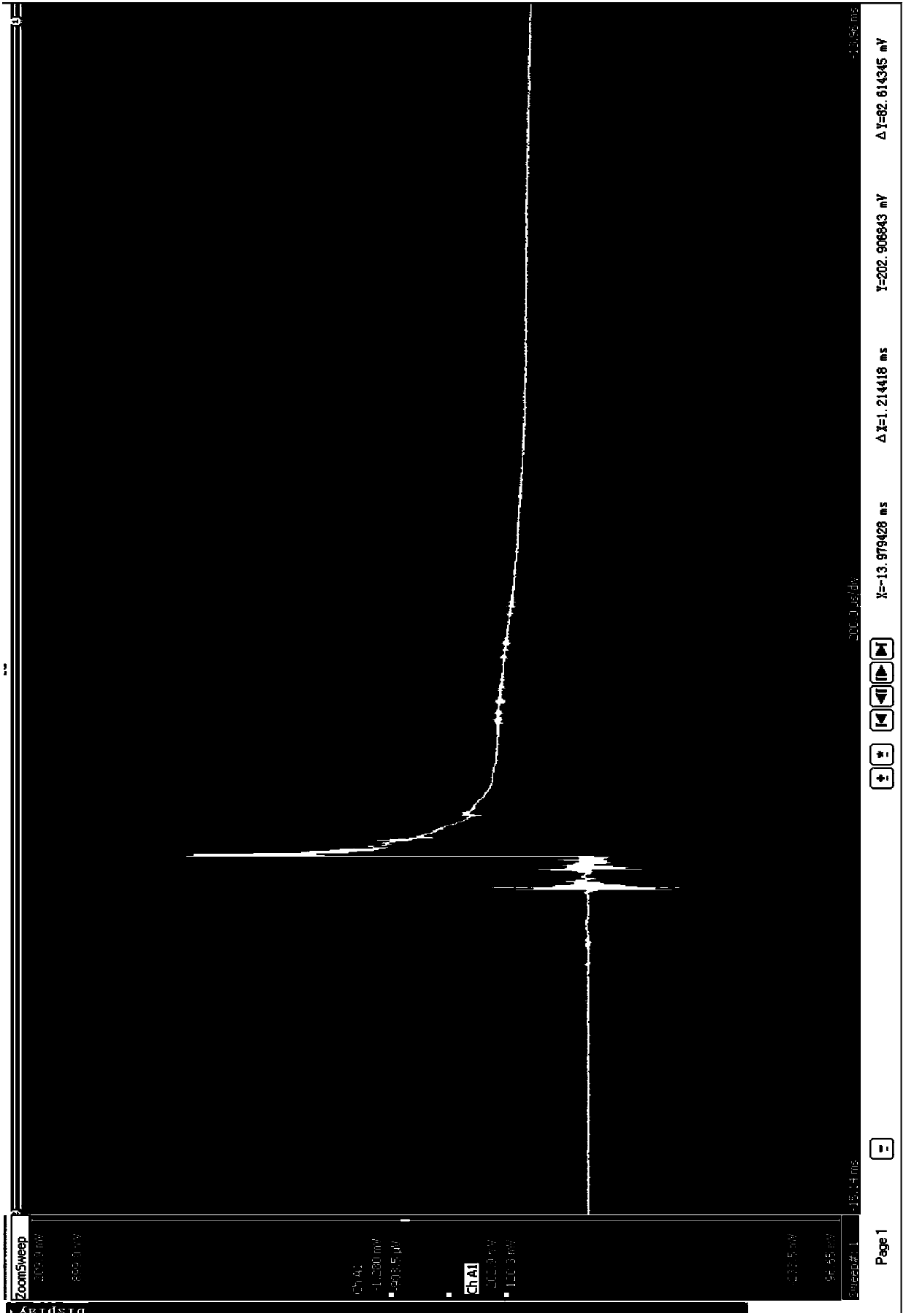

[0034] Step 1: Select the PVF2-11-.125.EK thin-film stress gauge from American DYNASEN Company, and polish the terminal of the thin-film stress gauge with 200-grit sandpaper to remove the oxide layer. Weld the SYV-50-3-1 type coaxial cable and the terminal of the film strain gauge to ensure that the solder joints must be smooth and welded firmly to prevent false welding. The solder should not be too much, and the welding time should not be too long. Generally, 3- 5 seconds, and there is no danger of breaking, and the solder joints are sealed with waterproof sealant, and waterproof insulating tape is wound to meet the requirements of waterproof and insulat...

Embodiment 2

[0048] The test process is carried out according to Example 1.

[0049] In this test, JH-14 explosive is used to verify the repeatability of the measurement results of this method. The amount of each test charge is 10g, the size of the charge is ф15mm×15mm, and the distance between the lower end of the sample and the sensitive surface of PVDF is 11cm. The test bracket of the sample was put into the pool, and the depth of the sample entering the water was 30cm. A total of 7 tests were carried out. The results obtained are listed in Table 2, and the standard deviation of the obtained test is 8.2%.

[0050] Table 2 Shock wave pressure near field of JH-14 explosive

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com