Process of preparing degradable tableware and containers by using straws and shell fibers

The invention relates to a preparation process and a husk technology, which is applied in the technological field of using straw and husk fibers to make degradable tableware and containers, and can solve the problems of the decline of farmland quality and the destruction of soil structure, so as to promote secondary utilization and improve economic value. , to ensure the effect of no breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

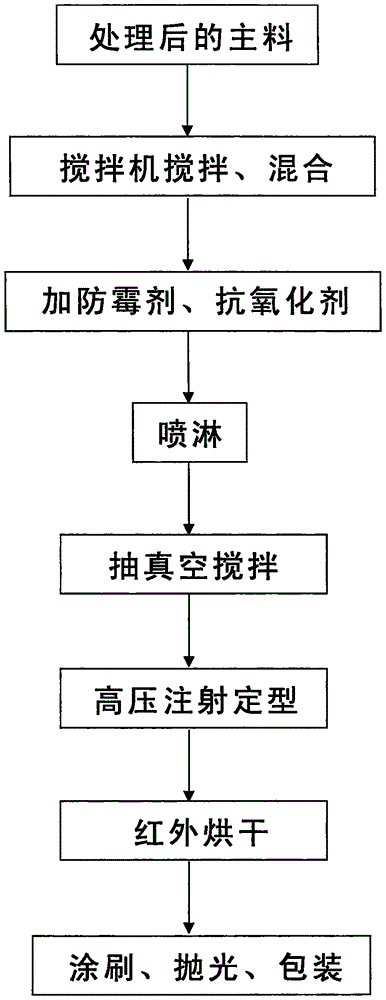

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with specific embodiment:

[0020] The present invention is a process for making degradable tableware and containers by using straw and fruit shell fiber. Shells Wheat husks, rice husks, rice bran, peanut shells, bean shells, corn cobs, sunflower seed shells and other crop husks, plant stems bagasse, reeds, thatch, wood chips, bamboo chips or other wild plants A variety of mixtures of stems, accounting for 80%. Other materials include hemp silk or pure cotton thread with a length of 10mm, accounting for 1-3%. Antifungal agents include compound feed antifungal agent 0.5%, wood antifungal agent 0.5%,

[0021] The anti-oxidant is ethoxyquin, accounting for 0.3%, and the surface treatment agent is wood wax oil and vegetable paint.

[0022] The process method includes a pretreatment process and a preparation process, and the pretreatment process method is as follows: the main material is crushed and screened, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com